High quality flange parts in carbon stainless and alloy steel meeting ASME ANSI DIN JIS standards for oil gas petrochemical and shipbuilding industries.

Vast Flange Parts – Quality You Can Trust

Vast supplies a full range of flange parts manufactured to international standards, backed by material certificates and third-party inspection. Whether you need steel flanges, forged flanges, or custom solutions, we have you covered with proven quality and consistency.

| Flange Type | Standard | Material |

|---|---|---|

| Weld Neck (WN) | ASME B16.5 | Carbon Steel, Stainless Steel |

| Slip-On (SO) | ANSI B16.47 | Alloy Steel, Duplex |

| Blind (BL) | DIN EN 1092-1 | Inconel, Titanium |

| Threaded (TH) | MSS SP-44 | High-Nickel Alloys |

| Socket Weld (SW) | API 6A | Custom Alloys |

Get started now:

Choose Vast for reliable flange parts made right, every time!

Product Overview

Flange parts are essential components in piping systems, connecting pipes, valves, pumps, and other equipment to create a secure and leak-proof flow path. They make installation and maintenance easier by allowing quick assembly or disassembly without disturbing the rest of the system. Flanges also help accommodate misalignment and provide a surface for gasket sealing to prevent leaks.

At vast, we bring over 30 years of experience crafting flange parts that meet strict international standards. With our in-house forging and precision machining capabilities, we control every step of production to ensure consistent quality. Plus, our global export presence means we understand diverse market needs and provide reliable flange solutions worldwide. Whether it’s carbon steel, stainless steel, or special alloys, you can trust vast flange parts for durable, high-performance piping connections.

For accuracy and quality, we use advanced techniques like CNC machining and third-party inspection, ensuring every flange part supports your system’s safety and efficiency. Explore how our expertise and manufacturing strength make vast a top choice for your flange needs.

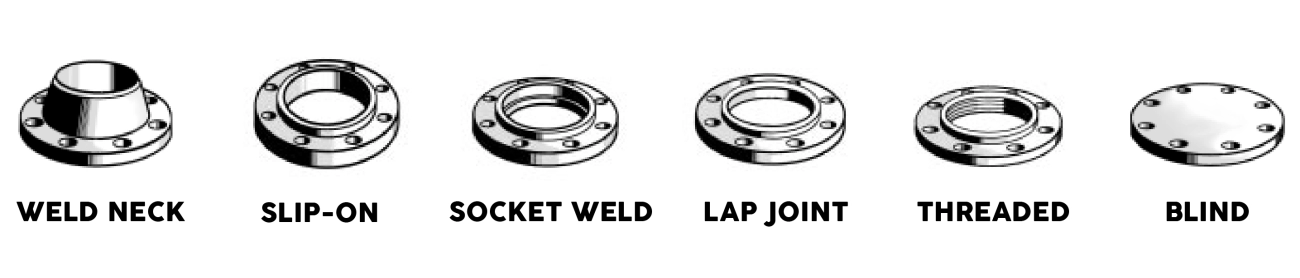

Types of Flange Parts We Supply

We offer a wide range of flange parts to fit every piping need, each designed to meet international standards. Here’s a quick overview of the most common types we supply:

- Weld Neck Flange (WN)Ideal for high-pressure systems, these flanges have a tapered hub that provides excellent strength and reduced stress concentration.

- Slip-On Flange (SO)Easy to install, these flanges slide over the pipe and are then welded in place, suitable for low-pressure systems.

- Blind Flange (BL)Used to close off the end of a pipe or pressure vessel, these flanges allow for future access and inspection.

- Socket Weld Flange (SW)Fits over the pipe and is welded around the socket, ideal for smaller diameter, high-pressure applications.

- Threaded Flange (TH)These flanges screw onto the pipe without welding, useful for non-welded connections and systems requiring disassembly.

- Lap Joint Flange (LJ)Used with a stub end, this flange type allows easy alignment and is perfect for frequent dismantling.

- Long Welding Neck FlangeExtended length weld neck flanges designed for special applications where extra reinforcement is necessary.

- Orifice FlangeSpecial flanges used in flow measurement systems, designed to fit orifice meters.

- Reducing FlangeAllows connection between different pipe sizes, facilitating transitions in pipe diameter.

- Expander FlangeDesigned to expand connections or allow modification within piping systems without cutting pipes.

- Spectacle Blind / Spacer & SpadeUsed for isolating or blanking off sections of pipework quickly, featuring a “spectacle” shape for easy handling.

Each flange type comes ready to meet your project’s demands, manufactured with precision and available in various materials and standards. For detailed specs and visuals, download our full flange catalog or get an instant quote today.

For more insights into welding and machining related to flange production, visit our guide on mastering tack welding tips for beginners.

