Discover the key differences between horizontal and vertical milling machines to choose the best setup for precision, efficiency, and your machining needs.

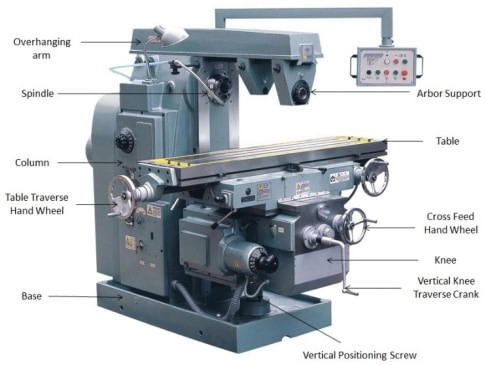

The Fundamentals What Are Horizontal and Vertical Milling Machines

Vertical Milling Machines The Versatile Workhorse

Let’s start with the basics: What exactly is a vertical milling machine, and why is it such a staple in workshops across the UK? A vertical milling machine has a spindle that runs vertically, meaning the cutting tool moves up and down. This setup makes it incredibly versatile for a wide range of milling jobs. You can tilt the spindle or the table to handle complex angles, which is great for precision prototyping and multi-axis machining.

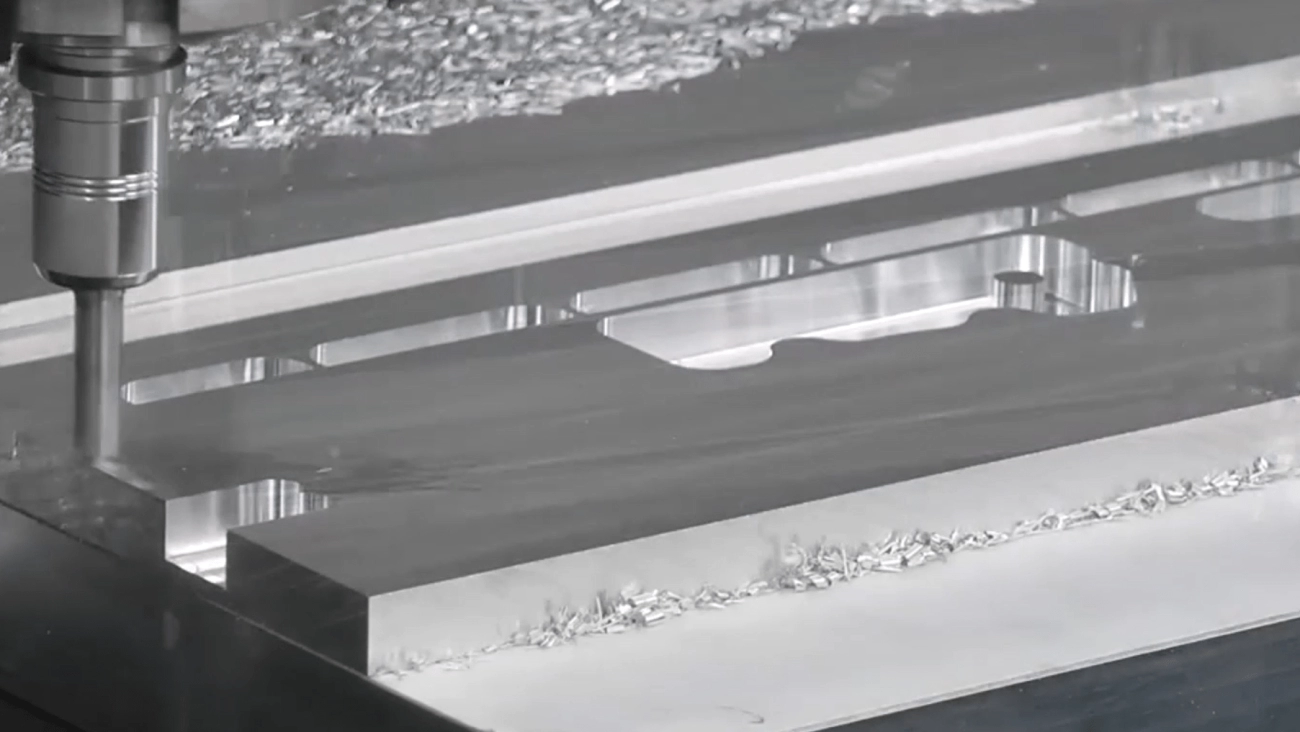

Vertical mills are often the go-to choice when you need flexibility. They excel at drilling, boring, and cutting slots or pockets with precision. Because the cutting tool faces down, gravity helps with chip evacuation—the debris falls away naturally, keeping your work area clean and reducing downtime. Plus, the vertical orientation makes changing tools quicker in CNC milling machines, speeding up production cycles.

