Discover the best tapping tools for precise thread cutting with expert guides on types, usage, and maintenance for DIY and pro projects.

Ever struggled with stripped threads or broken taps right when your project needed to be flawless? Tapping tools are the game-changers that every DIYer, mechanic, and fabricator needs in their arsenal. Whether you’re creating internal screw threads in metal, wood, or plastic, having the right tool—and knowing how to use it—makes all the difference. In this guide, we’ll cut through the confusion, showing you how to select, use, and maintain tapping tools like a pro, so every thread you make is precise, durable, and ready to hold strong. Let’s get threading!

What Are Tapping Tools A Beginner’s Breakdown The Core Components of a Tapping Tool Kit

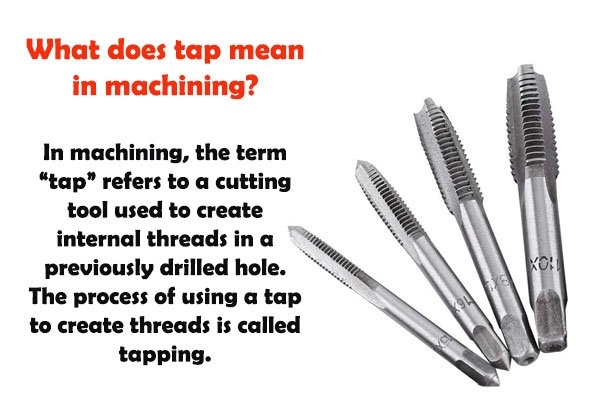

If you’ve ever needed to create internal threads in metal, plastic, or wood, tapping tools are your go-to solution. Simply put, tapping tools help carve precise threads inside holes so bolts or screws can securely fasten parts together. For beginners, understanding the core parts of a tapping tool kit is essential to getting started right.

A basic tapping tool kit typically includes:

- Hand tapsThese are the cutting tools used to create threads. They come in sets, usually with three types: taper tap, plug tap, and bottoming tap. Each has a distinct role in gradually cutting threads deeper and cleaner.

- Tap wrenchThis is the handle that holds the hand tap firmly. It provides the leverage needed to turn the tap smoothly and evenly, reducing the risk of breaking the tap inside the hole.

- Thread cutting tapsThese taps are designed to cut new threads. Options like spiral flute taps handle chips better, especially in blind holes, making your job easier and cleaner.

- Tap drill chartThis reference guide helps you choose the right drill size before tapping. Using the wrong drill bit can cause poor thread fit or damage.

- Specialty tapsSome kits include HSS taps for metal, carbide tapping accessories for hard materials, or internal thread forming taps that don’t cut but form threads by displacing material.

Many tapping tool manufacturers offer customized kits for specific needs, allowing you to match tools perfectly with your projects, whether you’re doing home repairs or professional machining.

Starting with a well-rounded tapping tool kit makes threading tasks manageable and sets a solid foundation for any DIY enthusiast or pro. Understanding these main components prevents confusion and frustration, helping you get precise, reliable results with every project.

Why Tapping Tools Matter in Modern Projects

Tapping tools are essential in many modern projects because they allow you to create internal threads in materials like metal, plastic, or wood. This means you can insert bolts or screws securely, making your builds stronger and more durable. Whether you’re fixing machinery, building furniture, or working on automotive repairs, tapping tools help ensure precise and reliable connections.

In today’s fast-paced work environments, tapping tools save time and improve accuracy. Using the right taps, like spiral flute taps for chips or HSS taps for metal, keeps your threads clean and reduces the risk of damaging parts. They’re especially important in custom manufacturing and workshops across the United States, where quality and efficiency are a must.

So, tapping tools aren’t just for pros—they’re valuable for anyone needing solid, threaded joints in their projects. The right tool can make all the difference in durability and professional finish.

