Explore the ultimate aluminum alloys chart with key properties types and selection tips for aerospace automotive and industrial applications.

Understanding Aluminum Alloy Basics From Pure Al to Advanced Blends

When you hear aluminum alloys, what comes to mind? Simply put, aluminum alloys are mixtures of aluminum with other elements like copper, magnesium, manganese, silicon, or zinc. These added elements change aluminum’s natural properties, making it stronger, lighter, or more corrosion-resistant depending on the blend.

What Are Aluminum Alloys

- Pure Aluminum (1xxx series) is soft, highly ductile, and great for electrical applications, but it lacks strength.

- Adding elements such as copper, magnesium, or zinc creates alloys that can handle tougher jobs and specialized uses.

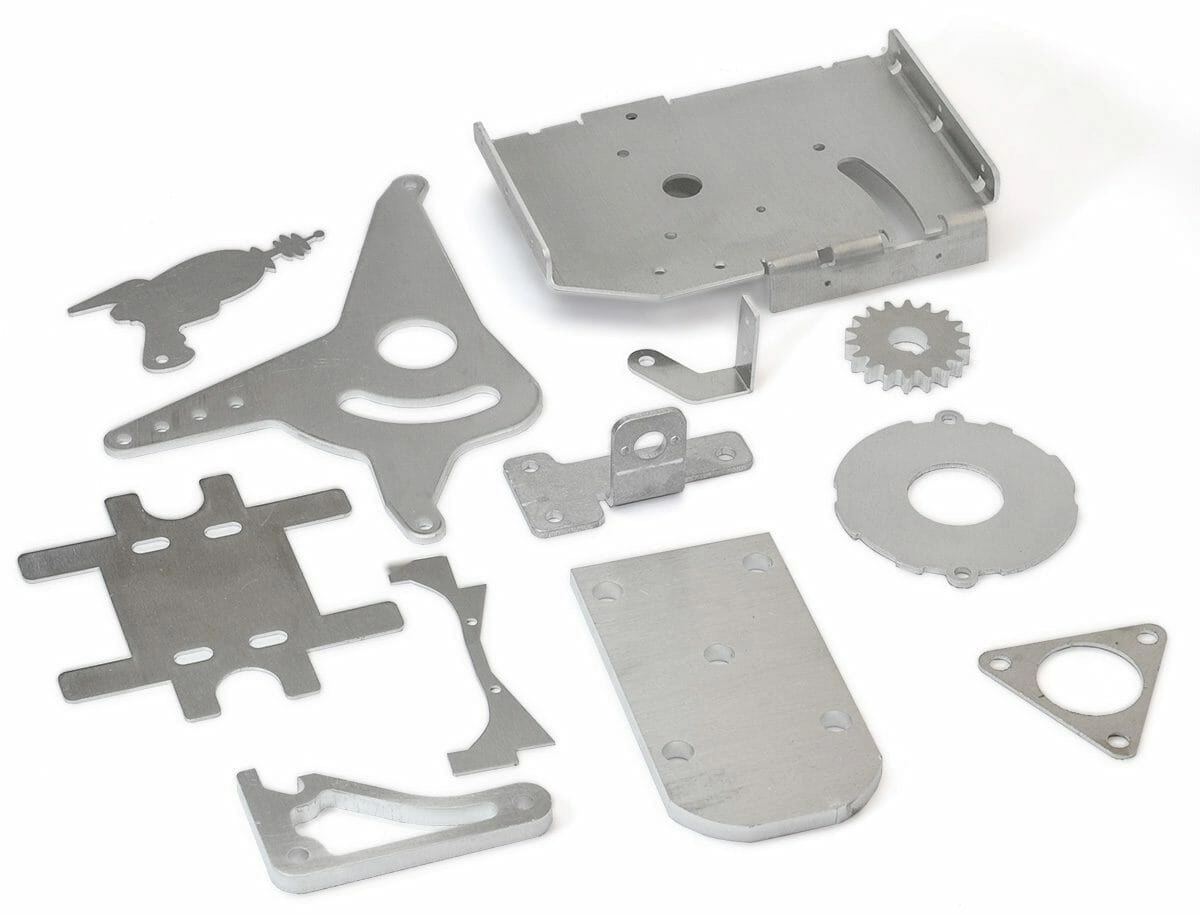

- These alloys are essential for industries from aerospace to automotive because they balance weight, strength, corrosion resistance, and cost.

Wrought vs Cast Aluminum Alloys

Knowing the difference helps when browsing an aluminum alloys chart:

- Wrought alloys are shaped by mechanical processes like rolling, extruding, or forging. They usually have better mechanical properties and are easier to work with.

- Cast alloys are melted and poured into molds, allowing complex shapes but often with lower strength and ductility compared to wrought alloys.

