Master injection moulding of PMMA with optimal temperatures, drying tips, and defect fixes for crystal-clear acrylic parts and precision prototypes.

If you’re working with injection moulding PMMA, you already know that producing crystal-clear, durable acrylic parts isn’t as simple as it looks. The key to flawless PMMA injection moulding lies in mastering the right processing parameters, understanding material behaviour, and avoiding costly defects.

In this guide, you’ll get straightforward, expert advice on everything from ideal drying times and temperatures to pressure settings, mould design tips, and troubleshooting common issues like bubbles and stress cracks. Whether you’re an engineer, product designer, or manufacturer aiming to optimise your acrylic parts production, keep reading—because nailing PMMA moulding can transform your projects from average to exceptional.

What is PMMA Properties Making It Ideal for Injection Moulding

Polymethyl methacrylate (PMMA) is a versatile amorphous thermoplastic widely known as acrylic or Plexiglas. Its unique chemical structure gives it outstanding clarity and excellent durability, making it a top choice for injection moulding.

Key Properties of PMMA

| Property | Value | Benefit |

|---|---|---|

| Density | 1.18 g/cm³ | Lightweight for easy handling and use |

| Light Transmission | 92% | Superior optical clarity for lenses & displays |

| Shrinkage | 0.2% – 0.5% | Minimal distortion, precise moulding |

| UV Resistance | Excellent | Long-lasting outdoor and automotive parts |

| Melt Temperature | 220°C – 260°C | Suitable for efficient injection moulding |

PMMA Grades for Various Applications

- High Flow PMMA: Ideal for intricate, thin-wall parts.

- Optical Grade: Perfect for lenses and clear displays.

- Impact Modified: Enhanced toughness for durable parts.

- Standard Durables: Balanced properties for everyday use.

PMMA vs Competitors

| Material | Clarity | Cost | Use Case |

|---|---|---|---|

| PMMA | Superior (92%) | Lower | Clear optics, automotive |

| Polycarbonate (PC) | Good (88%) | Higher | Impact-resistant parts |

| ABS | Moderate (85%) | Comparable | Structural Components |

PMMA stands out due to its superior clarity combined with lower cost compared to polycarbonate and ABS. This balance makes it ideal for industries seeking high-quality clear parts without breaking the budget.

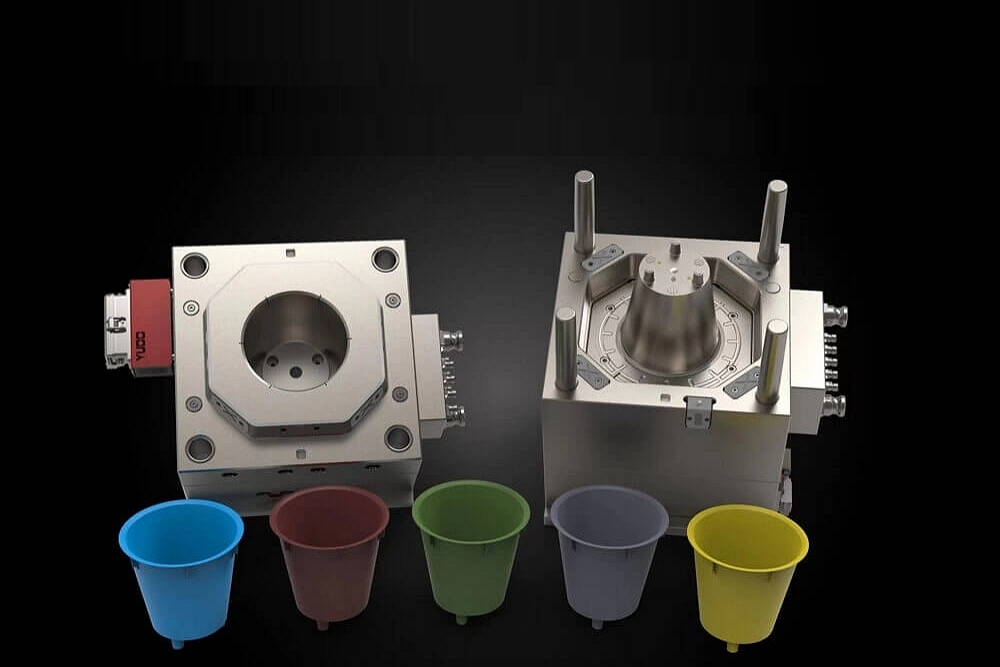

Step-by-Step PMMA Injection Moulding Process

Achieving the best results with PMMA injection moulding begins with closely following the correct process steps. Here’s a straightforward guide to what you should expect:

Material Preparation

Before moulding, dry the PMMA pellets at 80 to 85°C for 4 to 6 hours. This step is essential to remove moisture that causes bubbles and other defects in the finished parts.