Hand Taps for DIY Enthusiasts

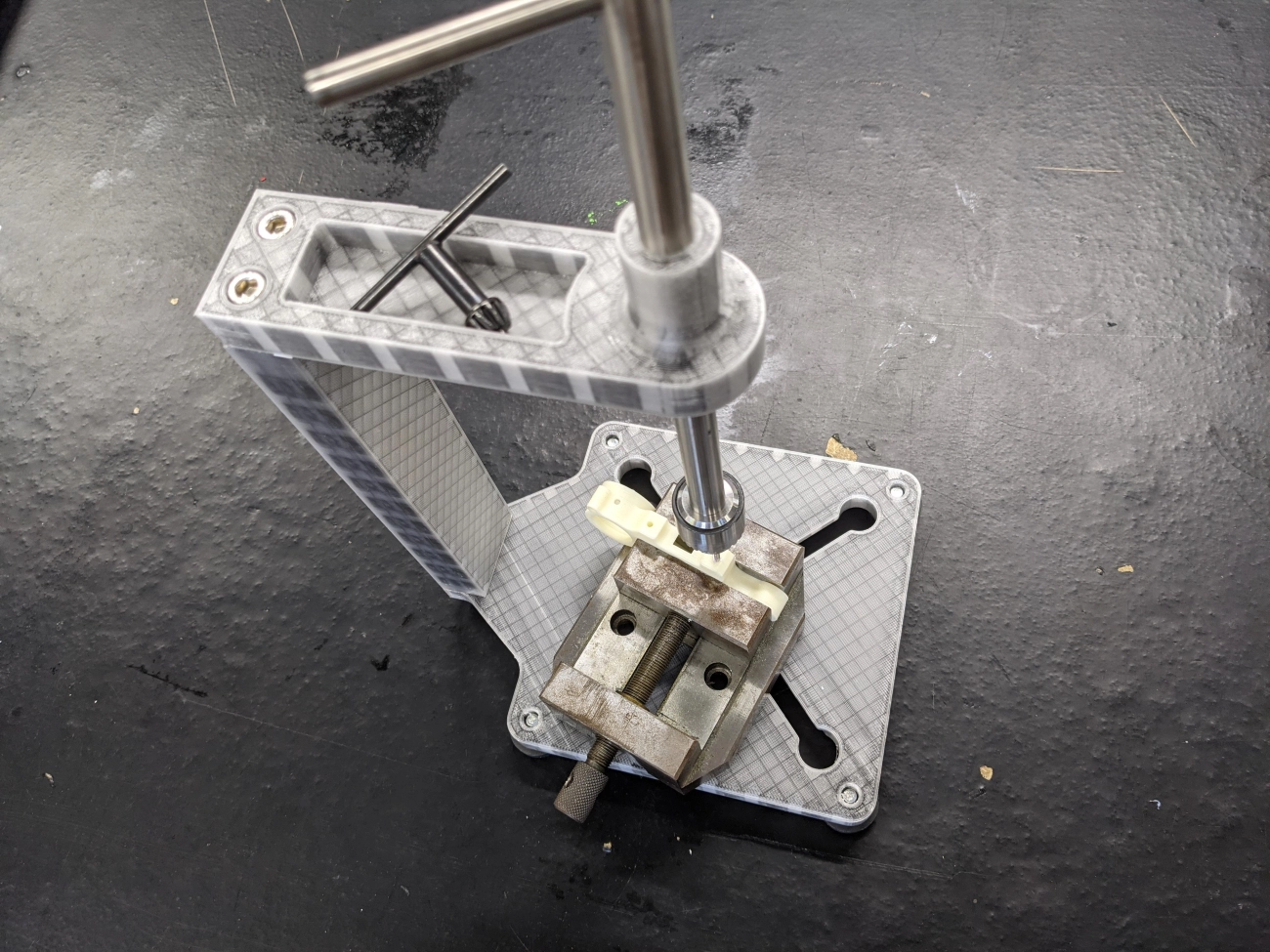

If you’re just starting out or enjoy taking on home projects, hand taps are your go-to tapping tools. These are simple, easy to use, and perfect for creating or repairing internal threads by hand without fancy machinery. Most hand taps come in sets—usually three: taper, plug, and bottoming taps—to help you gradually cut threads cleanly and avoid damaging the material.

Here’s why hand taps fit well with DIY projects:

- User-friendly: You can hold and control them with a standard hand tap wrench, so no special equipment needed.

- Versatile: Great for metal, plastic, wood, or even softer materials. HSS taps for metal are popular for durability.

- cURL Too many subrequests.: Hand tap sets are budget-friendly and widely available from both local stores and US-based manufacturers.

- cURL Too many subrequests.: You can easily find customized hand tapping tools if working on unique projects or materials.

