Discover expert insights on brushed finishing techniques for metals including stainless steel and aluminum with tips on applications benefits and care.

If you’ve ever admired the sleek, textured look on a stainless steel appliance or a custom metal fixture, you’ve seen brushed finishing in action. But what exactly makes this surface treatment so popular in manufacturing and design? Whether you’re a fabricator aiming for that perfect satin texture or a DIY enthusiast curious about the process, understanding brushed finishing is key to unlocking metal’s full potential. In this guide, we break down the technique, benefits, and expert insights you need to elevate your next project with confidence.

The Science Behind Brushed Finishing How It Transforms Metal Surfaces

Brushed finishing is more than just an aesthetic choice—it’s a precise surface abrasion technique that changes how metal looks and feels. This process uses mechanical surface polishing with a fine abrasive pad or brush to create a uniform, unidirectional texture on the metal. The result is a matte linear pattern that reduces glare and hides imperfections better than a polished or mirror finish.

At its core, brushed finishing works by removing a thin layer of the metal’s surface using #4 polish grit or similar abrasive materials. This controlled abrasion exposes tiny grooves and lines that give metals like brushed stainless steel their signature satin metal finish. This textured surface also enhances corrosion-resistant brushing benefits by making contaminants less likely to stick and easier to remove.

Overall, this science-backed approach transforms flat, reflective metals into visually appealing, touch-friendly surfaces widely loved in architectural metal finishes and industrial design. Whether for style or improved function, brushed finishing adds durability and sophisticated character to various materials.

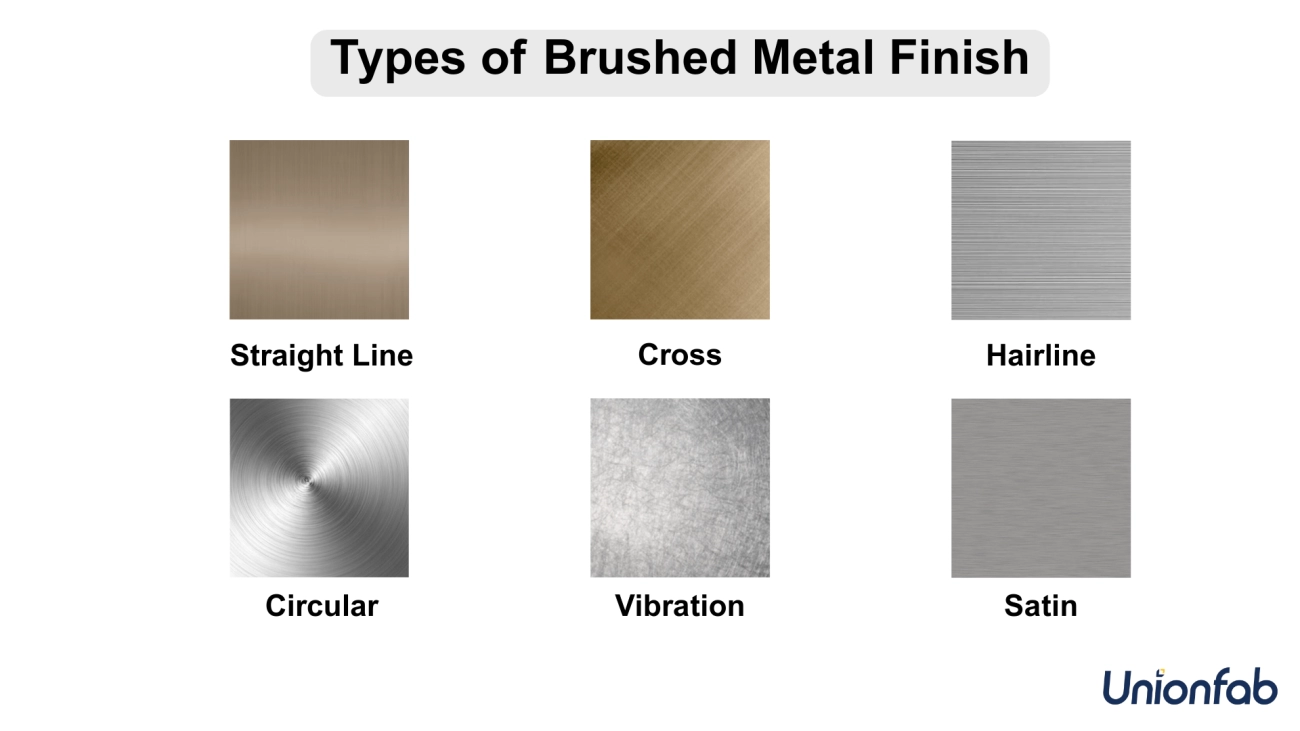

Types of Brushed Finishes Choosing the Right One for Your Needs

When it comes to brushed finishing, not all textures are the same. Different types of brushed finishes offer unique looks and feel, so picking the right one depends on your project and style.

