Discover expert CNC turning services for precise cylindrical parts with fast turnaround and tight tolerances perfect for prototyping and production.

What Is CNC Turning A Foundational Breakdown Core Definition and Evolution

Ever wondered what CNC turning really means and why it’s such a big deal in manufacturing? Simply put, CNC turning is a subtractive manufacturing process where a computer-controlled lathe machines rotating workpieces into precise shapes. Imagine shaping metal, plastic, or other materials by spinning them while a sharp tool cuts away excess material. That’s the essence of CNC lathe machining.

This process is the backbone of making precision turned parts like shafts, bushings, and other cylindrical components you see in cars, appliances, and even aerospace equipment. It’s evolved from manual lathe turning—which required skilled operators doing everything by hand—to a high-tech, automated system that delivers unmatched accuracy and repeatability.

The evolution is crucial: early lathes were mechanical and limited in capabilities. Today’s CNC turning machines harness multi-axis turning centers, allowing for complex cuts like threading and facing techniques with minimal human intervention. This leap means faster production, less waste, and the ability to create intricate designs that were impossible before.

In a nutshell, CNC turning is the fusion of traditional lathe turning operations with computer control, creating a powerful tool that drives modern manufacturing across countless industries.

What Is CNC Turning Key Components of a CNC Turning Machine

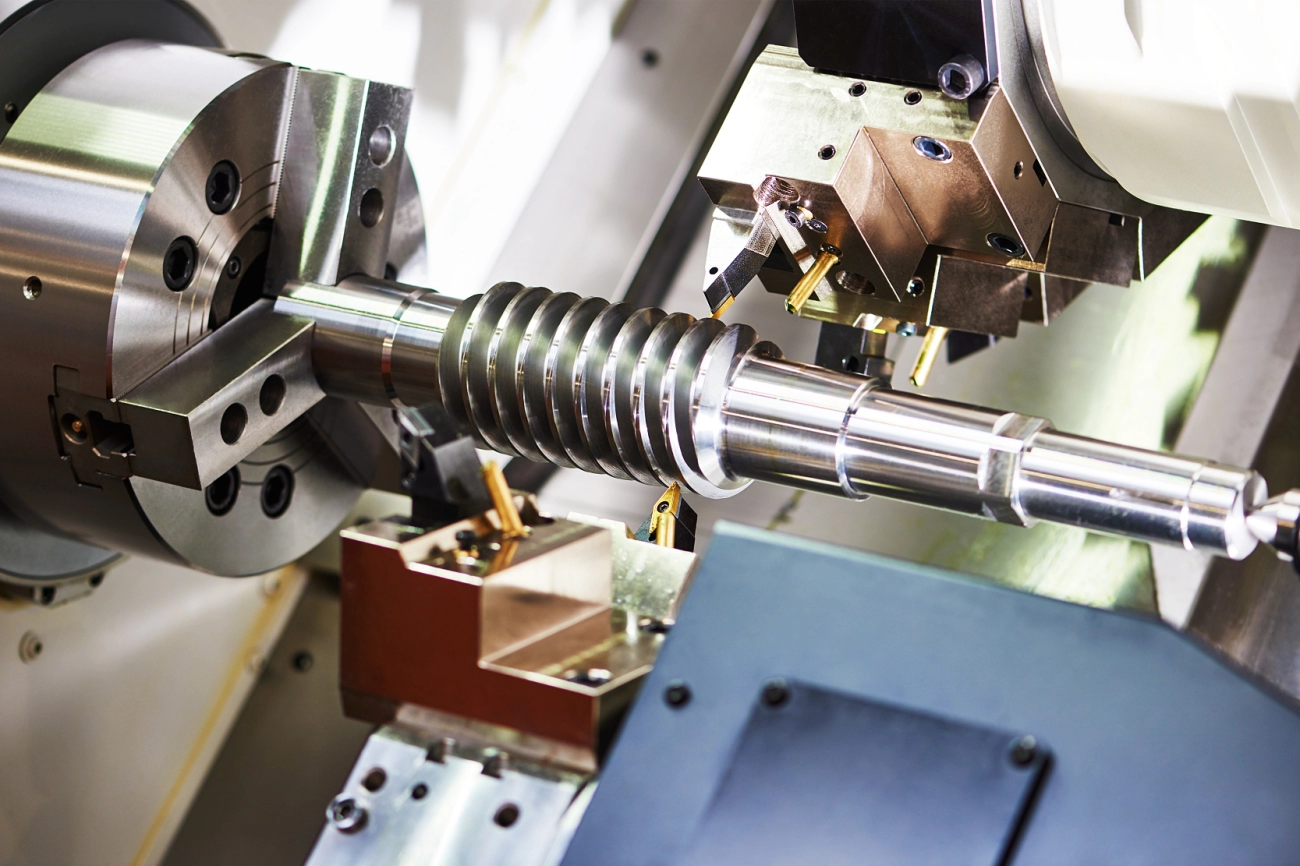

A CNC turning machine, also known as a CNC lathe, is built around a few key parts that make precision turned parts possible. Here’s a simple breakdown:

- Spindle: Holds and spins the workpiece. This is where your material is gripped during lathe turning operations.

- Tool Turret: Houses various cutting tools like drills, boring bars, and threading tools. It shifts tools in and out automatically based on the program.

- Chuck: Mounted on the spindle, the chuck clamps down on the cylindrical component for stability during the subtractive manufacturing process.

- Bed: The foundation of the machine, it supports the spindle and carriage, keeping everything aligned.

- Carriage: Moves the cutting tools along the bed to shape the material — both longitudinally and crosswise.

- Control Panel: The brain of the machine, where operators input CNC turning tolerances, commands, and monitor the machine’s actions through the CNC system.

- Tailstock (optional): Provides extra support for long or flexible materials during machining.

