Compare 7075 vs 6061 aluminum alloys for strength, machinability, corrosion resistance, cost, and ideal applications in aerospace and fabrication projects.

Chemical Composition and Microstructure

Let’s start with the basics: what elements make up 7075 and 6061 aluminum, and how do they shape their microstructures? Here’s a quick breakdown of major alloying elements by weight %:

| Element | 7075 | 6061 |

|---|---|---|

| Zinc (Zn) | 5.6 – 6.1 | 0.0 – 0.1 |

| Magnesium (Mg) | 2.1 – 2.5 | 0.8 – 1.2 |

| Copper (Cu) | 1.2 – 2.0 | 0.15 – 0.4 |

| Silicon (Si) | 0.0 – 0.4 | 0.4 – 0.8 |

| Chromium (Cr) | 0.18 – 0.28 | 0.04 – 0.35 |

| Iron (Fe) | ≤0.5 | ≤0.7 |

Zinc in 7075 is the heavy hitter here. Its high zinc content enables strong precipitation hardening—fine, dispersed MgZn2 precipitates form during heat treatment, locking dislocations and boosting strength dramatically. This microstructure features densely packed, hardening zones ideal for aerospace-grade performance.

6061 has a different story. It relies on magnesium and silicon forming Mg2Si precipitates during aging. The resulting microstructure is less dense in hardening particles, which translates to slightly lower peak strength but better ductility and corrosion resistance.

Looking under the microscope, 7075’s grain structure shows fine, closely spaced precipitates, which create that strong but less forgiving alloy. 6061’s micrograph reveals coarser, widely spaced Mg2Si phases, producing a more uniform and tougher matrix.

This elemental difference sets the stage for everything else, from machining to fatigue resistance.

Mechanical Properties Deep Dive Ultimate Tensile Strength and Yield Strength

When comparing 7075 vs 6061 aluminum in terms of strength, 7075 really stands out. In the popular T6 temper, 7075 offers an ultimate tensile strength (UTS) of about 83 ksi (kilo pounds per square inch), nearly double that of 6061-T6, which hits around 45 ksi. This high UTS makes 7075 a go-to choice where maximum strength is critical, like aerospace components and high-performance bike frames.

Yield strength follows a similar pattern, with 7075-T6 pushing about 73 ksi compared to 6061-T6’s 40 ksi. This means 7075 resists permanent deformation much better under heavy loads.

Fatigue strength is another key factor. 7075 is designed to handle cyclic stresses, which is why it’s so popular in aircraft parts where repeated loading is constant. It resists crack initiation and propagation better under these conditions. 6061, while not as strong, offers decent fatigue resistance suitable for less demanding uses like automotive brackets or recreational bike frames that see moderate cycling loads.

Key points:

- 7075-T6 UTS: ~83 ksi

- 6061-T6 UTS: ~45 ksi

- 7075-T6 Yield Strength: ~73 ksi

- 6061-T6 Yield Strength: ~40 ksi

- 7075 better for high fatigue life in aerospace

- 6061 suitable for moderate cyclic loads in structural and automotive use

For anyone needing strength and fatigue resistance, 7075 is the clear winner; but 6061 remains a solid, more affordable choice when ultra-high strength isn’t mandatory.

Mechanical Properties Deep Dive Hardness and Toughness

When comparing 7075 vs 6061 aluminum in hardness and toughness, there are clear differences to keep in mind.

Hardness:

- 7075-T6 typically scores around 150 Brinell Hardness Number (BHN), making it much harder than 6061-T6, which usually sits near 95 BHN.

- On the Rockwell B scale, 7075 comes in around 80 HRB while 6061 is closer to 60 HRB. This means 7075 resists surface indentation and wear better—important for aerospace parts and high-stress uses.

Toughness:

- Toughness is about impact resistance, and here 6061 takes a lead. In Charpy impact tests, 6061 shows higher energy absorption before fracturing, meaning it’s less likely to crack or shatter under sudden force.

- 7075, while stronger, is more brittle and can fail sooner under impact, so it’s not the best choice where toughness is critical.

