Explore the benefits of dark anodized aluminium, including durability, corrosion resistance, and a sleek black finish, ideal for architectural and industrial applications.

What is Dark Anodized Aluminium? Breaking Down the Basics

Dark anodized aluminium is aluminium treated through an electrochemical process that creates a durable, corrosion-resistant oxide layer with a rich, deep-black finish. Unlike paint or powder coating, anodising fuses this layer into the metal, locking in colour and strength for lasting protection.

Aluminium Alloys Suitable for Anodising

Not all aluminium alloys anodise equally well. Here are common alloys ideal for dark anodising:

| Alloy Series | Description | Suitability for Dark Anodising |

|---|---|---|

| 5000 Series | Magnesium alloy | Excellent corrosion resistance |

| 6000 Series | Silicon and magnesium | Most commonly used, versatile |

| 7000 Series | Zinc alloy | Stronger but less common anodised |

Differences Versus Powder Coating

| Feature | Dark Anodised Aluminium | Powder Coating |

|---|---|---|

| Process | Electrochemical oxide layer formation | Sprayed coloured powder baked on |

| Durability | Scratch-resistant and wear-proof | Thicker coating, but can chip |

| Heat Resistance | Better heat tolerance | Poor heat resistance |

| Appearance | Natural metallic, deep black finish | Thick, opaque, and less metallic |

Common Myths About Anodising

- Myth: Anodised aluminium can peel or flake like paint.

Fact: The anodised layer is part of the aluminium, so it won’t peel off. - Myth: Dark anodising fades quickly outdoors.

Fact: Proper sealing and dyeing prevent fading under UV exposure. - Myth: Any aluminium can achieve deep black anodising.

Fact: Alloy type and process control affect the final colour depth and uniformity.

How Vast Ensures Consistent Deep-Black Results

Vast combines expertise and advanced anodising technology to guarantee a rich, uniform black finish every time. By carefully selecting alloys, optimising pre-treatment, controlling oxide thickness, and using proprietary sealing methods, Vast delivers durable, fade-resistant black anodised aluminium that stands out for its quality and consistency.