- Good for small jobs: Perfect for fixing stripped threads or creating new ones on bolts and fasteners around the house or workshop.

If you’re planning on threading holes without the need for machine precision, hand taps are reliable, effective, and fit right into any DIY toolkit. Just remember to use the right tap drill size to match your thread cutting taps to avoid breaking or damaging your tap.

Types of Tapping Tools Which One Fits Your Needs

Machine Tapping Tools for Precision Pros

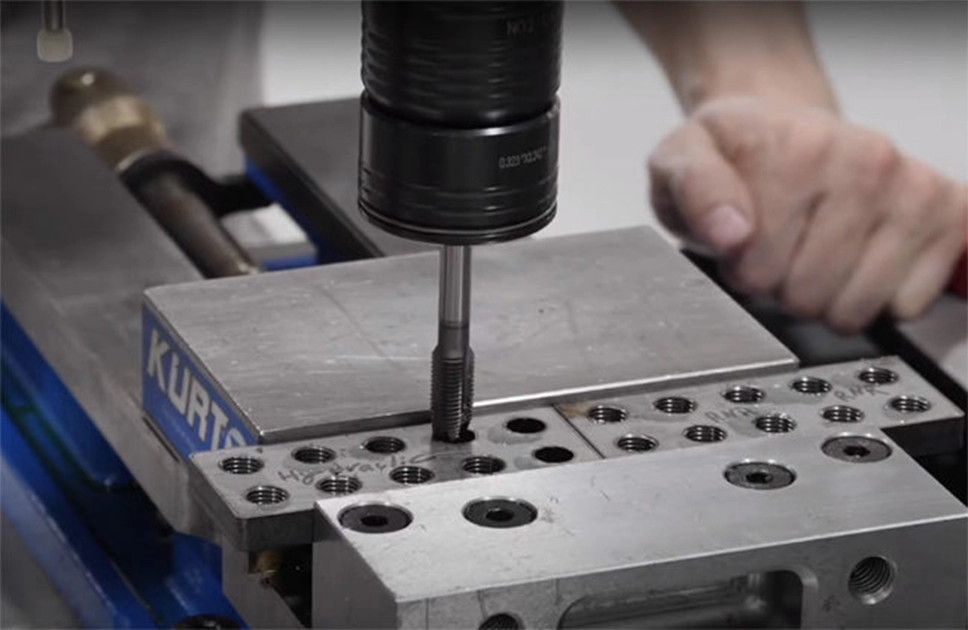

When it comes to precision and efficiency, machine tapping tools are the go-to choice for professionals and serious hobbyists. These tools are designed to work with drill presses, CNC machines, or tapping machines, delivering consistent, clean threads much faster than hand taps.

Key features of machine tapping tools:

- Spiral flute taps and chip breaker taps help clear chips quickly, reducing the risk of breakage.

- Made from HSS taps for metal or carbide for tougher materials, ensuring durability and long tool life.

- They come in a variety of sizes, compatible with standard tap drill charts cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests., cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.. cURL Too many subrequests.

Types of Tapping Tools Which One Fits Your Needs

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- Spiral flute tapscURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Bottoming taps: Perfect for threading to the bottom of a blind hole where space is tight.

Choosing the right specialty tapping tool depends on your material and project requirements. Using the wrong tap risks damaging your workpiece or tool, so always match your tap to the job.

For US workshops dealing with custom jobs or less common materials, working with a customized tapping tools manufacturer can help get the exact specs you need, boosting efficiency and thread quality.

How to Choose the Best Tapping Tools for Your Project Key Factors to Consider

Picking the right tapping tools for your project makes all the difference. Here’s what you need to keep in mind:

- Material You’re Working WithDifferent taps suit different materials. For example, HSS taps work well on metals like steel and aluminum, while carbide tapping accessories are better for harder, tougher materials.

- Type of Thread NeededUnderstand if you need a standard thread or something more specific like internal thread forming. This decides the kind of tap you should pick—straight flute, spiral flute taps, or specialized ones.

- Hand vs Machine TappingIf you’re DIY or working on small projects, hand taps with a tap wrench might be enough. For precision or larger scale jobs, consider machine threading tools.