In , 7075 offers superior surface hardness but at the cost of lower toughness compared to 6061. For applications needing high wear resistance, 7075 is ideal. If you need a balance of strength and impact resistance, 6061 is the better pick.

Mechanical Properties Deep Dive Elastic Modulus and Density Weight Critical Apps

When comparing 7075 vs 6061 in terms of elastic modulus and density, both alloys have similar stiffness but differ slightly in weight — a key factor for critical applications.

- Elastic Modulus: Both 7075 and 6061 aluminum offer an elastic modulus around 10 million psi (69 GPa). This means they flex about the same under load, making neither dramatically stiffer than the other for structural uses.

- Density: 7075 is a bit denser at about 2.81 g/cm³, while 6061 weighs slightly less, approximately 2.70 g/cm³. That might not sound like a lot, but in aerospace or automotive frames, cutting even a fraction of a pound adds up.

Why does this matter?

- 7075 excels when strength-to-weight is critical, like in aircraft wings or high-performance bike frames, where saved weight boosts efficiency and performance.

- 6061’s lighter weight and good stiffness make it popular in applications where cost and machinability matter as much as weight, such as in structural supports and automotive parts.

In short, if your build demands top-end strength without much weight penalty, 7075 edges ahead. For lighter, versatile parts that still hold their own, 6061 is a smart pick.

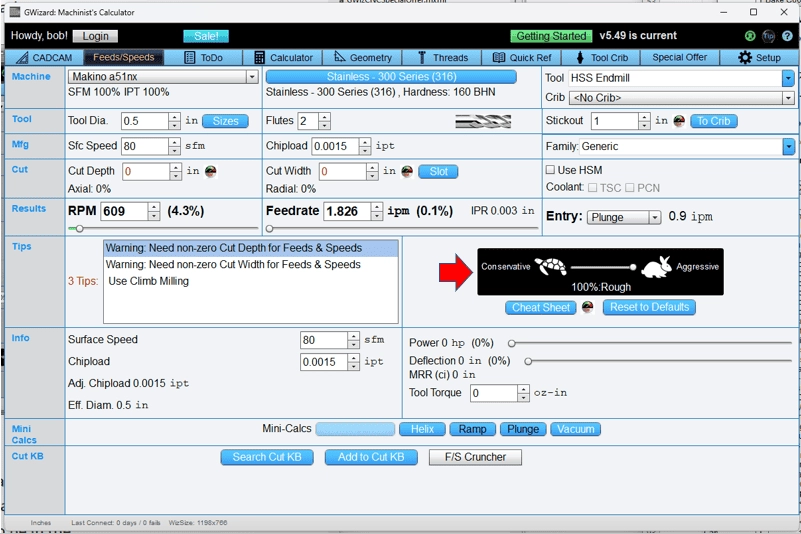

Fabrication and Machinability CNC Cutting Speeds and Feeds

When it comes to CNC machining, both 7075 and 6061 aluminum alloys machine well, but there are key differences to keep in mind for US-based shops balancing speed and finish.

7075 aluminum is harder and stronger, so it requires slower cutting speeds compared to 6061 to avoid excessive tool wear and heat buildup. Recommended surface feet per minute (SFM) for 7075 typically range around 300-400 SFM with proper coolant. Chip load per tooth should be kept moderate to reduce chipping on cutting edges, usually about 0.002–0.004 inches/tooth depending on tool size and operation.

6061 aluminum is softer and easier to machine, allowing faster cutting speeds—up to 600-800 SFM—with higher chip loads (0.004–0.006 inches/tooth). This means jobs using 6061 can often run quicker and put less strain on tooling, making it attractive for large production runs or rapid prototyping in the US.

Here’s a quick comparison for typical CNC milling (using carbide end mills):

| Alloy | Recommended Speed (SFM) | Chip Load (in/tooth) | Notes |

|---|---|---|---|

| 7075 | 300 – 400 | 0.002 – 0.004 | Slower speeds prevent tool wear |

| 6061 | 600 – 800 | 0.004 – 0.006 | Runs faster, easier on tools |

For US fabricators, this means 6061 can often reduce cycle times and tooling costs. But if your project demands strength where 7075 shines, adjusting speeds and feeds for careful machining is key to avoid material and tool problems.