Together, these components enable multi-axis turning centers to perform threading and facing techniques with high precision. The design allows for efficient production of complex parts, whether it’s prototype turning services or high-volume factory runs.

What Is CNC Turning A Foundational Breakdown Types of CNC Turning Machines

When we talk about types of CNC turning machines, it’s all about fit for purpose and complexity of the job. There are a few main types, each designed to handle specific lathe turning operations and precision turned parts.

1. CNC Engine Lathes

These are the most common and versatile machines. They’re great for general cylindrical component production, handling everything from simple facing and threading techniques to more complex cutting. You’ll find these in most factories and prototype turning services setups.

2. CNC Vertical Turning Machines

Ideal for larger, heavier parts that are tougher to rotate horizontally. They excel in industries requiring large diameter parts like aerospace or heavy machinery.

3. Multi-Axis CNC Turning Centers

These are the heavy hitters in subtractive manufacturing processes. Multi-axis turning centers bring extra flexibility by combining multiple tools and axes, enabling complex shapes, undercuts, and advanced threading in one setup. They save time and increase CNC turning tolerances and quality.

4. Swiss-Type CNC Lathes

Built for precision turned parts at very small scales, especially in medical and electronics industries. They have a sliding headstock and guide bushing for tight tolerances and detailed threading.

Each type offers different levels of accuracy, material compatibility, and production speed, making it important to select the right CNC turning machine type for your specific needs in the U.S. manufacturing market.

How CNC Turning Works Step-by-Step Process Preparation Phase

Before starting any CNC turning job, preparation is key to getting precise results. Here’s what usually happens in this stage:

- Design and Programming: The first step is creating a digital design, often using CAD software. This design is then translated into a CNC program through CAM software, which sets the tool paths and machine instructions for the lathe turning operations.

- Material Selection: Choosing the right material depends on the final product’s needs. Common CNC turning materials include metals like aluminum, steel, and brass, plus plastics used for prototype turning services or production runs.

- Machine Setup: The CNC lathe machining setup involves loading the chosen raw material into the machine’s chuck. Tooling is also installed, which may include cutting, threading, or facing tools depending on the project.

