Compare aluminium vs titanium on strength weight cost and durability to choose the best lightweight metal for engineering and outdoor projects.

The Fundamentals Physical Properties Density Weight and Melting Points

When comparing aluminium vs titanium, understanding their basic physical properties is a great starting point. These qualities lay the groundwork for how each metal performs in different applications.

- Density and WeightAluminium is much lighter than titanium. Its density is about 2.7 g/cm³, whereas titanium sits around 4.5 g/cm³. This means aluminium is easier to handle and often preferred when weight reduction is key. However, titanium offers a better strength-to-weight ratio despite being heavier.

- Melting PointsTitanium melts at a significantly higher temperature, roughly 3,034°F (1,668°C), compared to aluminium’s 1,221°F (660°C). This higher melting point contributes to titanium’s superior heat resistance and stability under extreme conditions.

Mechanical Properties Strength Durability and Fatigue Resistance

Titanium stands out for its incredible strength and durability. Its tensile strength often exceeds that of aluminium alloys, making it ideal for high-stress environments. It also resists fatigue better than aluminium, which means it maintains its integrity over repeated use without cracking or deforming.

Aluminium, while not as strong, is still tough enough for many everyday and industrial uses. Its excellent fatigue resistance and lightweight nature make it a solid choice where cost and weight matter more than maximum strength.

Chemical and Environmental Properties Corrosion Resistance and Conductivity

- Corrosion ResistanceTitanium is highly corrosion-resistant. It naturally forms a protective oxide layer that shields it from rust, saltwater, and many chemicals — a huge advantage in marine or medical applications. Aluminium also forms an oxide layer but is less durable in harsh environments, especially when exposed to saltwater or acidic conditions.

- ConductivityAluminium is a much better conductor of electricity and heat. This makes it useful in electrical components and heat exchangers where efficient conductivity is necessary. Titanium, on the other hand, has lower thermal and electrical conductivity, which can be beneficial in specific thermal insulation roles.

Understanding these fundamentals helps clarify the practical pros and cons of aluminium and titanium. Both bring unique strengths to the table, which we’ll explore further in terms of cost, machinability, and real-world use.

Cost and Manufacturing Price Comparison Why Titanium Costs 5–10x More Machinability and Fabrication Ease of Working with Each Metal

When comparing aluminum vs titanium on cost, titanium generally runs about 5 to 10 times more expensive. The main reasons are raw material scarcity and the complex, energy-intensive processes needed to extract and refine titanium. Aluminum is much more abundant and easier to mine, which keeps its price far lower.