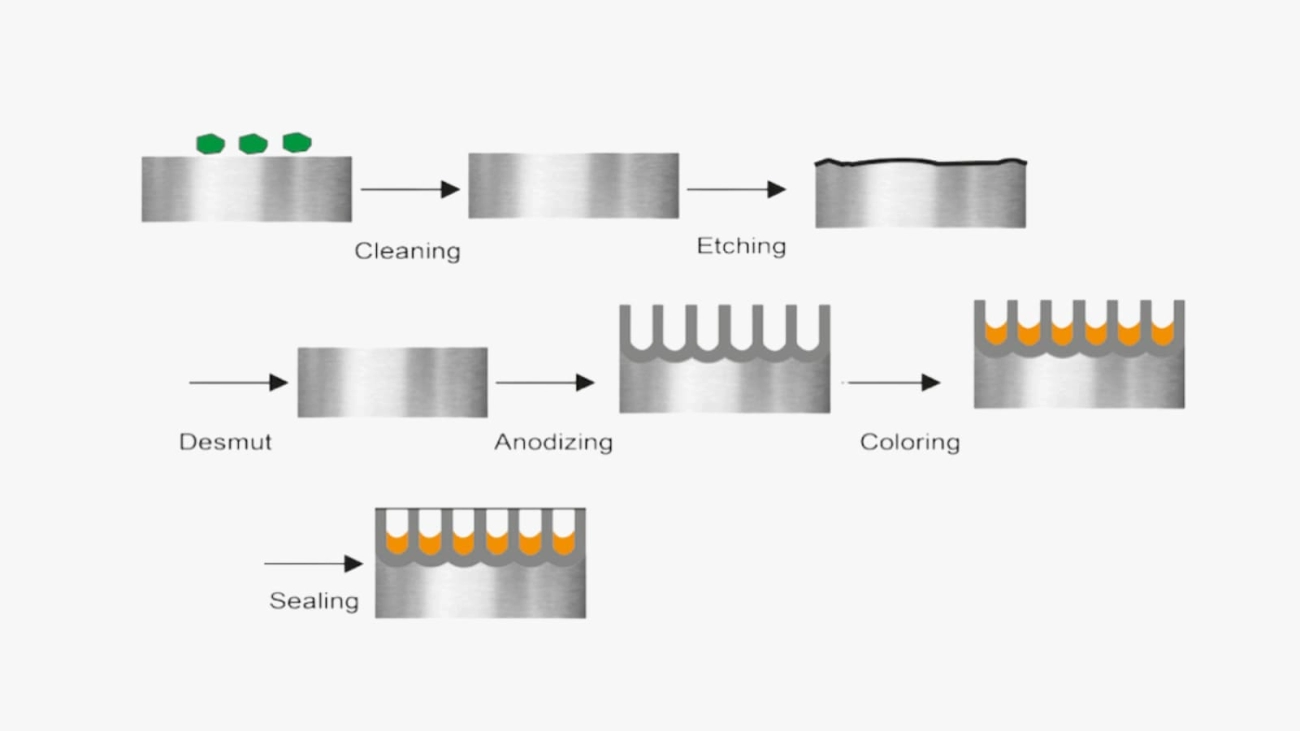

The Anodising Process Step-by-Step Guide

Preparation Cleaning and Pre-Treatment

Before anodising dark anodised aluminium, the surface needs thorough cleaning. This removes dirt, grease, and oxides that could interfere with the finish. Typically, the aluminium is soaked in alkaline cleaners and rinsed with water. Sometimes, a mild acid etch is performed to smooth the surface and improve adhesion. Pre-treatment ensures the anodising layer forms evenly and adheres well.

Electrochemical Anodising and Oxide Layer Thickness

The core of anodising is an electrochemical process. The aluminium part acts as the anode in an acid bath—usually sulphuric acid—and an electric current passes through it. This creates a controlled oxide layer on the surface, which is hard and porous. Layer thickness varies depending on the desired durability and appearance. For dark anodised finishes, thickness often ranges from about 15 to 25 microns or more. Thicker layers generally mean better corrosion and scratch resistance.

Dyeing and Sealing Techniques

Once the porous oxide layer is formed, it’s ready for dyeing. Black dyes soak into the pores, creating the distinct dark anodised aluminium look. Dyeing must be precise: too light, and the colour might fade quickly; too thick, and it can peel. After dyeing, the surface is sealed—usually by hot water or steam—which closes the pores and locks in the colour. Sealing also enhances corrosion resistance.

Factors Affecting Colour Shade and Common Pitfalls

Several factors influence the final colour shade of dark anodised aluminium:

- Alloy type and surface texture

- Anodising bath temperature and current density

- Dye quality and immersion time

- Seal method and timing

Common pitfalls include uneven colouring, fading over time, and poor adhesion if preparation or sealing is rushed. Choosing high-quality dyes and controlling the process tightly helps avoid these issues and guarantees consistent deep-black finishes.

Key Benefits of Dark Anodised Aluminium

Durability advantages

Dark anodised aluminium offers outstanding protection against corrosion, scratches, and wear. The anodising process forms a tough oxide layer that bonds to the metal surface, making it far more scratch resistant than paint or powder coatings. This tough finish holds up well in outdoor conditions, resisting fading and damage from UV rays and moisture.

Thermal and optical properties

The anodised surface improves heat resistance, helping aluminium maintain its strength under high temperatures. Plus, the dark black finish absorbs heat efficiently, which makes it useful in applications where heat absorption or thermal management is important—like electronics and certain architectural uses.

Aesthetic and functional perks

- Deep black finish that stays consistent over time

- Non-reflective surface reduces glare

- Customisable shades through dyeing options

- Enhances both the look and feel of products with a smooth, elegant finish

Environmental benefits

Dark anodised aluminium is eco-friendly. The anodising process is non-toxic, uses less energy than powder coating, and produces no hazardous waste. Plus, aluminium itself is highly recyclable, making this a sustainable option that aligns with greener building standards.