Standards & Specifications

Our flange parts comply with all major international standards to ensure compatibility and quality for every project. We supply flanges manufactured according to:

| Standard | Description |

|---|---|

| ASME/ANSI B16.5 | Pipe flanges and flanged fittings (up to 24″) |

| ASME/ANSI B16.47 (Series A & B) | Large diameter welded flanges (up to 72″) |

| MSS SP-44 | Steel pipeline flanges for gas and oil |

| API 6A | Flanges for wellhead equipment |

| AWWA C207 | Flanges for waterworks and hydrant pipe fittings |

| DIN / EN 1092-1 | European flange standards with various pressure classes |

| BS 4504 | British Standard steel flanges |

| JIS B2220 | Japanese Industrial Standard flanges |

| KS 1503 | Korean Standard flanges |

| GOST 12820 / 12821 | Russian standards for steel flanges |

Custom and Non-Standard Flanges

We also manufacture flanges based on your specific drawings and requirements, ideal for unique applications or when off-the-shelf products don’t fit.

For machining critical flange features, we rely on precise techniques like CNC drilling and turning, similar to those described in our guide on different types of drill bit heads. This guarantees tight tolerances and proper flange dimensions every time.

Our compliance with these standards ensures you get flanges that perform reliably and fit perfectly in your piping systems worldwide.

Material Grades of Flange Parts

We offer a wide range of flange parts made from top-quality materials to suit different applications and environments. Here’s a quick overview of the material grades we supply:

Carbon Steel

- ASTM A105

- A350 LF2

- P250GH

- C22.8

- S235JR

Stainless Steel

- 304 / 304L

- 316 / 316L

- 321

- 347

- 310S

- Duplex 2205

- Super Duplex 2507

Alloy Steel

- F11

- F22

- F91

- F5

- F9

High-Nickel Alloys

- Inconel 625

- Monel 400

- Hastelloy C276

- Titanium Grade 2 / Grade 5

Each material meets international standards, ensuring durability, corrosion resistance, and mechanical strength for various industry demands. Whether you need carbon steel flanges for general use or super duplex stainless steel for extreme conditions, we have you covered. Explore our manufacturing expertise that maintains strict quality control across all material types.

Size Range & Pressure Ratings

Our flange parts cover a wide size range from 1/2″ to 72″ (DN15 to DN1800), making them suitable for virtually any piping system. We offer pressure classes from Class 150 up to Class 2500, including metric ratings like PN6 to PN420, and flange pressure ratings such as 5K to 63K.

To meet various sealing requirements, we supply different flange facings:

- Raised Face (RF)

- Flat Face (FF)

- Ring Type Joint (RTJ)

- Tongue & Groove

- Male & Female

This flexibility ensures you get the right flange parts tailored for your specific pressure and connection needs. Our range supports both standard and specialized applications worldwide.

Manufacturing Capabilities

We offer a wide range of manufacturing capabilities to ensure quality and precision in every flange part. Our flanges are available in both forged and plate-cut options, allowing us to meet diverse project needs. Advanced CNC machining and precise drilling guarantee tight tolerances and consistent performance. We also provide professional heat treatment to enhance strength and durability.

For surface protection, we apply various treatments including anti-rust oil, black or yellow paint, hot-dip galvanizing, and 3PE coating to suit different environments and specifications. Every batch undergoes thorough third-party inspection from trusted agencies like BV, SGS, TUV, and Lloyd’s to meet international standards and give you peace of mind.

Explore our surface treatment options in detail to understand how we protect flange parts for long-lasting use.

Applications & Industries Served

Our flange parts are built to meet the toughest demands across a wide range of industries:

- Oil & Gas: Suitable for upstream exploration, midstream transportation, and downstream processing, ensuring reliable connections in critical environments.

- Petrochemical & Refinery: Ideal for high-pressure and corrosive conditions commonly found in refining and chemical plants.

- Power Generation & Nuclear: Engineered to withstand extreme temperatures and pressures in power plants and nuclear facilities.

- Water Treatment & Desalination: Durable flanges designed for piping systems in water purification and desalination plants.

- Shipbuilding & Offshore: Corrosion-resistant materials and precise manufacturing ensure safe and strong joints for marine and offshore platforms.

With Vast’s expertise, you get flange parts that perform consistently across these demanding sectors, backed by thorough quality checks and certification. For manufacturing insights related to high-performance alloys used in these industries, check out our guide on high temperature alloy casting.

Quality Assurance & Certifications

At Vast, quality assurance is at the heart of everything we do. All our flange parts meet strict international standards, backed by ISO 9001 certification to guarantee consistent product excellence. We also comply with PED 2014/68/EU and AD2000 directives, ensuring our flanges are fit for pressure vessel applications worldwide.

