Discover comprehensive material testing methods ensuring safety durability and compliance with expert on-site and lab services by Vast.

The Critical Importance of Material Testing in Modern Industries

Have you ever wondered how manufacturers ensure the products you use every day are safe and reliable? That’s where material testing steps in. In today’s fast-paced industries, testing materials thoroughly isn’t just an option—it’s a necessity.

Material testing affects everything from construction materials to high-tech electronics. It helps verify that raw materials and finished products meet strict quality and safety standards. When a bridge needs to hold heavy loads or a smartphone has to resist drops, material testing ensures those expectations are met.

Ensuring product safety and reliability is the first line of defense. For example, tensile strength testing measures how much stress a material can withstand before breaking. This type of mechanical property analysis helps prevent failures that could lead to costly accidents or recalls.

Beyond safety, companies must comply with strict regulations like ASTM material standards. These guidelines ensure consistent quality across industries and protect consumers. Meeting regulatory compliance isn’t just good practice; it’s a legal requirement that builds trust in a brand.

On top of avoiding risks, material testing drives cost savings and innovation. Identifying weaknesses early on in a material’s lifecycle prevents expensive production delays or warranty claims. Plus, testing allows R&D teams to develop eco-friendly alternatives or enhanced materials that stand out in the market.

In short, material testing is vital for modern industries to deliver safe, reliable, and cost-effective products. It balances safety, compliance, and innovation, keeping businesses competitive and customers confident.

Core Types of Material Testing A Breakdown

Material testing covers several key types, each serving a specific purpose in making sure materials meet the needs of modern industries. Here’s a simple breakdown:

Mechanical Testing

This tests how materials hold up under different forces. Common methods include tensile strength testing, fatigue testing, and mechanical property analysis. It checks how much stress or strain a material can handle before breaking or deforming.