Standards and quality comparisons

| Feature | Dark Anodised Aluminium | Powder Coating |

|---|---|---|

| Scratch Resistance | High | Medium |

| UV Stability | Excellent | Good |

| Environmental Impact | Low (non-toxic process) | Higher (chemical use) |

| Colour Consistency | Very consistent with quality control | Can vary more |

| Maintenance | Low (easy to clean, no peeling) | Moderate (may chip or fade) |

In short, dark anodised aluminium combines durability, great looks, and environmental friendliness, making it a smart choice for many UK-based industries and projects.

Applications of Dark Anodised Aluminium

Architectural Panels and Facades

Dark anodised aluminium is a go-to choice for architectural panels and building facades across the UK. Its deep black finish adds a modern, sleek look while standing up to outdoor wear and tear, including weather and UV exposure. Architects and builders rely on it because it’s both lightweight and corrosion resistant aluminium, making installation easier and longer-lasting than painted surfaces.

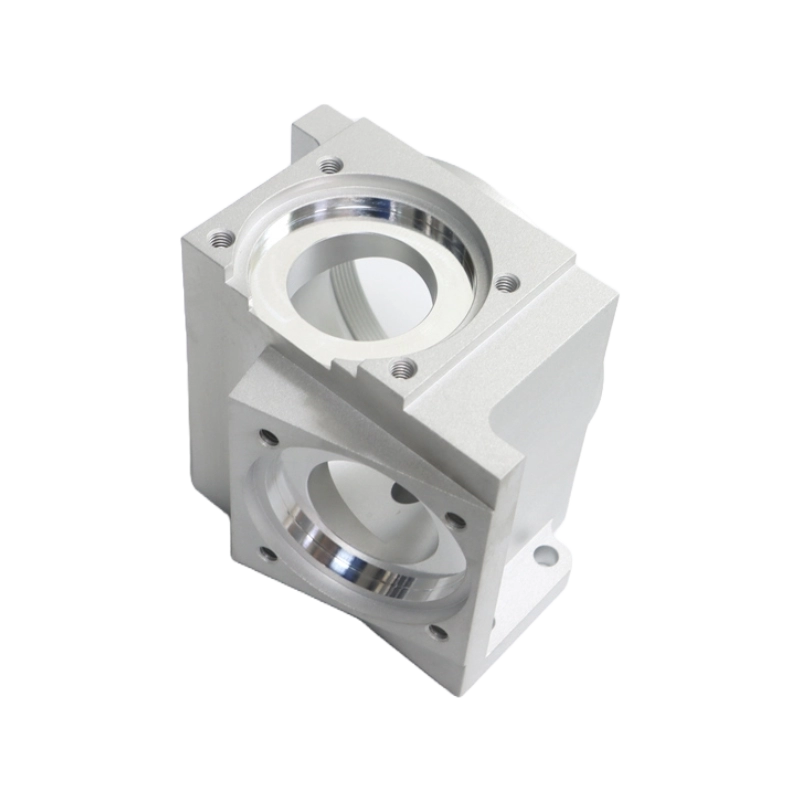

Industrial and Manufacturing Uses

In industrial settings, dark anodised aluminium parts are used for machinery components, panels, and protective covers. The scratch-resistant metal finishes and enhanced durability help equipment withstand rough conditions. Plus, the heat absorbing aluminium properties make it useful where temperature regulation is important, such as in heat sinks or control panels.

Consumer and DIY Projects

For home or DIY projects, the black anodised finish offers a stylish, durable option for things like furniture, lighting fixtures, or custom hardware. People working with aluminium extrusions appreciate how easy it is to work with dark anodised surfaces without worrying about paint peeling or rust. Vast also supports DIY aluminium dyeing for custom looks, perfect for hobbyists who want professional results at home.

Emerging Automotive and Electronics Uses

In the automotive and electronics industries, dark anodised aluminium is gaining traction for parts and casings needing both durability and a premium appearance. From black oxide aluminium coating on engine parts to customised anodised extrusions for gadgets, the finish helps prevent corrosion and maintains a clean aesthetic. Its thermal and optical qualities also support performance in electronic housings and automotive trims.