Melting and Barrel Conditions

Melt PMMA in the barrel between 220 and 260°C. Use a screw with an L/D ratio greater than 20:1 to ensure good melting and mixing. Proper melting helps achieve a smooth, clear final product.

Injection Pressure and Speed

Maintain injection pressures between 80 and 150 MPa. Inject quickly, especially for thin-walled parts, to fill the mould completely before cooling begins.

Cooling the Mould

Cool the mould uniformly at temperatures between 40 and 80°C. Consistent cooling reduces internal stress and prevents warping or cracking.

Ejection and Post-Processing

After the part is ejected, anneal it at around 80°C for 1 hour. Annealing relieves internal stresses, improving durability and optical clarity.

Following this step-by-step PMMA injection moulding process ensures high-quality parts with minimal defects.

Optimal Processing Parameters for Flawless PMMA Parts

Achieving perfect PMMA parts starts with fine-tuning the correct processing settings. Here’s a quick reference guide to keep your injection moulding process smooth and free of defects.

| Parameter | Recommended Range | Notes |

|---|---|---|

| Barrel Temperature | 220°C to 260°C (428°F-500°F) | Uniform melting without overheating |

| Mould Temperature | 40°C to 80°C (104°F-176°F) | Ensures even cooling and less stress |

| Injection Pressure | 80 MPa to 150 MPa | Fast fill to avoid short shots, especially thin walls |

| Drying Temperature | 80°C to 85°C (176°F-185°F) | 4 to 6 hours to remove moisture, prevents bubbles |

| Cycle Time | 30 to 60 seconds | Depends on part size and mould complexity |

Machine Setup

- Use High precision screws to control melt viscosity and ensure smooth flow.

- A Screw L/D ratio greater than 20:1 helps achieve better melting and mixing.

- Maintain tight control over barrel zones to avoid overheated or under-melted PMMA.

- Regularly check and fine-tune your injection speed for optimal thin-wall filling.

Fine-tuning these parameters keeps your PMMA parts clear, strong, and free from defects like bubbles or stress cracks.

Design Guidelines for Mould and Part Optimisation for PMMA

Optimising your mould and part design is key to achieving the best results with PMMA injection moulding. Follow these practical tips to avoid common issues and improve part quality.

Wall Thickness

- Ideal range: 1.5 to 3 mm

- Keep walls uniform to prevent sink marks and internal stresses

- Avoid thick sections that cause shrinkage and warping

Draft Angles

- Use 1 to 2 degrees draft on vertical walls

- Helps with easy part release from the mould without damage

Radii and Fillets

- Minimum radius of 0.5 mm on all corners and edges

- Reduces stress concentrations and lowers the risk of cracks

Mould Surface Finish

| Feature | Recommendation | Benefit |

|---|---|---|

| Mirror polish SPI A1 | Use for optical parts | Clear and smooth finish |

| Hot runners | Maintain consistent flow | Reduce waste and cycle time |

CAD Design Tips

- Avoid sharp corners that cause flow hesitation and stress points

- Use simulation tools like Moldflow to check flow and cooling before making moulds

- Design for balanced flow to reduce weld lines and sink marks

Case Study Highlight

A lens mould redesign following these guidelines increased yield to 99.9%, showing how proper design optimisations directly improve quality and reduce scrap.

By paying attention to these design rules, you ensure your PMMA parts not only look great but also perform reliably in their applications.

For more on optimising optical plastic moulding, check out our guide on [optical PMMA parts].

Common Defects in PMMA Moulding and Proven Fixes

When moulding PMMA, certain defects can pop up that affect the quality and clarity of your parts. Here’s a quick look at the usual suspects and how to fix them:

Bubbles

- Cause: Moisture trapped in the material.

- Fix: Always dry PMMA thoroughly before moulding. Use vacuum drying and venting in the mould to release any trapped gases.

Sink Marks

- Cause: Thick sections cool unevenly, causing surface dents.

- Fix: Design parts with uniform wall thickness. Lower the hold pressure and consider annealing parts to reduce internal stresses.

