Discover what an end mill is its types coatings and uses with expert tips on choosing the right CNC milling tool for precision cutting.

Imagine this: you’re trying to mill a precise pocket on a metal part, but your cut goes sideways—wasting time, material, and frustration. What went wrong? Most likely, you reached for a drill bit when you really needed an end mill.

An end mill is a specialized rotary cutting tool, built with sharp teeth on the end face and sides, designed not just to plunge but to cut laterally with pinpoint accuracy. It’s the backbone of modern milling, delivering versatility and precision across metals, plastics, and composites.

Whether you’re a beginner or a seasoned machinist, understanding what an end mill is and how it differs from a drill bit is the first step toward better machining results—and smarter tool choices. Ready to dive in?

End Mill vs. Drill Bit: Clearing the Confusion

Let’s clear up a common mix-up: an end mill and a drill bit may look similar, but they’re built for very different jobs. Here’s a quick side-by-side:

| Feature | End Mill | Drill Bit |

|---|---|---|

| Flute Count | 2 to 8 flutes, sometimes more | Usually 2 flutes |

| Cutting Direction | Can cut sideways and plunge | Designed primarily to plunge |

| Applications | Milling slots, contours, pockets | Drilling straight holes |

The key myth? People often think drill bits can only plunge vertically—and that’s true. But end mills can plunge like drills e cut sideways, making them versatile for shaping, slotting, and 3D contouring. Think of a drill bit as a hammer driving straight down, while an end mill acts like both a hammer and a saw, carving out intricate paths.

Knowing this difference is crucial when selecting the right tool for CNC milling tasks—using a drill bit sideways risks breakage and sloppy cuts, whereas end mills are designed to handle that stress.

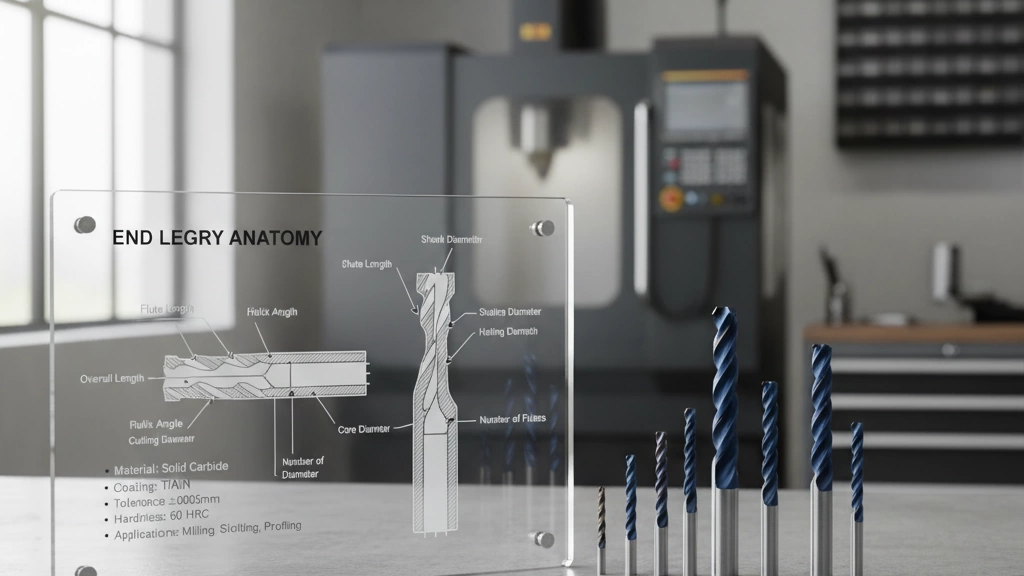

Anatomy of an End Mill

Understanding the anatomy of an end mill helps you pick the right tool for your job. Here’s a breakdown:

Shank:

This is the part that fits into your machine’s collet. Common diameter sizes in the U.S. include 1/4″ and 1/2″, with metric sizes also widely used depending on the machine. Shank types vary:

- Straight shank is the most common and fits standard collets.

