Explore comprehensive insights on aluminum and aluminum alloys covering key properties types manufacturing and applications for engineers and fabricators.

Core Properties of Aluminum and Its Alloys What Makes Them Stand Out

When you choose aluminum or its alloys, you want to know what really sets them apart. Here’s a quick look at their core properties and why they are favored, especially in the US where corrosion resistance often drives alloy selection.

Physical Properties

- Density: Lightweight at about 2.7 g/cm³ — almost one-third the weight of steel.

- Thermal Conductivity: Excellent heat conductor making it ideal for heat exchangers and electronics.

- Electrical Conductivity: High conductivity, though less than copper, perfect for wiring.

- Reflectivity: Reflects up to 90% of visible light and heat, useful in lighting and insulation.

Mechanical Properties

- Strength to Weight Ratio: Aluminum alloys are strong but still light, allowing efficient design without heavy mass.

- Ductility: Can be stretched or formed without breaking — great for complex shapes.

- Formability: Easy to roll, extrude, or forge.

- Fatigue Resistance: Holds up well under cyclic loading, important in transportation.

Corrosion and Environmental Resistance

- Natural Oxide Layer: Aluminum naturally forms a tough oxide layer that protects against corrosion.

- Galvanic Considerations: When paired with other metals, it requires care to prevent galvanic corrosion.

- Recyclability: 100% recyclable without loss of properties, making it a sustainable choice.

Pure Aluminum vs Common Alloys Comparison

| Property | Pure Aluminum (1xxx series) | Common Alloy Example (6061, 7075) |

|---|---|---|

| Tensile Strength (ksi) | 13–25 | 30–83 |

| Elongation (%) | 35–50 | 10–20 |

| Corrosion Resistance | Excellent | Good (varies by alloy) |

Local Insight US Market Preferences

In the US, aluminum alloys are preferred over pure aluminum, especially for applications exposed to harsh environments. Why? Alloys offer better strength and corrosion resistance tailored to local needs like marine conditions or road salt exposure.

At Vast, we support US-based projects that rely on these alloys, helping manufacturers pick the right grades for durability and performance without over-engineering.

Classification of Aluminum Alloys Breaking Down the Types

When it comes to aluminum and aluminum alloys, understanding the different types is key, especially for US customers who rely on specific grades for unique applications.

Wrought vs Cast Alloys

- Wrought Alloys: These are shaped by rolling, extrusion, or forging. They’re highly ductile and great for making sheets, plates, and complex profiles. Think architectural frames or automotive parts that need to be strong yet formable.

- Cast Alloys: These are poured into molds for complex shapes. While generally less ductile, cast alloys excel where intricate forms are needed, like engine blocks or housings.

The 8 Series Breakdown

- 1xxx Series

- Nearly pure aluminum (99%+).

- Great corrosion resistance but lower strength.

- Common in wiring, foil, and chemical applications.

- 2xxx Series

- Copper is the main alloying element.

- Known for high strength and heat-treatable.

- Widely used in aerospace, like 2024 alloy.

- 3xxx Series

- Contains manganese.

- Moderate strength and very formable.

- Found in beverage cans, roofing, and traffic signs.

- 4xxx Series

- Silicon-based for lower melting points.

- Used in welding applications and automotive pistons.

- 5xxx Series

- Magnesium enhances corrosion resistance.

- Marine-grade tough, perfect for shipbuilding and coastal structures.

- 6xxx Series

- Combines magnesium and silicon.

- Versatile and extrudable, great for architectural and structural parts (e.g., 6063 alloy).

- 7xxx Series

- Zinc dominant for ultra-high strength.

- Common in aircraft frames but sensitive to stress corrosion cracking.

- 8xxx Series

- Includes other elements like lithium.

- Emerging use in aerospace and advanced composites.

Heat Treatable vs Non Heat Treatable Alloys

- Heat Treatable: These alloys respond to precipitation hardening (aging). Examples include 2xxx, 6xxx, and 7xxx series. Heat treatment improves strength substantially.

- Non Heat Treatable: Alloys like 1xxx, 3xxx, and 5xxx rely on cold working for strength, not heat treatment.

For those interested, Vast offers a handy infographic visually breaking down these alloy series, perfect for quick reference when choosing the right aluminum alloy.

Understanding these classifications helps US manufacturers and buyers target the right alloy for corrosion resistance, strength, and formability—key for industries from automotive plants in Michigan to aerospace hubs across the country.

