Discover the complete guide to milling m/c machines including types, features, and tips to choose the perfect milling machine for your workshop needs.

What Is a Milling Machine The Basics You Need to Know How Does a Milling Machine Work

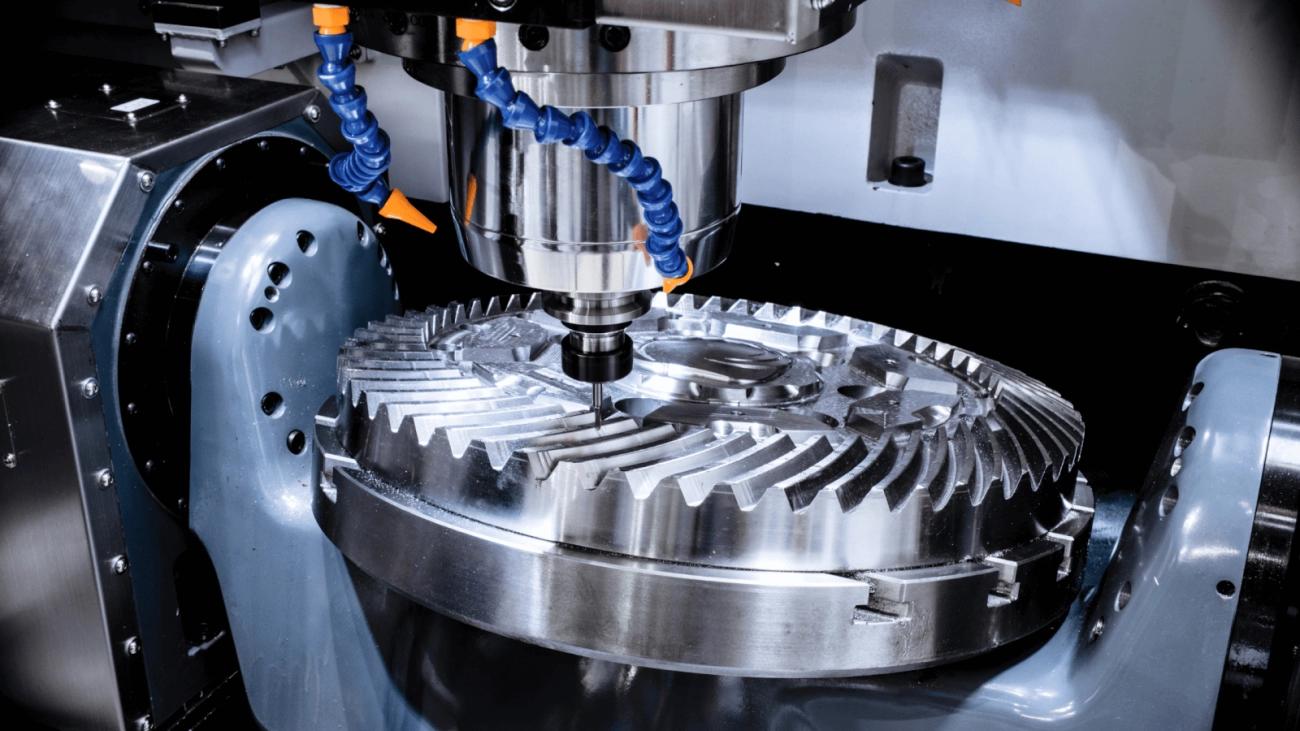

Have you ever wondered how precise parts for cars, electronics, or machinery get made? That’s where a milling machine comes in. A milling machine, often called a milling m/c, is a powerful tool used to cut, shape, and drill materials like metal, wood, or plastic with great accuracy. It uses rotary cutters, called milling cutter tools, to remove material from a workpiece, creating complex shapes and designs.

So how does it work? At its core, a milling machine holds the workpiece steady while a spinning cutter moves across the surface. This cutting action removes tiny layers of material, allowing you to shape the object exactly as needed. The machine’s table moves in multiple directions—usually X, Y, and Z axes—giving full control over the milling process. Depending on the setup, you can achieve everything from simple grooves to intricate patterns.