- Weldon shank features side flats for better grip, preventing slips under heavy loads.

- Whistle notch shanks have a groove that locks into the holder for quick tool changes.

Flutes:

Flutes are the cutting edges twisted down the tool. End mills come with anywhere from 2 to 8 flutes:

- Fewer flutes (2-3) mean better chip evacuation, great for soft materials like aluminum.

- More flutes (4-8) provide smoother finishes and longer tool life, perfect for steel or harder metals.

Helix angles usually range between 30° and 45°, affecting how aggressively the tool cuts and clears chips. Steeper angles flush chips faster, reducing heat buildup.

Cutting Diameter & Length of Cut:

Specs on the end mill packaging or datasheets tell you these numbers. The cutting diameter is the width of the cut made by your tool, while the length of cut is how deep it can mill into the material. Understanding these ensures you don’t overload the tool or machine.

End Geometry:

The shape at the tip changes what the end mill is best at:

- Square end mills deliver sharp corners, good for slots and pockets.

- Ball nose mills have rounded tips, ideal for 3D contouring and molds.

- Corner radius end mills add a small curve to edges, reducing stress and extending tool life.

- Roughing profiles look rougher but quickly remove large amounts of material before finishing passes.

Knowing these details makes choosing the right end mill straightforward for your milling projects.

Common End Mill Types & When to Use Them

Knowing which end mill to pick makes all the difference in your machining work. Here’s a quick breakdown of common types and when to use them:

- Square End MillPerfect for slotting, profiling, and pocketing straight edges and flat surfaces. It leaves crisp corners and is a go-to for general machining.

- Ball Nose End MillGreat for 3D contouring and mold making. Its round tip lets you create smooth curves and complex shapes without sharp edges.

- Corner Radius End MillAdds a small radius to the cutting edge, reducing stress on the tool and workpiece. Ideal for fillets and improving tool life in finish passes.

- Roughing & Finishing End MillsRoughing (Hogging): Removes large amounts of material fast with serrated edges. Not for smooth finishes but saves time on bulk cuts.

Finishing: Provides clean, mirror-like surface finishes for precision parts.Specialty End MillsDesigned for specific jobs like T-slotting, dovetail grooves, keyseats, or tiny detailed cuts using micro end mills. These fill niche roles you won’t get from standard cutters.

Choosing the right type based on your project material and finish needs will save you time and improve results on your CNC or manual mills.

Materials & Coatings Demystified

When choosing an end mill, material matters. Here’s a quick look at the top options:

- HSS (High-Speed Steel): Affordable and tough, HSS is great for general use and softer materials like wood or plastic. It wears faster with harder metals but is easy to sharpen.

- Carbide: Harder and more expensive, carbide end mills hold their edge longer and cut faster. Perfect for tough materials like steel, stainless, and titanium. They’re less flexible but deliver better precision and lifespan.

- Cobalt: A step between HSS and carbide, cobalt blends heat resistance with some flexibility. It does well in higher temperature cuts but isn’t quite as hard as carbide.

Coating Guide

Coatings boost tool life by handling heat and wear. Here’s a quick rundown you’ll see in U.S. shops:

- TiN (Titanium Nitride): Gold color, general-purpose, reduces wear.

- TiCN (Titanium Carbonitride): Harder than TiN, great for tougher materials.

- TiAlN (Titanium Aluminum Nitride): Handles high heat better, perfect for high-speed steel and stainless.

- AlTiN (Aluminum Titanium Nitride): Even higher heat resistance, ideal for dry machining.

- ZrN (Zirconium Nitride): Excellent for abrasive materials like aluminum, helps prevent built-up edges.

Carbide Grade Spotlight

Not all carbide is the same. For the U.S. market, sub-micron grain carbide is top-tier—fine particles fused for supreme toughness and sharpness. It’s especially popular for machining aluminum, steel, and titanium where precision and tool life count.

Bottom line: Match your end mill material and coating to the job’s demands for the best balance of cost and performance.

