Explore small precision turned parts with tight tolerances CNC machining for automotive aerospace medical devices and more reliable quality.

In today’s fast-paced manufacturing world, small precision turned parts are the unsung heroes driving innovation across industries—from aerospace to medical devices. Getting these tiny, high-accuracy components right isn’t just about skill; it’s about mastering tight tolerances, fast turnarounds, and material choices that meet exacting specs. Whether you’re an engineer or procurement pro searching for reliable solutions, understanding the nuances of precision CNC turning can transform how you scale from prototype to production. Ready to explore what makes these micro components essential—and how to source them with confidence? Let’s dive in.

What Are Small Precision Turned Parts A Breakdown of the Basics

Small precision turned parts refer to components manufactured primarily through lathe-based turning processes, designed to create detailed cylindrical features such as threads, grooves, and bores. Unlike general machining, which can include milling or grinding, precision turning focuses on shaping parts by rotating the material against cutting tools for accuracy and repeatability.

These parts typically measure under 1 inch in diameter and require tight tolerances—often around IT7—which means deviations are kept within a few microns. Surface finishes are also critical, commonly achieving up to 16Ra to ensure smooth, functional surfaces.

Small precision turned parts range from simple fasteners like screws and pins to highly complex assemblies featuring multi-axis turning for added intricacy. This versatility makes them essential across many industries.

