Explore how aluminium 3D printers create lightweight durable parts with top alloys and expert tips to overcome common printing challenges.

The Science Behind Aluminium 3D Printing How It Works and Key Technologies

If you’re curious about aluminium 3D printing, you’re not alone. It’s a game-changer in manufacturing, combining metal strength with design flexibility. But how does it really work? Let’s break it down.

Core Processes Explained

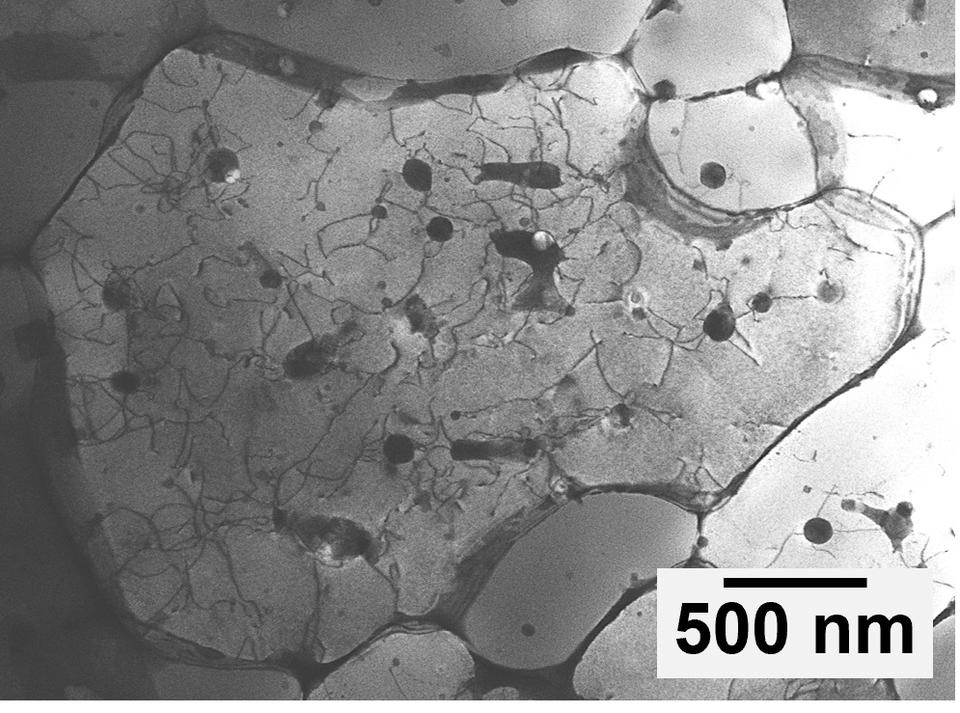

Aluminium 3D printing mainly uses two methods: Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). Both rely on powerful lasers to fuse aluminium powder layer by layer, creating precise, complex parts.

- SLM printing techniques fully melt aluminium powder, forming dense, strong parts ideal for aerospace aluminium prototypes.

- DMLS aluminium process slightly sinters the powder, also producing robust components but with subtle differences in finish and strength.

These processes let you build parts that are impossible or expensive to machine traditionally.

Aluminium Alloys Demystified

Not all aluminium powders are the same. The most popular one is AlSi10Mg, known for its excellent strength, lightweight nature, and corrosion resistance—perfect for high-performance applications. Understanding which metal 3D printing alloys suit your needs can save time and money.

Equipment Spotlight Top Aluminium 3D Printers for Every Budget

From industrial-grade machines to more affordable desktop metal filament printers, the market offers options for different budgets.

- High-end printers feature advanced laser systems and large build volumes, fitting for serious industrial work.

- Desktop aluminium 3D printers cater to hobbyists and startups eager to explore lightweight 3D printed parts without significant upfront costs.

At Vast, we know choosing the right equipment is key. Whether you’re after precision or cost-efficiency, starting with the right printer sets you up for success.

Benefits of Aluminium 3D Printing

Aluminium 3D printing offers a serious mix of lightweight strength and design freedom that’s hard to beat. The key advantage here is how you can create complex shapes and custom parts without adding weight. This is a big deal for industries like aerospace and automotive where reducing weight can improve fuel efficiency and overall performance.

Here’s why aluminium 3D printing stands out:

- Lightweight Strength: Aluminium alloys like AlSi10Mg provide excellent strength-to-weight ratios. That means parts can withstand tough conditions while being much lighter than steel equivalents.

- Design Freedom: Unlike traditional manufacturing, 3D printing allows you to build intricate internal structures or custom geometries that would be impossible or costly otherwise.

- Performance Advantages: With precise layer-by-layer construction, parts have excellent mechanical properties and thermal management, making them ideal for prototypes and functional end-use products.

- Industry Applications: Aluminium 3D printed parts are rapidly spreading in aerospace prototypes, automotive components, industrial tooling, and even medical devices.