There are different types of milling machines, but their fundamental function remains the same: to transform raw material into precise parts. Whether you’re a hobbyist working with a benchtop milling machine or a professional using a CNC mill, understanding how your milling m/c operates is the first step toward mastering precision machining equipment.

What Is a Milling Machine The Basics You Need to Know Common Applications in Modern Workshops

A milling machine is a key piece of precision machining equipment used in many workshops across the United States. It helps shape metal or other materials by removing small amounts with milling cutter tools. You’ll find milling m/c widely used for creating parts that need accurate cuts, holes, or slots.

Common applications in modern workshops include:

- Metal milling process for parts like brackets, gears, and engine components

- Prototype development where exact shapes and sizes are crucial

- Repair work on worn-out pieces by reshaping surfaces

- Custom fabrication for tools, fixtures, and jigs

- Wood and plastic shaping in smaller or specialized setups

Whether it’s a vertical milling machine for versatile cuts or a horizontal mill for heavy-duty work, milling machines fit into almost any workshop setup. For hobbyists, benchtop milling machines are popular thanks to their size and affordability, while larger full-size mills suit industrial needs.

Milling machines are key for anyone serious about precision and quality in metalworking. They make complex cuts easier and faster, saving time while improving results in a busy shop environment.

Types of Milling Machines Finding the Best Fit for Your Needs

Vertical vs Horizontal Milling Machines

When choosing a milling m/c, one of the first decisions is between a vertical and a horizontal milling machine. Both have their strengths, so understanding the difference helps you pick the right fit for your workshop needs.

Vertical Milling Machines

- The spindle is vertical, meaning it cuts straight down onto the workpiece.

- Great for precision machining and detailed cuts.

- Ideal for tasks like drilling, boring, and slotting.

- Easier to set up and use, making it a favorite for many small shops and beginners.

- Commonly used in metal milling processes that need flexibility and accuracy.

Horizontal Milling Machines

- The spindle is horizontal, allowing the cutter to work sideways across the material.

- Better for heavy-duty cuts and working with larger, thicker pieces.

- Suited for milling grooves, slots, and keyways.

- Typically more robust and powerful than vertical mills but can be more complex to operate.

- Preferred in workshops focusing on large metal parts or production runs.

For most local setups in the US, a vertical milling machine suits small to medium-sized jobs where precision is key. But if your work involves bigger or tougher materials, a horizontal mill may serve you better. Either way, knowing these basics helps narrow down your milling m/c choice confidently.

Types of Milling Machines Finding the Best Fit for Your Needs Manual vs CNC Milling Machines

When deciding between manual and CNC milling machines, it’s important to consider how you plan to use the milling m/c and what kind of precision you need.

Manual Milling Machines are great if you’re starting out or working on simple projects. You control the machine by hand, adjusting the table and spindle yourself. This gives you direct control but requires some skill to get precise cuts. Manual mills are usually more affordable and easier to maintain, making them a solid choice for hobbyists or small workshops.

CNC Milling Machines, on the other hand, use computer programs to control all movements automatically. This means you can achieve much higher accuracy and repeatability, especially for complex or detailed metal milling processes. CNC mills often come with a wider range of milling cutter tools and can handle heavy-duty tasks with consistent precision. They’re ideal for professional setups or anyone ready to invest in more advanced, precision machining equipment.

Key Differences at a Glance

| Feature | Manual Milling Machines | CNC Milling Machines |

|---|---|---|

| Control | Hand-operated | Computer-controlled |

| Precision | Good for simple jobs | High precision and repeatability |

| Complexity | Best for basic operations | Handles complex milling paths |

| Cost | Lower upfront cost | Higher initial investment |

| Learning curve | Easier to start | Requires programming knowledge |

| Maintenance | Simpler, less electronics | More complex, but automates work |

Whether you go manual or CNC depends on your budget, the type of projects you’ll tackle, and how much automation you want in your workshop. For beginners or small-scale work, a manual or benchtop milling machine might be enough. Meanwhile, a CNC mill can open doors to professional-level results if you’re ready to dive into programming and more advanced setups.