Here’s why vertical mills are called workhorses:

- Versatility: Handles diverse materials and intricate shapes

- Precision: Excellent for detailed machining and small parts

- Ease of use: Operator-friendly setups and adjustments

- Space-saving: Compact footprint ideal for smaller workshops

In short, vertical milling machines bridge the gap between manual craftsmanship and CNC efficiency. If you’re looking for a tool that adapts to multiple tasks without sacrificing accuracy, vertical mills might just be your workshop’s best investment.

Ready to dive deeper or compare with horizontal milling? Stick around!

Horizontal Milling Machines The Heavy-Duty Powerhouse

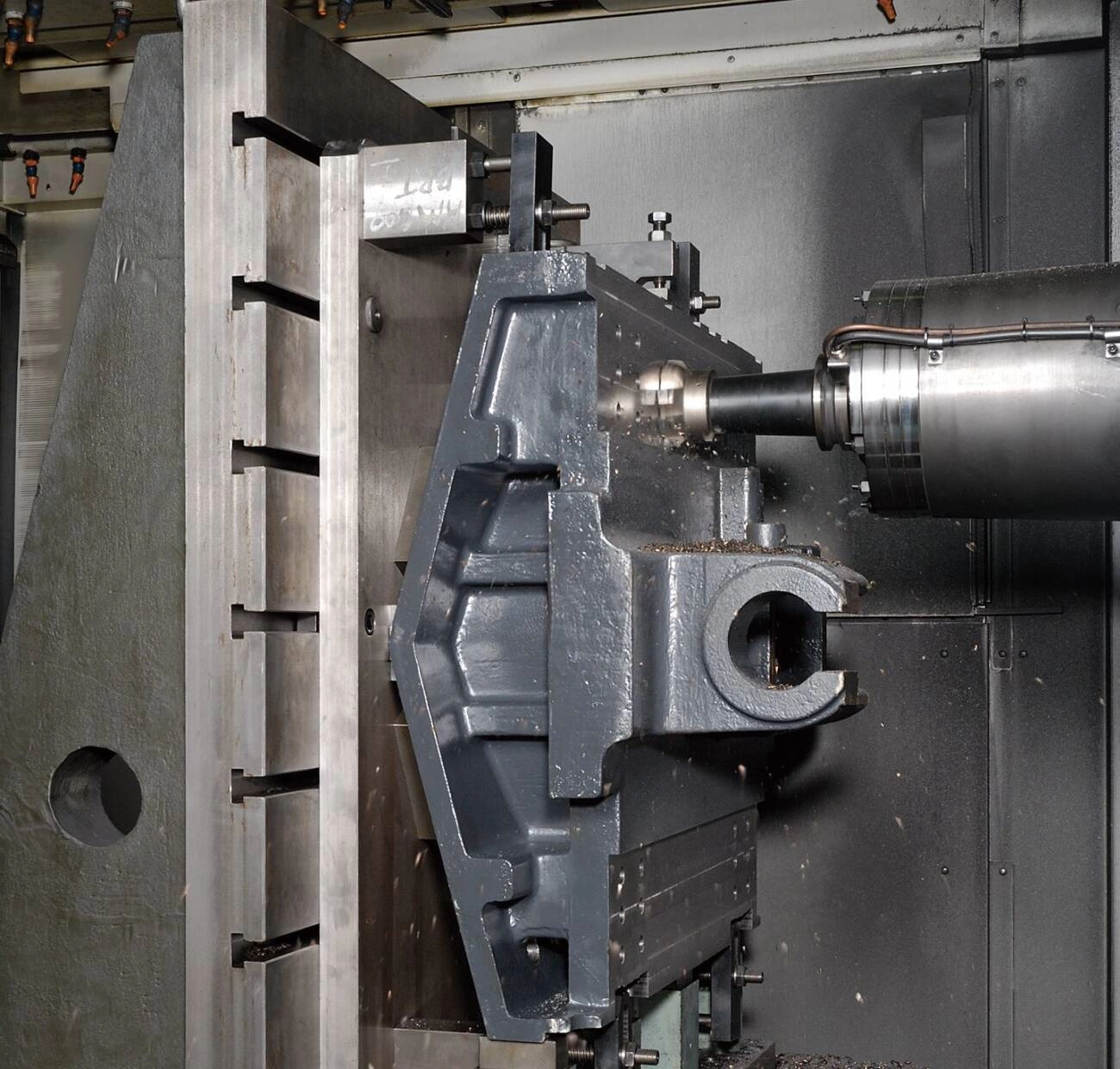

Horizontal milling machines are built tough for heavy-duty tasks. Their spindle sits horizontally, allowing the cutting tool to spin on a horizontal axis. This setup is great for cutting deep slots, grooves, and heavy material removal on large workpieces.

Because the spindle is fixed horizontally, chip evacuation is more efficient—chips fall away from the work area naturally, reducing downtime and tool wear. This makes horizontal mills perfect for high-volume production and machining tough metals.

These machines often have a rotary table or an arbor to hold multiple cutters at once, which helps speed up complex jobs. With their robust design, horizontal milling machines handle bigger, heavier parts with less vibration, boosting precision and tool life.

Whether you’re working on large automotive parts or industrial components, horizontal milling machines give you power, stability, and efficient material removal for demanding jobs.

Head-to-Head Comparison Horizontal vs Vertical Milling Breaking Down the Differences Design and Operation

When comparing horizontal and vertical milling machines, the main difference lies in their spindle orientation and overall design. Vertical milling machines have a vertically oriented spindle that moves up and down. This setup makes them great for precision prototyping and work that requires detailed cuts on the surface of the material. They typically come with a turret or ram style head, allowing for quick tool changes and versatile machining angles.

On the other hand, horizontal milling machines feature a spindle that runs parallel to the worktable. This design excels in heavy-duty material removal and high-volume production. The horizontal spindle, often paired with an arbor, allows larger cutting tools to be used, which improves chip evacuation and keeps the cutting area cleaner during long runs.

In terms of operation, vertical mills are usually easier to set up and programme, making them favourable for workshops with varying job types and smaller batch sizes. Horizontal mills demand a bit more in terms of setup and operator skill but reward with faster production speeds for bulk machining.