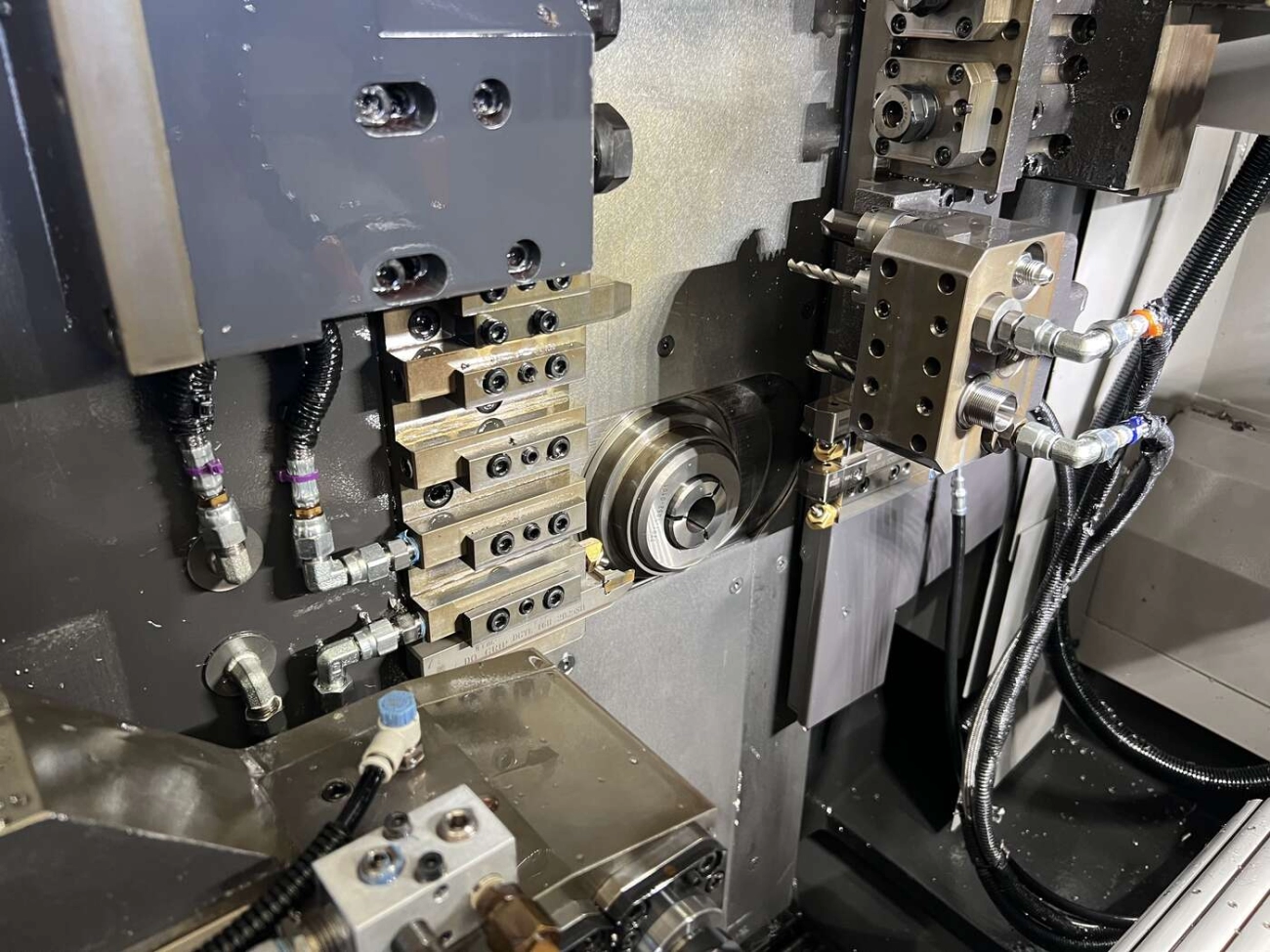

Below is a diagram that visually compares precision turned parts with milled components, highlighting their key differences in shape and application.

Vast specializes in delivering these parts with exacting standards to support your engineering needs. Ready to optimize your designs? Contact Vast for expert guidance on precision turned components.

The Precision Turning Process From Design to Delivery

The journey of small precision turned parts starts with smart CAD and CAM design. Using clear GD&T (Geometric Dimensioning and Tolerancing) is vital here—especially for tiny parts—to make sure features don’t distort during production. This step sets the baseline for accuracy and repeatability.

Next, material selection plays a big role. Common choices like stainless steel, aluminum, or brass feed into advanced CNC lathes and Swiss machines built specifically for tight tolerances under 1 inch diameter. These setups handle everything from simple single spindle tasks to complex multi-spindle operations with live tooling. That means multiple processes—turning, drilling, milling—can happen in one run, saving time and boosting precision.

Quality assurance is nonstop through the process. In-process checks include CMM (Coordinate Measuring Machines) and laser scanning to catch any deviations early. After machining, parts often get finishing treatments like anodizing or passivation for durability and corrosion resistance.

There are challenges to overcome—controlling vibrations, managing heat buildup, and clearing chips efficiently are key to hitting sub-micron accuracy. That’s why Vast integrates multi-tasking Mazak centers to keep production tight and turnaround fast. With this setup, prototype runs can be ready in as little as two weeks without sacrificing quality.

Materials for Small Precision Turned Parts Choosing the Right Fit

When selecting materials for small precision turned parts, choosing the right fit is crucial for performance, cost, and durability. Here’s a quick look at common materials and how they stack up.

Metals

- Stainless Steel: Known for corrosion resistance and strength, ideal for medical devices, aerospace, and automotive parts.

- Aluminum Alloys: Lightweight and great for parts where weight is a concern but strength still matters, such as electronics or hydraulics.

- Brass and Copper: Offer excellent conductivity and corrosion resistance, often used in plumbing fittings and electrical components.

Plastics and Exotic Materials

- Delrin: A high-strength plastic used for lightweight, corrosion-resistant parts.

- Titanium: Lightweight, strong, and biocompatible, perfect for implants and aerospace applications.

- Inconel: Handles extreme temperatures and corrosive environments, common in defense and specialized industrial uses.

Selection Criteria

- Machinability: Some materials cut easier than others, affecting speed and cost.

- Strength to Weight Ratio: Important for parts in aerospace, automotive, and medical fields.

- Cost per Part: Balancing performance with budget, especially in high-volume runs.

- Application Needs: Consider corrosion resistance, conductivity, and biocompatibility depending on the use case—for example, plumbing versus implants.

Sustainability

- Using recyclable alloys helps reduce waste.

- Bar-fed turning minimizes scrap by maximizing material usage from the start.

Material Comparison Table

| Material | Applications | Pros | Cons | Vast Capabilities |

|---|---|---|---|---|

| Stainless Steel | Medical, Aerospace, Automotive | Strong, corrosion-resistant | Heavier, harder to machine | Swiss machining, tight tolerances |

| Aluminum | Electronics, Hydraulics | Lightweight, good machinability | Lower strength than steel | Multi-axis CNC turning |

| Brass/Copper | Plumbing, Electrical | Conductive, corrosion-resistant | Softer, can wear quicker | High volume screw machining |

| Delrin | Lightweight assemblies | Corrosion-resistant, easy machining | Less heat resistant | Secondary machining services |

| Titanium | Implants, Aerospace | Strong lightweight, biocompatible | Higher cost, requires skill | Swiss turned micro parts |

| Inconel | Defense, High-temp parts | Heat/corrosion resistant | Difficult to machine | Advanced live tooling setups |

Choosing the right material is about balancing your specific needs with what each option offers. We help guide you through the choices so your small precision turned parts not only fit perfectly but last long and perform as expected.