- Calibration and Testing: The machine is calibrated to ensure accuracy within CNC turning tolerances. A test run or “dry run” without cutting material is often performed to confirm that the program runs correctly and that the tool paths are accurate.

- Safety Checks: Operators double-check setups for safety, making sure guards are in place and that machine parameters are correctly set to avoid errors during production.

This prep work sets the foundation for smooth, precise, and efficient CNC turning operations, reducing errors and boosting quality from the start.

How CNC Turning Works Step-by-Step Process Execution Steps

Once everything is set, the actual CNC turning process starts. Here’s how it generally goes down:

- Loading the workpiece: The raw material, often a metal rod or bar, is securely clamped into the CNC lathe chuck or collet.

- Machine calibration and tool setup: The cutting tools are positioned according to the design specs. This includes setting the right speed, feed rate, and depth.

- Starting the spindle: The lathe spindle spins the workpiece at high speed, allowing the cutting tool to remove material precisely.

- Tool movement and cutting: The CNC controls guide the cutting tool along the programmed path—performing turning, threading, facing, or grooving as needed.

- Monitoring and adjustments: Sensors and the operator keep an eye on the process to catch any errors, ensuring tolerances are tightly maintained.

- Finishing touches: After the primary cuts, finishing tools may smooth out surfaces or add detailed features.

The CNC lathe’s precision and automation make these steps quick, consistent, and highly repeatable—perfect for high-quality turned parts.

How CNC Turning Works Step-by-Step Process Advanced Techniques

Once you’re comfortable with the basics of CNC turning, advanced techniques take your parts to the next level. These methods improve precision, efficiency, and the complexity of shapes you can create.

Multi-axis turning is a big one. Unlike traditional lathes that rotate just one axis, multi-axis turning centers let the tool move on several axes. This allows you to handle more complex cuts, like angled threading or undercuts, without removing the part from the machine.

Another advanced technique is live tooling, where additional tools can rotate while the workpiece spins. This lets you do milling, drilling, or tapping right on the turning machine, reducing setup times and increasing productivity.

CNC threading and facing techniques have also evolved. With smart programming, you can cut ultra-fine threads or create smooth faces with tight tolerances, perfect for precision turned parts used in aerospace or medical devices.

High-speed machining is another advanced feature. With faster spindle speeds and optimized cutting paths, you can work with tougher materials or increase production rates without losing quality.

Finally, some shops use in-process measurement. This means checking the part’s dimensions while it’s still on the lathe to catch any deviations immediately, trimming down waste and rework.

In short, these advanced CNC turning techniques help manufacturers produce complex cylindrical components with superior accuracy and efficiency, meeting the high standards expected in today’s U.S. market.

Materials and Tolerances What Can CNC Turning Achieve Compatible Materials

CNC turning works with a wide range of materials, making it a flexible choice for many projects. Whether you’re working with metals, plastics, or composites, CNC lathe machining can handle it all with precision.

Common Materials for CNC Turning

- Metals: Steel, aluminum, brass, copper, titanium, and stainless steel are popular choices. These materials are ideal for creating durable and high-strength parts.

- Plastics: Materials like nylon, acrylic, PVC, and Delrin can be precisely shaped using CNC turning, perfect for lightweight or corrosion-resistant components.

- Composites: Some CNC turning machines can handle composite materials used in aerospace and automotive parts.

Each of these materials behaves differently during lathe turning operations, influencing factors like cutting speed and tool wear. That’s why having a machine setup optimized for your specific material is key.

Why Material Compatibility Matters

Matching the right material with CNC turning not only ensures better quality but also improves efficiency. For example, precision turned parts made from aluminum offer a lightweight solution for prototypes while stainless steel excels in high-tolerance, durable components.

In the U.S. market, the ability to work with diverse materials means manufacturers can meet the demands of various sectors—from medical devices to automotive parts—with confidence.