Types of Milling Machines Finding the Best Fit for Your Needs Benchtop vs Full Size Mills

When deciding on a milling m/c, choosing between a benchtop and a full-size mill is crucial. Both have their perks, but your choice depends on your workshop space, project size, and budget.

Benchtop Milling Machines

- Compact and lightweight, perfect for small spaces or home workshops

- Ideal for hobbyists, beginners, and light-duty metal milling process

- Usually less expensive but with limited power and capacity

- Great for precision machining equipment tasks on smaller parts

- Easy to move and store when not in use

Full Size Milling Machines

- Larger and heavier, designed for industrial or heavy workshop setups

- Provides higher power, speed, and capacity suitable for larger projects

- Can handle a wider variety of milling cutter tools and complex jobs

- Often includes advanced features and better stability during horizontal mill operations or vertical milling machine tasks

- Requires a dedicated space because of its footprint and weight

If you plan on tackling larger, more diverse jobs regularly, a full-size mill is the way to go. But if you’re tight on space and mostly working on smaller parts or beginner projects, a benchtop milling machine offers a great balance of function and convenience.

Key Features to Look for in a Milling Machine Essential Specs Power Speed and Capacity

When choosing a milling m/c, it’s important to focus on the basic specs that affect performance: power, speed, and capacity. These factors determine how well your machine handles different materials and job sizes.

Power

Look for a motor strong enough to handle the materials you plan to mill. Most benchtop milling machines have motors between 0.5 to 2 horsepower, while full-size mills often start at 3 horsepower and go higher. More power means smoother cuts, especially on tougher metals.

Speed

Milling machines offer variable spindle speeds, usually ranging from a few hundred to several thousand RPM. For precision machining equipment, adjustable speed is crucial—different materials and cutter tools need different speeds to avoid damage or poor finishes. A machine with a wide speed range lets you switch between fine and rough milling easily.

Capacity

This covers the size of the workpiece your milling m/c can handle and the travel range of the table (how far it moves left-right, forward-back, and up-down). If you’re working on bigger projects, make sure the mill’s working envelope matches your needs. Full-size mills have larger tables and greater travel, whereas benchtop milling machines are best for smaller jobs.

Keeping these specs in mind will help you pick a milling machine that fits your workshop setup and project demands without overpaying for features you don’t need.

Key Features to Look for in a Milling Machine Advanced Add Ons for Efficiency

When picking a milling m/c, look beyond the basics—advanced add-ons can boost your workflow and make tough jobs easier. Here are some handy features to consider:

- Digital Readouts (DRO): These give precise positioning feedback on all axes, cutting down mistakes and speeding up setups. A must-have for accurate metal milling process and precision machining equipment users.

- Automatic Lubrication Systems: Keeps your mill running smooth by automatically oiling the moving parts, reducing wear and saving you time on milling machine maintenance.

- Power Feed Controls: Automates the table’s movement during horizontal mill operations or vertical milling machine use, improving consistency and freeing you up for other tasks.

- Tool Changers: If you’re using a CNC mill, a tool changer can swap milling cutter tools faster than manual changes, boosting productivity.

- Built-in Coolant Systems: Helps keep your cutting tools and projects cool, preventing overheating and extending tool life during intense milling machine operations.

- Variable Speed Controls: Fine-tune your speed depending on the material or project, essential for getting smooth cuts whether you’re using a benchtop milling machine or a full size mill.

Adding these features can make a big difference in efficiency, accuracy, and overall ease of use. They help turn a basic milling machine into a powerful tool that fits your workshop milling setup and keeps projects moving smoothly.

Key Features to Look for in a Milling Machine Safety and Ergonomics

When choosing a milling m/c, safety and ergonomics should be a top priority alongside power and performance. A machine that’s comfortable and safe to use can make a big difference during those long workshop sessions.

