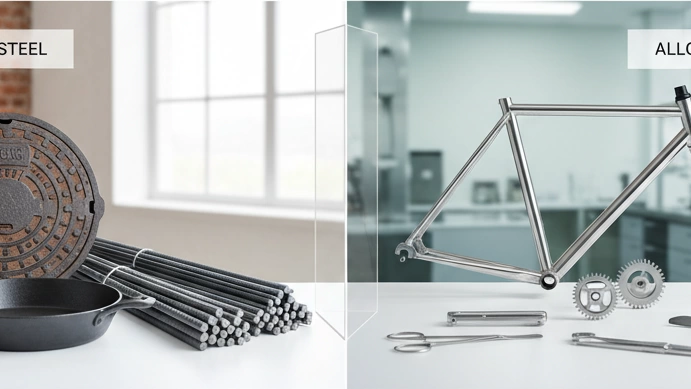

Compare carbon vs alloy steel to find the best material for strength durability corrosion resistance and cost in your next project.

Breaking Down the Basics – What Exactly Is Carbon Steel?

Carbon steel is essentially iron mixed with carbon, usually between 0.05% and 2.0%, with only small amounts of other elements like manganese (under 1.65%). This simple but powerful combination makes carbon steel the go-to metal for countless applications.

We classify carbon steel mainly by its carbon content:

- Low-carbon (mild) steel: Contains up to 0.3% carbon. It’s highly ductile and weldable, making it perfect for everyday fabrication tasks like building frames or automotive parts.

- Medium-carbon steel: With 0.3% to 0.6% carbon, this steel balances strength and toughness. It’s often used for gears, axles, and structural components needing more durability.

- High-carbon steel: Ranging from 0.6% to 2.0% carbon, this type is ultra-hard but more brittle. It’s ideal for cutting tools, blades, and springs where edge retention is crucial.

A quick history check: Carbon steel’s roots go way back to the Industrial Revolution. Thanks to its straightforward production method—mostly via basic oxygen furnaces—it remains the backbone of affordable construction and manufacturing projects today.

At Vast, we lean heavily on low-carbon steel stock. It’s reliable, cost-effective, and scalable, supporting large projects without compromising on quality or performance.

Alloy Steel Demystified – The Upgraded Iron Powerhouse

Alloy steel starts with a carbon steel base but adds between 1% and 50% other elements to boost performance. Common additions include chromium for improved hardness, nickel to increase toughness, and molybdenum for better heat resistance. These tweaks transform basic steel into a stronger, more durable material.

There are two main types of alloy steel:

- Low-alloy steel contains less than 8% alloying elements. It’s a smart choice for projects like bridges and pipelines because it offers extra wear resistance without a big jump in cost.

- High-alloy steel has over 8% alloy content and is made for heavy-duty, specialized use. Think aerospace turbine blades where extreme heat and stress demand the best materials.

Thanks to advanced manufacturing methods like electric arc furnaces, alloy steel’s mix can be precisely controlled to fit specific needs. At Vast, we focus on chromium-molybdenum alloys that handle tough conditions reliably, giving you long-lasting performance even in harsh environments.

Head-to-Head Comparison – Properties That Make or Break Your Choice

Here’s a quick look at how carbon steel and alloy steel stack up side-by-side:

| Property | Carbon Steel | Alloy Steel | Winner for… |

|---|---|---|---|

| Strength & Hardness | Good, improves with more carbon; high-carbon steel great for sharp edges | Superior strength; alloys boost tensile strength 20–50% | Alloy steel for heavy-duty parts |

| Corrosion Resistance | Easily rusts without coatings; needs upkeep | Great corrosion resistance thanks to chromium/nickel; protects itself | Alloy steel for outdoor or harsh environments |

| Weldability & Machinability | Very weldable (especially low-carbon); easy to shape but can crack if overheated | Moderate weldability; needs special prep and care to prevent brittleness | Carbon steel for faster assembly jobs |

| Durability & Toughness | Tough but loses strength under heat and repeated stress | Outstanding fatigue resistance; works well from -50°C to 600°C | Alloy steel for extreme temperature conditions |

| Cost | Cheaper upfront (20–50% less per ton) | Higher initial cost but lasts longer, lowering overall expenses | Carbon steel for budget projects or low volume |

What This Means for You

- Carbon steel is your go-to if you need something affordable, easy to weld, and suitable for most everyday projects.