If you’re looking for custom CNC turning in China or at a local factory, be sure to specify your material needs upfront to get the best results.

Materials and Tolerances What Can CNC Turning Achieve Precision Specs

When it comes to precision, CNC turning excels at delivering tight tolerances that many other machining processes struggle to match. Typically, CNC lathe machining can achieve tolerances as fine as ±0.001 inches, depending on the material and the complexity of the part. This accuracy makes it ideal for producing precision turned parts used in automotive, aerospace, and medical industries where exact fits are crucial.

Key precision capabilities include:

- Tight dimensional control: Consistent diameter and length measurements are maintained throughout the run.

- Surface finish: Smooth finishes suitable for both functional and aesthetic needs, often reducing or eliminating secondary processes.

- Complex geometries: Accurate threading, grooving, and facing techniques enable intricate designs on cylindrical components.

The ability to hold such tolerances relies heavily on both the quality of the CNC turning machine and the skill in programming it. Multi-axis turning centers push the envelope even further by allowing 3D contours and undercuts with high precision.

For manufacturers in the U.S. looking to meet strict industry standards or develop prototype turning services, these precision specs are a game-changer. They ensure parts fit perfectly the first time, cutting down on waste, rework, and delays.

Advantages of CNC Turning Why It’s a Manufacturing Game-Changer Core Benefits

CNC turning offers several clear advantages that have made it a go-to in modern manufacturing. Here’s why it stands out:

- High Precision and ConsistencyCNC lathe machining ensures precision turned parts meet tight tolerances every time. This repeatability means fewer mistakes and less waste.

- Faster Production SpeedsCompared to manual lathe turning operations, CNC turning speeds up production, making it easier to meet deadlines with less downtime.

- Complex Part CapabilityWith multi-axis turning centers, CNC machines can handle intricate threading and facing techniques, producing detailed cylindrical components that manual machining can’t match.

- Flexibility Across MaterialsFrom metals like aluminum and steel to plastics, CNC turning accepts a wide range of materials, adapting to whatever your project requires.

- Reduced Labor CostsOnce programmed, CNC turning runs mostly unattended, reducing the need for constant operator intervention and lowering overall labor expenses.

- Improved SafetyBecause the process is automated, operators have less direct contact with sharp tools and moving parts, enhancing workplace safety.

- Scalable ProductionWhether you need prototype turning services or full-scale manufacturing runs, CNC turning machines can adjust without sacrificing quality.

These core benefits make CNC turning a smart, efficient, and reliable choice for U.S. manufacturers looking to boost productivity while keeping quality top-notch.

Advantages of CNC Turning Why It’s a Manufacturing Game-Changer Industry Impact

CNC turning has transformed how U.S. manufacturers approach production across multiple industries. Its precision and repeatability mean less waste and fewer mistakes, which saves both time and money. Here’s how CNC turning impacts industries locally and nationwide:

- Automotive: CNC lathe machining helps produce high-quality cylindrical parts like shafts and bushings quickly. This speeds up assembly lines and increases reliability in vehicles.

- Aerospace: Precision turned parts made with CNC turning tolerances meet strict safety standards, ensuring components perform under extreme conditions.

- Medical Devices: The accuracy of CNC turning supports the creation of tiny, complex parts needed in surgical tools and implants without sacrificing quality.

- Electronics: Threading and facing techniques in CNC turning allow for consistent small parts, essential for connectors and housings used in devices.

- Oil and Gas: Durable components made via multi-axis turning centers stand up to harsh environments, extending the life of valuable equipment.

Overall, CNC turning drives innovation and efficiency across sectors, making it a must-have in American factories wanting to stay competitive. It enables local manufacturers to meet customer demands faster with superior consistency compared to older subtractive manufacturing processes. This game-changing technology is boosting U.S. production capabilities by combining speed, precision, and flexibility for custom CNC turning and prototype turning services.