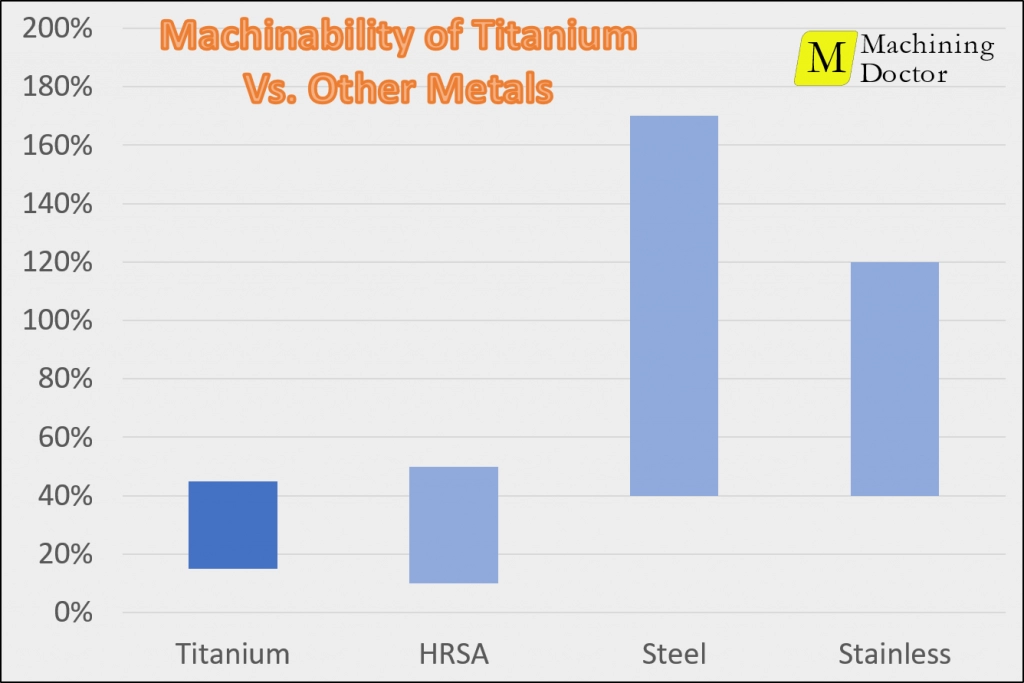

Titanium’s higher cost is also driven by its harder machinability. This metal is tough, requiring specialized tools and slower cutting speeds during fabrication. That means longer production times and higher labor costs. On the flip side, aluminum is easier to machine and shape, making it a favorite for manufacturers needing quick turnaround and lower expenses.

In short:

- Titanium: Higher raw material cost, tougher machining, more energy needed → higher price

- Aluminum: Cheaper raw material, easier and faster to work with → lower price

If your project budget is tight and manufacturing speed matters, aluminum is the more affordable choice. But if you want premium strength and longevity, titanium’s cost often makes sense for high-stakes applications despite the price.

Real World Applications Where Each Metal Shines

Aerospace and Automotive High Stakes Performance

Both aluminum and titanium play crucial roles in aerospace and automotive industries, but for different reasons. Aluminum’s lightweight alloys help reduce overall vehicle weight, improving fuel efficiency and lowering emissions. It’s widely used in airplane bodies, car frames, and engine parts where weight savings matter. Titanium, on the other hand, is prized for its superior strength-to-weight ratio and durability. It’s common in aircraft engines, turbine blades, and high-performance automotive parts that need to handle extreme stress and temperatures.

Medical and Marine Biocompatibility and Corrosion Demands

Titanium stands out in the medical field due to its excellent biocompatibility—it doesn’t react negatively with the human body, making it ideal for implants and prosthetics. Its corrosion resistance is also unmatched in marine environments, protecting ships, submersibles, and offshore equipment from salty water damage. Aluminum is less common in these fields because it’s more prone to corrosion and not as biologically inert, but it still finds use in lighter, less demanding marine structures and some medical device casings.

Outdoor Gear and Consumer Products Everyday Durability

For everyday items like bikes, camping gear, and sporting goods, aluminum is the go-to metal thanks to its low cost, light weight, and easy machinability. It offers decent durability for consumer use and is often chosen for products where budget and weight matter more than maximum strength. Titanium is used for premium outdoor gear and accessories—think high-end bicycles, multi-tools, and watches—where users want something tough, lightweight, and able to last a lifetime without wearing out or corroding.

In , both metals have their place: aluminum excels where budget and lightness are key, titanium leads when strength, toughness, and corrosion resistance can’t be compromised.

Pros Cons and Head to Head Decision Matrix

Here’s a quick look at how aluminum and titanium stack up side by side so you can decide which fits your needs best.

| Feature | Aluminum | Titanium |

|---|---|---|

| Weight | Lightweight | Even lighter for its strength |

| Strength to Weight | Good | Excellent |

| Corrosion Resistance | Moderate (can corrode) | Outstanding (very resistant) |

| Durability | Durable but less fatigue resistant | Superior fatigue resistance |

| Conductivity | High electrical conductivity | Low electrical conductivity |

| Cost | Budget-friendly | 5–10x more expensive |

| Machinability | Easier to work with | Harder to machine, needs special tools |

| Applications | Cars, packaging, construction | Aerospace, medical implants |

When to Choose Aluminum

- You need a budget-friendly metal without sacrificing too much strength.

- Your project requires good conductivity or easy machining.

- Lightweight alloys for everyday use, like outdoor gear or automotive parts.

- You want versatility with easier customization and faster fabrication.

When to Choose Titanium

- You need premium strength and longevity for high-performance uses.

- Corrosion resistance is a top priority, especially in marine or medical environments.

- You want the best strength to weight ratio for aerospace or racing applications.

- Durability and fatigue resistance over many years matter more than upfront cost.

Understanding these pros and cons helps you pick the right metal so your project hits the sweet spot between price, strength, and performance.