Discover precision CNC machining parts with Vast offering custom materials, tight tolerances, and fast turnaround for prototypes and production.

If you’re looking to unlock the full potential of CNC machining parts, you’ve come to the right place. Whether you’re an engineer, designer, or procurement pro, understanding how these precision-crafted components are made—and how to source them effectively—can transform your projects. From tight tolerances to quick turnarounds, the world of CNC machining parts is all about accuracy, speed, and reliability. In this guide, we’ll cut through the jargon and show you exactly what you need to know to get the best results—plus how partnering with Vast can take your prototypes and production runs to the next level. Let’s dive in!

What Are CNC Machining Parts A Foundational Breakdown

Are you wondering what CNC machining parts really are and how they come to life? At its core, the process starts with a CAD design—a digital blueprint of your part. This design is then converted into G-code, the language CNC machines understand. From there, the code guides mills, lathes, or multi-axis machines to precisely shape the material.

CNC machines come in various forms:

- Milling machines create flat or complex geometries by removing material across multiple axes.

- Turning machines produce cylindrical parts like shafts and bushings.

- Hybrid machining combines both milling and turning methods for more versatile shapes.

These processes cover a wide range of part types—whether flat, round, or intricate hybrids.

Common industries rely heavily on CNC parts. Think automotive pistons, aerospace turbine blades, medical implants, and electronics housings. Each requires precision, durability, and reliability.

At Vast, we specialize in ISO-certified 5-axis CNC machining, delivering parts with ultra-tight tolerances down to ±0.0001 inches. This capability allows us to craft the most intricate, high-precision components that meet stringent industry standards.

Ready to explore how precise CNC parts can elevate your project? Contact us for a quote and expert guidance.

Essential Components of CNC Machines How They Produce Flawless Parts

CNC machining parts come to life thanks to a few key components working together smoothly. Understanding the machine’s anatomy helps explain how precision parts get made every time.

At the heart is the bed frame, a solid base that keeps everything steady. Attached to it, the spindle spins the cutting tool or workpiece at high speeds for shaping. For lathes, the headstock holds and rotates the material, while on mills, the spindle moves in multiple axes. The tool turret or changer holds various cutting tools, allowing the machine to switch quickly for complex operations.