Real-World Applications Where CNC Turning Shines Sector Breakdown

CNC turning plays a vital role across many industries in the U.S. because of its precision and efficiency. Here’s a quick look at the main sectors where CNC lathe machining really makes a difference:

- Automotive: Precision turned parts like shafts, gears, and bushings are essential for engine and transmission systems. CNC turning ensures consistent quality and tight tolerances for enhanced performance.

- Aerospace: The aerospace industry relies heavily on CNC turning for producing complex cylindrical components with strict safety standards. Parts like turbine blades, landing gear components, and hydraulic fittings are often made using multi-axis turning centers.

- Medical Devices: CNC turning is key for crafting small, detailed pieces such as surgical instruments, implants, and prosthetic parts. Tight CNC turning tolerances support the critical precision required in this field.

- Oil and Gas: Components like drill bits, valves, and couplings need to withstand harsh environments. CNC turning delivers durability and accuracy for these heavy-duty parts.

- Electronics: From heat sinks to connectors, CNC lathe machining helps create tiny, precise parts essential to electronic devices.

- General Manufacturing: Prototype turning services and custom CNC turning projects support a broad range of manufacturing needs, helping businesses bring new ideas to life faster.

With CNC turning, industries benefit from consistent quality and fast turnaround times no matter the scale or complexity of production. This versatility makes it a go-to method for precision turned parts across the board.

Real-World Applications Where CNC Turning Shines Case Studies

Let’s look at some real-life examples where CNC turning made a big difference in production and quality.

1. Automotive Industry

A U.S. auto parts manufacturer used CNC lathe machining to produce precision turned parts like shafts and bushings. With CNC turning tolerances tight enough to meet safety standards, they improved part consistency and cut lead times by 30%.

2. Aerospace Sector

An aerospace company needed custom cylindrical component production with complex threading and facing techniques. Multi-axis turning centers allowed for high-precision parts that met stringent aerospace specs, helping the company reduce waste and up the reliability of engine parts.

3. Medical Device Manufacturing

A medical device firm turned to CNC turning for prototype turning services of surgical tools. The ability to handle a range of CNC turning materials ensured biocompatible parts with precise dimensions, speeding up development cycles while keeping costs down.

4. Oil and Gas Industry

A factory supplying valve components relied on subtractive manufacturing processes using CNC turning. This delivered durable, high-quality parts with tight CNC turning tolerances, essential for safety-critical applications in extreme environments.

Each case highlights how CNC turning adapts seamlessly to different industries, delivering efficiency, precision, and cost-effectiveness in custom CNC turning operations across the USA.

CNC Turning vs Other Machining When to Choose It Comparisons

Choosing between CNC turning and other machining methods depends on the part design, materials, and precision needed. CNC turning, or CNC lathe machining, is great for cylindrical parts, like shafts, bushings, and threaded components. It shines when you need consistent round shapes and tight CNC turning tolerances.

Here’s how CNC turning stacks up against common alternatives:

- CNC MillingBetter for complex shapes, flat surfaces, and multi-sided parts. Milling suits prototype turning services when parts need intricate features beyond simple cylinders.

- Manual Lathe TurningMore hands-on but less accurate and slower. CNC turning offers repeatability and faster cycle times, ideal for production runs.

- GrindingUsed for ultra-high precision finishing but limited to specific materials and shapes. CNC turning covers a wider range of materials and simpler cleanup needs.

- 3D PrintingGood for rapid prototypes but can’t match strength, surface finish, or precision specs of CNC lathe machining.

When to Choose CNC Turning

- You need precise cylindrical parts with tight tolerances

- Production involves threading and facing techniques

- Working with metals like steel, aluminum, or brass typically used in US manufacturing

- You want a fast, reliable subtractive manufacturing process for batch or custom orders

In short, CNC turning is your best bet for consistent, high-quality turned parts where round shapes and fine finishes are essential. For complex shapes or non-cylindrical parts, milling or hybrid approaches might work better.