Selecting the Right End Mill

Picking the right end mill comes down to the material you’re cutting and how you set up your tool.

Material Compatibility

- Aluminum: Use fewer flutes (2-3) and sharper geometry for smooth chips. Carbide or sub-micron carbide grades work best.

- Steel & Stainless: More flutes (4-6), tougher coatings like TiAlN help with heat and wear. Cobalt tools can boost life.

- Plastics & Exotics: Look for sharp edges and polished flutes to avoid melting or chipping.

Rigidity Rules

- Keep Length of Cut (LOC) short: The shorter your end mill’s cutting length, the less it will deflect.

- Oversized Shank: A bigger shank diameter adds strength and stability.

- Reduced Neck: Use necked tools only if you need deep cuts without rubbing, but avoid if rigidity is critical.

Speed & Feed Tips

- Match spindle speed and feed rate to material and tool specs.

- Use speed & feed calculators—many tool vendors offer free tools online to dial in the numbers.

Common Failures & Fixes

- Chatter: Reduce speed, increase rigidity, and check machine setup.

- Built-Up Edge: Often happens with steel; increasing speed or adding coolant helps.

- Breakage: Usually caused by too aggressive feeds or poor tool support—slow down and check tool fit.

Choosing smart here saves wear, breaks, and expensive downtime.

Practical Applications Across Industries

End mills play a key role across many industries here in the U.S., each with unique demands:

- Aerospace: Machining tough titanium wing spars requires carbide end mills with sharp edges and heat-resistant coatings like TiAlN to handle high-speed cuts without wearing out.

- Automotive: Aluminum engine blocks benefit from high-performance end mills that manage chip evacuation well, often using 3–4 flute designs to maintain surface finish and speed.

- Woodworking: CNC router signage relies on specialized square end mills and micro end mills for clean cuts and fine detail in softer materials like wood and composites.

- Medical: Implant prototyping demands ball nose cutters and corner radius end mills for smooth 3D contours and stress-free edges on stainless steel or titanium parts.

No matter the field, picking the right end mill often comes down to matching material and application needs with tool geometry and coating—key for efficiency and tool life.

Maintenance, Storage & Tool Life Hacks

Keeping your end mills sharp and well-stored is key to getting the most out of them. Here’s how to extend their life and save money:

- Regrinding Economics: Instead of tossing worn end mills, consider regrinding. It restores sharpness at a fraction of the cost of new tools. Just make sure your grinder knows the correct flute geometry and helix angle to avoid ruining the tool.

- Proper Collet Torque: Don’t overtighten or undertighten your collet. Use a torque wrench to get the right grip—too loose causes chatter and breakage; too tight can distort the shank and ruin accuracy.

- Storage Trays for Edge Protection: Store your end mills in dedicated trays or holders. This prevents contact with other tools, keeping edges sharp and avoiding nicks or chips, especially for micro end mills or specialty types.

These simple habits go a long way, especially when machining tougher materials like stainless steel or titanium where tool life is critical.

Buying Guide: Red Flags & Pro Tips

When it comes to buying end mills, knowing where to shop and what to look for is key. You can go direct to vast manufacturers for competitive prices and wider selections or choose authorized distributors if you want expert advice and easier returns. Both have pros—direct is often cheaper, while distributors may offer better support.

Key Red Flags to Watch Out For:

- Runout above 0.0002″: Too much tool runout means poor accuracy and faster wear.

- Unclear specs or no grade info: You want to know exactly what material and coating you’re getting.

- No warranty or support: Quality end mills often come with warranties or sample programs to test before bulk orders.

Pro Tips for Buying Smart:

- Always ask for runout and tolerance data—precision matters in US machine shops.

- Check if the brand offers sample end mills so you can try before a big buy.

- Look for warranty coverage or tool replacement policies, especially if you’re investing in premium carbide or coated tools.

- Remember, buying cheap can cost more if the tools chip or wear out early.

Keep these in mind and you’ll get the best end mills, whether you’re cutting aluminum, steel, or exotic materials right here in the USA.