Both machines can support multi-axis machining, but vertical mills often integrate well with CNC setups focused on precision work, while horizontal mills are preferred where consistent material removal rate and toughness are key. Understanding these design and operational differences helps you choose the right milling machine for your specific workshop needs.

Head-to-Head Comparison Horizontal vs Vertical Milling Breaking Down the Differences Capabilities and Precision

When it comes to capabilities and precision, both horizontal and vertical milling machines have strengths that fit different needs. Vertical milling machines excel in versatility and detail work. Their spindle orientation allows for easy access to multiple sides of the workpiece, making them great for precision prototyping, complex cuts, and multi-axis machining. You can expect high levels of accuracy, especially on smaller and medium-sized parts.

Horizontal milling machines, on the other hand, shine in heavy material removal and high-volume production. The horizontal spindle arrangement helps with better chip evacuation, which keeps the cutting area cleaner and reduces heat buildup—this improves tool life and consistency in long runs. They are typically more rigid, which boosts precision on larger, tougher materials where strength and stability matter.

In brief:

- Vertical milling:

- Better for detailed, precise work

- Easier setup for complex shapes and multi-angle cuts

- Ideal for smaller parts and prototypes

- Horizontal milling:

- Superior for heavy-duty cuts and thicker materials

- Efficient chip removal helps maintain precision over long production runs

- Suits larger, high-volume jobs

Choosing between the two depends largely on what kind of milling tasks you prioritise—precision and flexibility or power and production scale.

Head-to-Head Comparison Horizontal vs Vertical Milling Speed Efficiency and Production Scale

When it comes to speed and efficiency, horizontal and vertical milling machines each bring something different to the table. Horizontal mills generally handle higher material removal rates thanks to their spindle orientation and chip evacuation design. This makes them ideal for heavy-duty, high-volume production where speed matters most.

Vertical milling machines usually offer more precision but may run slower on large jobs because of their design. They’re great for detailed work and smaller production runs where accuracy is a priority over raw speed.

If your shop focuses on fast turnaround for large batches, horizontal milling often delivers better throughput. On the other hand, vertical milling machines excel in settings requiring precision prototyping or mixed-production runs that need flexibility.