We provide comprehensive material certificates in accordance with EN 10204 3.1 and 3.2, confirming the traceability and chemical properties of every batch. For added confidence, a full range of non-destructive testing (NDT) methods—ultrasonic testing (UT), magnetic particle testing (MT), and penetrant testing (PT)—are available on request to verify the integrity of all flange parts.

This rigorous quality control ensures reliable performance in demanding environments, whether for oil & gas, power plants, or water treatment projects. For detailed insights into our precision processes, explore our CNC milling guide and process overview.

Technical Resources for Flange Parts

We provide a range of technical resources to make your flange selection and installation easier and more accurate. These include:

- Dimension TablesCovers key standards like ASME B16.5, B16.47, DIN, and others for all common flange types and sizes.

- Torque Values & Bolt Selection GuideHelps you pick the right bolt strength and torque for your flange connection to ensure a secure, leak-free seal.

- Gasket Selection GuideDetails which gasket types work best with various flange facings, pressures, and materials.

- Flange Weight ChartsDownloadable PDFs listing weights by size and material, useful for transport and design calculations.

| Resource | Key Standards Included | Format |

|---|---|---|

| Dimension Tables | ASME B16.5, B16.47, DIN, EN 1092-1 | Online & PDF |

| Torque & Bolt Guide | Matches flange class & size | |

| Gasket Selection Guide | Raised face, RTJ, RF, FF facings | |

| Flange Weight Charts | Carbon steel, stainless, alloy |

These resources are designed to complement our flange parts offering, helping engineers, designers, and procurement teams get the right specs right first time. For more on flange dimensions and specifications, check out our detailed guides for types of pipe flanges.

Why Choose vast Flange Parts

When you choose vast flange parts, you get more than just quality. Here’s why we stand out:

| Feature | Details |

|---|---|

| Stock Availability | Over 50,000 pcs in common sizes ready to ship |

| Lead Time | Fast turnaround in 3–15 days |

| Pricing | Competitive factory-direct prices |

| One-stop Solution | Flanges, fittings, and fasteners all from one supplier |

Our large inventory means you won’t wait long for the parts you need, whether it’s standard or custom flanges. Direct factory pricing ensures you get excellent value without middlemen driving up costs. Plus, with our full range including pipe fittings and studs, we simplify your sourcing.

Need flanges paired perfectly with fittings? Check our precision manufacturing capabilities for custom solutions that fit your project timeline and budget.

Choose vast for reliable stock, speedy delivery, and a full package—everything needed for your piping system in one place.

FAQ: Common Questions About Flange Parts

What is the difference between weld neck and slip-on flanges?

Weld neck flanges are designed with a long tapered hub that provides excellent strength and stress distribution, making them ideal for high-pressure and high-temperature applications. Slip-on flanges, on the other hand, slide over the pipe and are then welded both inside and outside. They are easier to install but generally suited for lower-pressure systems.

How do I choose the right flange facing type?

Flange facing depends on the sealing needs of your piping system:

- Raised Face (RF): Most common, provides good sealing with gaskets.

- Flat Face (FF): Used when flanges connect to equipment with flat face nozzles.

- Ring Type Joint (RTJ): For high-pressure, high-temperature services requiring metal-to-metal sealing.

- Tongue & Groove or Male & Female: For special sealing configurations.

Choosing the correct facing ensures leak-free connections and long service life.

Can you supply flanges with special requirements?

Yes, we can provide flange parts that meet special demands such as NACE MR0175 for sour service, low-temperature materials, or custom specifications. Our manufacturing process supports custom material grades and heat treatments suited to your exact needs.

For more detailed guidance on flange machining and precision, you might find our complete guide to spotface holes and applications useful.

Feel free to contact us for any custom flange inquiries or technical assistance.

Related Products

Alongside our extensive flange parts range, we also supply essential pipe fittings like elbows, tees, and reducers to complete your piping system. Our forged fittings and olet branches offer durable, high-strength solutions for demanding applications. To ensure reliable, leak-free connections, we provide stud bolts and gasket kits designed to match flange specifications perfectly.

Together, these related products form a one-stop source for your piping needs, making it easier to manage procurement and maintain consistent quality across all components.

Get Your Free Quote in 2 Hours

Ready to find the perfect flange parts for your project? Request a free, no-obligation quote and get a detailed offer within 2 hours. Our team is here to provide fast, accurate pricing and answer any questions you have.

Contact Options:

- Fill out our quick contact form below

- Message us directly on WhatsApp for instant replies

- Email your requirements any time

We’re committed to helping you source the right flanges—fast, reliable, and at competitive prices. Get in touch now and keep your project moving forward!