Explore how automation in casting process boosts efficiency, quality, and cost savings with robotic pouring, AI inspection, and smart foundry tech.

Understanding the Casting Process

Casting is a core manufacturing method where molten metal is poured into molds to create parts and components. Traditional casting methods include:

- Sand Casting: Using sand molds to form metal shapes; versatile but labor-intensive.

- Die Casting: Forcing molten metal into metal molds under high pressure; good for high volume and precise parts.

- Investment Casting: Also called lost-wax casting, it produces highly detailed and complex parts.

Despite their strengths, these manual processes face challenges like:

- Labor Intensity: Skilled workers are needed for molding, pouring, and finishing.

- Inconsistent Quality: Variations in mold-making and pouring can cause defects and rework.

- Variability in Yield: Defects, such as porosity or misruns, impact production efficiency.

Because of these issues, automation is becoming essential in modern foundries. It helps reduce labor demands, control defects, and improve consistency—key factors for competing in today’s metal casting market. Automation in casting drives better process control and supports the shift toward smart foundry technology, aligning with Industry 4.0 standards.

What is Automation in the Casting Process

Automation in the casting process means using machines and technology to handle tasks that were traditionally done by hand in foundries. It covers everything from making molds to pouring molten metal and inspecting finished parts. The goal is to boost efficiency, improve quality, and reduce risks tied to manual labor.

Key components of casting automation include:

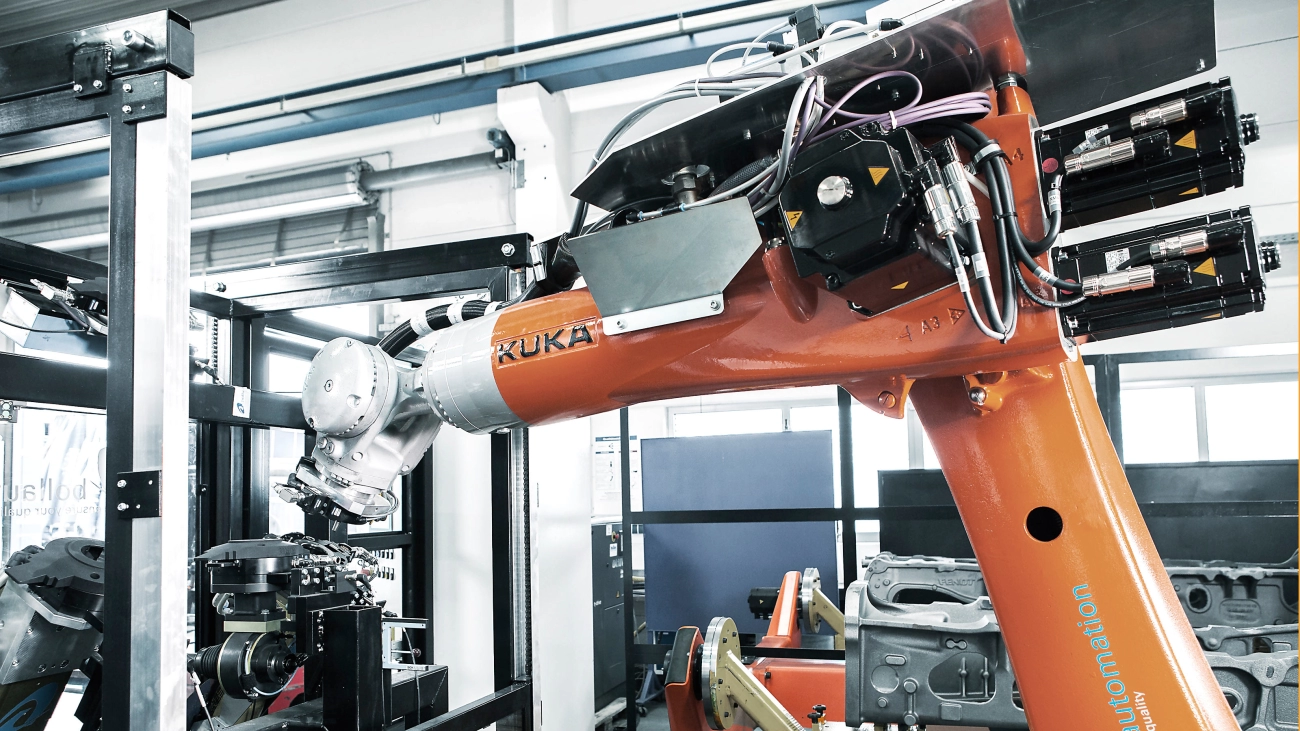

- Robotic arms that handle pouring and ladling with precision

- Conveyor systems for smooth movement of molds and castings

- Automated molding machines that create consistent molds quickly

- Robot Inspection Systems (RIS) that use cameras and sensors to catch defects early

These technologies often connect with Industry 4.0 setups, bringing smart manufacturing into play. This means foundries can collect real-time data, remotely monitor the process, and optimize operations continuously—making the casting process smarter and more reliable.

