Discover the precise 1018 steel yield strength ranging from 310 to 420 MPa and learn about its mechanical properties and applications.

What Is AISI 1018 Steel A Quick Primer

If you’ve ever worked with mild steel in the U.S., chances are you’ve encountered AISI 1018 steel. It’s one of the most common low carbon steels out there, valued for its versatility and balance of strength and machinability.

Chemical Composition

At its core, 1018 steel is a low carbon steel with the following makeup:

- Carbon: Approximately 0.18% – this low carbon level keeps it soft and easy to work with

- Manganese: Around 0.60–0.90% to improve strength and hardenability

- Trace Elements: Small amounts of sulfur and phosphorus, usually under 0.04%, help with machinability but don’t affect mechanical properties much

This simple yet effective formula gives 1018 steel its dependable characteristics for broad industrial use.

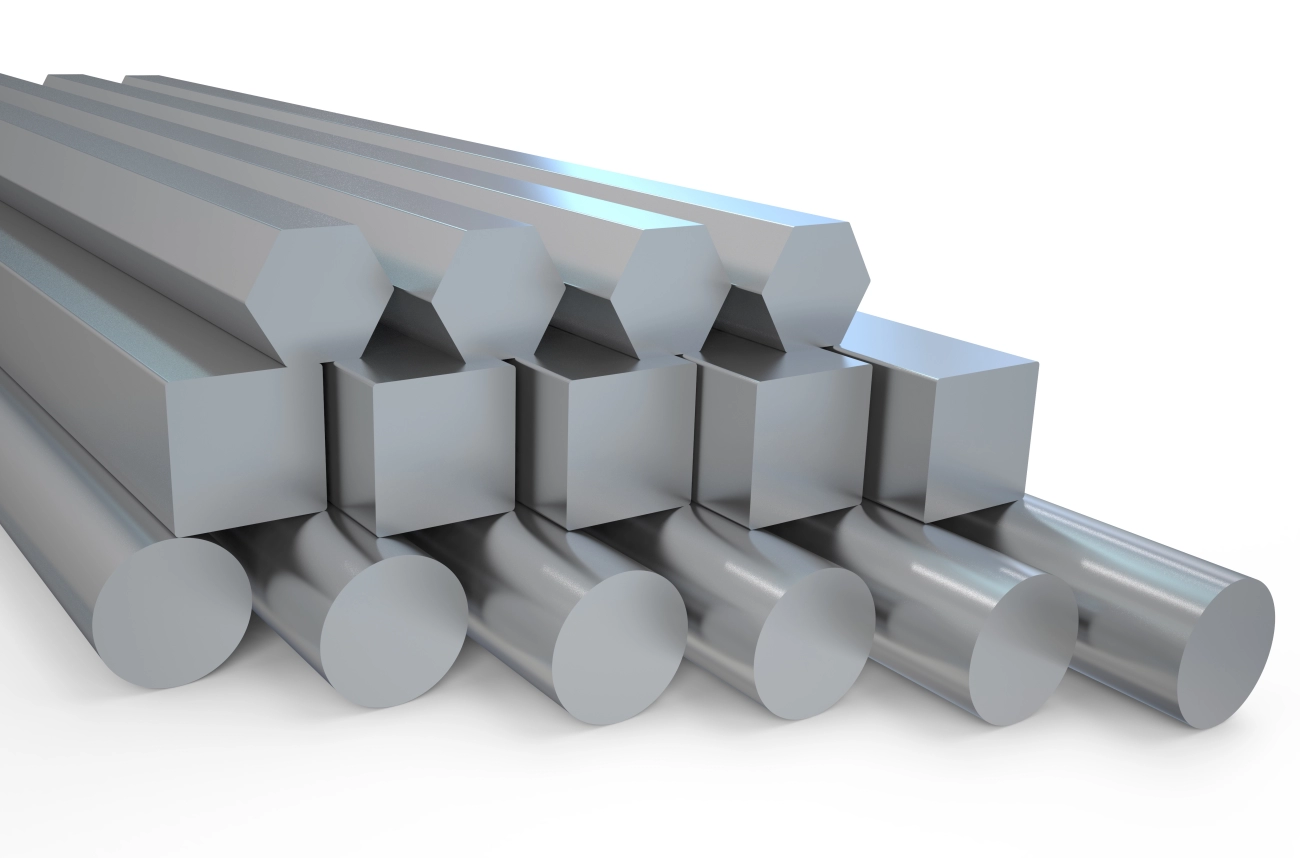

Common Forms and Processing

1018 steel comes in several popular forms, each impacting its yield strength differently:

- Hot Rolled: The baseline form, offering good ductility and ease of welding

- Cold Drawn: This one gets pulled through dies while cold, increasing yield strength by refining the grain structure and work hardening the metal

- Normalized: Heat treated to slightly improve uniformity and mechanical properties without sacrificing machinability

Cold drawing is especially important if your project demands higher yield strength while maintaining good surface finish.