Here are the common types of brushed finishes you’ll find:

- Fine Brushed FinishThis gives a subtle, smooth matte linear pattern. It’s perfect when you want a sleek, modern look without too much texture. Often used on brushed stainless steel in kitchens and appliances.

- Medium Brushed FinishOffers more visible unidirectional texture metal effect. It strikes a balance between shine and roughness, making it popular for architectural metal finishes, like wall panels or fixtures.

- Coarse Brushed FinishHas deeper surface abrasion techniques and more pronounced grain. This style is great if you want a bold industrial or rustic vibe on metals like aluminum or brass.

- Satin Finish (#4 Polish Grit)A standard in mechanical surface polishing, this type provides a smooth, soft finish that’s corrosion-resistant brushing friendly. It’s widely used in commercial settings for a clean, durable surface.

When choosing a brushed finish, consider:

- Material type (some finishes work better on certain metals)

- Visible texture preference (subtle vs bold)

- Wear and tear (corrosion resistance and maintenance)

- End use (indoor, outdoor, decorative, or practical)

Selecting the right brushed finish helps you get the look and durability you want for your metal surfaces, whether you’re working on appliances, architectural details, or DIY brushed aluminum projects.

Materials Ideal for Brushed Finishing From Stainless Steel to Brass

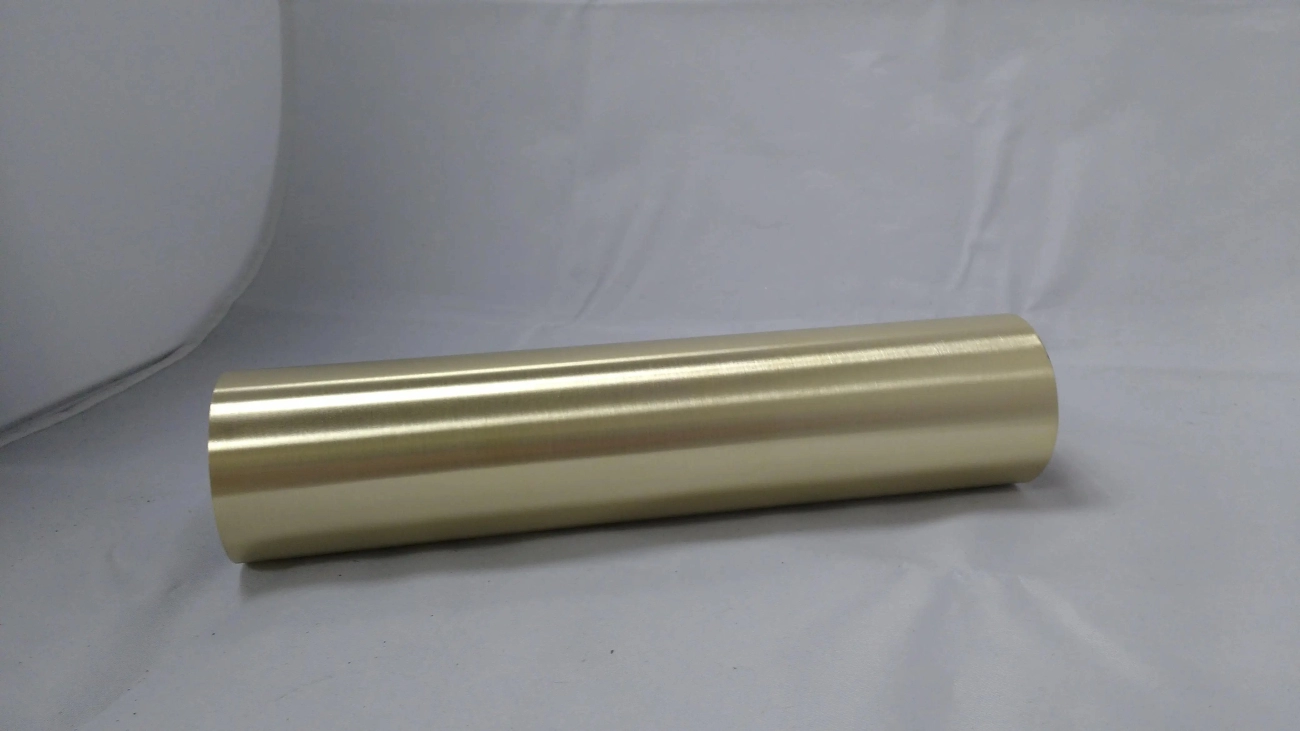

Brushed finishing works great on a range of metals, but some materials respond better than others. Stainless steel is the top choice, known for its corrosion resistance and clean look when brushed. The process enhances the metal’s surface, creating that popular satin metal finish with subtle matte linear patterns that look sleek and modern.

Aluminum is another favorite, especially for DIY brushed aluminum projects. It’s lightweight and easy to work with, making it perfect for both industrial and home use. The surface abrasion techniques used in brushing bring out a smooth unidirectional texture metal that resists fingerprints and smudges.

Brass and copper also take well to brushed finishing, offering a warm, elegant look when polished mechanically. These metals benefit from brushing because it softens their shiny surface into a more understated matte style, which helps hide minor scratches.

Other metals like titanium and nickel can also be brushed, especially in architectural metal finishes where durability and style both matter. Just keep in mind that softer metals may show wear faster over time.

In short, brushed finishing suits stainless steel, aluminum, brass, copper, and some specialty metals, making it a versatile choice for many applications.

Step by Step Guide How to Achieve Professional Brushed Finishing

Getting a professional brushed finishing look doesn’t have to be complicated. Here’s a simple step-by-step guide to help you create that attractive satin metal finish with a smooth, matte linear pattern.

