Learn what a slip fit is in precision engineering including tolerance classes, comparisons, and real-world uses for machinists and beginners.

Slip Fit vs Other Fits

A slip fit is a type of clearance fit, designed to allow easy assembly where the shaft slides freely into the hole without force. Clearance fits include ranges from very loose (RC1–RC4) that permit free-running movement, to tighter clearances like RC5–RC9, which still allow sliding but with minimal play. In contrast, interference fits such as locational interference (LN), press fits (FN), or force fits require pressing or force to assemble, creating a strong, immovable joint.

Here’s a quick visual and functional comparison:

| Fit Type | Tolerance Range | cURL Too many subrequests. | Typical Use |

|---|---|---|---|

| Slip Fit (Clearance) | RC1 – RC4 (looser) | Easy sliding | Bearings, pins, moving parts |

| Tighter Clearance | RC5 – RC9 | Controlled sliding | Shafts with low friction play |

| Interference Fit | Negative clearance (LN,FN) | Press or force assembly | Permanent joints, heavy load |

Using slip fits ensures smooth assembly and disassembly without the need for tools or heat, making them ideal for applications requiring frequent maintenance or adjustment. Vast’s tolerance tools can help you select the precise clearance fit you need to meet your design goals efficiently.

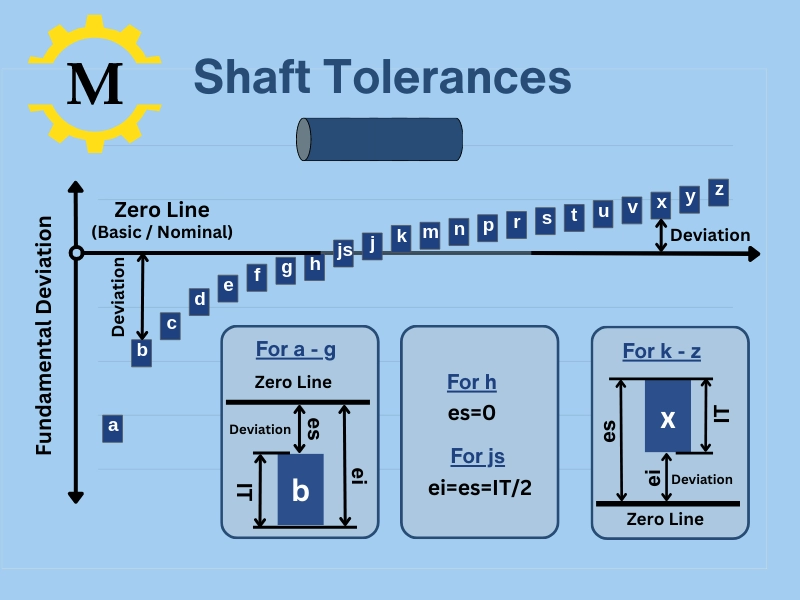

Tolerance Classes and Standards

Slip fits and other clearance fits follow specific tolerance classes that control how tight or loose parts can be. The most common standard is ISO 286, which defines several RC (Running Clearance) classes. For example, an RC3 clearance fit typically allows between 0 to 25 microns of clearance, making it ideal for slip fits where parts need to slide smoothly without too much play.

In the U.S., you’ll often see ANSI B4.1 standards used, which align closely with ISO but have subtle differences in tolerance ranges. Both standards help you pick the right fit for your application, balancing ease of assembly with reliable performance.

Several factors can affect tolerance beyond just the raw numbers:

- Material properties like thermal expansion, which can change part size with temperature

- cURL Too many subrequests., cURL Too many subrequests.

- Lubrication, cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

Useful Resources

- You can download free tolerance calculators like the vast tool, which helps you input sizes and tolerances to get precise clearance values quickly.

cURL Too many subrequests.

- Temperature Changes: Materials expand or contract with heat, which can tighten or loosen fits unexpectedly.

- Plating or Coating Thickness: Surface finishes add extra thickness that affects fit; ignoring this can cause parts to stick or be loose.

Keeping these factors in mind ensures your slip fits are accurate, reliable, and easy to assemble in real-world applications.

Real-World Applications of Slip Fit

Slip fits are common in many industries where smooth, reliable movement between parts is key. In automotive manufacturing, slip fits are used for piston pins and gear shafts, allowing parts to slide or rotate without binding. Aerospace applications rely on slip fits for actuator rods and hinge pins where precision and ease of assembly are critical.

Consumer products also benefit from slip fits. Adjustable laptop hinges and camera lens mounts often use these fits to combine durability with smooth motion.

A great example is a recent case with a robotics client who switched to RC3 slip fits. This change reduced assembly time by 40%, showing how the right slip fit can improve efficiency without compromising performance. These real-world uses highlight how slip fit tolerances and clearance classes play into making practical, dependable designs across different sectors.

Assembly and Inspection Best Practices

Getting slip fits right means careful assembly and inspection to keep parts moving smoothly without too much play. Here’s what I recommend:

Tools to Use

- Go/no-go gauges: Quick and reliable for checking if shaft and hole sizes fall within the slip fit tolerances.

- Coordinate Measuring Machines (CMM): Offers precise measurement and helps spot subtle deviations.

- Optical comparators: Great for visual inspection of part profiles and small dimensional differences.

Lubricants Matter

Use light oils or anti-seize compounds during assembly. These help prevent wear and corrosion while allowing easy sliding without sticking.

Quality Checklist

- Verify dimensions against slip fit tolerance classes (e.g., RC2 or RC3).

- Inspect surface finish—roughness affects assembly ease and fit consistency.

- Confirm cleanliness—debris or burrs can cause binding or wrong fits.

- Monitor ambient temperature, especially for tight fits, since thermal expansion can influence clearances.

For easier reference, I suggest downloading a quality checklist PDF available from tooling and metrology suppliers. It guides you step-by-step through inspection and assembly, helping avoid common slip fit issues.

Following these practices ensures your slip fits assemble smoothly, last longer, and perform reliably in everyday use.

FAQs about Slip Fit

Here are some quick answers to common questions about slip fit and related topics:

| Question | Answer |

|---|---|

| Difference between slip fit and sliding fit | Slip fit allows easy assembly with a small clearance. Sliding fit is tighter, allowing controlled movement but less clearance. |

| Does a slip fit become loose over time? | It can, especially if parts wear or if there’s vibration. Proper material choice and lubrication help maintain fit. |

| Is slip fit suitable for high-speed rotation? | Yes, but it depends on tolerance consistency and lubrication to avoid wobble or vibration at high speeds. |

| Are slip fit tolerances consistent in vast applications? | cURL Too many subrequests. |

cURL Too many subrequests.