Types of Automation Technologies Used in Casting

Automation in casting involves a mix of smart technologies that boost efficiency and quality throughout the process. Here are the main types used in modern foundries:

- Robotic Pouring and Ladling Systems: These systems handle molten metal with precision, reducing spillage and improving safety. They help maintain a consistent pour, which is key for high-quality castings.

- Automated Mold Making and Handling: Automation speeds up mold preparation by using machines that shape and transport molds without manual labor. This reduces errors and keeps production steady.

- Sensors for Real-Time Quality Control and Defect Detection: Advanced sensors monitor temperature, flow, and surface conditions during casting. This immediate feedback helps catch defects early, ensuring better final products.

- Automated Post-Processing: Tasks like fettling, grinding, and finishing can be automated to boost productivity and maintain uniformity in cast parts, minimizing manual rework.

- AI and Machine Learning Applications: These technologies analyze data from the process to predict maintenance needs and spot potential quality issues before they happen, making predictive maintenance and quality assurance smarter and more reliable.

Benefits of Automation in Casting

Automation in the casting process brings clear advantages that directly impact foundry efficiency and product quality. Here’s why adopting robotic casting automation and other smart foundry tech makes a difference:

Improved Product Consistency and Quality Control

- Automated systems reduce human error, ensuring uniform molds and precise pouring.

- Real-time quality control sensors catch defects early, boosting overall product reliability.

Increased Production Speed and Output

- Robots and conveyors streamline repetitive tasks like pouring and handling molds.

- Faster cycle times mean more castings produced without sacrificing quality.

Reduction in Labor Costs and Health Hazards

- Automation cuts down on manual labor, lowering costs over time.

- Workers face less exposure to high heat, fumes, and heavy lifting, improving safety.

Minimization of Casting Defects and Material Waste

- Consistent process control reduces scrap rates and rework.

- Automated defect detection helps identify issues early, saving material and time.

Enhanced Data Collection for Continuous Process Improvement

- Automation systems collect data throughout the casting process.

- This data feeds into AI and Industry 4.0 platforms to optimize production further.

| Benefits | Impact |

|---|---|

| Consistency and Quality | Uniform products, fewer defects |

| Production Speed | Higher output, faster turnaround |

| Labor and Safety | Lower costs, healthier work environment |

| Defect Reduction | Less waste, better yields |

| Data-Driven Insights | Ongoing improvements through analytics |

For U.S. foundries looking to stay competitive, these benefits make a strong case for investing in casting process automation solutions.