- Cost and Efficiency Gains: By reducing material waste and decreasing tooling requirements, aluminium 3D printing lowers overall costs and accelerates the development process — ideal for small to medium production runs.

If you’re looking to create lightweight 3D printed parts that don’t compromise on durability, aluminium is definitely worth considering. Plus, the performance benefits make it a preferred choice for businesses in the United Kingdom aiming for innovation with reliable materials.

Challenges in Aluminium 3D Printing

Aluminium 3D printing offers significant benefits, but it’s not without its challenges. Understanding common pitfalls helps you avoid costly mistakes and speeds up achieving quality prints.

Common Technical Obstacles

- Warping and Cracking: Aluminium tends to warp due to rapid cooling during processes like DMLS and SLM printing techniques. This can cause cracks or weak spots if not carefully managed.

- Powder Handling: The fine aluminium powder is tricky to work with—it requires strict safety measures and careful equipment cleaning to avoid contamination or health risks.

- Surface Finish: Getting a smooth surface on aluminium prints usually means extra post-processing like sanding or CNC machining, which adds time and cost.

Cost and Accessibility Barriers

- Expensive Equipment: High-quality aluminium 3D printers, especially those using metal 3D printing alloys, come with a steep price tag. Desktop metal filament options are cheaper but don’t always match the strength and precision needed for serious projects.

- Material Costs: Aluminium alloys like AlSi10Mg used in aerospace aluminium prototypes aren’t cheap. This drives up the cost per part, making it tough for small businesses or hobbyists.

- Limited Local Services: Depending on where you are in the United Kingdom, finding local suppliers or service providers for aluminium sintering or DMLS aluminium processes could be challenging, impacting turnaround time.

Insights from Reddit and Community Experiences

The 3D printing community on Reddit often shares fixes and hacks:

- Preheating the build plate to reduce warping

- Using optimised print settings shared by experienced users for AlSi10Mg properties

- Exploring hybrid methods combining printing with traditional machining to improve quality and reduce waste

Navigating these challenges with a mix of tech know-how and community advice can make your first aluminium 3D printing projects a success.

Step-by-Step Guide Getting Started with Your First Aluminium 3D Print

Starting your first aluminium 3D print might seem tricky, but breaking it down makes it manageable. Here’s a simple guide to get you going.

Design Best Practices

- Keep it simple: Aluminium 3D printing works best with clean, straightforward designs. Avoid overly thin walls or tiny details that can be hard to print accurately.

- Use the right alloy: AlSi10Mg is popular for its strength and lightweight properties—it’s a great starting point.

- Consider supports: Some parts may need extra support during printing. Plan your design to minimise these or make them easy to remove.

Printing and Post-Processing

- Choose the right printer and settings: DMLS aluminium process and SLM printing techniques require precise temperature and speed controls. Follow your printer’s manual to optimise these.

- Be patient with build time: Aluminium prints can take longer than plastic, so expect the process to take a few hours depending on your part size.

- Post-processing is key: After printing, parts often need heat treatment or polishing to improve strength and surface finish.

- Handling shrinkage: Aluminium tends to shrink during cooling; adjust your design dimensions slightly to compensate.

Sourcing Materials and Services Locally

- Find local suppliers: Check for UK-based metal 3D printing companies or distributors that offer aluminium powders or filaments compatible with desktop metal filament printers.

- Consider printing services: If you don’t own a metal 3D printer yet, local services can print your aluminium parts using professional equipment with DMLS aluminium process.

- Compare costs and turnaround: Local sources often offer faster shipping and support, cutting down delays and shipping fees.

Getting started with aluminium 3D printing in the UK means knowing where to find quality materials and having realistic design expectations. Stick to these basics, and you’ll avoid common issues while unlocking the real benefits of lightweight, strong 3D printed parts.

Future Trends in Aluminium 3D Printers

The future of aluminium 3D printing looks promising, especially here in the UK. We’re seeing rapid advancements that make these printers more accessible and efficient for businesses and hobbyists alike. One big trend is smarter machines that use AI-driven software to optimise print settings automatically, reducing errors and wasted materials.

Innovations like improved DMLS aluminium processes and faster SLM printing techniques are making it easier to produce parts with better strength and surface finish. Plus, new aluminium alloys tailored specifically for 3D printing, such as enhanced AlSi10Mg properties, are pushing the limits in aerospace prototypes and lightweight 3D printed parts.

A company called Vast is at the forefront of this movement, developing larger-scale and more affordable aluminium 3D printers designed for real-world applications. They’re working to lower the cost of metal 3D printers so smaller workshops across the UK can benefit, bridging the gap between industrial-grade equipment and desktop metal filament setups.

As these technologies mature, expect faster turnaround times, higher quality builds, and even greater design freedom—all making aluminium 3D printing a smart investment for industries focused on performance and efficiency.