CNC Turning vs Other Machining When to Choose It Hybrid Approaches

In many manufacturing projects, using CNC turning alone might not cover everything you need. That’s where hybrid approaches come in—combining CNC turning with other machining methods to get the best of both worlds.

Why Use Hybrid Approaches

- Complex Parts: Some components require turning for cylindrical shapes but need milling or drilling for flat surfaces or holes.

- Better Precision: Combining methods can improve tolerances and surface finishes beyond what one process can do alone.

- Faster Production: Switching between processes like CNC lathe machining and milling on multi-axis turning centers saves time and reduces setups.

- Cost-Effective: Instead of outsourcing separate operations, hybrid machining can handle multiple steps in one machine, cutting costs.

Common Hybrid Combinations

- CNC turning + CNC milling

- Turning with live tooling for threading and facing techniques

- Multi-axis turning centers for 3D part creation

- Combining subtractive manufacturing processes to meet complex specs

When to Choose Hybrid Approaches

- Your part has both cylindrical and complex angular features.

- You need prototype turning services that require flexibility.

- Tight CNC turning tolerances and detailed finishing are critical.

- You want to reduce lead time by avoiding multiple machine setups.

In short, hybrid machining with CNC turning boosts your capability, letting you manufacture challenging parts efficiently and precisely for local US markets. It’s a smart choice when single-method machining falls short.

Partnering with Vast Elevate Your CNC Turning Projects Why Vast

When it comes to CNC turning, Vast stands out as a trusted partner for businesses across the United States. Here’s why working with Vast can take your CNC lathe machining projects to the next level:

- Custom Solutions Tailored to YouWe understand that every project is unique. Vast offers custom CNC turning services that meet your exact specifications, whether you need precision turned parts for prototypes or large-scale production runs.

- Advanced Technology and ExpertiseVast uses state-of-the-art multi-axis turning centers and the latest subtractive manufacturing processes. Our team knows how to optimize lathe turning operations to maximize quality and efficiency.

- Reliable Quality and PrecisionWith tight CNC turning tolerances and strict quality control, you get parts that consistently meet your dimensional and surface finish requirements. This reliability reduces waste and speeds up your production timeline.

- Strong U.S. Market FocusUnderstanding local regulations, supply chain needs, and turnaround times keeps your project on track. Vast’s connection to the U.S. market means smoother communication and faster delivery.

- Wide Range of Materials ExpertiseWhether it’s aluminum, steel, or specialty CNC turning materials, Vast handles them all with care. Our experience ensures your parts perform well in real-world applications.

In short, choosing Vast means you’re backed by a partner who values precision, customization, and on-time delivery. That support helps your CNC turning projects meet market demands without compromise.

Partnering with Vast Elevate Your CNC Turning Projects Getting Started

If you’re ready to take your CNC turning projects to the next level, partnering with Vast is a smart move. We specialize in custom CNC turning services tailored to meet the specific needs of businesses across the U.S. Whether you need prototype turning services or large-scale production of precision turned parts, Vast has the experience and technology to deliver.

Here’s how to get started with us:

- Reach Out for a ConsultationContact our team to discuss your project details. We’ll walk you through what’s possible and recommend the best approach for your CNC lathe machining needs.

- Share Your Design FilesUpload your CAD drawings or sketches. This helps our experts understand your design goals and tolerances for accurate production.

- Receive a Custom QuoteWe provide clear, competitive pricing based on your materials, turnaround time, and production volume.

- Approve and Begin ProductionOnce you give the green light, we start the CNC turning process using the latest multi-axis turning centers to ensure quality and precision.

- Ongoing SupportVast stays committed to your project success, offering communication throughout production and after delivery.

Working with Vast means you get access to a trusted CNC turning factory in China with a focus on reliability, speed, and U.S. market standards. Our goal is to help your manufacturing run smoothly with parts that match your quality expectations — from cylinder component production to complex threading and facing techniques.

Start your CNC turning journey with Vast today and experience how we make custom machining easy and dependable.