- Project Size and FrequencyFor occasional use, a simple tap and die set might do. But if you’re running a workshop or handle projects often, investing in professional tapping tools and maybe even customized options from a reputable manufacturer is smarter.

- Tap Drill Chart MatchingMake sure you’re following the right tap drill chart for drill size before tapping. A mismatch can ruin threads and waste materials.

- Tool Quality and Brand ReputationChoose reliable brands known for durable tapping tools. This saves you money and hassle over time.

These factors steer you toward tools that work efficiently and last long—important when you want your project to come out just right without frequent tool changes or breakdowns.

How to Choose the Best Tapping Tools for Your Project Top Brands and Vast Recommendations

When picking tapping tools, sticking with trusted brands can make a huge difference. In the U.S., brands like Irwin, GearWrench, and Starrett are popular for their reliable thread cutting taps and durable hand tap wrenches. These manufacturers often offer a vast range of tapping tools, from spiral flute taps to HSS taps for metal, covering most needs whether you’re DIY’ing or working in a pro shop.

Here’s a quick rundown of recommended names and what they bring to the table:

- Irwin: Great for affordable, high-quality taps ideal for general purpose and DIY use.

- GearWrench: Known for machine threading tools and precision sets, perfect for serious users.

- Starrett: Offers premium tapping sets with excellent durability and accuracy, often favored by industries.

- OSG: A leader in specialty taps, including carbide tapping accessories and internal thread forming taps.

- Dormer Pramet: Trusted for both hand taps and machine tapping tools with a focus on innovation.

When searching for your next tap and die set, check if the brand provides helpful extras like tap drill charts or customized kits that fit your project size. Many local U.S. workshops prefer tools that are easy to resharpen or replace—so invest in brands with accessible service and good customer support.

By sticking with these brands, you gain access to a vast inventory of tapping tools designed to match your needs—whether you’re threading aluminum, steel, or unique materials. This helps avoid common headaches with tool wear or breakage, keeping your project on track and your budget in check.

How to Choose the Best Tapping Tools for Your Project

Common Mistakes to Avoid When Buying

Picking the right tapping tools can make or break your project. To save time and money, avoid these common mistakes when shopping:

- Choosing the wrong tap typeDon’t grab a hand tap when you really need a machine threading tool, or vice versa. Match the tap style (like spiral flute taps or HSS taps for metal) to your material and machine type.

- Ignoring the material you’re working withDifferent materials need different taps. Using a standard HSS tap on hard metals or specialty materials can ruin your tap and your workpiece. Look for carbide tapping accessories or internal thread forming taps for tougher jobs.

- Skipping the tap drill chartWithout the right drill size, your threads won’t fit. Always reference a tap drill chart before buying taps or drill bits.

- Buying low-quality tools to save moneyCheap taps wear out fast and can damage your work. Invest in well-reviewed brands that offer durability and precision.

- Not considering if you want a tap and die set or single tapsBeginners often buy large sets they don’t need. Focus on what you actually use to avoid extra clutter and expense.

- Ignoring tool compatibility with your equipmentMake sure your hand tap wrench or tapping machine matches the tool shank size and type.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.: Refer to a tap drill chart to drill the right-sized hole before tapping. This is key—too small or too big won’t cut clean threads.

- Lubricate for Smooth Tapping: Apply cutting fluid or oil to reduce friction. This helps preserve your HSS taps for metal and prevents breakage.

- Align Tap Straight: Position the tap perpendicular to the workpiece to avoid crooked threads.

- Turn Slowly and Steadily: Rotate the tap clockwise about half a turn, then back it off a quarter turn. This peck tapping technique clears chips and keeps the threads clean.

- Keep a Consistent Speed: Avoid forcing the tap. Tapping tools work best at a steady, manageable speed.

- Finish With Care: Once you feel resistance lessen, remove the tap slowly while still rotating it back and forth slightly. This prevents damaging the newly cut threads.

Manual tapping is all about patience and precision. Stick to these steps, and you’ll handle internal thread forming like a pro in your US workshop, whether you’re using standard HSS taps or even spiral flute taps for chip control.

cURL Too many subrequests.