Non Destructive Testing NDT

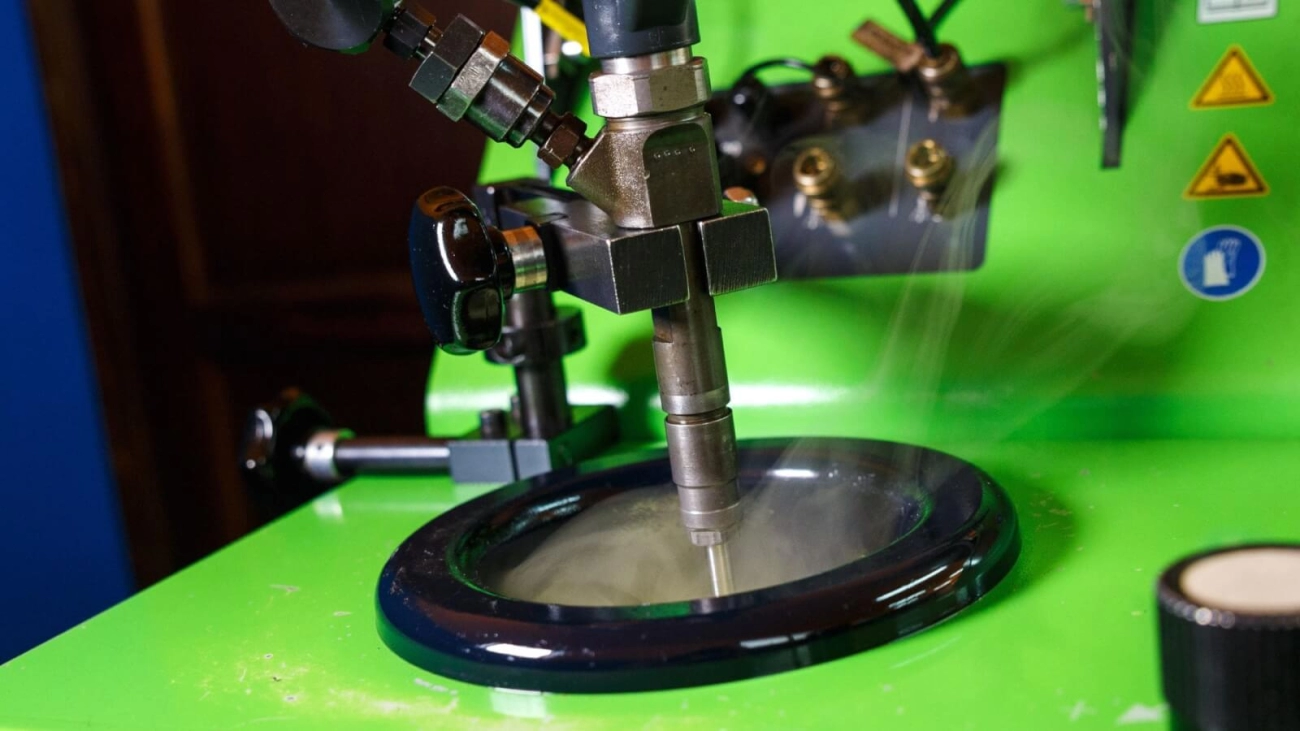

NDT methods let you inspect materials without causing damage. This includes non destructive evaluation techniques like ultrasonic testing, X-rays, and on site material inspection. It’s great for checking welds, surfaces, and internal flaws without ruining the item.

Thermal and Electrical Testing

These tests measure how materials respond to heat or electrical current. It’s important for things like polymer durability assessment and electrical components. Knowing how a material reacts to temperature or electricity helps avoid failures in real-world conditions.

Chemical and Corrosion Testing

This type of testing checks how materials resist chemical reactions or corrosion. Corrosion resistance testing is especially vital for metals exposed to harsh environments. It ensures the material will last without deteriorating quickly.

Destructive vs Non Destructive When to Choose Each

- Destructive Testing like tensile or fatigue testing destroys the sample but gives detailed info on material limits.

- Non Destructive Testing keeps the item intact and is perfect for ongoing quality control or checking finished products.

Choosing the right method depends on what you need—whether it’s detailed data or preserving the material for use. Both types work hand in hand to keep products safe and reliable in the U.S. market.

Step by Step Process of Material Testing at Vast

At Vast, our material testing process is straightforward and designed to deliver clear, reliable results that help you make sound decisions.

Sample Preparation and Initial Assessment

Before any testing begins, we carefully prepare your samples. This step ensures the material is clean, correctly sized, and ready for testing according to ASTM material standards. We also do an initial check to understand the material’s condition and identify what tests are most relevant.

Conducting the Tests

Depending on your needs, we perform a range of tests, such as tensile strength testing, fatigue testing methods, non destructive evaluation (NDE), corrosion resistance testing, or polymer durability assessment. Our team uses advanced equipment in our construction materials lab and can even offer on site material inspection to maintain quality control in manufacturing.

Data Analysis and Reporting

Once testing is complete, we analyze the mechanical property analysis and other data carefully. We provide clear, easy-to-understand reports that highlight the key findings and what they mean for your project or product performance.

Common Challenges and Solutions

We know testing materials can sometimes run into problems like inconsistent samples, unexpected defects, or environmental factors affecting results. At Vast, we tackle these by:

- Following strict sample preparation protocols

- Using precise calibration of testing equipment

- Applying non destructive testing methods wherever possible to avoid wasting material

- Offering expert advice to interpret tricky results

This structured process ensures you get accurate, trustworthy information every time, helping your team meet safety, quality, and regulatory demands with confidence.

Emerging Trends and Future Proofing with Vast

At Vast, we’re always looking ahead to keep material testing up to date with industry needs. Here’s how we’re bringing future-proof solutions to the table.

Advancements in AI and Automation

Automation and AI are game changers in material testing. With AI-driven data analysis, we quickly identify patterns and potential issues in tensile strength testing, fatigue testing methods, and corrosion resistance testing. Automation speeds up mechanical property analysis and non destructive evaluation processes, helping us deliver faster, more accurate results. This means better quality control in manufacturing for you, with less downtime and more reliable products.

Sustainable Testing for Eco Friendly Materials

Sustainability matters now more than ever. Vast has adopted methods that focus on polymer durability assessment and eco-friendly construction materials lab practices. We help companies test biodegradable materials and recycled metals to meet environmental standards without sacrificing performance. Our corrosion resistance testing also includes green solutions, ensuring your products last longer and reduce waste.

Integrating Testing into Supply Chains

On site material inspection and quick turnaround testing are vital for smooth supply chains. Vast integrates testing early and throughout your supply chain, helping catch problems before they escalate. This proactive approach keeps your manufacturing line moving and compliance in check. Plus, it supports just-in-time deliveries and reduces costly delays, saving you both time and money.

By combining technology, sustainability, and smart supply chain practices, Vast stays on the cutting edge of material testing to serve your modern industry needs.