Weld Lines

- Cause: Poor or slow flow of molten PMMA where two flow fronts meet.

- Fix: Increase melt temperature to improve flow. Optimize gate placement to ensure smooth material convergence and reduce weld lines.

Stress Cracks

- Cause: Rapid cooling causes internal stresses leading to cracks.

- Fix: Control mould temperature with a gradual ramp-up. Slow down cooling to let parts relax and prevent stress buildup.

By addressing these issues upfront, you can get flawless, clear PMMA parts every time with injection moulding.

Applications and Industries Leveraging PMMA Moulding

PMMA injection moulding is popular across several industries thanks to its clarity, durability, and ease of processing. Some of the top uses include:

- Automotive: PMMA parts are widely used for tail lights and interior panels since they offer excellent light transmission and weather resistance.

- Medical Devices: The material’s biocompatibility and precision moulding make it ideal for medical tools, lenses, and protective housings.

- Displays and Lighting: PMMA is perfect for screens, light diffusers, and camera lenses because it delivers superior optical clarity.

- Aquariums and Signage: Its UV resistance and toughness make it great for large aquarium panels, outdoor signs, and protective covers.

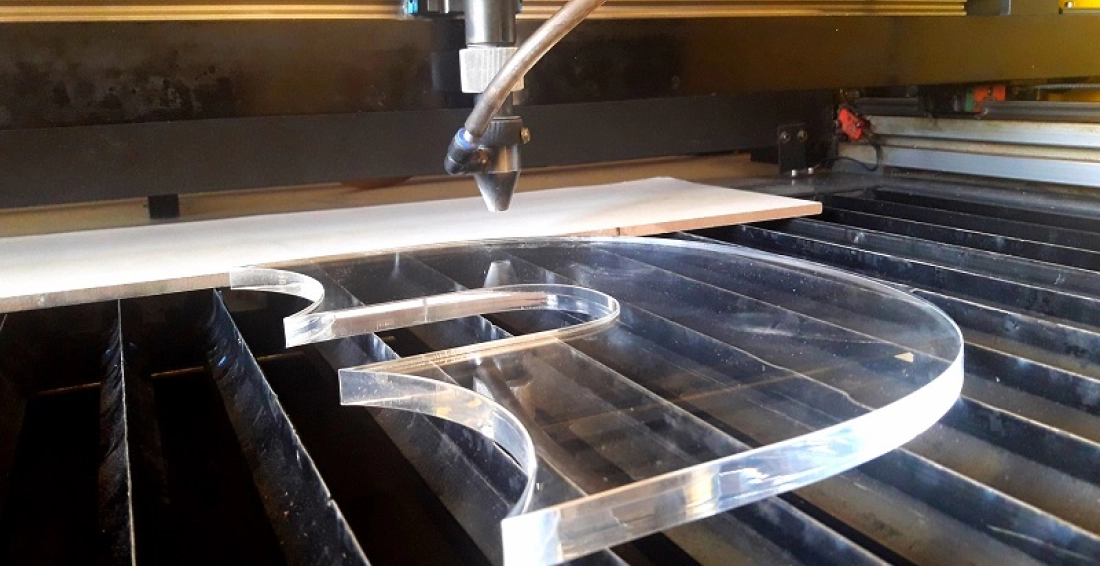

Many companies in the United Kingdom benefit from custom PMMA prototypes with fast turnaround times—often just one week—allowing rapid product development and testing. This makes PMMA moulding a go-to choice for projects requiring quick, high-quality transparent parts.

Cost Factors Sustainability and Next Steps with PMMA Injection Moulding

When it comes to PMMA injection moulding, cost plays a big role in deciding if it’s the right fit for your project. On average, raw PMMA material costs range from $0.01 to $0.05 per gram, making it a competitive choice for clear plastic parts. Tooling expenses, depending on mould complexity and size, usually fall between $5,000 and $50,000. This upfront investment pays off quickly in high-volume runs thanks to PMMA’s excellent flow and finish quality.

Sustainability is another key advantage. PMMA is 100% recyclable, and processing it requires less energy compared to other plastics like polycarbonate. This makes PMMA a more environmentally friendly option, especially for companies prioritising green manufacturing.

Ready to get flawless PMMA parts? Take advantage of our free PMMA design review—upload your CAD files now for expert feedback and optimise your injection moulding project before you start.