The 4-Digit Naming System

Aluminum alloys follow a simple 4-digit system that tells you what elements dominate:

- 1xxx series – basically pure aluminum (≥99%)

- 2xxx series – copper as the main alloying element

- 3xxx series – manganese

- 4xxx series – silicon

- 5xxx series – magnesium

- 6xxx series – magnesium and silicon

- 7xxx series – zinc

- 8xxx series – other elements (like lithium)

For example, 6061 is a popular 6xxx series alloy, containing magnesium and silicon, known for versatility.

Why Aluminum Alloys Charts Matter

Choosing the right aluminum alloy isn’t guesswork. A well-designed aluminum alloys chart puts essential data—like strength, density, corrosion resistance, weldability, and temper conditions—all in one accessible place.

- They simplify comparisons across hundreds of alloys.

- Save time and avoid costly mix-ups.

- Help engineers and buyers match alloys to project needs precisely.

Think of an aluminum alloys chart as your quick reference guide when balancing performance, manufacturability, and budget.

If you want a handy version for your next project, check out Vast’s customizable aluminum alloys chart for the US market—packed with clear data and practical insights.

Ready to dive deeper? Next, we’ll explore the complete aluminum alloys chart highlighting key series and popular choices.

The Complete Aluminum Alloys Chart Key Series Properties and Data at a Glance

Vast offers a custom aluminum alloys chart that breaks down the key properties for all 8 major series. This chart makes it easy to compare important factors side by side, helping you pick the right alloy fast. Here’s what you’ll find in the chart columns:

- Alloy Designation: Identifies each specific alloy by its 4-digit series number

- Density: Shows weight differences important for lightweight design

- Strength: Tensile and yield strength ratings to match your strength needs

- Corrosion Resistance: How well the alloy holds up in different environments

- Weldability: Guides you on how easy it is to weld or join the alloy

- Tempers: Lists common heat treatments and mechanical conditions that affect performance

The chart features popular alloys like 6061, 2024, 3003, 5052, 7075, and more, with clear examples of where each fits best. With this info all in one place, it’s much simpler to find the perfect aluminum alloy for your project or product – whether you’re working in aerospace, automotive, construction, or marine.

Breaking Down Popular Aluminum Alloys Strengths Weaknesses and Use Cases

When looking at aluminum alloys, each series has its own strengths, weaknesses, and typical uses. Here’s a simple breakdown to help you get a clear picture.

1xxx Series – Pure Aluminum

- Characteristics: Over 99% pure aluminum.

- Strengths: Excellent corrosion resistance, high ductility, and great electrical conductivity.

- Weaknesses: Low strength compared to other alloys.

- Uses: Electrical conductors, chemical industries, and food packaging.

2xxx Series – Copper Alloys

- Characteristics: Copper is the main alloying element.

- Strengths: High strength and good machinability.

- Weaknesses: Poor corrosion resistance and can be costly.

- Uses: Aerospace parts, military applications, and high-strength structural components.

3xxx and 5xxx Series – Manganese and Magnesium Alloys

- Characteristics: 3xxx uses manganese; 5xxx features magnesium as the main alloy.

- Strengths: Good formability, excellent corrosion resistance (especially 5xxx), and decent strength.

- Weaknesses: Not heat-treatable, lower strength than 2xxx or 7xxx series.

- Uses: Roofing, siding, marine environments, and automotive panels.

6xxx Series – Magnesium Silicon Alloys

- Characteristics: Magnesium and silicon for a balanced alloy.

- Strengths: Versatile, good strength, excellent corrosion resistance, and good weldability.

- Weaknesses: Moderate strength, not as strong as 7xxx.

- Uses: Automotive parts, structural applications, bicycle frames.

7xxx Series – Zinc Alloys

- Characteristics: Zinc is the primary alloying element.

- Strengths: Ultra-high strength, great for aerospace-grade materials.

- Weaknesses: Lower corrosion resistance and more expensive; sometimes prone to stress corrosion cracking.

- Uses: Aerospace components, sporting equipment, high-performance vehicles.

Cast Aluminum Alloys

- Characteristics: Designed for casting with better fluidity.

- Strengths: Complex shapes possible, good wear resistance.

- Weaknesses: Generally lower strength compared to wrought alloys.

- Uses: Engine blocks, housings, pump components.

Understanding these differences helps you select the right aluminum alloy for your specific needs, whether it’s for high strength, corrosion resistance, or formability.

How to Read and Use an Aluminum Alloys Chart for Optimal Selection

Using an aluminum alloys chart may seem tricky at first, but it’s really about matching your project needs with the right alloy features. Here’s a simple step-by-step guide to help you navigate the chart and make the best choice:

Step 1: Identify Your Key Needs

Think about what matters most—weldability, strength, corrosion resistance, or formability. For example, if you need an alloy that welds easily, look for options marked with good weldability.