Case Study on Vast’s Project

Vast recently completed a large project supplying dark anodised aluminium panels for a commercial building in the South West. The client wanted consistent deep-black architectural anodised panels that could endure harsh sun and desert conditions. By using Vast’s proprietary anodising process, every panel met strict quality standards, delivering durability, aesthetics, and top corrosion resistance—exactly what the building needed to stay sharp and functional for years.

How to Choose and Maintain Dark Anodised Aluminium

Selection Guide by Alloy and Thickness

Choosing the right alloy and thickness is key for durable dark anodised aluminium. Here’s a quick guide:

| Alloy | Best For | Thickness (mil or µm) | Notes |

|---|---|---|---|

| 6061 | Structural, outdoor uses | 15-25 (Type II) | Good corrosion resistance |

| 5052 | Marine, high corrosion | 20-35 (Type II/III) | Great for harsh environments |

| 5005 | Architectural panels | 10-20 (Type II) | Smooth, even anodising |

| 7075 | High strength parts | 15-30 (Type III) | Hard anodising option |

Choosing thicker anodised layers improves scratch and corrosion resistance, especially for outdoor applications.

Sourcing Tips and RoHS Compliance

- Look for suppliers who provide RoHS-compliant aluminium; it ensures no harmful substances are in the product.

- Choose vendors with clear certifications and traceability of batches.

- Local suppliers are great for faster delivery and easier communication—important for supporting UK-based projects.

Maintenance Best Practices

Maintaining your dark anodised aluminium keeps it looking sharp over time:

- Clean with mild soap and water, avoid harsh chemicals.

- Use a soft cloth or sponge to prevent scratches.

- Avoid abrasive tools that can damage the anodised layer.

- Apply a thin layer of clear wax for extra protection if needed.

Troubleshooting Fading and Uneven Colouring

If your finish fades or looks uneven, consider these common causes:

- Improper sealing during anodising can let moisture in.

- Exposure to strong UV rays might lighten the colour over many years.

- Surface contamination before anodising can create blotchy hues.

- Use reputable anodisers like Vast that guarantee consistent deep-black results to avoid these issues.

Local Supplier Recommendations

For customers in the United Kingdom seeking trusted dark anodized aluminium suppliers:

- Vast Aluminium Solutions – Known for quality and deep-black finishes.

- Local metal distributors in your region offering RoHS-compliant stock.

- Regional fabricators specialising in black anodized finishes for industrial and architectural needs.

Choose suppliers who back their product with technical support and customisation options—this helps keep your projects on track.

vast’s Dark Anodized Aluminium Solutions

At vast, we take pride in our proprietary dark anodized aluminium process that guarantees a consistent, deep-black finish every time. Our unique approach goes beyond standard anodising, combining advanced dyeing methods and strict quality controls. This means you get a finish that’s not only sleek and durable but also highly resistant to corrosion and fading—perfect for anything from architectural panels to custom metal parts.

Product Range and Customisation Options

We offer a range of dark anodised aluminium products to suit your needs, including extrusions, sheets, and custom profiles. Whether you need Type III hard coat anodising for extra toughness or standard black anodised finish for aesthetics, we can tailor the coating thickness, colour depth, and dimensions to meet UK market demands. Our team works closely with you to understand your project requirements, ensuring each order matches your expectations in quality and performance.

Get in Touch

Ready to upgrade your projects with dark anodised aluminium you can trust? Contact vast today to discuss your needs and get a free consultation. Our experts are here to help you select the right alloy, coating type, and customisation options—plus answer any questions about maintenance or compliance like RoHS.

What Our Clients Say

Don’t just take our word for it. Here’s what some of our customers have to say:

- “vast delivered a flawless, deep-black anodised finish on our architectural panels. The durability and colour consistency have been impressive.” – A local building contractor

- “Their custom anodised extrusions helped us create a sleek and scratch-resistant finish for our product line. Exceptional service from start to finish.” – Manufacturing manager

Choose vast’s dark anodised aluminium for professional-grade finishes that stand out and withstand real-world conditions.