Professional CNC machining service offering precision 5-axis milling, fast quotes, ISO-certified quality, and custom parts for aerospace, automotive, and more.

Looking for a CNC machining service that delivers precision, speed, and reliability without breaking the bank? You’re not alone. In today’s fast-paced manufacturing world, delays and inconsistent quality can derail your entire project timeline. Whether you need rapid prototyping or low-volume production, finding the right CNC machining partner is critical for getting your parts right the first time—every time. Stick around to discover how Vast’s cutting-edge CNC capabilities and customer-focused approach are revolutionizing precision machining in 2025. Let’s get your project off the ground with confidence and speed.

What is CNC Machining Service

CNC machining service uses computer-controlled machines to shape parts with high precision. The process starts with CAD (Computer-Aided Design) models, then moves to CAM (Computer-Aided Manufacturing) software that guides machines like mills, lathes, and laser cutters.

Core Processes

- Multi-axis Milling: Moves cutting tools across several axes (3, 4, or 5) for complex shapes.

- Turning: Spins the material to cut round parts like shafts or bolts.

- Laser Cutting: Uses focused beams to cut or engrave thin materials.

Types of CNC Machining

| Type | Description |

|---|---|

| 3-axis Milling | Cuts along X, Y, and Z axes — ideal for flat or simple parts. |

| 4-axis Milling | Adds rotational axis for angled features. |

| 5-axis Milling | Simultaneous cutting on five axes for complex shapes. |

| Turning | Perfect for cylindrical parts, removes material with a rotating spindle. |

| Swiss Machining | High-precision turning for tiny, intricate parts often used in medical and electronics. |

Materials We Work With

We machine a wide range of materials suited for various industries:

| Metals | Plastics | Composites |

|---|---|---|

| Aluminum | ABS | Carbon fiber |

| Steel | Nylon | Fiberglass |

| Titanium | Polycarbonate | |

| cURL Too many subrequests. |

Benefits of CNC Machining Services

- Precision up to ±0.001 inches ensures tight tolerances and consistent parts.

- Speed: Prototypes ready in 24-48 hours accelerate your product development.

- cURL Too many subrequests. From single prototypes to high-volume orders, CNC adapts smoothly.

CNC machining offers unmatched accuracy and flexibility for custom parts across industries. Ready to explore precision machining for your project? Let’s dive deeper into why professional CNC services matter.

Why You Need Professional CNC Machining Services

Handling CNC machining in-house often comes with several challenges. Limited equipment and expertise can lead to quality issues and production delays. Plus, high minimum order quantities (MOQs) can tie up your budget and inventory, especially if you need prototypes or small batches.

That’s where professional CNC machining services come in. At Vast, we’re ISO-certified and operate over 100 high-precision machines, ensuring reliability and consistent quality. With a 99.9% on-time delivery rate, we help keep your projects on schedule without cutting corners.

Our CNC machining services cater to diverse industries including automotive, medical implants, aerospace components, and consumer electronics. Whether you need custom CNC milling, precision turning, or rapid prototyping, partnering with a pro supplier like Vast means better results and less hassle.

How to Choose the Best CNC Machining Service Provider

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- Tolerances: cURL Too many subrequests.

- Materials: cURL Too many subrequests.

cURL Too many subrequests.

| Type | cURL Too many subrequests. | When to Use |

|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | 5-10 days | cURL Too many subrequests. |

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

Quality Control

- Check for certifications like cURL Too many subrequests. or AS9100

- Confirm they use full CMM inspection for accuracy

- Ensure traceability is maintained for every part

cURL Too many subrequests.

- 24/7 chat or phone support

- Engineering consultations to optimize your design

- Free Design for Manufacturability (DFM) reviews to avoid costly revisions

Local vs Global Provider

| Factor | Local (CA, TX, etc.) | Global (UK, China) |

|---|---|---|

| cURL Too many subrequests. | Faster, often same-day or next-day | Longer, but can be cheaper |

| Communication | Easier collaboration, no time zone issues | May have delays or language gaps |

| Warehousing | Closer inventory for quick restocking | Larger capacity for big orders |

Choosing wisely means balancing these factors based on your budget, timeline, and project complexity for the best CNC machining service fit.

Step-by-Step Guide to Getting Started with Vast CNC Machining

Starting your project with Vast CNC machining is simple and fast. Here’s how it works:

- Upload Your CAD FileWe accept common formats like STEP and IGES to make things easy for you.

- Get an Instant Online QuoteIn under 30 seconds, you’ll see a clear, upfront price with no hidden fees.

- Free Design for Manufacturability (DFM) AnalysisOur experts review your design to suggest improvements that save time and cost, ensuring your part is CNC-ready.

- Choose Your Materials and FinishesPick from options like anodizing or powder coating to meet your specific needs.

- Production and ShippingOnce approved, your parts go into production. We ship with full tracking and insurance for peace of mind.

- Post-Delivery SupportIf revisions are needed, we offer free adjustments within 30 days of delivery to guarantee your satisfaction.

This easy flow helps you move from concept to finished part without hassle, perfect for prototype runs or scaling up to volume production.