In :

- Horizontal milling: Better for fast, heavy cutting and large volume work

- Vertical milling: Better for detailed, precise jobs with moderate volume

Choosing between the two comes down to balancing your production scale with the type of work you do most often. For many shops, a mix of both or CNC integration can help optimise run times and overall workflow.

Advantages of Vertical Milling

Vertical milling machines are popular in many shops because they offer flexibility and precision. Here’s why they stand out:

- Versatility: Vertical mills handle a wide range of tasks, from simple drilling to complex multi-axis machining, making them perfect for precision prototyping and detailed work.

- Easy Setup and Use: With the spindle oriented vertically, changing tools and adjusting the workpiece is straightforward, helping operators work faster and with less hassle.

- Better Chip Evacuation: Gravity helps clear chips away from the cutting area, reducing the chance of tool damage and keeping the work surface clean.

- Compact Footprint: Vertical milling machines usually take up less floor space, which is great if your shop is tight on room.

- Cost Effective: Generally, vertical mills are more affordable upfront and easier to maintain, which suits small to medium-sized shops focused on precision work.

- Wide Tool Selection: They support a variety of milling tools – from end mills to drills – allowing shops to handle diverse materials and projects.

- Suitable for Prototyping and Small BatchesVertical mills excel when you need high precision and quick changeovers for low to medium volume runs.

If your workshop values flexibility, precision, and efficient use of space, vertical milling machines offer distinct advantages that suit many manufacturing and prototyping needs in the United Kingdom.

Disadvantages of Vertical Milling

While vertical milling machines are popular for their versatility, they do have some drawbacks you should consider for your workshop.

- Limited Material Removal RateVertical mills usually handle lighter cuts compared to horizontal ones. If your projects require fast, heavy stock removal, vertical machines may slow you down.

- Less Efficient Chip EvacuationBecause of their spindle orientation, vertical mills can struggle with chip clearance during deep cuts. This can lead to more frequent stops for cleaning, reducing efficiency.

- Lower Rigidity for Heavy-Duty JobsThe design of vertical mills makes them less stable under high loads. This can affect precision and tool life when working with tougher materials or large parts.

- Size ConstraintsVertical milling setups often have smaller work envelopes. If you need to machine large components or fixtures, this can limit your options or require extra handling.

- Longer Setup for Complex AnglesWhen it comes to multi-axis machining or intricate angles, vertical machines may require additional fixtures or setups, adding time to your workflow.

Knowing these downsides will help you decide if a vertical milling machine fits your production needs or if a horizontal mill might serve you better.

Pros and Cons Weighing the Trade-Offs for Your Workshop

Advantages of Horizontal Milling

Horizontal milling machines bring some strong benefits to your workshop, especially if you’re handling heavy-duty or high-volume work. Here’s why they stand out:

- Better Chip EvacuationWith the spindle oriented horizontally, chips fall away more easily. This keeps your work area cleaner and reduces the chance of recutting chips, which improves surface quality and tool life.

- Higher Material Removal RateThese machines excel at taking big cuts, perfect when you need to remove lots of material quickly. That’s great for tough metals or large parts.

- Strong and Sturdy SetupThe horizontal design usually means a more rigid setup, giving you steadier cuts and less vibration. This translates to better consistency and durability over long runs.

- Ideal for Heavy or Large WorkpiecesThe bed and table setup supports bigger parts comfortably, which is often a necessity in industries like automotive or aerospace.

- Efficient Multi Axis and Turret Milling: Many horizontal mills come equipped with turrets or can handle multi-axis machining, adding flexibility for complex jobs without switching setups.

- Longer Tool Life: Thanks to better chip flow and cooling, your milling tools tend to last longer, saving you money over time.

In short, if your workshop deals with heavy work, high production volumes, or materials that wear down tools quickly, horizontal milling offers a reliable edge. It’s about power, efficiency, and managing bigger jobs smoothly.

Disadvantages of Horizontal Milling

While horizontal milling machines are powerful and ideal for heavy-duty work, they come with some downsides that might affect your workshop’s workflow.

- More Complex Setup: Horizontal mills often require more time and skill to set up properly because of the spindle orientation and tooling needed. This can slow down production if your operators aren’t experienced.

- Larger Footprint: These machines usually take up more floor space. If your workshop is tight on room, a horizontal mill might not be the best fit.

- Chip Evacuation Challenges: Although horizontal mills generally handle chip removal better than vertical machines, managing chips can still be tricky in certain jobs. Improper chip flow might cause damage or compromise surface finish.