1. Prepare the Surface

- Clean the metal thoroughly to remove dirt, grease, or old coatings.

- Use a degreaser or mild soap and water, then dry completely.

2. Choose the Right Grit

- Start with a coarse abrasive like #120 grit to remove scratches or blemishes.

- For brushed stainless steel, moving up to a #4 polish grit is common to get that signature unidirectional texture.

3. Sand with Consistent Motion

- Use a sanding block or mechanical polisher.

- Always move in the same direction to create uniform surface abrasion techniques and avoid swirling.

4. Progress to Finer Grits

- Move to finer grits like #220 or #320 to smooth out the surface and refine the texture.

- Each pass should follow the direction of the previous one, building layers of those parallel lines.

5. Clean Between Steps

- Wipe down the metal after each sanding step to remove dust and debris.

- This prevents contamination and gives you a clear view of the progress.

6. Apply Brushing Tools

- For a more consistent finish, use abrasive pads or specialized wire brushes designed for metal finishing.

- These help enhance the unidirectional texture metal look and give a lovely matte feel.

7. Optional Surface Treatment

- Some use light corrosion-resistant brushing treatments to protect the finish, especially on outdoor or kitchen surfaces.

8. Final Cleaning and Inspection

- Remove any leftover dust with a clean cloth.

- Inspect the surface for evenness and consistency in the brushing pattern.

Brushed finishing is a mechanical surface polishing technique that’s ideal for turning plain metals into stylish, subtle finishes perfect for everything from appliances to architectural metal finishes. Whether you’re working on brushed aluminum or stainless steel, following these steps will get you that professional look every time.

Benefits and Drawbacks of Brushed Finishing Is It Right for You

Brushed finishing offers a sleek, satin metal finish that many homeowners and businesses in the US find appealing. Here’s a quick look at the benefits and drawbacks to help you decide if it fits your needs.

Benefits

- Hides Scratches and Fingerprints: The matte linear patterns and unidirectional texture metal make scratches and smudges less obvious compared to polished surfaces.

- Corrosion Resistance: Especially on brushed stainless steel, the surface abrasion techniques improve corrosion resistance, making it great for kitchens and outdoor use.

- Modern and Stylish Look: It gives metal a subtle shine without being flashy, fitting well with contemporary and industrial design trends.

- Durable Surface: Mechanical surface polishing creates a tough finish that withstands everyday wear and tear.

- Versatile: Works well on various materials, from brushed aluminum in DIY projects to brass and stainless steel in architecture.

Drawbacks

- Can Be Harder to Clean Deeply: The tiny grooves in a #4 polish grit brushed finish can trap dirt or grease, needing regular upkeep.