- Alloy steel is the better pick if your parts face heavy loads, tough weather, or extreme temperatures.

Trade-Offs to Consider

- Carbon steels are easier to cold-form and faster to work with but may need more maintenance.

- Alloy steels respond well to heat treatment, offering better strength and durability over time.

Pro Tip

Both steels are 100% recyclable. However, alloys often reduce waste in the long run because they last longer, making them a more sustainable choice for many U.S. industries.

Choosing between carbon vs alloy steel really boils down to balancing upfront costs, durability needs, and project conditions.

Real-World Applications – Where Each Steel Shines (and Falls Short)

When it comes to real-world use, carbon steel is the go-to for projects that need strength without breaking the bank. You’ll find it everywhere—from construction beams and rebar to automotive frames and pipelines. It’s also common in everyday consumer goods like cookware. Carbon steel’s main appeal here is affordability and availability, making it ideal for large-scale or volume-driven work where cost matters most.

On the other hand, alloy steel steps in when performance can’t be compromised. It’s the preferred choice in aerospace for landing gear, in the oil and gas industry for drill bits, and in power generation for valves. Tools like wrenches also rely on alloy steel’s toughness and durability. These are applications where failure isn’t an option, so alloy’s enhanced strength, heat resistance, and corrosion protection are critical.

For example, one Vast client upgraded from 1045 carbon steel to 4140 alloy steel for hydraulic cylinders. The result? A 30% reduction in downtime, thanks to the alloy’s better durability under stress and heat.

Looking ahead, alloy steel is playing a bigger role in green technologies, like components for wind turbines, due to its long life and toughness in harsh conditions. Meanwhile, carbon steel continues to support sustainable urban building projects where cost efficiency and recyclability are key.

How to Choose: A Step-by-Step Decision Framework

When picking between carbon vs alloy steel, here’s a simple way to decide what fits your project best:

1. Assess Your Project Needs

- Load Type: Static (steady stress) or dynamic (moving parts, shocks)

- Environment: Indoor dry space or corrosive/outdoor conditions

- Budget: Initial cost vs. long-term performance

2. Test Key Properties

| Test Type | What It Shows | Why It Matters |

|---|---|---|

| Hardness (Rockwell) | Resistance to wear and dents | Choose hard steels for tools or cutting parts |

| Tensile Strength | How much force steel holds | Strong steels for heavy loads or impact zones |

| Corrosion Simulation | Resistance to rust or damage | Essential for outdoor or chemical exposure |

3. Avoid Common Mistakes

- Don’t overspend: Avoid heavy alloy steel for simple jobs to save cost

- Don’t skimp: Avoid weak coatings on carbon steel to prevent early rust

4. Use Vast’s Expertise

We offer free material consultations and rapid prototyping to ensure your steel choice matches your exact specs—saving you time and cost down the road.

This approach helps you choose smart, balancing strength, durability, and budget right here in the U.S. market.

Maintenance and Sustainability – Long-Term Strategies for Both Steels

When it comes to keeping carbon and alloy steels in top shape, their care needs differ. Carbon steel usually calls for protective coatings like galvanizing or epoxy paint to guard against rust, especially in outdoor or humid environments. Alloy steel, on the other hand, tends to resist corrosion better thanks to elements like chromium and nickel—but it still benefits from regular inspections to catch any wear or stress early.

From an environmental standpoint, both carbon and alloy steels are fully recyclable, which is great for cutting waste. However, alloy steel’s longer lifespan means fewer replacements over time, reducing the overall carbon footprint. This durability aligns well with Vast’s commitment to green sourcing and sustainable materials.

Looking ahead, new tech like nano-alloy coatings is blending the strengths of both steels—offering enhanced protection and performance without adding extra weight or cost. These innovations make it easier to future-proof your projects, balancing durability with environmental responsibility.