- Higher Initial Cost: Horizontal mills tend to cost more upfront, especially when you factor in tooling and maintenance. This makes them less accessible for smaller workshops or workshops just starting to scale up.

- Less Versatility on Complex Angles: Horizontal machines are great for certain cuts but can be less flexible than vertical milling when it comes to intricate, multi-axis machining or precision prototyping.

Understanding these factors will help you decide if a horizontal milling machine fits your workshop’s capacity, budget, and project needs.

Ideal Projects for Vertical Milling

Vertical milling machines are a go-to for workshops focused on precision and flexibility. Their spindle orientation, facing down, lets you handle a wide range of tasks—from drilling and slotting to detailed finishing work. They shine in projects that need tight tolerances and complex shapes, making them perfect for precision prototyping and custom parts.

Here’s where vertical milling really stands out:

- Small to medium-sized parts: Ideal for detailed features and intricate designs.

- Multi-axis machining: Easy to set up for 3-axis or 4-axis work, boosting versatility.

- Material variety: Works well on aluminium, plastics, and softer steels.

- Low to medium production runs: Great for workshops that need flexibility rather than high-volume output.

- Tool changes and setups: Fast and straightforward, helping you stay efficient.

If your workshop handles mainly detailed parts, custom prototypes, or jobs that require quick tool changes, vertical mills are a solid choice that balances precision with speed.

Ideal Projects for Horizontal Milling

Horizontal milling machines excel in heavy-duty tasks and high-volume production settings. Their spindle orientation allows the cutting tool to work on a horizontal plane, which is great for removing large amounts of material quickly. This makes them ideal for projects that need deep cuts or extensive chip removal, such as manufacturing automotive parts, engine blocks, gears, and large metal sheets.

Because of their robust design, horizontal mills handle tougher materials like steel and cast iron with ease. They’re also well-suited for jobs that require multiple milling tools operating simultaneously, thanks to their turret or arbor setup. This setup boosts efficiency by allowing faster tool changes and continuous machining, reducing downtime.

You’ll often find horizontal milling machines in production lines focused on:

- High-volume batch manufacturing

- Parts with complex features requiring multi-axis machining

- Workpieces needing precise surface finishes on large surfaces

- Situations where chip evacuation needs to be efficient to avoid tool wear

If you’re looking to ramp up productivity on large, tough jobs without sacrificing precision, horizontal milling is a solid choice. It’s a powerhouse built for heavy workloads in shops that demand strength and repeatability.

Applications and Use Cases Where Each Mill Shines

Hybrid Scenarios When to Combine or Upgrade

Sometimes, the best setup isn’t sticking to just horizontal or vertical milling. Many shops find great success by combining both or upgrading their machines as their needs evolve. Here’s when going hybrid or making a switch makes sense:

- Balancing versatility and power: If your projects require fine detail work and heavy material removal, pairing a vertical mill for precision prototyping with a horizontal mill for high-volume production can cover all bases.

- Expanding capabilities: When your shop starts moving into multi-axis machining or needs faster chip evacuation for demanding jobs, upgrading to a CNC machine that supports both horizontal and vertical spindle orientations can boost productivity.

- Space and workflow optimisation: In smaller shops, swapping between vertical and horizontal tables on a turret mill can save floor space while allowing for different types of milling without buying separate machines.

- Scaling production: As orders grow, adding a horizontal milling centre can handle larger parts and longer production runs, while keeping your vertical mill for customised or precision tasks.

- Cost-effective upgrades: Instead of replacing equipment entirely, some operators retrofit older vertical mills with attachments to perform light horizontal milling, stretching your budget further.

Key takeaway: If your shop juggles a mix of detailed prototyping and heavy-duty bulk milling, combining or upgrading to hybrid CNC milling machines offers flexibility and efficiency. This approach keeps you competitive while managing costs and shop space effectively.

Factors to consider before choosing cost setup and maintenance

Budget Breakdown

When selecting between horizontal and vertical milling machines, your budget plays a significant role. Here’s what to keep in mind:

- Initial Cost: Vertical mills generally cost less upfront. They’re simpler in design and usually smaller, so the price tag suits smaller shops or startups better. Horizontal mills tend to be pricier because of their heavy-duty build and more complex spindle orientation.

- Maintenance: Vertical milling machines are easier and cheaper to maintain. Their parts are more common, and simple setups mean fewer surprises during repairs. Horizontal mills require more care due to things like chip evacuation systems and heavier components, which can increase long-term costs.