In :

- Use slower speeds and moderate chip loads with 7075.

- Feel confident pushing 6061 at higher speeds and chip loads for faster turnaround on structural parts and prototypes.

Fabrication and Machinability Weldability and Formability

When it comes to welding, 6061 aluminum is the clear winner. It’s highly TIG and MIG friendly, making it easy to join and shape without much fuss. This makes 6061 a popular choice for structural parts, automotive brackets, and other projects where welding or bending is needed.

On the other hand, 7075 is tricky to weld. It’s prone to cracking during the process because of its high zinc content and heat treatment sensitivity. When welded, 7075 can lose much of its strength since the heat changes its temper (T6 mostly), which means you often need post-weld heat treatments to regain some of that strength. Forming 7075 is also tougher since it’s less ductile, so it’s not the best option if your project involves lots of bending or shaping.

In :

- 6061 = easy to weld (TIG/MIG), good formability, no major heat treat concerns

- 7075 = poor weldability, cracking risk, strength loss after welding, limited formability

If your job needs welding and bending, 6061 is your go-to. For machining or applications where welding isn’t needed, 7075 can deliver higher strength but demands more care in fabrication.

Fabrication and Machinability Anodizing and Surface Finish

When it comes to anodizing, both 6061 and 7075 respond well to Type II and Type III processes, offering good corrosion protection and an attractive finish. However, 7075’s higher copper content makes a difference in the surface look—it tends to develop a darker, richer anodized color compared to 6061. If you want a deep, intense dye uptake, 7075 is your go-to alloy.

That said, 6061 is easier to get uniform finishes on because it anodizes more evenly. With 7075, you might notice some variation in the anodized layer thickness and color intensity, so it can require tighter process control. This makes 6061 more popular for parts where a consistent, bright finish is a priority, like consumer products or automotive trims.

In short, choose 7075 for darker, more durable anodizing when strength and appearance matter, but pick 6061 for easier, more uniform surface finishing on lighter structural parts.

Corrosion Resistance and Environmental Suitability

When it comes to corrosion resistance, 6061 aluminum clearly outperforms 7075, especially in harsh environments like marine settings. Under ASTM B117 salt spray testing, 6061 typically holds up well for over 500 hours before signs of corrosion appear. In contrast, 7075 tends to show corrosion much quicker, often around 100 to 200 hours. This difference is mainly due to the higher zinc content in 7075, which makes it more vulnerable to corrosive damage.

Another important factor is stress corrosion cracking (SCC). 7075-T6 is notorious for SCC issues; under tensile stress and a corrosive environment, cracks can develop and propagate, which is a major concern in aerospace and structural parts. On the other hand, 6061 is much more resistant to SCC, making it a safer choice for marine and outdoor applications where corrosion and stress combine.

- 6061 offers better resistance to salt spray corrosion per ASTM B117 standards

- 7075-T6 has higher risk of stress corrosion cracking, especially under load and moisture

- For marine uses and environments prone to corrosion, 6061 is the preferred alloy

- 7075 requires protective coatings or anodizing for outdoor durability

Choosing between 7075 and 6061 depends on balancing strength needs with environmental exposure. If corrosion resistance is critical, especially in salty or wet conditions, 6061 stands out.

Cost and Availability

When it comes to price, 6061 aluminum is much more budget-friendly, typically around $3.50 per pound. On the other hand, 7075 costs nearly double, ranging from $6 to $8 per pound depending on market demand and supplier. This price difference reflects 7075’s higher strength and aerospace-grade status.

Both alloys come in various stock forms like plate, bar, and sheet, but availability varies. 6061 is widely stocked and easier to source quickly, making it ideal for projects with tight timelines. 7075, however, often has longer lead times, especially for larger or custom sizes, due to its more limited production and demand concentration in specialized industries.

If cost and quick availability are your priorities, 6061 is the clear winner. But when strength and performance matter most, many U.S. buyers accept the higher cost and wait times for 7075.