Machine Tapping Best Practices

Using machine tapping tools correctly makes all the difference between clean, precise threads and damaged parts. Here’s how to get the best results when working with machine threading tools in your workshop:

- Choose the Right Tap: Match your tap to the material and thread specs. HSS taps for metal work great in most cases, but for tougher materials, carbide tapping accessories might be necessary. Check your tap drill chart to pick the correct tap size.

- Set Up Your Machine Correctly: Secure your workpiece firmly. Use a tapping head or chuck that fits your tap wrench and ensures steady, straight tapping.

- Control Speed and Feed: Use slow, consistent speeds. Too fast can overheat your tap and ruin threads; too slow might cause binding. The ideal speed depends on material and tap type — a quick tip is to start slow and increase speed carefully.

- Use Peck Tapping Technique: This means tapping in small steps by reversing slightly after every turn. Peck tapping helps clear chips and reduces tool breakage, especially in deeper holes or tougher metals.

- Keep It Cool and Lubricated: Use cutting fluid or oil made for threading tasks to reduce friction and extend tap life. Proper lubrication also helps maintain thread quality.

- Monitor Progress: Listen and feel for changes. Any unusual resistance or noise can mean the tap is misaligned or damaged. Stop immediately to check and avoid costly mistakes.

- Clean Taps Regularly: Chips get stuck easily. Periodically withdraw the tap fully to clear debris before continuing. This avoids clogging and tool damage.

By following these machine tapping best practices, especially with the right combinations of machine threading tools and accessories, you’ll get professional-grade threads every time — perfect for US shops focused on quality and efficiency.

cURL Too many subrequests.

Local Tips for US Workshops Adapting to Habits

When using tapping tools in US workshops, there are a few local habits and tips to keep in mind that can make your work smoother and more efficient:

- Use tap drill charts commonly accepted hereMost US machinists rely on standard tap drill charts for sizing holes before tapping. Make sure to keep a printed or digital chart handy to match internal thread forming or thread cutting taps perfectly.

- Opt for HSS taps for metal workingHigh-speed steel (HSS) taps are widely used in American shops for durability and precision on metals like steel and aluminum. They balance cost and performance well for most projects.

- Take advantage of hand tap wrenches for small jobsIn many local small to mid-size shops, hand taps with quality hand tap wrenches remain popular for quick fixes or DIY-style work. They offer great control before switching to machine threading tools.

- Apply the peck tapping technique when using machinesPeck tapping—lifting the tap out periodically to clear chips—is common practice in US machine shops to avoid tool breakage and ensure clean threads, especially in deeper holes.

- Invest in local manufacturer support or customized tapping toolsBuying tapping tools from US-based manufacturers or facilities offers faster shipping and access to customer support. Many provide customized tap and die sets suited to specific industries or materials common in the area.

- Regular maintenance fits US shop routines wellDaily cleaning, inspecting for wear, and storing taps properly aligns with American shop habits, extending tool life. Make it part of your standard operating procedure.

By adopting these local habits and tips, you’ll not only get better results but also reduce downtime and save money on tapping tools in your workshop.

Maintenance and Troubleshooting for Long-Lasting Tapping Tools

Cleaning and Storage Tips

Keeping your tapping tools in great shape starts with proper cleaning and storage. Here’s what I recommend for any tapping tool user in the US:

- Clean After Every UsecURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

Maintenance and Troubleshooting for Long-Lasting Tapping Tools

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

To really step up your tapping game, it’s smart to combine tapping tools with other essential gear in your workshop. When you integrate your tapping tools with items like tap drill charts, a solid hand tap wrench, and carbide tapping accessories, you make the process smoother and more accurate.

Here’s what works best for U.S. users:

- Use tap drill charts for precision: Matching the right drill size before tapping saves time and prevents thread damage. It’s a simple tool that makes a big difference.

- Pair hand tap wrenches with spiral flute taps: This combo is perfect for manual tapping, especially in tight or tricky spaces. The spiral flute helps clear chips, reducing jamming.

- Include machine threading tools for bigger projects: If you’re working on larger or repetitive tasks, combining machine tapping tools with your hand taps speeds up production without sacrificing quality.

- Add carbide tapping accessories for tough materials: When dealing with hardened metals, customized carbide taps hold up better and keep threads clean.

- Keep a tap and die set nearby: It’s not just for making threads but also for maintenance, fixing thread damage, or customizing threads on the spot.

