Discover essential tools for the lathe including turning, boring, and threading options with expert tips for beginners and pros.

Understanding the Basics Why the Right Lathe Tools Matter

Choosing the right tools for your lathe is essential for both the quality of your work and your safety. Lathe turning tools are designed to shape, cut, or finish materials by rotating the workpiece and applying the tool at precise points. Using the right tool ensures sharper cuts, cleaner finishes, and less wear on your machine.

Core Functions and Tool Interaction

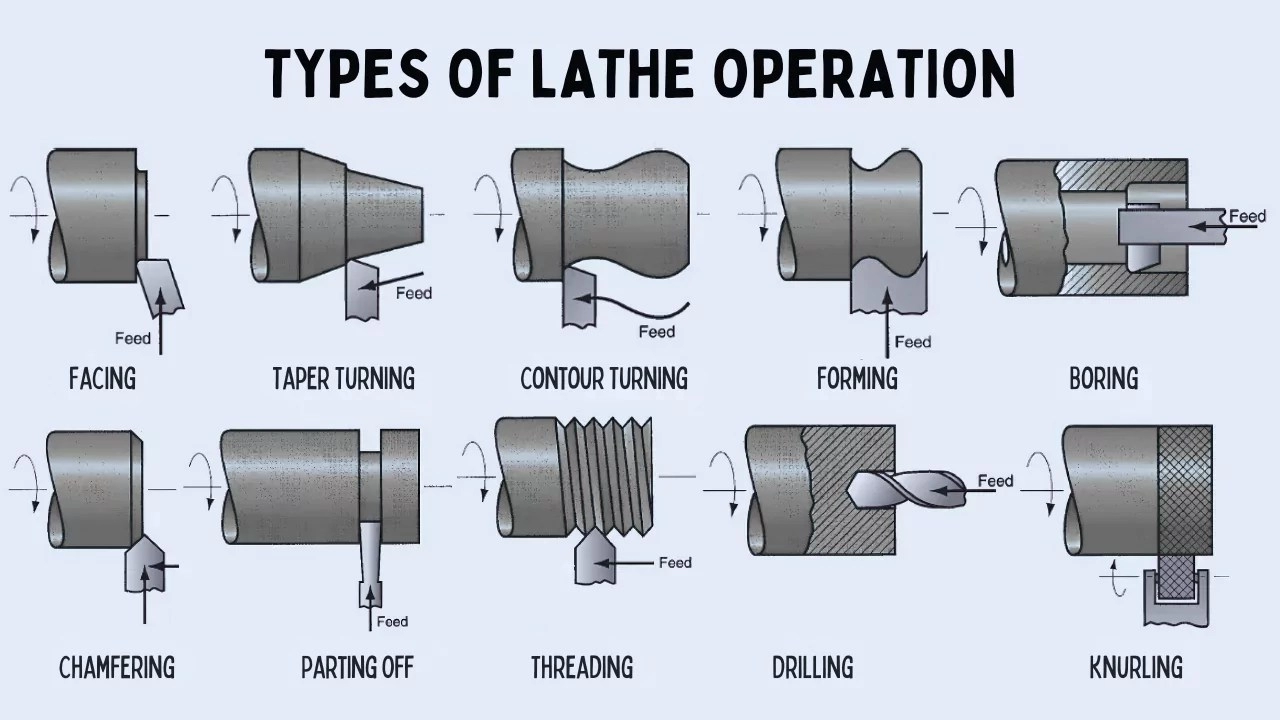

Lathe tools perform different functions like cutting, facing, boring, or threading by interacting with the spinning material. Each tool has a specific shape and cutting edge designed for its task, and using the wrong tool can cause poor results or even damage your workpiece.

Tool Anatomy and Key Parts

Most lathe tools share some common parts:

- Shank: The part clamped into the tool holder.

- Cutting Edge: The sharp part that contacts and removes material.

- Relief Angles: Designed to reduce friction and prevent tool rubbing.

Knowing these basics helps you understand how tools work and how to handle them properly for the best results.

Material Comparison HSS Carbide CBN and Their Pros and Cons

Lathe tools usually come in three main materials:

- High-Speed Steel (HSS): Affordable, easy to sharpen, and great for beginners, but wears faster at high speeds.

- Carbide: Harder and more heat-resistant, offering longer tool life and better performance on tough materials, but requires special sharpening.

- CBN (Cubic Boron Nitride): Extremely durable and ideal for hard materials but more expensive and used mainly in professional CNC settings.

Each material fits different needs and budgets, so pick based on your projects and skill level.

Safety and Performance Impact of Tool Quality

Using high-quality tools isn’t just about good results—it’s critical for your safety. Poor-quality or dull tools can slip, break, or cause uneven cuts that risk injury or damage to your lathe. Investing in reliable tools pays off in smoother, safer operation and longer-lasting equipment.

Local Hobbyists Preferences and Tool Choices

Many hobbyists lean toward versatile, easier-to-use tools like HSS tool bits and wood lathe chisels because they offer a good balance of performance and price. In the U.S., local machinists often favor carbide inserts for lathe work due to their durability and precision, especially for metal projects. Checking with local communities and suppliers can give you insight into what works best in your area.