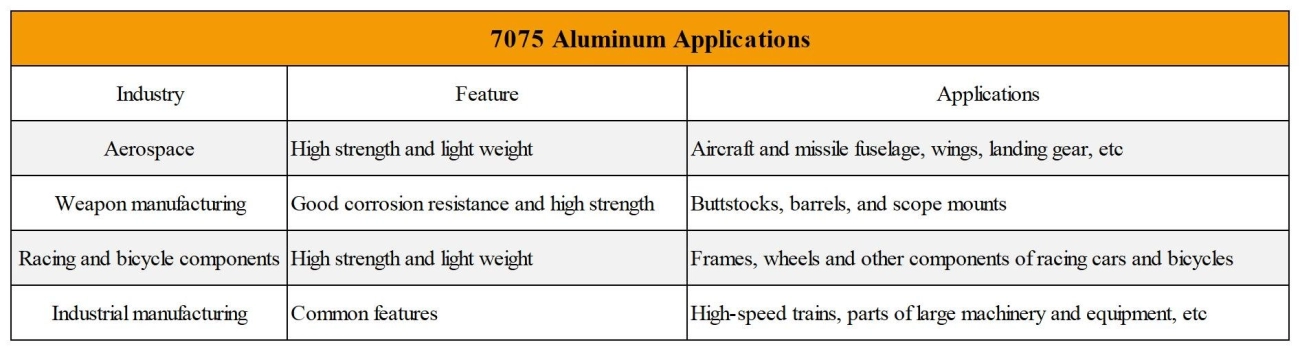

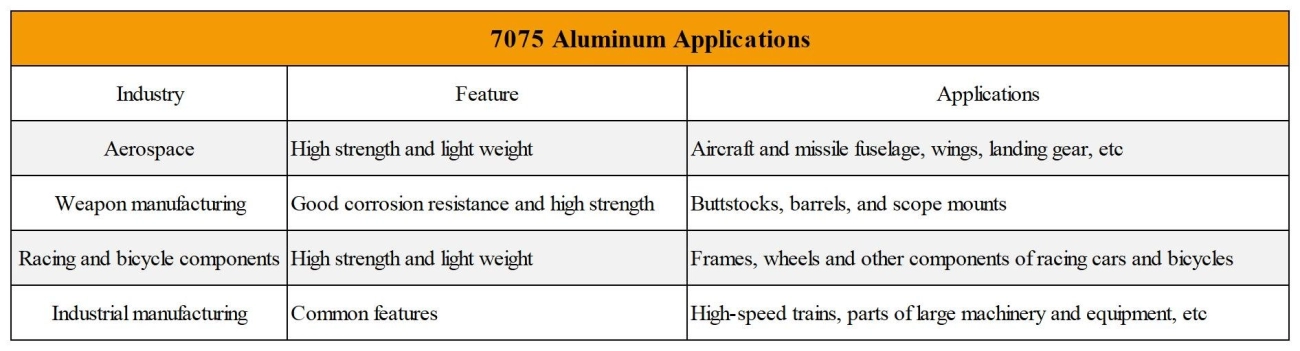

Application Showdown When 7075 Dominates aerospace spars rock climbing carabiners

7075 aluminum shines when strength and weight savings are top priorities. This alloy’s high tensile strength (up to 83 ksi in T6 temper) makes it perfect for aerospace spars where every pound counts, but reliability and durability can’t be compromised. You’ll find 7075 used extensively in aircraft structural parts because it handles high loads and stress without adding unnecessary bulk.

It’s also the go-to for rock climbing gear like carabiners and quickdraws. The combination of toughness, fatigue resistance, and light weight means climbers get secure, strong gear that won’t fail under repeated use. In gear where safety is critical, 7075’s superior mechanical properties truly stand out compared to 6061.

In short, when your project demands the highest strength-to-weight ratio, like in aerospace or critical climbing equipment, 7075 dominates thanks to its advanced chemical makeup and hardened microstructure.

Application Showdown When 6061 Wins structural frames automotive brackets prototyping

6061 aluminum shines when you need strong, reliable material that’s easy to work with. It’s the go-to for structural frames, automotive brackets, and prototyping projects because it balances strength and weldability without breaking the bank. Here’s why 6061 wins in these areas:

- Structural frames: 6061’s good stiffness and toughness make it perfect for load-bearing parts in construction and machinery. It holds up well under stress, making your frames both durable and lightweight.