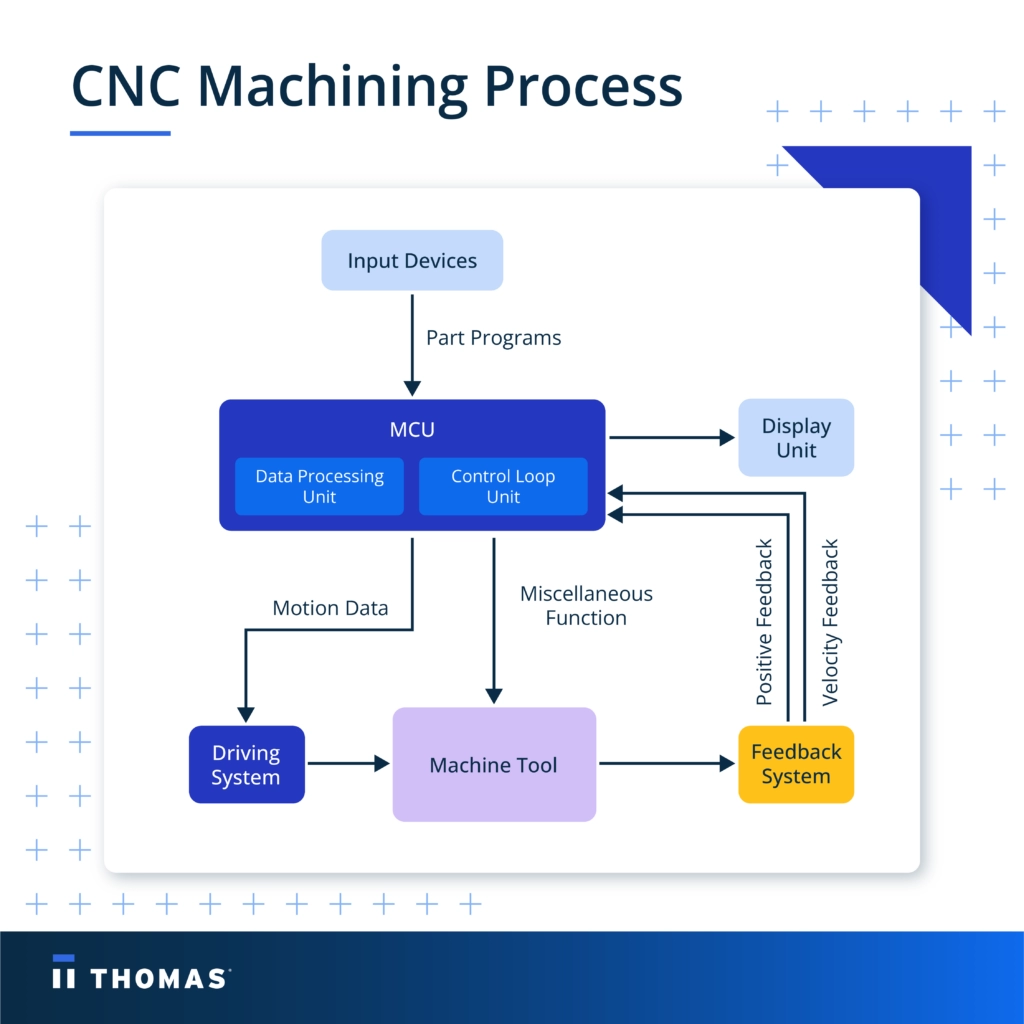

Axis motors control precise movement along X, Y, and Z directions, plus additional rotary axes on 3, 4, or 5-axis machines. The control panel or CNC controller processes commands, reads the G-code, and sends instructions to the MCU (microcontroller unit) for flawless execution.

During machining, the spindle rotation removes material accurately, while coolant systems keep temperatures down to ensure smooth finishes and avoid warping. This combination delivers tight tolerances and exceptional surface quality needed for high-precision CNC parts.

To keep your CNC machining parts flawless, regular maintenance and calibration are crucial. Proper alignment checks and service audits help prevent downtime and guarantee consistent quality. At Vast, we offer thorough service audits to keep machines running at peak performance so your parts meet specs every time.

Materials for CNC Machining Parts Choosing the Right One for Your Project

Picking the right material for your CNC machining parts is critical. It affects cost, durability, and how well the part performs. Here’s a quick rundown of common materials we work with:

Metals

- Aluminum: Lightweight and corrosion-resistant, great for prototypes and parts needing a good strength-to-weight ratio.

- Stainless Steel: Durable with excellent corrosion resistance, ideal for parts that face wear or harsh environments.

- Titanium: Combines high strength with low weight, used in aerospace and medical fields where performance matters most.

Plastics

- ABS: Impact-resistant and tough, suited for functional prototypes and housings.

- Nylon: Flexible with good wear resistance, perfect for moving parts or where some give is needed.

- Acrylic: Offers clear, optical-grade finishes, great for display covers or light-diffusing components.

What to Consider

- Machinability: Some materials cut easier and faster, affecting turnaround time.

- Cost: Aluminum is generally more affordable than titanium or stainless steel.

- Environmental Resistance: Think about exposure to heat, moisture, or chemicals.

- Tolerance Needs: Metals like steel can hold tighter tolerances than most plastics.

| Material | Machinability | Cost | Strength | Corrosion Resistance | Typical Tolerance |

|---|---|---|---|---|---|

| Aluminum | High | Low | Medium | Good | ±0.001 in |

| Stainless Steel | Medium | Medium | High | Excellent | ±0.0005 in |

| Titanium | Low | High | Very High | Excellent | ±0.0005 in |

| ABS | High | Low | Medium | Fair | ±0.005 in |

| Nylon | Medium | Low | Medium | Good | ±0.005 in |

| Acrylic | Medium | Medium | Low | Fair | ±0.003 in |

Vast’s Edge in Materials

We offer custom material sourcing with over 100 options, including eco-friendly alloys and specialty plastics. This means we can tailor your CNC machining parts to meet precise performance and sustainability goals without compromise.

Choosing the right material upfront saves time and money later—let us help you get it right the first time.

The CNC Machining Parts Process Step by Step from Concept to Completion

Getting your CNC machining parts right starts with a clear, organized process. Here’s how we break it down:

Step 1: CAD Modeling and DFM Review

We begin with detailed CAD modeling, making sure designs avoid thin walls under 0.8mm and sharp corners that cause stress points. Our design-for-manufacturing (DFM) review helps catch potential issues early, saving time and money.

Step 2: CAM Programming and G-Code Generation

Next, the CAD file moves to CAM software, where G-code and M-code are generated. This code tells the CNC machines exactly how to move, cut, and shape your parts.

Step 3: Machine Setup and Tool Path Programming

Setup includes securing materials and tools. For complex parts, multi-axis programming – 3, 4, or 5-axis – is used to reach hard-to-get areas and create intricate features.

Step 4: Inspection and Quality Control

Once machined, parts go through inspection using Coordinate Measuring Machines (CMM) and surface roughness testing. We follow ISO 2768 standards to guarantee precision and finish quality.

Step 5: Finishing and Delivery

After inspection, parts receive finishing touches like anodizing or polishing. Depending on the job, turnaround time ranges from 1 to 5 days, getting your parts to you quickly and ready to use.

Common Pain Points and How Vast Helps

Overtooling and inefficient design choices often add cost and delay. Vast offers expert DFM feedback that helps clients reduce expenses by 20-30%, streamlining production and cutting unnecessary steps.

This step-by-step process makes sure your CNC machining parts meet exact standards, on time, and within budget.

Design Best Practices for CNC Machining Parts Avoid Costly Mistakes

Getting your CNC machining parts right starts with smart design. Follow these guidelines to save time, reduce costs, and avoid headaches:

- Minimum wall thickness: Keep walls between 0.5mm and 1.5mm. Thinner walls risk warping or breakage.