Historical Context

The 1018 steel grade has been a staple in the U.S. manufacturing sector since the early 1900s thanks to the SAE and AISI standards. These bodies standardized steel grades to help engineers and fabricators pick the right material every time, and 1018’s consistent performance kept it among the favorites for decades.

In short, 1018 steel is a reliable, low carbon choice with multiple forms tailored to various strength and processing needs. It’s an essential material that continues to power industries across the country.

Curious how its yield strength stacks up? Stick with me as we explore that next.

Decoding Yield Strength The Core Metric for 1018 Steel

Yield strength is the stress level at which 1018 steel starts to deform permanently. Think of it as a line in the sand — push the steel harder than this, and it won’t bounce back to its original shape. This is different from tensile strength, which is the absolute maximum stress the steel can handle before breaking. If yield strength is when the rubber band starts to stretch, tensile strength is when it snaps.

For AISI 1018 steel, yield strength varies based on how it’s processed:

| Form | Yield Strength (psi) | Yield Strength (MPa) | ASTM A108 Range (MPa) |

|---|---|---|---|

| Hot Rolled | 53,700 | 370 | 310–480 |

| Cold Drawn | 63,800 | 440 | 400–520 |

| Normalized | ~55,000 | 380 | 330–490 |

Cold drawing noticeably boosts yield strength by tightening the grain structure.

Several factors influence yield strength in 1018 steel:

- Heat treatment – Normalizing or annealing adjusts grain size and stress levels, typically improving toughness but slightly lowering yield strength.

- Grain size – Smaller grains mean higher yield strength (Hall-Petch relationship); cold working refines grains here.

- Impurities – Excess sulfur or phosphorus can lower yield strength and toughness.

Here’s a simple example calculating load capacity for a 1018 steel rod in a structural setting:

Given a 1-inch diameter cold drawn 1018 rod (yield strength ~63,800 psi),

- Cross-sectional area = π × (0.5)^2 ≈ 0.785 in²

- Max load without permanent deformation = Yield strength × Area = 63,800 psi × 0.785 in² ≈ 50,103 lbs

So, this rod can safely carry just over 50,000 pounds before yielding. Knowing this helps in making smart choices for construction, automotive parts, or agricultural machines common in the US market.

Full Mechanical Profile Beyond Yield Strength

When looking at 1018 steel, yield strength is just one part of the bigger picture. Here’s how its other mechanical properties play into performance:

- Tensile Strength measures the maximum force the steel can handle before breaking. For 1018, it usually ranges from 440 to 580 MPa (64,000 – 84,000 psi).

- Elongation shows ductility—how much the steel can stretch before snapping. 1018 typically offers 15% to 20% elongation, making it fairly flexible.

- Together with yield strength, these help ensure the material won’t crack under normal use.

Hardness and Modulus of Elasticity also matter, especially in fatigue resistance, which is how steel holds up under repeated stress:

- Hardness for 1018 is often between 120–180 HB (Brinell Hardness).

- Modulus of elasticity stays steady around 200 GPa (29,000 ksi), a sign of consistent stiffness.

Mechanical Properties Table for 1018 Steel

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Yield Strength | 370–440 MPa | 54,000–64,000 psi |

| Tensile Strength | 440–580 MPa | 64,000–84,000 psi |

| Elongation (%) | 15–20% | 15–20% |

| Hardness (HB) | 120–180 | 120–180 |

| Modulus of Elasticity | ~200 GPa | ~29,000 ksi |

Testing Methods

To ensure these numbers stand up in the real world, tensile testing is done per ASTM E8 standards. This test measures both yield and tensile strength by slowly stretching a steel sample until it deforms or breaks. It’s a reliable way to verify mechanical properties and ensure quality before steel hits the shop floor.

Together, these mechanical properties help explain why 1018 is a go-to steel in many industries—from automotive parts to farm equipment—where durability and some flexibility are key.