- Automotive brackets: Its machinability and corrosion resistance mean brackets stay strong and rust-free over time, ideal for cars and trucks exposed to all kinds of weather.

- Prototyping: Because 6061 is easier to cut, weld, and form, it’s favored by manufacturers and engineers when testing new designs. Using 6061 means faster turnaround and less hassle during the build phase.

Plus, 6061 costs almost half as much as 7075 per pound, making it a smart choice when budget and versatility matter most. If you want solid performance without the premium price, 6061 is often the best pick.

Application Showdown Hybrid Use Cases 7075 Inserts in 6061 Extrusions

Combining 7075 and 6061 alloys is a smart move when you want the best of both worlds. Using 7075 inserts inside 6061 extrusions lets you get high strength where it counts, like in critical mounting points or fastener holes, while keeping the overall weight and cost down with 6061.

Here’s why this hybrid approach works well for many U.S. applications:

- Strength Boost: 7075 inserts handle heavy loads and stress, thanks to their superior tensile strength (up to 83 ksi) compared to 6061’s 45 ksi.

- Machinability and Cost: 6061 extrusions are easier to machine and weld, lowering fabrication time and cost.

- Weight Savings: Using 7075 only where strength is essential keeps projects lighter than all-7075 designs.

- Corrosion and Finish: 6061 offers better corrosion resistance and anodizing results for the exterior, while 7075 maintains structural integrity within.

This combination is popular in aerospace fixtures, custom automotive parts, and rugged outdoor gear like climbing equipment frames, where durability and performance matter without breaking the bank. It’s a local U.S. favorite for balancing toughness, price, and fabrication ease.

Expert Verdict and Material Selector Tool

Choosing between 7075 and 6061 aluminum really comes down to your specific needs. If strength tops your list and budget allows, 7075 is the clear winner. It offers high tensile strength great for aerospace parts and rugged gear. On the other hand, 6061 shines when you need solid performance, excellent machinability, and better weldability—all while keeping costs lower.

Here’s a quick decision matrix to help guide you:

| Criteria | 7075 Aluminum | 6061 Aluminum |

|---|---|---|

| Ultimate Strength | Very High (up to 83 ksi) | Moderate (around 45 ksi) |

| Machinability | Moderate | Excellent |

| Cost | Higher ($6–$8 per lb) | Lower (~ $3.50 per lb) |

| Weldability | Poor (heat treat loss) | Excellent |

| Corrosion Resistance | Moderate to Low | Good |

| Application Fit | Aerospace, high-stress parts, rock climbing gear | Structural frames, automotive, prototyping |

For those still unsure, try our free Vast Alloy Selector Quiz. It’s quick and easy—giving you an instant recommendation tailored to your project requirements. You can also get an instant quote to see how your choice impacts your budget.

Selecting the right alloy doesn’t have to be guesswork. Use the right tools and info to make your project both strong and cost-effective.

FAQ

Can you weld 7075 to 6061?

Welding 7075 to 6061 is tricky. 6061 welds well with TIG or MIG thanks to its magnesium and silicon content. But 7075, with its high zinc level, is prone to cracking and losing strength near the weld. Welding these two alloys together typically leads to weak joints unless specialized techniques and post-weld heat treatments are applied. For most projects, it’s better to avoid welding 7075 or use mechanical fastening instead.

Is 7075 worth 2x the price for AR lowers?

7075’s strength and fatigue resistance make it a top pick for AR-15 lowers, especially if you want lighter, stronger parts. However, it costs about twice as much as 6061. If you’re building a high-performance rifle where durability and weight matter, 7075 is worth the extra cost. For budget builds or less demanding use, 6061 is good enough and much more affordable.

What is the best anodized finish for 7075?

7075 anodizes nicely but tends to take on a darker tone because of its copper content. Type II anodizing is common for everyday wear and corrosion resistance, while Type III (hardcoat) anodizing adds extra surface hardness for tough environments. If you want the best balance of appearance and durability on 7075, Type III hardcoat anodizing is usually the go-to finish.