- Internal radii: Add rounded corners inside pockets and cavities to match tool radius. Sharp internal corners aren’t machinable.

- Hole depths: Drill holes less than 3 times their diameter deep. Deeper holes can cause tool wear and accuracy loss.

- Tool diameter match: Design features to fit common cutter sizes and avoid specialty tooling costs.

Advanced Design Tips

- Use 5-axis machining for undercuts and complex shapes to improve finish and precision.

- For engraved text, go with sans serif fonts above 20 pt for clarity and machinability.

Cost Optimization

- Plan batch sizes carefully. Larger runs reduce per-part cost, but too many increase inventory.

- Stick with standard tooling whenever possible—custom tools increase setup and production costs.

- Refer to tolerance tables to balance precision needs versus expense. Tight tolerances add cost.

Vast Example

We recently helped a client redesign a prototype part before machining. By adjusting wall thickness and hole placement, we cut their lead time by 40%. This saved money and sped up delivery—proof that thoughtful design really pays off.

Following these best practices ensures your CNC machining parts are accurate, cost-effective, and ready for production.

Advantages and Limitations of CNC Machining Parts

When it comes to CNC machining parts, there are clear pros and cons to keep in mind.

Advantages

- High precision and repeatability: CNC machines can hold tight tolerances often better than ±0.0005 inches, making them perfect for parts that need exact fits.

- Versatility: Whether you need custom milled parts or CNC turning services, this process handles a wide range of materials and designs.

- Ideal for prototypes to mid-volume production: You can run anything from one-off rapid prototyping metals to batches of 10,000+ parts without losing quality.

- Fast design to production: Quick iterations help reduce time to market, especially with multi-axis machining like 5-axis machining tolerances for complex geometries.

Limitations

- Higher setup costs: For very low volume runs or one-off parts, setup and programming can add to costs.

- Material waste: Since CNC is a subtractive manufacturing guide, it removes material which can be less efficient versus additive methods like 3D printing — better for organic shapes or prototypes.

- Not the best choice for very high volume: For large-scale runs, injection molding or casting can be more cost-effective.

When to Choose CNC Machining Parts

Use CNC machining when you need:

- Tight tolerances less than ±0.005 inches

- Complex geometries that require precision cutting or turning

- Rapid iteration from prototypes to small or mid-sized runs

CNC Machining vs Injection Molding vs Casting Comparison

| Factor | CNC Machining | Injection Molding | Casting |

|---|---|---|---|

| Setup Cost | Moderate to high | High | Moderate |

| Cost per Part | Higher (low volume) | Low (high volume) | Moderate |

| Tolerances | ±0.0001 to ±0.005 | ±0.005 to ±0.01 | ±0.01+ |

| Production Volume | 1 to 10,000+ parts | 10,000+ | 1,000+ |

| Material Waste | Yes (subtractive) | Minimal (additive process) | Moderate |

| Design Flexibility | High | Limited by mold design | Moderate |

For U.S. customers needing precision CNC machining parts, the choice often comes down to balancing part complexity, volume, and budget. At Vast, our CNC machining parts combine high accuracy with fast turnaround to meet those exact needs.

Industries Thriving with CNC Machining Parts Real World Impact

CNC machining parts play a key role across many industries in the US, helping solve tough manufacturing challenges with precision and speed.

- Automotive: CNC makes gears and connectors for electric vehicles, ensuring high performance and durability in demanding conditions.

- Medical: Biocompatible implants with ultra-smooth finishes (Ra less than 16 microinches) are common, supporting patient safety and comfort.

- Aerospace and Energy: Lightweight turbine parts that handle temperatures over 1000°F are critical, enabling efficiency and reliability in aircraft and power systems.

- Consumer Electronics: Custom enclosures for gadgets benefit from CNC’s ability to produce intricate designs with consistent quality.

At Vast, we’ve helped clients across these sectors. For example, our precision CNC parts powered an entire drone fleet, showcasing how our ISO-certified 5-axis machining can support complex, high-tolerance applications. This track record proves CNC machining parts not only meet but exceed industry demands.

Sourcing CNC Machining Parts Partnering with Vast for Seamless Results

When it comes to sourcing CNC machining parts, choosing the right partner makes all the difference. Look for manufacturers with ISO certifications like 9001 and 13485, ensuring quality and consistency in every run. A trusted supplier should offer instant quoting and support a global-local network, combining worldwide capacity with quick local turnaround.

In the US market, customers often search for “CNC parts near me”, so having US-based fulfillment centers matters for speed and reliability. A smart sourcing strategy blends this local touch with hybrid sourcing options to balance cost and delivery times effectively.

At Vast, we bring real value with over 700 CNC machines ready to handle your projects, whether simple or complex. We hit a remarkable 95 percent on-time delivery rate, so your schedule stays on track. Plus, we offer free DFM upload from your CAD files when you request a quote, streamlining communication and reducing errors.

Ready to get started? Get your instant Vast quote today—simply upload your CAD file and see how we can bring your CNC machining parts from concept to completion seamlessly.