Applications Where 1018 Steel Yield Strength Shines

AISI 1018 steel’s yield strength makes it a reliable choice for many practical applications, especially in automotive and machinery parts. It’s commonly used for pins, shafts, and gears—components that need to handle steady loads without deforming. For example, a shaft made from cold-drawn 1018 with a yield strength around 370 MPa (54,000 psi) can easily withstand typical torsional stresses in light vehicles or industrial machines.

In construction and agriculture, 1018 steel is popular in the U.S. for farm equipment and structural parts where moderate strength and excellent machinability are essential. Its ability to endure daily use without fatigue makes it a go-to metal for tools and supports in these sectors.

One standout use is in custom fabrication projects. For instance, a conveyor system designed for 50,000 cycles relied heavily on 1018 steel’s balance of yield strength and ductility. The steel handled repetitive loading with minimal wear—proving its value in machinery running continuous operations.

Still, 1018 isn’t always the best option. For applications demanding higher strength or heavier loads, steels like 1045 or alloy steels offer better yield strength (up to 600 MPa or more) but at a higher cost and reduced machinability. When strength is a priority over ease of fabrication, upgrading to these materials is worth considering.

In , 1018 steel works well where moderate yield strength and good workability meet, especially across U.S. automotive, agricultural, and light industrial uses.

Comparisons 1018 Yield Strength Versus Similar Steels

When picking steel, understanding how 1018 matches up against similar grades makes a big difference, especially in yield strength and cost.

| Steel Grade | Approximate Yield Strength (ksi) | Key Benefit | Cost Factor | Best Use Case |

|---|---|---|---|---|

| 1008 | 30-35 | Cheaper | Lower Cost | Basic low-stress parts |

| 1018 | 53-58 | Precision machining | Moderate | Shafts, pins, and gears needing better strength |

| A36 | 36-58 | Structural steel | Similar to 1018 | Construction, general fabrication |

| 1045 | 70-90 | Much higher strength | Higher Cost | Heavy-duty, high-stress parts |

1018 vs 1008

1018 steel offers a noticeably higher yield strength than 1008, making it worth the extra cost when parts need durability and better wear resistance. 1008 is fine for basic, low-stress uses but isn’t ideal when strength matters.

1018 vs A36

A36 steel’s yield strength overlaps with 1018 in the mid-range, but 1018 shines in machining precision and finishes smoother. If you need tight tolerances and better surface quality for parts like pins or pins in machinery, 1018 is usually the better pick.

1018 vs 1045

1045 steel has much higher yield strength, often nearly double that of 1018, but it comes with a cost premium and is tougher to machine. It’s great for heavy-duty applications but can be overkill for general fabrication or moderate load parts.

Cost Benefit Snapshot

- 1018 offers a solid balance between performance and machining ease.

- 1008 may save money upfront but lowers durability.

- A36 fits structural needs but lacks the finesse for precise parts.

- 1045 is premium strength but with heavier machining costs.

Locally in the US, 1018 is widely available at good prices, making it a top choice for many industries needing reliable yield strength without breaking the budget.

Sourcing and Working With 1018 Steel Practical Advice

When sourcing 1018 steel, it’s smart to pick suppliers with proper certifications like ASTM A108 to ensure consistent quality and reliable yield strength. Lead times can vary, but many US industrial hubs—such as Chicago, Houston, and Cleveland—stock large inventories ready for quick shipping. This means you can often get what you need without long waits.

For machining, 1018 steel rates well thanks to its low carbon content and good machinability rating. To keep yield strength intact, avoid excessive heat buildup during cutting. Use sharp tools and proper cooling to prevent softening. Welding is straightforward but stick to recommended guidelines to prevent weakening. Preheating isn’t usually needed, but controlling heat input during welding is key to maintaining mechanical properties.

Here’s a quick checklist to keep yield strength solid when working with 1018 steel:

- Choose certified suppliers with ASTM or SAE compliance

- Use sharp tooling and coolants for machining

- Follow welding guidelines to manage heat input

- Minimize post-machining heat treatments unless specified

Local availability also makes it easier to source smaller batches or custom sizes without breaking the bank. Many suppliers offer quick quote options online, helping you compare costs and delivery quickly.

Finally, 1018 steel is quite sustainable. Being a low carbon, mild steel, it’s highly recyclable, supporting eco-friendly manufacturing practices within the US. This makes it a practical choice for companies aiming to reduce their environmental footprint without sacrificing performance.