Learn what are chamfers and how beveled edges improve safety, durability, and design in machining, woodworking, architecture, and CAD projects.

What Exactly Is a Chamfer

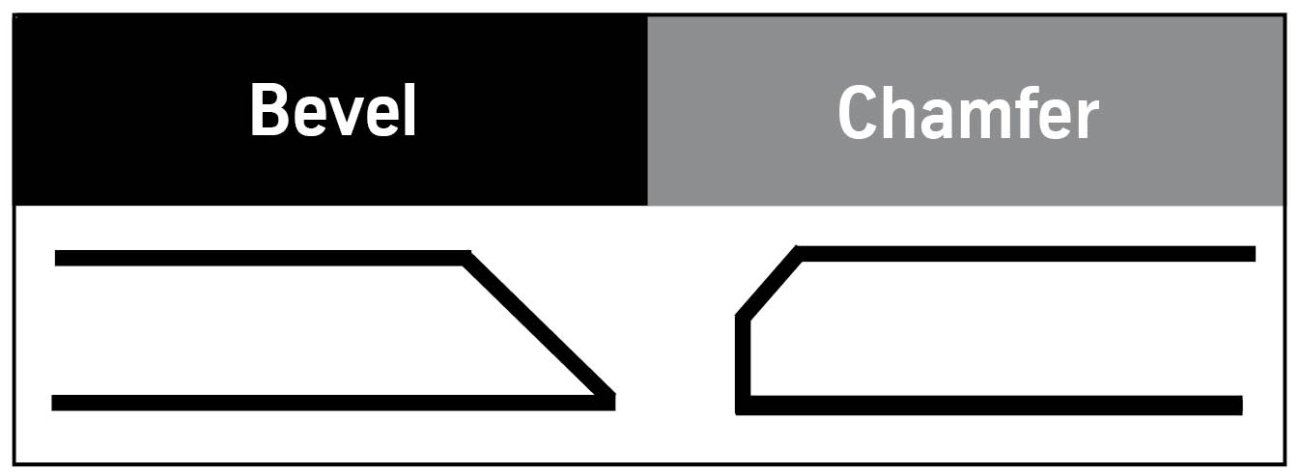

A cURL Too many subrequests. is a beveled edge that connects two surfaces, usually cutting off a sharp 90-degree corner at a consistent angle—commonly 45 degrees. Think of it as a small, angled slice that smooths the junction between two flat surfaces. Unlike a fillet, which rounds off an edge with a curve, a chamfer is flat and straight. While the terms “chamfer” and “bevel” are often used interchangeably, a bevel generally refers to any sloping edge, whereas a chamfer has a precise, defined angle and length.

Visually, imagine the corner of a metal block or wooden piece trimmed at a sharp angle, producing a clean, flattened corner instead of a crisp point. This angled cut is what defines the chamfer’s distinct look.

Historically, chamfers have been used for centuries in craftsmanship and engineering—from ancient stone masonry to modern machine parts—because they help with both function and form. You’ll see them in everything from furniture edges to gear teeth, showcasing their versatility.

So, why do chamfers matter? Besides offering a polished look, they reduce the risk of injury by removing sharp edges, and they limit edge wear by preventing damage from knocks and friction. This simple design detail plays a huge role in safety and durability across countless applications.

The Key Purposes of Chamfers

Chamfers serve several important roles across different uses. Here’s why they matter:

Safety Benefits

- Remove sharp edges that can cause cuts or injuries.

- Make handling parts and tools safer for workers and users.

Engineering Advantages

- Reduce stress concentration especially in vibrating or moving parts.

- Help prevent cracks and extend the life of machinery and gear components.

Aesthetic Appeal

- Chamfers add a clean, polished look to furniture and architectural features.

- They soften harsh edges while keeping a modern, precise finish.

Assembly and Manufacturing Help

- Chamfers make parts easier to fit together during assembly, welding, or installation.

- Assist in the deburring process by smoothing rough edges left from cutting or machining.

