Explore top injection moulding machine products, their industry applications, precision features, and how advanced machines boost efficient high-volume production.

If you’ve ever wondered how everyday plastic parts — from automotive panels to medical devices — get made with precision and efficiency, then injection moulding machine products are your gateway to that answer. Whether you’re a manufacturer, designer, or engineer, understanding how these machines turn molten plastic into high-volume, complex components can transform your production process. In this post, you’ll discover the most common products crafted through injection molding, the industries driving demand, and why advanced machines like vast are revolutionizing output quality and speed. Ready to unlock the full potential of injection moulding machine products? Let’s dive in!

How Injection Molding Machines Transform Ideas into High-Volume Products

Have you ever wondered how simple plastic ideas turn into thousands—or even millions—of precise, durable parts? Injection molding machines make that possible by transforming raw materials into complex products efficiently and consistently.

Overview of the Process

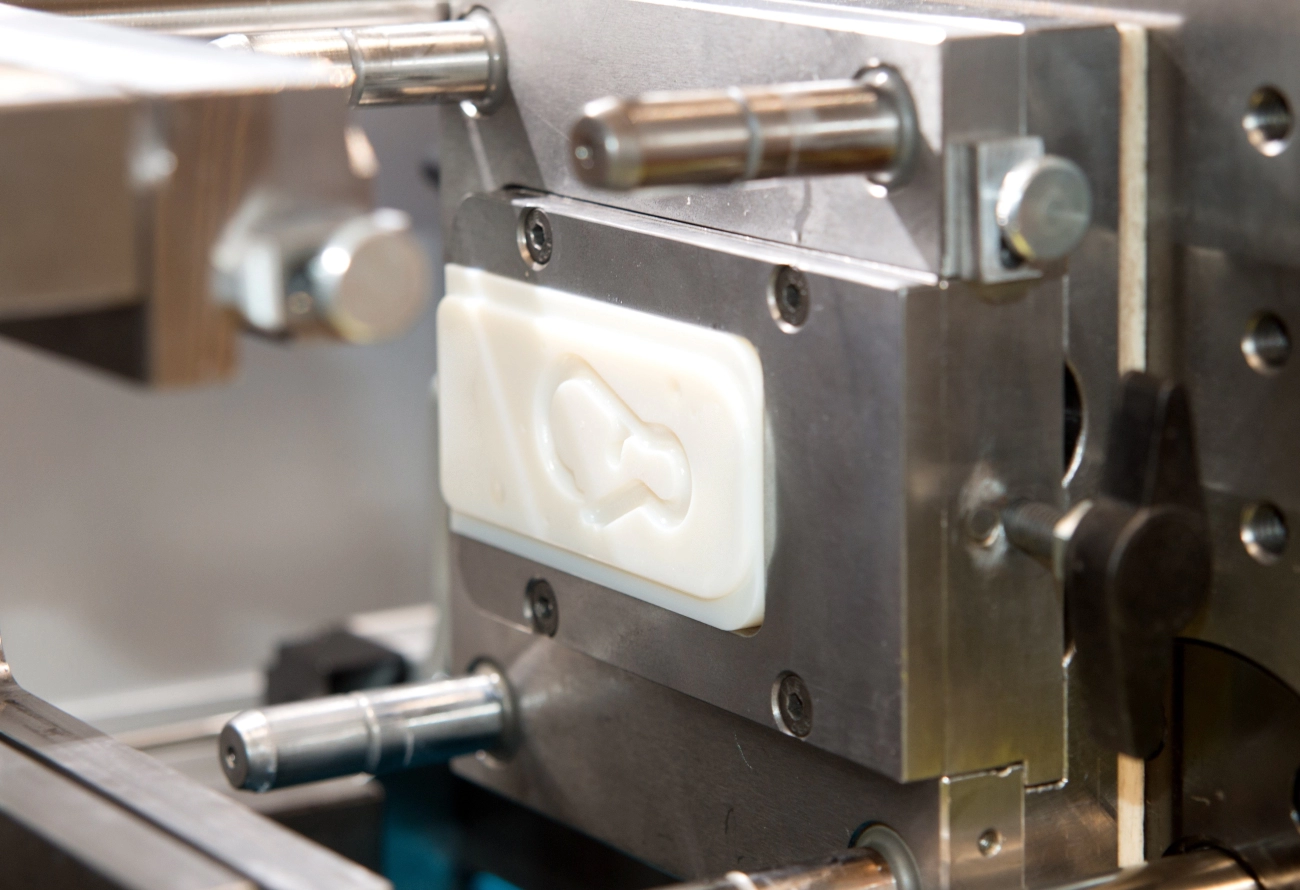

At its core, injection molding involves melting plastic pellets and injecting the molten material into a mold cavity shaped like the final product. Once cooled and solidified, the part is ejected, and the cycle repeats. Here are the key stages:

- Clamping: The mold closes tightly to withstand pressure.

- Injection: Heated plastic is pushed into the mold.

- Cooling: The plastic hardens inside the mold.

- Ejection: The finished part is released.

Each machine includes critical components like the injection unit, mold, clamping unit, and hydraulic or electric drive systems that work together seamlessly.

