Discover the types of milling tools with detailed guides on end mills face mills coatings and selection tips for precision machining success.

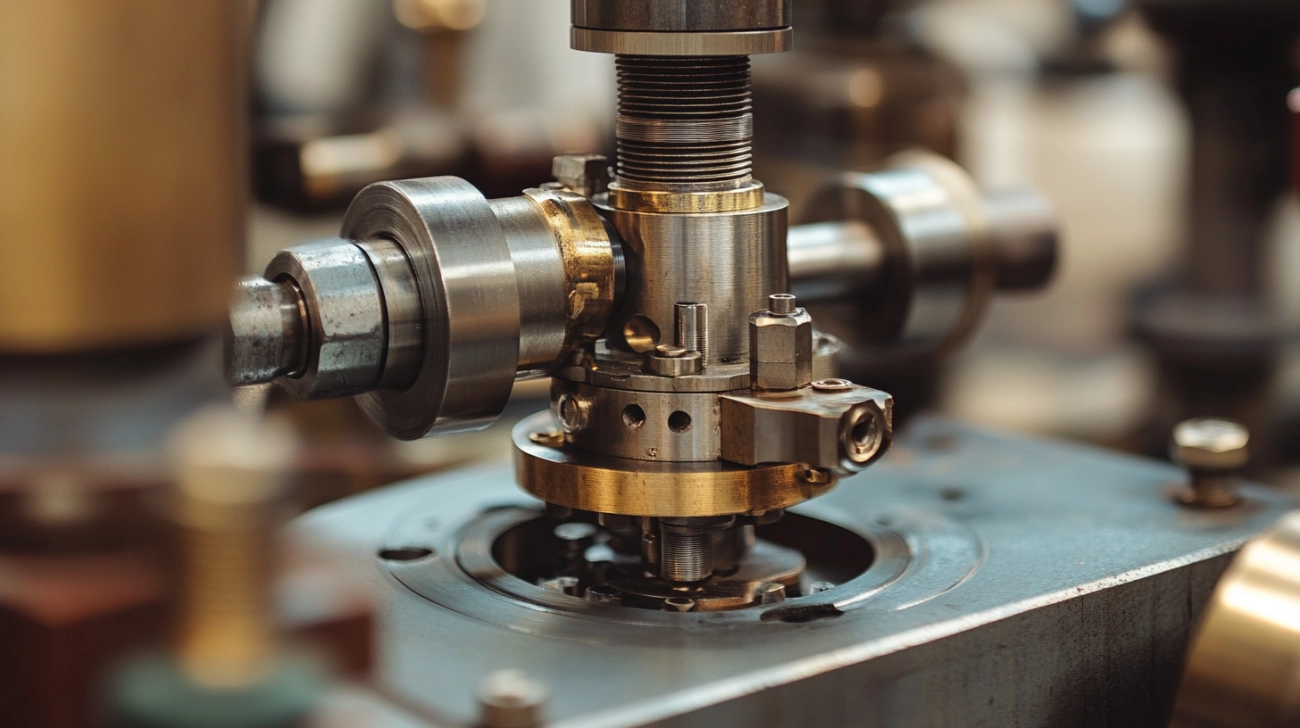

The Fundamentals of Milling Tools Anatomy and Key Classifications

If you’re new to milling or want to sharpen your knowledge, understanding the basic anatomy of milling tools and their main types is a great place to start. Milling tools come with specific parts that define how they perform, and knowing these helps you pick the right tool for your job.

Core Components of Milling Tools

- Shank: This is the part that fits into the machine spindle. It needs to be sturdy and precise to keep the tool stable.

- Body: The main part of the tool connecting the shank to the cutting section.

- Cutting edges: These are the sharp surfaces doing the actual cutting.

- Teeth: The individual points on the cutting edge that remove material.

- Flutes: Spiral grooves along the body that help clear chips and reduce heat.

Primary Classifications

Milling tools are broadly grouped based on their function, material, and design:

- By Function

- Roughing tools: Designed to remove large amounts of material quickly, often with serrated or specialised edges.

- Finishing tools: Provide smooth, precise cuts for the final surface quality.

- By Material

- High Speed Steel (HSS): Great for softer materials and budget-friendly options.

- Carbide: Harder and more wear-resistant, perfect for high-speed machining and tougher metals.

- By Design

- Solid Tools: Made from one solid piece of metal, often carbide or HSS.

- Indexable Insert Tools: Use replaceable cutting inserts, making them cost-effective and versatile.

Coating Overview

Advanced coatings enhance milling tools by protecting them and improving performance:

- TiN (Titanium Nitride): Boosts heat resistance and tool life.

- TiAlN (Titanium Aluminium Nitride): Suits high-speed operations with excellent oxidation resistance.

Understanding these fundamentals lets you make smarter choices, save money, and get better results on your projects. Next, we’ll explore the essential types of milling tools and how to use them effectively.