On top of these, use internal thread forming techniques with suitable tapping tools for materials where cutting threads isn’t ideal. This integration helps in reducing wear on your taps and improves thread strength.

By syncing your tapping tools with these essentials, your projects become more efficient and reliable. It’s about building a workflow that fits local standards and gives you confidence on the shop floor, whether you’re DIYing at home or running a commercial facility.

Advanced Tips Elevating Your Tapping Game

Innovations in Tapping Technology

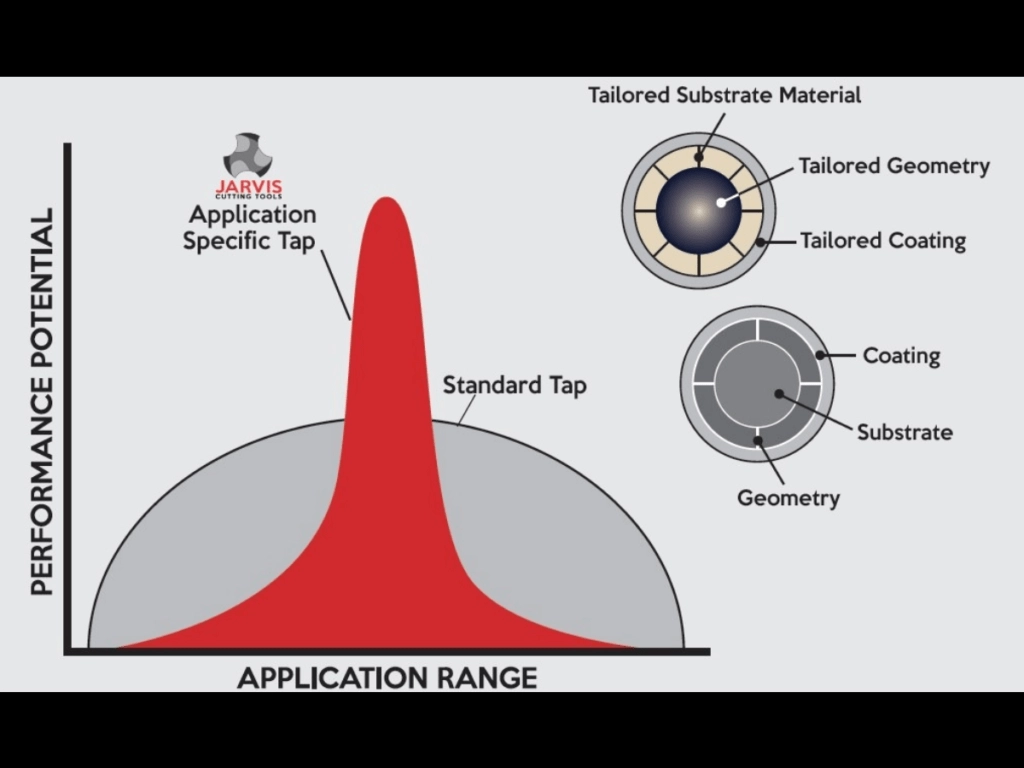

If you want to step up your tapping game, keeping an eye on the latest innovations is a smart move. Tapping tools have come a long way thanks to new materials and design improvements.

- Carbide Tapping Accessories: These are tougher than your standard HSS taps for metal, offering longer life and better performance when working with hard materials. Carbide options reduce wear and help maintain precise threads over time.

- Thread Cutting Taps with Improved Flutes: Innovations like spiral flute taps help clear chips more effectively, preventing jams during deep hole tapping. This innovation is a game-changer for cleaner, smoother threads.

- Internal Thread Forming Tools: Instead of cutting, these tools form threads by displacing material, which can increase strength and finish quality. They’re becoming popular in projects where precision and durability matter.

- Peck Tapping Technique: While not a tool itself, many machine threading tools now support automated peck tapping, which breaks up the cutting process to reduce stress and extend tap life. This method works well with CNC machines used in US workshops.

- Customized Tapping Solutions: Many manufacturers now offer tapping tools tailored to specific project needs—think customized tap and die sets designed for unique materials or special thread sizes common in local industries.

Keeping up with these innovations can boost your efficiency and make threading tasks more reliable. For anyone regularly working with tapping tools in the USA, investing in the right tech means less downtime and better results every time.