Safety Features to Consider

- Emergency stop buttons are a must for quickly shutting down the mill if something goes wrong.

- Protective guards around moving parts like the milling cutter tools reduce the risk of injury.

- Properly insulated electrical components help avoid shocks and electrical hazards.

- Some modern CNC mills come with interlocks that prevent the machine from running if guards aren’t in place.

Ergonomics for Comfortable Use

- Look for machines with adjustable tables and handwheels to reduce strain and improve control.

- A readable, well-lit control panel helps reduce eye strain.

- Machines designed with good balance and vibration reduction improve precision and user comfort.

- For benchtop milling machines, having easy access to controls without overreaching makes a big difference.

In the U.S., where workplace safety standards are important, investing in a milling machine with solid safety and ergonomic design not only protects you but also helps maintain productivity and precision in your metal milling process.

How to Choose and Buy Your First Milling M C Step by Step Guide Assessing Your Budget and Space

When you’re ready to buy your first milling m/c, the first thing to think about is your budget and how much space you have in your workshop. Milling machines come in all price ranges, from affordable benchtop mills perfect for hobbyists to larger, more expensive CNC mills meant for precise industrial work.

Here’s what to consider:

- Set a clear budget: Decide how much you’re willing to spend. If you’re a beginner, a benchtop milling machine or an entry-level CNC mill might be the best fit without breaking the bank.

- Plan your workshop space: Milling machines aren’t small, especially full-size vertical or horizontal milling machines. Measure your available space carefully to make sure you have room not just for the machine, but for operators to work safely and comfortably.

- Think about power needs: Larger mills usually require more power and a stable power source. Check your setup to avoid surprises when the machine arrives.

- Future use: If you plan to upgrade or expand your precision machining equipment later, buy a machine that can grow with your needs.

Keeping these points in mind helps you avoid overspending on something too big or buying a small mill that won’t handle your projects. A smart choice here saves you time, money, and space in your workshop.

How to Choose and Buy Your First Milling M C Step by Step Guide

Top Brands and Where to Buy Locally

When it’s time to buy your first milling m/c, picking the right brand makes a big difference. In the U.S., you want something reliable, backed by good support, and easy to find parts for. Here are some top brands trusted by American workshops:

- BridgeportThe go-to name for vertical milling machines. Known for durability and precision, these are a staple in many metal shops across the U.S.

- GrizzlyGreat for beginners and hobbyists, Grizzly offers affordable benchtop milling machines and full-size mills with solid performance.

- JETPopular for quality and good customer service, JET’s milling m/c options range from benchtop models to larger CNC mills.

- HaasIf you’re ready to step into CNC milling, Haas machines are American-made, reliable, and found in many professional shops.

- TormachPerfect for affordable CNC mills for beginners, Tormach combines user-friendly features with precision machining equipment.

Where to Buy Locally

It’s smart to buy from local dealers or distributors where you can see the machine and get hands-on advice. Try these places:

- Industrial Equipment DealersMany cities have industrial tool shops or machinery dealers carrying milling m/c brands like Bridgeport or JET.

- Machinery Auctions and Used Equipment DealersYou can often find lightly used machines at better prices, but inspect them carefully or bring an expert.

- Tool Supply Stores in Your AreaStores like MSC Industrial Supply or Grainger sometimes carry entry-level machines or can connect you with local sales reps.

- Trade Shows and Manufacturing ExposEvents like the International Manufacturing Technology Show (IMTS) or local maker fairs are great spots to meet vendors and see milling machines in action.

Tips for Local Buying

- Ask about service agreements and warranty coverage before buying.

- Check if nearby repair shops or technicians specialize in the brand you choose.

- Look for demo units so you can test the machine before committing.

- Consider delivery and setup support, especially for larger mills.

Choosing the right milling m/c locally makes maintenance and future upgrades easier, keeping your workshop running smooth in the long run.