Quick Look Table

| Purpose | Benefit | Common Use |

|---|---|---|

| Safety | Prevent cuts and injuries | Tools, furniture, electronics |

| Engineering | Reduce stress on edges | Gears, vibrating parts |

| Aesthetic | Improve visual appeal | Furniture, architecture |

| Assembly & Deburring | Ease fitting, remove burrs | Machining, welding, manufacturing |

By combining these benefits, chamfers play a crucial role in making products safer, stronger, and more attractive — all of which are essential for the US market where quality and safety standards are high.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

| cURL Too many subrequests. | Best For | cURL Too many subrequests. |

|---|---|---|

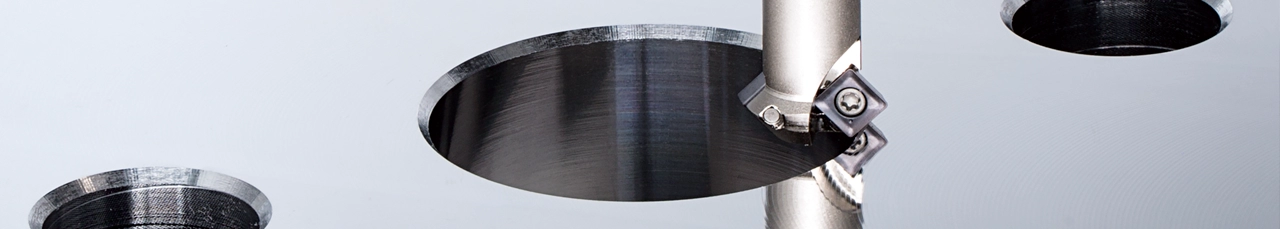

| cURL Too many subrequests. | Metals and plastics | Can create precise chamfers quickly |

| Plasma Cutting | Sheet metals | Cuts chamfers through heat, good for heavy gauge materials |

| Router with Chamfer Bit | Wood, plastics | Fast and smooth chamfering for edges |

| Grinder or Belt Sander | Quick edge smoothing | Common for deburring and minor chamfer needs |

Machine methods speed up the process and are best for repeatability, especially in manufacturing.

Dimensioning and CAD Specifications

- Specify angle and size – Chamfers usually have a 45-degree bevel or other standard angles.

- Use CAD software – Most CAD programs, like AutoCAD or SolidWorks, let you easily add chamfers to designs.

- Add tolerances – Critical for machining to ensure the chamfer fits perfectly with other parts.

Step-by-Step Guide for Beginners

- Mark the chamfer line with a pencil or scribe.

- Select your tool (plane, file, or machine).

- Start cutting at the marked edge, keeping a steady hand.

- Check frequently to maintain the correct angle and smoothness.

- Finish with fine sanding or polishing for a clean edge.

Common Mistakes to Avoid

- Uneven angles – Make sure your tool maintains a consistent angle.

- Removing too much material – Measure carefully before cutting.

- Ignoring safety – Wear goggles and gloves when using power tools.

- Skipping deburring – Always clean the edge for safe handling and better finishes.

Using the right tools and attention to detail will help you create chamfers that improve safety, fit, and style across your projects.

Chamfer vs Similar Features

When talking about chamfers, it’s important to know how they differ from similar edge treatments like bevels, fillets, and rounds. Here’s a quick breakdown to clear things up.

Differences Between Chamfers and Bevels

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

Quick Comparison Table

| Feature | cURL Too many subrequests. | Purpose | cURL Too many subrequests. | Typical Uses |

|---|---|---|---|---|

| Chamfer | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Bevel | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Fillet | cURL Too many subrequests. | cURL Too many subrequests. | Radius cutters, routers | Engineering, metal parts |

| Round | Rounded outside | Safety, comfort, aesthetic | Rounding tools, sanders | Furniture, handles, plastic parts |

Tips on Choosing Chamfers vs Alternatives

- Pick chamfers for precise angled edges, easier assembly, and better edge wear.

- Use bevels when a custom angle is needed, or for decorative finishes.

- Choose fillets or rounds to reduce stress points or create a smoother surface.

This helps you match the right edge treatment to your project’s needs, saving time and improving results.