Key Applications Where Small Precision Turned Parts Drive Innovation

Small precision turned parts are at the heart of many industries driving innovation and performance improvements. Here’s where they really make a difference:

- Automotive and EVParts like fuel injectors and sensor housings demand high-volume production with tight tolerances. Precision turning ensures these components meet strict quality standards at scale, critical for modern vehicles and electric models.

- Aerospace and DefenseHydraulic fittings and actuator pins require FAA-compliant precision to function reliably in extreme conditions. Small turned parts here must have exact dimensions and flawless finishes to ensure safety and performance.

- Medical DevicesImplant screws and surgical tool components rely on biocompatible materials and precise machining to meet sterilization and durability requirements. These parts must be consistently accurate for patient safety and effectiveness.

- Hydraulics and PneumaticsValves and connectors need leak-proof tolerances to maintain system integrity. Small precision turned parts enable these components to fit and operate perfectly under pressure.

- ElectronicsThreaded inserts and standoffs used in compact PCB assemblies benefit from precise cylindrical features to save space and improve reliability.

Case Study: At Vast, we supported a medtech client’s production of 50,000 implant screws with a 99.9% yield rate. Our expertise in small precision turned parts helped ensure every component met their rigorous quality needs on time and on budget.

Benefits of Investing in High Quality Precision Turned Parts

Investing in high quality small precision turned parts brings several key advantages that can boost your production and product performance.

Accuracy and reliability

Precision turned parts help reduce assembly failures because they meet tight tolerances consistently. This leads to longer-lasting components and fewer costly reworks.

Efficiency gains

With advanced CNC turning, many features are completed in one setup. This cuts machining time by 30 to 50 percent compared to traditional methods, resulting in faster prototypes and quicker time-to-market.

Scalability

Whether you need a small pilot run of 100 pieces or a high-volume order exceeding 100,000 units, quality stays consistent. High-end Swiss machining and multi-axis CNC lathes support both short and large production runs without sacrificing precision.

Compliance

For industries like aerospace, defense, and medical devices, meeting strict regulatory standards is critical. Top precision turning shops maintain ISO 9001 and AS9100 certifications, ensuring parts comply with industry requirements.

Cost savings with ROI calculator

Using precision turned parts made locally can lower overall costs compared to offshoring. Reduced lead times, lower scrap rates, and less logistical hassle all improve your return on investment. A good ROI calculator helps you clearly see these savings before you begin.

Choosing quality small precision turned parts is not just about the part itself but how it impacts your entire operation—from quality control to speed and long-term costs.

Overcoming Common Challenges in Small Precision Turning

Small precision turned parts come with their unique hurdles, but modern solutions keep production smooth and reliable.

- Tool deflection in micro featuresSmall parts often mean tiny tools, which can bend or vibrate during cutting. Using rigid Swiss machining setups fixes this by providing stable support and precise control, keeping features sharp and accurate.

- Material inconsistenciesVariations in raw materials can cause problems like uneven finishes or tolerances out of spec. Partnering with qualified vendors and strict incoming inspections help maintain consistent quality across batches.

- Lead time pressuresSpeed is crucial, especially for prototypes or urgent production runs. Lean manufacturing cells enable quick turnarounds, often delivering accurate quotes within 48 hours and fast shipping without sacrificing quality.

- Emerging trendsIn 2025, AI-driven optimization is making big strides. Smart software adjusts feeds and speeds in real-time, enhancing tool life, reducing scrap, and improving sustainability in the small precision turning process.

These advancements ensure that even the most complex, tiny turned parts meet high standards without delays or unexpected issues.

Partnering with Vast Your Source for Superior Small Precision Turned Parts

With over two decades of experience in CNC turning, Vast is a trusted U.S.-based partner for small precision turned parts. Our facility houses more than 50 advanced machines, ensuring high-volume capacity paired with consistent reliability right here in the United States.

What sets Vast apart is our zero defect guarantee—quality is never compromised. We offer custom prototyping tailored to your exact needs, plus value-added secondary services like grinding and coating to deliver ready-to-use parts fast.

Our clients often share how partnering with Vast has reduced their costs and lead times significantly, helping them stay competitive without sacrificing quality.

Ready to get started? Request your free tolerance analysis and take advantage of our online quote tool to see how Vast can support your next project with precision and speed.