- Setup Expenses: Vertical mills set up more quickly since their tooling and workpieces are usually easier to position. For horizontal mills, expect additional setup time and possibly more tooling investment because of the bed and turret mill designs often involved.

- Operating Costs: Consider power consumption and tooling wear. Horizontal milling machines running high-volume production might use more energy but deliver a higher material removal rate, offsetting costs over time. Vertical mills use less power but might wear tools faster depending on the job.

- Upgrade Potential: Think about future CNC integration and automation. Vertical mills often have more affordable CNC retrofit options, ideal if you want to grow gradually without a large initial investment. Horizontal mills may require bigger investments for advanced multi-axis machining and full automation.

Balancing these budget factors ensures you select a milling machine that matches your current needs and scales with your shop’s growth—without draining your finances too quickly.

Shop Space and Operator Skill

When choosing between horizontal and vertical milling machines, shop space is a significant factor. Vertical mills have a smaller footprint, so they fit better in tighter workshops common across many UK shops. If you’re working out of a garage or small industrial space, a vertical mill usually makes more sense.

Horizontal mills are larger and require more room, especially because of their bigger beds and horizontal spindle orientation. You’ll want to ensure your shop can accommodate that extra space without crowding other equipment or workstations.

Operator skill also plays a role. Vertical milling machines tend to be simpler to operate and learn, making them ideal for shops with a range of experience levels or entry-level machinists. Additionally, the control setup on vertical CNC mills is often more straightforward for precision prototyping or basic parts.

Horizontal mills generally require more experienced operators. The setup involves managing chip evacuation and tool access differently, which can be challenging for less experienced machinists. However, the trade-off is worthwhile when aiming for high-volume production or machining larger, tougher parts efficiently.

In short, if space is limited or your team has less experience, vertical milling machines are the safer choice. For larger workshops with skilled operators focused on heavy-duty jobs, horizontal milling machines can significantly enhance productivity.

Factors to consider before choosing cost setup and maintenance

Future-Proofing with CNC Integration

When choosing between horizontal and vertical milling machines, considering CNC integration is a wise decision. CNC milling machines are now standard in many shops because they offer precision and automation that manual mills cannot match. Whether you choose horizontal or vertical, ensure the machine supports CNC controls or can be upgraded in the future.

Here’s what to keep in mind:

- Compatibility: Most modern vertical mills come CNC-ready, making them easier to upgrade or retrofit. Horizontal mills can be CNC-compatible, but older models might require more modifications to update.

- Software and Control: Check if the mill works well with popular CNC software. Good integration means faster setup and less downtime.

- Multi-axis machining: CNC-enabled mills often support multi-axis operations, which add flexibility and finer control—ideal for complex parts or precision prototyping.

- Maintenance and Upgrades: CNC systems need regular software updates and occasional calibration. Choose a model with accessible parts and good local support to avoid long downtimes.

- Scalability: If you plan to increase production or move into high-volume manufacturing, CNC-equipped milling centres can grow with your business.

- Training: Your operators will need CNC training, so factor the learning curve into your plans. A mill with user-friendly controls helps speed this along.

By considering future CNC integration early, you protect your investment and keep your workshop competitive as technology evolves. This approach works well for workshops based in the United Kingdom aiming to stay flexible and efficient in a changing market.

Expert Tips from Vast Optimising Your Milling Workflow

To get the most out of your horizontal and vertical milling machines, here are some simple tips based on real-world experience:

- Choose the right milling tool for your specific job. Using the correct cutter improves precision and speeds up material removal rate.

- Keep chip evacuation in mind. Horizontal mills usually handle chips better, but for vertical mills, make sure your coolant and chip management system is up to date to avoid downtime.

- Set up your machining centre properly every time. Consistent setup reduces errors and keeps production smooth.

- Train your operators well on both horizontal and vertical milling machines. Skilled hands mean fewer mistakes and better parts.

- Use CNC milling machines for better precision prototyping and to simplify complex cuts with multi-axis machining.

- Plan your production scale wisely. Vertical milling suits small to medium runs, while horizontal milling shines in high-volume production.

- Keep maintenance regular. Simple upkeep prevents costly breakdowns and keeps your workflow steady.

- Combine the strengths of both mills when needed. Integrating hybrid setups can tackle more complex projects without extra machines.

Following these tips helps your shop stay efficient, competitive, and ready for future growth in the UK manufacturing market.