Real-World Case Studies Vast Success Stories

At Vast, our CNC machining service has delivered real results across industries. For aerospace, we produced a titanium drone part using 5-axis machining with a fast 48-hour turnaround—crucial for tight project deadlines. In medical, we crafted a stainless steel prototype with extreme precision held to ±0.001 tolerance, perfect for implant-quality demands. We even helped a local auto shop with same-day custom aluminum parts, supporting quick repairs and upgrades.

Our customers consistently report significant improvements:

- 40% cost savings compared to competitors

- Reduced lead times speeding up product launches and repairs

- High-quality parts that meet exact specs the first time

These success stories highlight how Vast’s precision CNC machining and rapid prototyping can boost your project’s efficiency and quality.

CNC Machining Costs Breakdown and Savings Tips

CNC machining costs vary based on several factors like the complexity of the part, order volume, and material used. Generally, prices range from cURL Too many subrequests., cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- Material: cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. Save on shipping and speed up delivery times by working with nearby CNC shops.

By understanding these cost factors and applying simple strategies, you can get quality CNC machining without blowing your budget.

FAQs about CNC Machining Service

What is the cost of CNC machining services?

Costs vary depending on complexity, material, and volume. Typical prices range from $50 up to $500 per part. Prototypes and small runs tend to be higher per piece, while larger batches reduce costs.

How long does CNC machining take?

Standard turnaround is usually 5 to 10 days. Many providers, like Vast, offer fast options with prototype delivery in 24 to 48 hours for urgent needs.

Where can I find the best CNC machining service near me?

Look for local providers with ISO certifications, fast shipping, and strong reviews. Vast offers multiple locations across the U.S., including California and Texas, making collaboration and delivery easier.

How does Vast compare to competitors like Xometry and PCBWay?

Vast stands out with a large fleet of 100+ machines, 99.9% on-time delivery, and detailed quality controls. Their free design for manufacturability reviews and 24/7 customer support add value over typical services.

Can Vast handle custom CNC projects?

Yes. Vast specializes in custom CNC milling, turning, and multi-axis machining for metals, plastics, and composites. They provide free DFM analysis and support from prototype to full production runs to fit unique project needs.

Local SEO CNC Machining Services Near You

Choosing a local CNC machining service means faster shipping, easier collaboration, and lower costs. Working with nearby providers reduces delays and lets you stay involved during production. It also cuts down on shipping fees and simplifies returns or revisions.

Benefits of Local CNC Machining

| Benefit | Why It Matters |

|---|---|

| Faster Shipping | Get parts in days, not weeks |

| Easier Collaboration | Quick feedback and adjustments |

| Reduced Costs | Lower shipping and handling fees |

Vast Service Areas

We serve key U.S. regions, making local CNC machining easy:

- California

- Texas

- Illinois

- New York

- Florida

Optimized Google Business Profile

Find us quickly with all details ready:

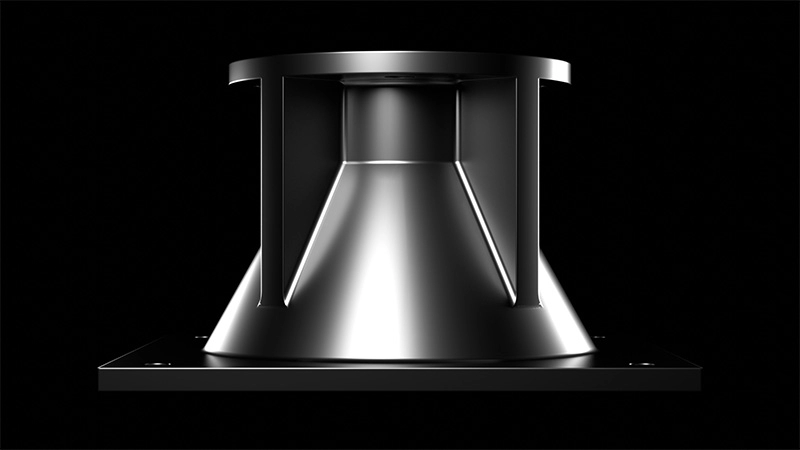

- Clear photos of our facility and parts

- Verified reviews from real customers

- Easy contact options including phone and chat

Local CNC machining near you means reliable service with less hassle. Reach out for fast quotes and expert support right in your area.

The CNC Machining Process with Vast

At Vast, our CNC machining process is designed to be smooth, precise, and reliable from start to finish. It all begins with your design file—usually a CAD model—that our engineers review to ensure it’s ready for production. We convert your design into G-code, the language CNC machines use, setting up the exact toolpaths to shape your parts accurately.

We use advanced CAM software to optimize these toolpaths, which helps reduce cycle times and improves surface finish. Our state-of-the-art CNC machines handle everything from multi-axis milling to turning and laser cutting, all programmed for maximum precision.

Quality control is key at every step. Each part goes through thorough inspection using precision measurement tools to meet tight tolerances and ensure consistency. This attention to detail guarantees you get parts that match your exact specifications every time.

With Vast’s streamlined CNC machining process, you experience high-quality parts delivered fast, backed by expert support whenever you need it.

Industries Served by Vast CNC Machining Services

cURL Too many subrequests.

- AerospacecURL Too many subrequests.

- AutomotivecURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.