Compare 7075 aluminum vs 6061 for strength, machinability, corrosion resistance, and applications to find the best alloy for your project needs.

Struggling to pick between 7075 aluminum vs 6061 for your next project? You’re not alone. Whether you’re building high-stress aerospace components or crafting reliable bike frames, choosing the right alloy can make all the difference in strength, durability, and cost. In this guide, we cut through the noise and give you a clear, side-by-side look at these two industry favorites—so you can decide which aluminum alloy truly fits your needs. Let’s get started.

Chemical Composition

When comparing 7075 aluminum vs 6061, the difference starts right at their chemical makeup. 6061 belongs to the 6000 series aluminum alloys, which mainly combine silicon (Si) and magnesium (Mg). This blend strikes a solid balance between strength and formability, making 6061 versatile and easy to work with. On the other hand, 7075 is part of the 7000 series alloys, known for their ultra-high strength. It features higher amounts of zinc (Zn) along with significant amounts of magnesium and copper (Cu), pushing the limits on tensile strength but introducing some trade-offs.

Here’s a quick breakdown of the key elements in both alloys:

| Element | 6061 Aluminum (%) | 7075 Aluminum (%) |

|---|---|---|

| Silicon | 0.6 | 0.4 |

| Magnesium | 1.0 | 2.5 |

| Zinc | 0.25 | 5.6 |

| Copper | 0.15 | 1.6 |

This composition reveals exactly why these alloys perform so differently. The high zinc and copper content in 7075 boosts tensile and yield strength, making it a favorite for aerospace and high-stress parts. However, these same elements can reduce corrosion resistance, making 7075 more prone to environmental wear unless properly treated. Meanwhile, 6061’s lower zinc and copper levels mean it handles outdoor and marine environments better but sacrifices some strength.

Understanding this chemical tug-of-war helps us appreciate why 6061 is often chosen for projects where corrosion resistance and ease of fabrication matter, while 7075 is the go-to when maximum strength and fatigue resistance are non-negotiable. Next, we’ll dive into the mechanical properties to see how these chemical differences play out in the real world.

Mechanical Properties

When comparing 7075 aluminum vs 6061, the biggest difference lies in strength. The 7075 T6 alloy nearly doubles the tensile and yield strength of 6061 T6. This makes 7075 the clear choice for stress-critical applications where maximum power and durability matter, like aerospace parts or high-performance gear.

7075 also outperforms 6061 in hardness and fatigue resistance. It has a higher Brinell hardness and better shear strength, which means it’s tougher when it comes to impacts and heavy wear. For parts that face repeated stress or rough conditions, 7075 stands out.

On the flip side, 6061 shines with better ductility and elongation, giving it an edge for projects requiring bending or forming without cracking. This makes 6061 more forgiving when you need to shape metal without breaking it.

Here’s a quick side-by-side for the T6 temper:

| Property | 6061 T6 | 7075 T6 |

|---|---|---|

| Tensile Strength (ksi) | ~45 | ~83 |

| Yield Strength (ksi) | ~40 | ~73 |

| Brinell Hardness | ~95 | ~150 |

| Density (g/cm³) | 2.7 | 2.81 |

| Strength to Weight | Good | Excellent |

In real-world use, think about aerospace gears where 7075’s ultra-high strength is necessary to handle extreme forces, versus structural beams or frames where 6061’s combination of strength and flexibility keeps costs down and fabrication easier.

Overall, 7075’s strength-to-weight ratio makes it ideal when strength can’t be compromised. Meanwhile, 6061 offers a balance that suits many everyday structural needs.

Machinability Weldability and Formability

When it comes to machinability, 6061 has the edge. It machines smoothly with easier chip flow and lower tool wear, making it ideal for fast, efficient production. On the other hand, 7075 is fair but trickier—higher speeds can cause galling, so it needs more careful handling and tooling.

In terms of weldability, 6061 stands out. It works well with both TIG and MIG welding without cracking, making it a go-to for welded structures. 7075, however, is prone to weak spots in the heat-affected zone and often needs post-weld heat treatment to prevent cracking, so welding should generally be avoided unless necessary.

Formability also favors 6061 thanks to its higher ductility. It’s easier to extrude, bend, and shape without cracking. 7075 is much tougher to work with and usually requires annealing before complex bends or extrusions to prevent fractures.

Pro tips for working with 7075:

- Use carbide tooling to handle its hardness and avoid excessive wear.

- Watch out for stress corrosion in humid or coastal environments—it’s more vulnerable than 6061 and may need protective coatings.

For jobs requiring easier machining, reliable welding, and flexible forming, 6061 is usually your best bet. But if strength is the priority and careful machining is an option, 7075 can deliver unmatched performance.

Corrosion Resistance and Finishing

Both 6061 and 7075 aluminum anodize nicely, but their corrosion resistance differs. 6061 has lower copper and zinc content, giving it better marine and outdoor durability without the exfoliation problems that 7075 can face. This makes 6061 a go-to for untreated applications in automotive and general outdoor use.

7075, on the other hand, often needs cladding or protective coatings to handle harsh environments, especially in aerospace where corrosion can’t be risked. It resists wear well after anodizing but isn’t as naturally corrosion-resistant as 6061.

Finishing options

- 6061: Anodizing enhances looks and corrosion resistance, perfect for visible, untreated parts.