In Depth Breakdown 8 Essential Types of Milling Tools and Their Applications

When it comes to types of milling tools, knowing which one fits your job makes all the difference. Here’s a straightforward look at eight key milling cutters and where they shine.

End Mills

These are the go-to tools in milling. End mills come in various shapes: flat or square for cutting slots and straight edges, and ball nose for smooth 3D contours. Use them for profiling, pocketing, and detailed work. They work great on materials like aluminium and steel, making them versatile for most workshops.

Face Mills

Face mills are perfect for broad, flat surfaces. They use multiple cutting edges arranged radially to cover large areas quickly. Many face mills come with indexable inserts, so you swap worn edges instead of the whole tool—ideal for automotive and heavy-duty face milling tasks.

Slab Side and Face Mills

These specialise in shoulder and slot milling. With cylindrical teeth, they handle parallel surfaces well and fit straddle milling setups perfectly. They’re your choice for milling wide, flat, or stepped surfaces accurately.

Angle Mills

Angle mills are all about precision bevels and dovetail cuts. They come in single or double-angle variations, commonly used for chamfering gears and angled edges. When your job demands tight angles, these tools deliver.

Fly Cutters

If you’re after a smooth, mirror-like finish on flat surfaces, fly cutters are simple and budget-friendly. They have a single cutting point and work well for hobbyists or small workshops doing finishing passes.

Form Mills

Form mills handle custom contours like T-slots, woodruff keys, or gear teeth shapes. They’re specialised tools made to cut irregular profiles that typical end mills can’t handle efficiently.

Roughing End Mills

For high volume material removal, roughing end mills are your workhorses. Their serrated edges reduce chatter and prevent overheating, perfect for aggressive cuts on castings and heavy-duty work.

Specialty Mills

These are niche tools designed for very specific profiles—think involute gear cutters, conic discs, or the latest high-feed variants. They handle complex shapes and emerging milling techniques, great if you need unique machining options.

Understanding these basic types of milling tools helps you pick the right cutter for the job and keeps your operations smooth and efficient.

How to Select the Right Milling Tool A Step by Step Guide

Choosing the right milling tool can make all the difference in your project’s success. Here’s how to narrow it down:

Factor 1 Workpiece Material

- Carbide tools are your go-to for tough materials like titanium or stainless steel. They hold up well under heat and stay sharp longer.

- For softer materials, like wood or aluminium, High Speed Steel (HSS) cutters often work fine and are more budget-friendly.

Factor 2 Operation Type

- Axial (down) milling pushes the tool straight into the workpiece, ideal for heavy cuts.

- Radial (side) milling moves the tool sideways to shape edges or profiles.

- Choose down milling for better surface finish and less tool wear, but up milling can help with removing scale or rust before finishing.

Factor 3 Machine Specs

- Check your CNC’s rigidity and spindle speed (RPM) to match the tool. Running tools too fast or slow can cause wear or breakage.

- Use this simple RPM formula to fine-tune speeds:

[

RPM = ℟{Cutting Speed times 4}{Diameter}

] - Rely on your machine’s manual or tool suppliers for recommended speeds and feeds to get the best results.

Common Pitfalls

- Avoid overheating, which dulls the tool quickly and damages the workpiece.

- Prevent breakage by using the right tool holder and setup.

- Consider anti-vibration holders (like those from Vast) to stabilise the tool and reduce chatter for cleaner cuts.

Local Angle Tips for UK Users

- Always check for ANSI standards compliance when buying from local suppliers. This ensures your tools meet quality and safety requirements.

- Look for suppliers who stock popular tooling types compatible with UK-made machines.

- Connecting with local tool experts can save time and give you access to timely support.

Getting the right combo of tool, material, and machine specs keeps your job moving smoothly and protects your investment in tooling.

Maintenance and Best Practices Extending Tool Life in Your Shop

Keeping your milling tools in top shape saves money and boosts your shop’s efficiency. Here’s how to do it right.

Daily Care

- Clean tools after every use to remove debris and prevent buildup that wears down cutting edges.

- Inspect tools frequently for signs of wear, chips, or dullness.

- Use coolant properly—it keeps tools cool, reduces friction, and extends tool life. Make sure your coolant system is working well and choose the right coolant for your material.

Optimization

- Adjust your feeds and speeds for the best balance of tool life and cutting efficiency. For precise settings, check out Vast’s online feeds and speeds calculator—it’s a helpful tool tailored for shops in the United Kingdom.

- Use rigid tool holders and ensure your CNC machines are properly maintained to avoid vibration and tool breakage.

Sustainability

- When tools do wear out, recycle them through Vast’s local buy-back programme. This helps your shop stay green and offsets replacement costs.

Case Study

A Midwest fabricator cut costs by 20% using Vast’s carbide end mills. By switching to high-quality, durable tools and following maintenance best practices, they reduced downtime and improved finish quality—a win for both productivity and budget.

Following these steps will keep your milling cutters sharp, save money, and increase your shop’s output without compromise.