How to Choose and Buy Your First Milling M C Step by Step Guide

Maintenance Tips for Longevity

Keeping your milling m/c in good shape is key to making it last and perform well. Here are some easy maintenance tips to help you get the most out of your machine:

- Keep it clean: Regularly wipe down the machine to remove metal shavings, dust, and oil buildup. This prevents wear and keeps parts moving smoothly.

- Lubricate moving parts: Follow the manufacturer’s guide on oiling or greasing the spindle, slides, and gears. Proper lubrication reduces friction and extends the machine’s life.

- Check belts and gears: Inspect belts and drive gears often. Replace any worn or damaged parts to avoid breakdowns during critical milling jobs.

- Align and calibrate: Make sure the table, spindle, and other components stay properly aligned. A quick check every few uses helps maintain precision.

- Change coolant regularly: If your milling m/c uses coolant, replace it on schedule to prevent corrosion and keep the metal milling process smooth.

- Store tools properly: Organize milling cutter tools to avoid damage and keep them sharp for accurate cuttings.

- Schedule professional service: Even if you handle basic upkeep, having a pro inspect your CNC mill or vertical milling machine at least once a year can catch hidden problems early.

By sticking to these simple maintenance habits, you’ll keep your milling machine running reliably and ready for any shop project. Proper care saves you money on repairs and downtime while ensuring precision machining equipment stays at its best.

Beginner Projects to Build Confidence

Starting out with your milling m/c can feel overwhelming, but jumping into beginner projects is a great way to build skills and confidence. Here are some simple projects that are perfect for new users:

- Keychain or Dog Tag: These small, flat pieces are easy to mill and perfect for practicing basic shapes and engraving with a CNC mill or manual machine.

- Tool Holder: Create a custom holder for your milling cutter tools. It’s practical and helps you learn about precise cuts and fitting.

- Simple Brackets: Making metal brackets helps you get comfortable with vertical milling machine controls and horizontal mill operations.

- Custom Washers or Spacers: These require precision but are straightforward, improving your measurement and setup accuracy.

When you start, focus on clean setups and take your time. Each small project teaches you valuable lessons in speed control, tool changes, and material handling. Keep a notebook to track what works and what doesn’t—it’ll save time and headaches later.

Ready to move beyond basics? Try combining simple cuts into a small assembly or experiment with different materials. This hands-on approach helps you quickly learn milling machine maintenance and understand your equipment better.

Building confidence with these projects makes the whole metal milling process less intimidating and sets a strong foundation for more complex work.

Common Mistakes and How to Fix Them

Getting started with your milling m/c can be exciting but also a bit tricky. Here are some common mistakes new users face and how to fix them:

1. Skipping Safety Checks

Many beginners jump straight into cutting without checking the machine’s safety features. Always double-check guards, emergency stops, and wear proper safety gear before starting.

2. Using the Wrong Milling Cutter Tools

Using dull or inappropriate cutters can cause poor finishes or damage your workpiece. Match your milling cutter tools to the material and task. Keep them sharp and clean.

3. Ignoring Machine Setup

Poor setup leads to inaccurate cuts. Take your time to level the table, secure the workpiece firmly, and calibrate your mill, whether it’s a benchtop milling machine or a full-size CNC mill.

4. Overloading the Machine

Pushing your mill beyond its power and capacity causes wear and poor results. Know your machine’s limits – this applies to both vertical milling machines and horizontal mill operations.

5. Not Maintaining Your Milling Machine

Skipping regular maintenance leads to breakdowns. Clean chips after each use, lubricate moving parts, and inspect for wear regularly.

6. Rushing Through Projects

Starting with complex jobs too soon can cause frustration. Begin with simple projects and gradually increase difficulty to build confidence and skills.

Fix These Issues by

- Planning and reviewing safety every time

- Matching cutter tools to the job

- Setting up carefully before each run

- Sticking to your machine’s operational limits

- Following a maintenance schedule

- Taking your time with beginner-friendly projects

With these tips in mind, you’ll avoid common pitfalls and get the most from your milling m/c in your US workshop setup.