Manufacturing and Processing How Aluminum Alloys Are Made and Shaped

Alloying Process

Aluminum starts as bauxite ore extracted via the Bayer process, creating pure aluminum. Then, specific elements like copper, magnesium, or silicon are added to produce different aluminum alloys. This melting and mixing ensure the metal has the right properties.

Key Techniques

Aluminum alloys are shaped using several techniques:

| Technique | Purpose | Examples |

|---|---|---|

| Casting | Form complex shapes | Die casting, sand casting |

| Wrought forming | Make ductile, strong products | Rolling, forging, extrusion |

| Heat treatment | Improve strength and durability | Annealing, aging |

Finishing Options

To enhance corrosion resistance and durability, aluminum alloys often undergo:

- Anodizing: Adds a protective oxide layer

- Painting: For extra surface protection and aesthetics

- Cladding: Like Alclad used in aerospace for corrosion resistance

Challenges and Solutions

- Galvanic corrosion: Happens when aluminum contacts other metals; proper coatings or isolators help.

- Sourcing: US manufacturers rely on quality inputs from Canada, Europe amid supply chain shifts.

Pro Tip

For precision parts, Vast offers CNC machining with 6061 T6 aluminum alloys—ideal for durable, lightweight custom components.

This know-how ensures that aluminum alloys meet local industrial demands across the US, from aerospace to automotive sectors.

Applications Across Industries Real World Impact of Aluminum Alloys

Aluminum and aluminum alloys play a big role across many industries here in the US, thanks to their unique mix of light weight, strength, and corrosion resistance.

Aerospace and Automotive

In aerospace, alloys like 7075 are favored because they keep planes strong but light, improving fuel efficiency and performance. On the automotive side, 5182 alloys are common for car bodies, helping reduce weight while maintaining safety—something especially important as electric vehicle manufacturing grows in hubs like Michigan.

Construction and Architecture

Aluminum alloys like 6063 are widely used for durable window frames and building extrusions. These alloys offer excellent corrosion resistance, making them ideal for both new construction and renovation projects across the country.

Electrical and Packaging

For electrical wiring, the high conductivity of 1350 alloys makes them a go-to. Aluminum’s formability also shines in packaging, where alloys like 3004 are used to make beverage cans—combining lightweight design with strength and ease of shaping.

Emerging Uses

We’re also seeing aluminum alloys in new fields: EV battery housings, solar panel frames, consumer electronics like laptops, and renewable energy components. These applications benefit from aluminum’s recyclability and strength-to-weight ratio.

Case Study

At Vast, we recently partnered with a US automotive supplier to produce custom alloy components tailored to meet strict performance and environmental standards—showing how local expertise supports American manufacturing.

Local Trends

In the US, there’s a clear trend toward using aluminum alloys in EV manufacturing, especially in Michigan’s growing automotive belt. These alloys fit well with the focus on lightweighting and sustainability that’s driving innovation here.

Selecting the Right Aluminum Alloy A Buyers Guide

Choosing the right aluminum alloy means balancing a few key factors like strength, cost, and corrosion resistance. Here’s what to keep in mind:

Decision Factors

- Strength: Do you need high tensile strength or lightweight with moderate strength?

- Cost: Some alloys like 1xxx series are cheaper but less strong, while 7xxx alloys cost more but offer higher performance.

- Corrosion Resistance: For outdoor or marine use, alloys like 5xxx or 6xxx work best due to their natural corrosion resistance.

- Formability and Welding Needs: Different alloys handle forming and welding differently—know what your project demands.

Common Pitfalls to Avoid

- Ignoring Heat Treatment: Some alloys need heat treatment to reach peak strength; skipping it can ruin performance.

- Alloy Compatibility: Mixing incompatible alloys can cause problems in fabrication or durability.

- Welding Issues: Not all aluminum alloys weld easily; check compatibility before production.

Sustainability Angle

- Aluminum is highly recyclable, saving up to 95% energy compared to primary aluminum.

- Many alloys used in the U.S. come from eco-friendly sources, including recycled content.

- Working with suppliers like Vast ensures you get alloys from responsible, sustainable sources.

Tools for Choice

- Use online quizzes and calculators to match your needs with the best alloy.

- Vast offers branded resources tailored for U.S. buyers based on application and industry.