- 7075: Anodizing mainly boosts wear resistance, important for high-stress surfaces.

Environmental notes

- 7075 is prone to corrosion if left bare, especially in humid or marine environments.

- Watch out for galvanic corrosion when either alloy contacts other metals like steel or copper; proper coatings or isolation is key to avoid damage.

In short, for outdoor or marine uses where corrosion is a factor, 6061 holds the edge. For wear resistance and high-strength parts that need finishing, 7075 shines but needs a little extra care to stay protected.

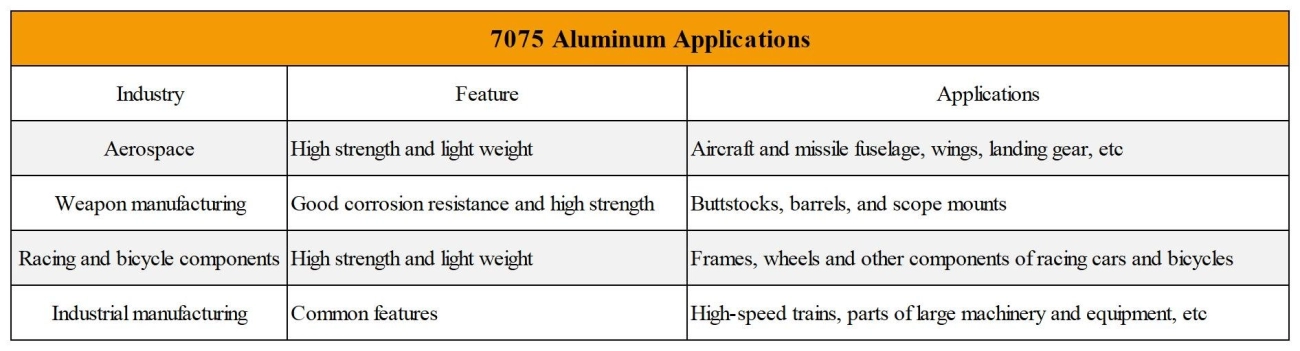

Applications

6061 aluminum is a go-to for everyday uses like structural piping, bike frames, and marine fittings. It’s versatile and perfect for projects where cost matters but reliability can’t be ignored. Whether you’re building outdoor gear or general fabrication, 6061 delivers solid performance without breaking the bank.

On the flip side, 7075 shines in high-stakes situations. It’s the top choice for aircraft wings, rock climbing equipment, and AR-15 lowers—places where strength and durability aren’t just nice-to-have but critical. When failure is not an option, 7075’s ultra-high tensile strength makes it the clear winner.

Many designs now blend the two alloys, using 6061 for the main body to save weight and budget, while reinforcing stress points with 7075 for maximum strength. This hybrid approach balances performance and cost efficiently.

In industry terms, aerospace relies heavily on 7075 aluminum for its strength-to-weight benefits. Automotive often opts for 6061, especially in prototypes and consumer products where affordability and ease of fabrication are priorities. This split reflects how each alloy plays to its strengths in real-world applications.

Cost Availability and Sourcing

When it comes to cost, 7075 aluminum is generally pricier than 6061. This is mainly due to its more complex processing and alloying elements. If you’re prototyping or working on a budget-friendly project, 6061 is usually more accessible and easier on your wallet.

Both alloys are widely stocked across the U.S., so availability isn’t usually a problem. However, 7075 can have longer lead times, especially if you need custom tempers or sizes. If time is tight, 6061 tends to be easier to source quickly.

Total cost of ownership is worth considering beyond just the price per pound:

- 6061 often saves you money during machining and welding because it’s easier to work with.

- 7075 may cost more upfront but offers better longevity and higher strength, which pays off in heavy-duty and long-term applications.

| Alloy | Approximate Cost per Pound | Notes |

|---|---|---|

| 6061 | $1.80 – $2.50 | Widely available, easy to machine and weld |

| 7075 | $2.50 – $4.00 | Higher strength, longer lead times |

Bulk sourcing tips:

- Order in larger quantities to lower per-pound cost.

- Build relationships with local suppliers for faster turnaround.

- Ask about stocked tempers to avoid wait times on custom orders.

Whether you prioritize upfront affordability or long-term performance, balancing cost against your project needs is key when choosing between 7075 aluminum vs 6061.

To wrap it up, 7075 aluminum stands out when maximum strength is the top priority, making it perfect for elite, stress-critical applications like aerospace and high-performance gear. On the other hand, 6061 offers a great balance of strength, affordability, and versatility, especially if you need better weldability and easier formability for everyday structural uses.

Quick Decision Guide

| Need | Choose |

|---|---|

| Maximum strength | 7075 Aluminum |

| Weldability and formability | 6061 Aluminum |

| Cost-effective solution | 6061 Aluminum |

| Fatigue and corrosion resistance | 6061 Aluminum |

We stock vast inventories of both 6061 and 7075 alloys and provide custom fabrication services tailored to your needs. Reach out if you want to test samples or get professional advice.

FAQ

Is 7075 stronger than 6061?

Yes, 7075 is about 84% stronger than 6061, making it the go-to choice for high-strength aluminum needs.

If this helped you, feel free to share and subscribe for more straightforward metal insights!