Understanding these fundamentals will help you make smarter choices, get the most out of your lathe, and enjoy the process more safely and efficiently.

Essential Types of Lathe Cutting Tools

When working with a lathe, choosing the right cutting tools is key for good results and smooth operation. Here’s a simple breakdown of the main types of lathe turning tools you’ll encounter:

Turning and Facing Tools

These are your go-to tools for shaping and smoothing the outside of a workpiece or cutting the face at the end. Turning tools usually have a pointed tip for cutting straight or angled surfaces, while facing tools are designed to create flat surfaces. For beginners, high-speed steel (HSS) tool bits work well, but carbide inserts offer longer life and better finish for pros.

Boring and Drilling Tools

Boring bars help enlarge holes or shape internal surfaces with good control. To keep stability and accuracy when boring or drilling, make sure your tool is firmly secured, and use the right speeds for your material. Using proper boring bars for lathe setups helps avoid chatter and uneven cutting.

Threading and Grooving Tools

Threading tools cut precise screw threads, and grooving tools make grooves or recesses on your workpiece. Inserts come in handy here, especially indexable ones that you can flip or replace easily. Common mistakes include using the wrong insert angle or feed rate, which can ruin the threads or groove.

Specialized Tools for Wood Lathes

Wood lathe chisels like gouges, scrapers, and skew chisels are shaped specifically for woodturning. Gouges remove large chunks quickly, scrapers smooth surfaces, and skew chisels create clean cuts and bevels. These require different handling from metal lathe tools, so knowing their uses is a big plus.

Indexable and CNC Ready Options

For more advanced or production environments, indexable lathe tooling with modular holders works perfectly. These let you swap inserts fast, reduce downtime, and maintain precision—great for CNC lathe cutters and automated setups.

Knowing which tools fit your needs can make a huge difference in results, whether you’re turning metal or wood. Each tool type plays a specific role, so having a well-rounded selection is smart for tackling different projects.

How to Select the Best Tools for Your Lathe Setup

Picking the right tools for your lathe comes down to matching them with your lathe type, the materials you work with, and your skill level. For example, if you have a wood lathe, you’ll want wood lathe chisels like gouges and scrapers instead of heavy-duty carbide inserts meant for metal. For metalworking, HSS tool bits and carbide inserts for lathe are solid choices depending on the job.

Budget and Starter Kits

If you’re just getting started, look for beginner lathe tool kits. These kits give you a good range of essential tools without breaking the bank. As you grow your skills, you can scale up to indexable lathe tooling or CNC lathe cutters for more precision and versatility.

Common Mistakes to Avoid

- Don’t overbuy; start small and add tools as needed.

- Pay attention to shank sizes to make sure your tools fit your lathe’s tool holder.

- Avoid cheap low-quality tools that won’t hold an edge or may cause safety issues.

Local Considerations

Here in the U.S., rust resistance is a big deal—especially if you’re in more humid areas. Opt for corrosion-resistant coatings or keep tools dry and oiled. Also, voice search is getting popular for finding tools fast—so brands that optimize for that will catch your attention.

Pro Tips and Resources

Use online tool finder resources to match your lathe model with compatible boring bars lathe or facing and parting tools quickly. These tools help narrow down choices and save time, making it easier for both beginners and pros to get exactly what they need.

Maintenance and Best Practices for Long Lasting Performance

Keeping your lathe tools in top shape is key to getting the best results and extending their life. Here’s how you can maintain your tools effectively:

Sharpening and Storage Techniques

- Sharpen regularly: Whether you use HSS tool bits or carbide inserts for lathe work, dull tools reduce cutting quality and strain your lathe. Use proper sharpening stones or diamond wheels depending on the tool material.

- Use correct angles: Keep the recommended cutting angles when sharpening to avoid poor cuts or tool damage.

- Store tools properly: Store lathe turning tools and wood lathe chisels in a dry place, ideally in a toolbox or rack that prevents knocking or rust. For HSS tools, applying a light coat of oil can stop rust forming.

Optimal Usage Speeds and Troubleshooting

- Stick to recommended speeds: Each tool material, from HSS to CBN, performs best within specific RPM ranges. Running tools too fast can wear them prematurely, while going too slow can cause burnishing.

- Watch for chatter and vibration: If you notice uneven cuts or excessive vibration, check that your tools are sharp and properly secured in the tool post.

- Replace or regrind inserts as needed: Indexable lathe tooling like carbide inserts often have multiple cutting edges—flip them before replacing to save money.

Eco Friendly Recycling and Sustainability Programs

- Many manufacturers and local tool suppliers now offer recycling programs for used inserts and worn-out tool bits. Sending these back helps reduce waste and supports sustainability.

- Consider buying durable tools that last longer instead of cheap disposables to minimize environmental impact.

- Proper disposal of cutting fluids and lubricants used with lathe tools is also important to keep your workshop eco-friendly.

By following these maintenance best practices, your lathe tools will stay sharp, safe, and ready for quality work—whether you’re working on metal or wood projects at home or in a small shop here in the US.