Picking the right alloy upfront saves time, money, and headaches down the road—especially for U.S.-based businesses focused on quality and sustainability.

Future Trends in Aluminum Alloys Innovation on the Horizon

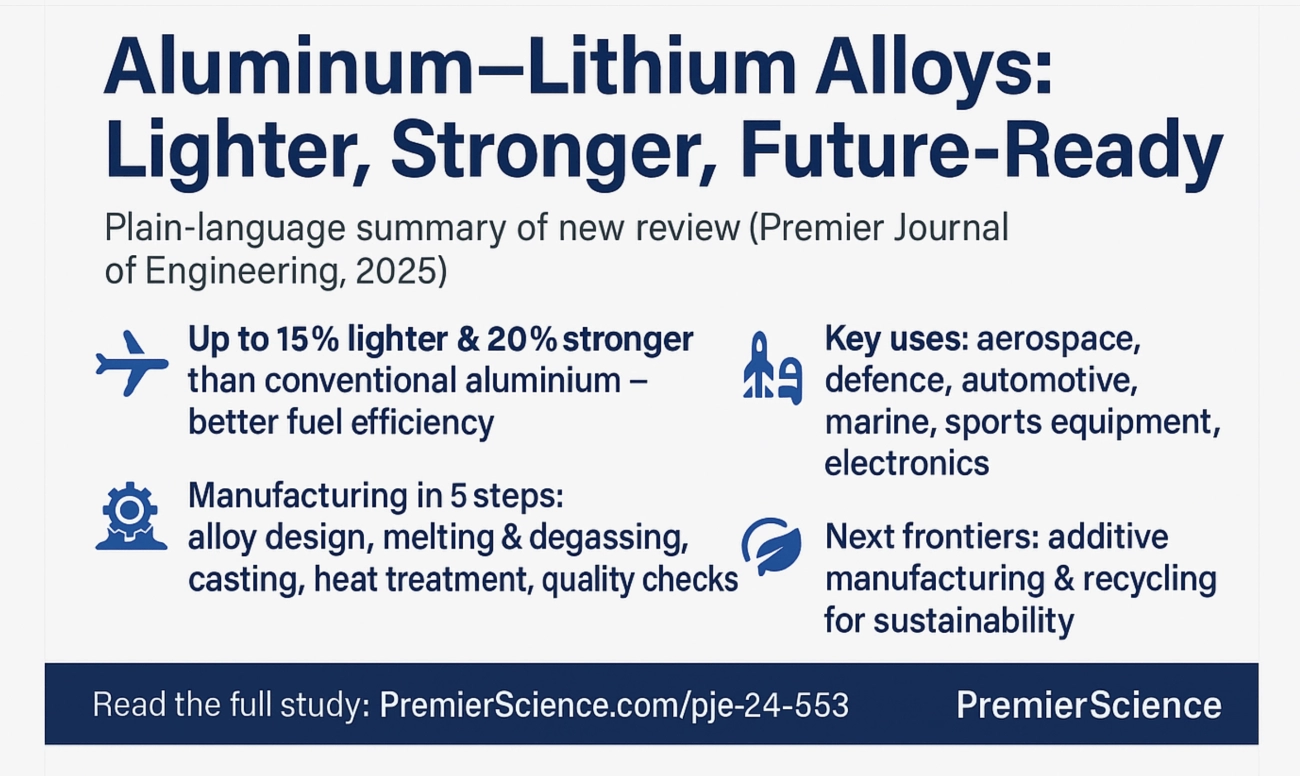

The future of aluminum and aluminum alloys is shaping up with some exciting innovations. One big trend is the development of nano-enhanced alloys, which boost strength and durability without adding weight. We’re also seeing more work on aluminum-lithium (Al-Li) alloys, especially for space travel and aerospace, where every ounce counts. Plus, there’s growing compatibility with additive manufacturing (3D printing), making it easier to create complex, lightweight parts quickly and with less waste.

From a market perspective, the U.S. still relies heavily on aluminum imports, but demand is rising domestically, especially as Canada and the EU boost their production capabilities. The push for green technologies and lightweight materials in electric vehicles (EVs), renewable energy, and aerospace is driving this change fast.

At Vast, we’re stepping up with new R&D efforts focused on advanced aluminum alloys that meet these evolving needs—helping local industries stay competitive while pushing for sustainability and innovation.