Key Advantages

Injection molding machines shine for several reasons:

- Precision: They produce complex shapes with tight tolerances.

- Cycle Speed: Fast production cycles translate to high-volume output.

- Material Versatility: Compatible with a wide range of plastics including thermoplastics and elastomers.

- Scalability: Easy to scale from prototypes to mass production.

Common Challenges and Solutions

Like any manufacturing process, injection molding can face hurdles:

- Flash: Excess material leaking from mold joints can cause defects. This is prevented by precise mold design and proper clamping force.

- Material Waste: Excess plastic scraps impact cost and sustainability. Regrinding and recycling within the process helps minimize waste.

- Complexity: Managing various materials and design requirements can be challenging, but hybrid injection molding machines combine electric and hydraulic tech for energy efficiency and better control.

With the right machine and expertise, these challenges become manageable, allowing injection molding to consistently deliver high-quality, cost-effective products.

Essential Injection Moulding Machine Products Real-World Examples Across Industries

Injection moulding machine products have a huge impact across many industries here in the U.S. Let’s look at some clear examples showing how this process shapes day-to-day products.

Automotive Sector

From dashboards and bumpers to cup holders and interior panels, injection moulding helps create parts that are lightweight and UV-resistant. These features are a must for durability and fuel efficiency, keeping American vehicles competitive and reliable.

Healthcare and Medical

Medical devices like syringes, inhalers, and device housings rely on injection moulding for sterility and FDA compliance. This makes sure parts meet strict safety standards while allowing for high-volume production.

Consumer Goods and Packaging

Injection moulding is behind many common items like bottle caps, reusable containers, and toys. It offers the flexibility to produce customized designs at scale, perfect for meeting diverse consumer demands.

Electronics

Housings, connectors, and keypads benefit from injection moulding’s precision. Using ESD-safe plastics, manufacturers protect sensitive electronic components, which is critical in today’s tech-driven market.

Agriculture and Construction

Durable parts like irrigation components, troughs, and roofing vents are molded to withstand tough outdoor conditions, making injection moulding vital for these industries.

Emerging Trends

We’re seeing growth in thin-wall packaging and living hinges—lightweight, flexible designs that reduce material use without sacrificing strength.

Case Study

A great example of injection moulding efficiency is Vast’s success in lowering automotive part costs. By optimizing design and process, they cut waste and boosted production—showing how smart injection moulding machine products save money and time.

Injection moulding continues to be the backbone of many industries here in the U.S., driving quality, volume, and innovation every day.

Choosing the Right Injection Moulding Machine for Your Products

Picking the best injection molding machine for your product is key to getting quality results and staying efficient. Here’s a quick rundown of what you need to consider.

Machine Types

- Hydraulic machines are strong and good for heavy-duty molding but use more energy.

- Electric machines offer precision and faster cycles, plus they’re energy-efficient—great for detailed or smaller parts.

- Hybrid machines combine the best of both—power with efficiency—ideal if your production needs vary.

Sizing and Specs

Make sure you match your machine’s specs to your product’s demands:

- Tonnage is the clamping force—the stronger the part, the higher the tonnage you’ll need.

- Shot volume is the amount of plastic injected at once. Bigger parts need higher shot volumes.

- Clamp force keeps the mold closed during injection, so it has to fit your part size and pressure needs.

Material Selection Guide

Choosing the right plastic is just as important:

- Common resins like ABS, polypropylene, and PET offer different strengths, flexibility, and costs.

- Consider recycled materials for sustainability, but check how they affect part quality.

- Some resins are easier to mold; others might require special machine settings or help with reducing waste.

Sustainability Focus

More manufacturers in the U.S. want eco-friendly options:

- Look for machines designed to use recycled plastics smoothly without clogging or defects.

- Low-energy models save on electricity and shrink your carbon footprint over time.

Pro Tips

- Audit your specs carefully—don’t just go for the biggest machine, but the one that fits your product’s complexity.

- Think about automation integration to speed up production and cut labor costs, especially for high-volume runs.

Choosing right upfront helps your injection molding process stay lean, reliable, and ready for whatever products you design next.

Future-Proofing Your Production Innovations in Injection Moulding Machine Products

The injection molding industry is evolving fast, and future-proofing your production means staying ahead of key shifts. One big change is the move toward bio-based plastics—materials made from renewable sources that help reduce environmental impact. Alongside this, Industry 4.0 technologies like smart sensors and automation are becoming standard, making manufacturing smarter and more efficient. For tiny, complex parts, micro-molding is gaining traction, opening doors to new markets like electronics and medical devices.

To save costs and boost output, manufacturers are focusing on smarter mold design, using multi-cavity tools to make multiple parts in one cycle. Digital tools such as digital twins let you simulate and optimize the process before production starts, cutting waste and downtime.

The demand for eco-friendly products is growing fast in the U.S., with buyers expecting recycled content and sustainable practices. Manufacturers are responding by increasing recycled plastics use and targeting lower carbon footprints.

Companies like Vast are leading the way with AI-powered R&D, optimizing injection molding processes for speed, precision, and minimal waste. This innovation helps meet today’s challenges while preparing for tomorrow’s market demands.