- Limited Shine: If you want a mirror-like, glossy finish, brushed finishing may feel too muted or dull.

- Reapplication Needed for Heavy Wear Areas: Over time, the surface may need re-brushing to restore the original look, adding to maintenance.

- Not Ideal for All Styles: For classic or ornate looks, the modern vibe of brushed finishes might not match your design goals.

If you want a practical, stylish surface that hides flaws well and offers some corrosion resistance, brushed finishing is a solid choice. Just remember it requires routine care and isn’t for those needing a high-gloss mirror shine.

Real World Applications Where Brushed Finishing Shines

Brushed finishing is everywhere around us, and it’s no surprise why it’s so popular. Its unique satin metal finish with that matte linear pattern adds style and functionality at the same time. Here are some common places where brushed finishing really stands out:

- Kitchens: Brushed stainless steel appliances like refrigerators, ovens, and dishwashers resist fingerprints and scratches better than glossy finishes. They keep that clean, modern look even with daily use.

- Architectural Details: You’ll find brushed metal on handrails, elevator panels, and door handles in offices and hotels. The unidirectional texture gives a sleek, professional vibe while hiding wear.

- Automotive Parts: Some car interiors and trim pieces use brushed finishing to reduce glare and add a premium feel.

- Consumer Electronics: Many laptops, smartphones, and audio gear feature brushed aluminum or steel for a stylish yet durable surface.

- Furniture and Decor: Brushed metal lamps, tables, and fixtures provide a subtle shine without being overly flashy, fitting well with modern and industrial designs.

- Industrial Equipment: The surface abrasion techniques behind brushed finishing improve corrosion-resistant brushing and make equipment easier to clean and maintain.

The versatility of brushed finishing means it works in plenty of other places too. Wherever you want a surface that looks good, hides scratches, and isn’t too shiny, this finishing method is a solid choice.

Maintenance and Care Keeping Your Brushed Finish Looking New

Brushed finishing gives metal surfaces that sleek matte linear pattern, but to keep it looking fresh, some simple care goes a long way. Here’s how to maintain that satin metal finish and protect your brushed stainless steel or aluminum from wear:

- Regular cleaning: Use a soft cloth and mild soap with water. Avoid harsh cleaners or abrasive pads, as they can ruin the #4 polish grit texture or unidirectional surface abrasion.

- Wipe with the grain: Always clean following the direction of the brushing lines. This helps preserve the mechanical surface polishing and avoids scratches.

- Prevent stains and corrosion: Brushed finishes are often corrosion-resistant, but spills—especially from salt or chemicals—should be cleaned promptly.

- Avoid rough handling: Keep metal items from bumps or heavy scrapes to maintain that consistent brushed look.

- Use appropriate products: If polishing is needed, pick ones made specifically for brushed metals to maintain the surface abrasion techniques without damaging the finish.

By following these easy steps, whether on architectural metal finishes at home or DIY brushed aluminum projects, you’ll keep your brushed finish looking like new for longer.

FAQs Common Questions on Brushed Finishing

What is brushed finishing?

Brushed finishing is a surface treatment where metal gets a unidirectional texture through surface abrasion techniques. This creates a matte linear pattern that looks sleek and reduces glare.

Which metals work best for brushed finishing?

Stainless steel, aluminum, brass, and sometimes copper are ideal. Brushed stainless steel is especially popular for its corrosion-resistant brushing and durability.

How is brushed finishing different from polishing?

Polishing makes metal shiny and smooth, while brushed finishing leaves a satin metal finish with visible fine lines, giving it a textured look.

Can I DIY brushed finishing at home?

Yes, with the right tools like #4 polish grit sandpaper or abrasive pads, you can create a classy brushed aluminum finish at home. Just make sure to work carefully in one direction to keep the pattern consistent.

Is brushed finishing durable?

It holds up well, especially on stainless steel, since the surface abrasion technique helps hide scratches and fingerprints better than polished surfaces.

How do I maintain a brushed finish?

Simply clean regularly with mild detergent and a soft cloth. Avoid abrasive cleaners that can ruin the linear patterns.

Can brushed finishing prevent rust?

While it doesn’t make metal rust-proof, it’s commonly used on corrosion-resistant metals like stainless steel, helping the surface hold up better over time.

Where is brushed finishing used most?

You’ll see it a lot in architectural metal finishes, kitchen appliances, automotive trim, and even consumer electronics for that modern look with less visible wear.