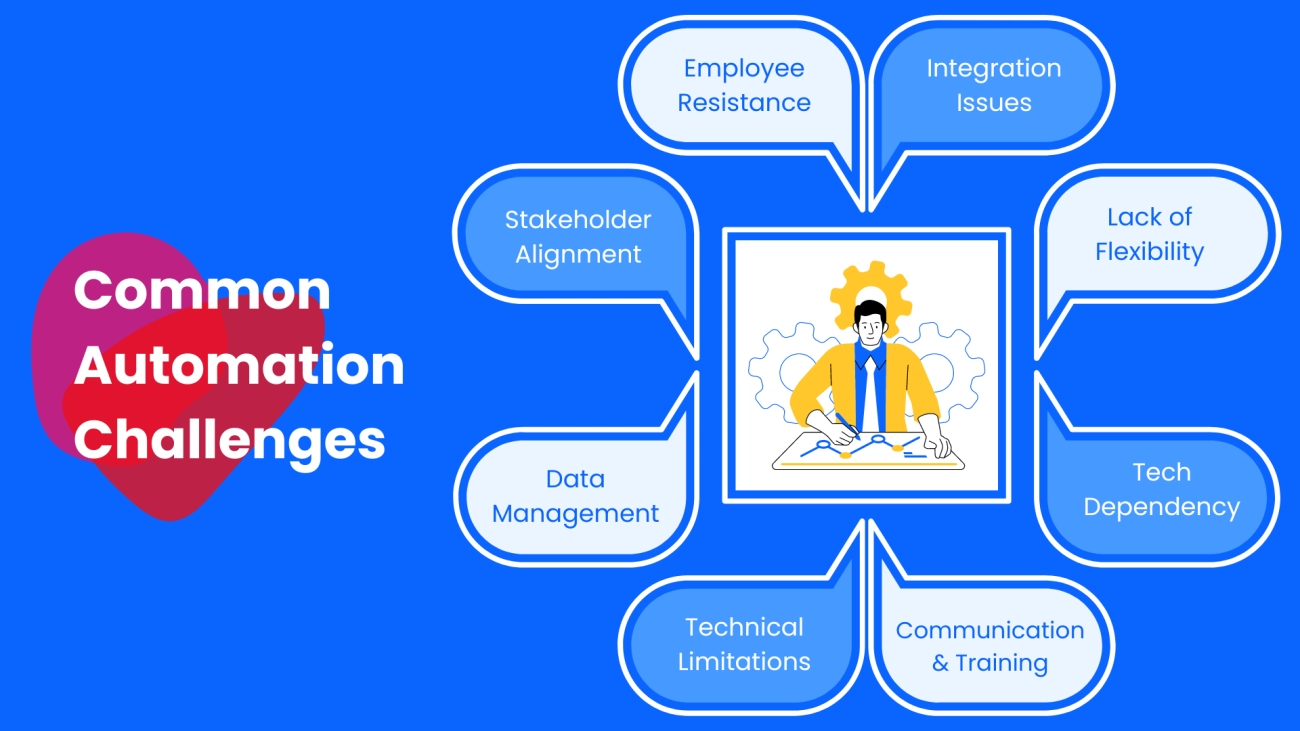

Challenges and Considerations in Implementing Automation

Switching to automation in the casting process comes with some hurdles you need to plan for. First off, the initial investment can be high. Buying robotic casting automation systems, automated molding machines, or automated quality control tools isn’t cheap. You’ll want to calculate the ROI carefully to make sure the upgrade pays off over time.

Another challenge is the skill gap. Your team may need training or upskilling to operate and maintain smart foundry technology like robotic arms or sensor-equipped inspection systems. Without proper training, the benefits of automation can be limited, or worse, cause downtime.

Integrating automation with your existing equipment and processes can also get tricky. Foundry automation solutions often require adjustments in workflow or layout. The more diverse your cast metals and alloys, the more complex this becomes. Different materials might need customized handling or inspection techniques, which means a one-size-fits-all approach rarely works.

Plus, automated systems come with their own set of maintenance and troubleshooting needs. Unlike manual processes, you’ll need skilled technicians familiar with the technology to keep things running smoothly and quickly address any faults.

Keep in mind, these considerations vary widely across cases. An automated sand casting line might pose different challenges compared to AI-driven inspection in investment casting. Planning these details upfront helps make your transition smoother and more effective.

Real World Case Studies and Industry Examples

Automation in the casting process isn’t just theory—many foundries across the U.S. have already seen real benefits. Take a regional foundry that integrated an automated sand casting line. By using robotic molding and automated core handling, they cut cycle times nearly in half and reduced defects significantly. This upgrade also lowered labor intensity, making the work environment safer for operators.

Another strong example is a high-volume die casting manufacturer that implemented AI-driven quality inspection systems. These smart sensors catch casting defects in real time, ensuring consistent product quality while minimizing scrap. The AI analyzes patterns, helping predict maintenance needs and avoid production downtime.

At Vast Precision Cast Parts Inc., we’ve helped various clients like these modernize their casting workflows. Our foundry automation solutions include robotic casting automation and automated quality control in casting, designed to optimize process control for investment castings. Partnering with us means integrating Industry 4.0 technology with proven robotics for faster, smarter production.

Future Trends in Casting Process Automation

The future of automation in the casting process is moving toward fully autonomous foundries, where robots and AI handle almost all casting tasks from start to finish. Advances in robotics are making it easier to automate complex steps like pouring, molding, and finishing, while AI improves decision-making, quality control, and predictive maintenance.

3D printing and hybrid manufacturing are also starting to change the game. They enable faster prototyping and new ways to make molds or parts that combine traditional casting with additive methods. This blend of technologies can reduce lead times and open up new design possibilities.

Sustainability is a big focus too. Automated processes help cut waste, reduce energy use, and minimize harmful emissions. By optimizing material use and lowering defects, automation supports greener casting practices that meet stricter environmental standards.

Overall, smart foundry technology powered by Industry 4.0 will keep pushing metal casting forward, making processes more efficient, accurate, and eco-friendly.

How to Get Started with Automation in Your Foundry

Getting started with automation in your foundry means taking clear, practical steps to ensure a smooth transition. Here’s how you can approach it:

Assess Your Current Casting Process

- Identify pain points: Look for areas where manual labor slows production, causes defects, or raises safety concerns.

- Evaluate existing equipment: Check if your machines can support automation or need upgrades.

- Measure process consistency: Know your current output quality and where variability happens.

Choose the Right Automation Technologies

- Match tech to needs: For example, use robotic casting automation for pouring and ladling, or automated sand casting for molding.

- Consider scalability: Start with systems that fit your current volume but allow future growth.

- Focus on integration: Technologies like RIS (Robot Inspection Systems) and sensor-based quality control should work seamlessly together.

Partner with Experienced Providers

- Work with specialists: Companies like Vast Precision Cast Parts Inc offer tailored foundry automation solutions designed for the U.S. market.

- Custom solutions: Get help designing systems that fit your unique casting process and metals.

- Support and service: Ensure your partner offers ongoing maintenance and prompt troubleshooting assistance.

Prioritize Training and Continuous Support

- Upskill your workforce: Automation changes roles, so training in robotics and process control is key.

- Create an automation culture: Encourage staff to embrace new tech and suggest improvements.

- Keep up with updates: Regularly maintain systems and update software to optimize performance.

Taking these steps will help your foundry move confidently toward automation, boosting productivity, quality, and safety while controlling costs.