Step 2: Understand Temper Designations

The temper codes (like T6 or O) show how the alloy has been treated, which directly affects strength and flexibility. Make sure to pick the temper suited for your use, such as T6 for high strength or O for soft and malleable.

Step 3: Check Processing and Application

Some alloys are better for machining, others for casting or forming. The chart breaks these down. Match your processing method so you avoid costly mistakes.

Common Pitfalls to AvoidDon’t assume all aluminum alloys are interchangeable — strength, weight, and corrosion resistance vary widely.

Avoid alloys that aren’t designed for your environment (like choosing poor corrosion resistance in marine applications).

Don’t overlook the temper; it can make or break performance.Try Vast’s Alloy Selector Quiz and Download the Chart

To make things easier, Vast offers an interactive alloy selector quiz to guide you based on your specific application. Plus, grab our downloadable aluminum alloys chart to have all the essential info at your fingertips.

Using the chart smartly helps you pick a reliable, cost-effective alloy, avoiding common headaches in fabrication and performance.

Real World Applications Matching Alloys to Industries with Vast Solutions

When it comes to aluminum alloys, choosing the right one for your industry can make all the difference. Here’s a quick look at how different alloys fit various sectors—and how Vast’s solutions help you get it right.

Aerospace and Defense

Aerospace relies heavily on high-strength, lightweight alloys like the 7xxx series (zinc-based) and some advanced aluminum-lithium (Al-Li) blends. These alloys offer excellent strength-to-weight ratios, crucial for aircraft and defense equipment. For example, Vast helped a manufacturer reduce aircraft weight by 15% using a custom 7xxx alloy that improved performance without compromising safety.

Automotive and Transportation

In auto manufacturing, the 6xxx series (magnesium-silicon alloys) is king due to its versatility, good strength, and corrosion resistance. These alloys handle everything from body panels to structural parts. Transportation companies favor these for durability and lightweight benefits, helping improve fuel efficiency and reduce emissions.

Construction and Building

For buildings and infrastructure, corrosion resistance is key. The 5xxx series (magnesium alloys) stands out here, especially in outdoor and coastal settings. These alloys withstand harsh environments, making them the preferred choice for facades, roofing, and structural elements in the U.S.

Marine Applications

Marine environments demand excellent resistance to saltwater corrosion and good electrical conductivity. Aluminum alloys like the 5xxx series again are popular, with the 5052 alloy leading the pack. Vast’s marine alloy selections ensure longer-lasting, low-maintenance parts for boats, docks, and underwater equipment.

Emerging Trends with Aluminum-Lithium Alloys and Sustainability

Aluminum-lithium alloys are gaining momentum for their super lightweight and strength benefits—perfect for sustainable transportation and aerospace innovation. They reduce weight and energy consumption, supporting green initiatives across industries. Vast is actively working to bring these cutting-edge alloys to U.S. markets, helping companies meet sustainability goals without sacrificing performance.

No matter your industry, Vast’s aluminum alloys chart and expert guidance make it simple to find the perfect match for your toughest demands.

Frequently Asked Questions About Aluminum Alloys

Here are answers to some of the most common questions about aluminum alloys to help you choose the right one.

What is the strongest aluminum alloy

The 7xxx series alloys, especially 7075, are known for their ultra-high strength. They’re commonly used in aerospace and military applications where max strength is critical. However, these alloys can be less corrosion-resistant and harder to weld.

How do aluminum alloys compare in density

Aluminum alloys generally have a low density around 2.7 g/cm³, but this varies slightly:

- 1xxx series (pure aluminum): ~2.70 g/cm³

- 2xxx and 7xxx series (copper and zinc alloys): slightly higher density, around 2.78–2.85 g/cm³

- 5xxx and 6xxx series (magnesium and silicon alloys): about 2.68–2.72 g/cm³

These small differences matter for weight-sensitive projects like aerospace or transportation.

What are the main differences between 6061 and 6063 alloys

| Property | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

| Strength | Higher | Medium |

| Extrudability | Good | Excellent |

| Surface Finish | Moderate | Very good for anodizing |

| Common Uses | Structural parts, frames | Architectural, trim |

6061 is stronger and more versatile for structural applications, while 6063 is preferred when surface finish and precise shapes matter.

What is the best aluminum alloy for welding

For easy welding, look into 5xxx series alloys like 5052 and 5356 filler metals. They combine good strength and excellent weldability with corrosion resistance. The 6xxx series alloys like 6061 weld well but usually require special preparation and post-weld heat treatment for best results.

If you’re still unsure about which alloy fits your project, check out our full aluminum alloys chart and use our alloy selector quiz for personalized help.