Discover reliable pressure transmitters with high accuracy 4-20 mA output ATEX certification and easy installation for industrial applications.

If you’re working in industrial settings like manufacturing, oil & gas, or water treatment, you know that pressure transmitters are the silent heroes keeping processes safe and efficient. But what exactly is a pressure transmitter, and why is it so critical to your operation? In this guide, you’ll discover how these devices convert pressure into reliable signals, the types available, and what to look for when choosing one. Whether you’re troubleshooting, installing, or upgrading, understanding pressure transmitters will help you make smarter decisions—and avoid costly downtime. Ready to get to the core of pressure measurement? Let’s dive in!

What Is a Pressure Transmitter

A pressure transmitter is an essential device in industrial process control that measures the pressure of gases or liquids and converts this physical pressure into an electrical signal. At its core, it consists of a pressure sensor (often piezoresistive or capacitive), signal conditioning electronics, and an output interface, typically a standardized 4-20 mA current loop. This output allows seamless communication with control systems, ensuring accurate process monitoring.

People often confuse pressure transmitters with pressure transducers or sensors, but there are clear differences. While a pressure sensor detects the pressure and produces a raw electrical signal, a transmitter processes and conditions this signal, providing a standardized, calibrated output ready for remote reading. A transmitter adds value by encompassing the sensor and electronics in one robust, industrial-grade device.

Imagine a pressure sensor as a microphone capturing sound; the transmitter is like the sound system that amplifies and shapes that sound into clear signals you can use. This distinction is critical for reliable industrial pressure measurement, especially where accuracy and safety cannot be compromised.

Visualizing this, an infographic would show three parts:

- The pressure sensing element detecting pressure changes

- Signal conditioning electronics converting the raw signal

- Output stage sending calibrated data to controllers

Understanding what a pressure transmitter is helps set the foundation for navigating the variety of models and features in the market. Are you clear about how this device fits into your process control needs?

How Does a Pressure Transmitter Work

A pressure transmitter, or transmetteur de pression, measures pressure by converting the physical force of a fluid or gas into an electrical signal you can use. Here’s a simple step-by-step breakdown of how it works:

- Sensing PressureThe transmitter uses a pressure sensor, often a piezoresistive sensor, that reacts when pressure pushes on it. This sensor detects changes in pressure, whether it’s absolute, gauge, or differential.

- Signal ConversionThe mechanical pressure causes a change in the sensor’s electrical properties (like resistance). This change is then converted into an analog electrical signal.

- Signal ConditioningElectronics inside the transmitter amplify and condition this signal to make it stable and accurate. This usually results in a standard output like 4-20 mA, which is easy to read by industrial control systems.

- Output TransmissionThe transmitter sends this electrical signal through wires or wirelessly to a control panel or monitoring system for real-time pressure monitoring.

Factors Affecting Accuracy

- Temperature Changes can cause sensor drift.

- Vibrations and Mechanical Stress impact sensor stability.

- Process Conditions such as media type and pressure spikes.

- Electrical Noise interfering with signal quality.

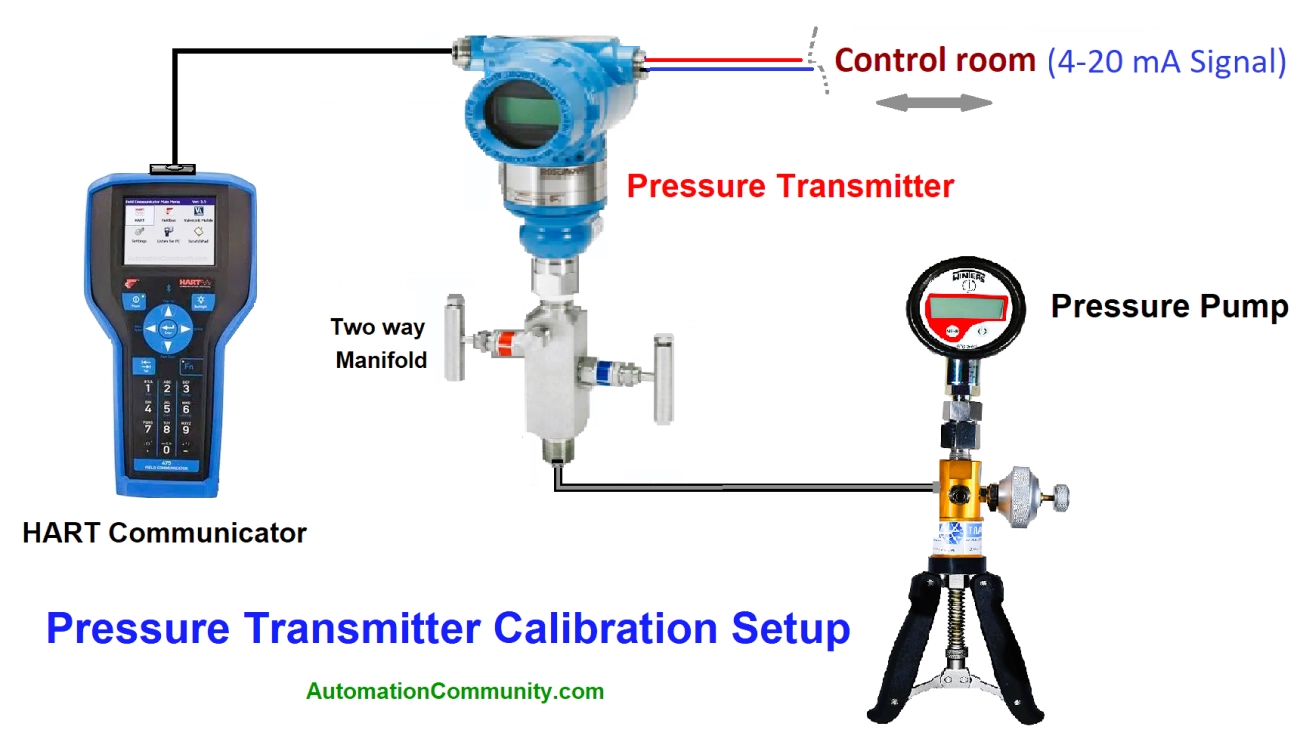

Calibration Process

Calibration is key to maintaining precision. It involves:

- Comparing transmitter readings against known pressure standards.

- Adjusting output signals to correct deviations.

- Performing calibration regularly, based on manufacturer recommendations or process criticality.

Keeping calibration up-to-date ensures reliable industrial pressure measurement, whether you’re working with HVAC systems, oil and gas pipelines, or water treatment plants.

By understanding this flow, you can appreciate how a transmetteur de pression turns raw pressure data into actionable information with great accuracy and consistency.

Types of Transmetteur de Pression

There are several types of pressure transmitters designed to fit different measurement needs in industry. Here’s a quick rundown of the main types you’ll find:

- Absolute Pressure TransmittersMeasure pressure relative to a perfect vacuum (zero pressure). These are great for applications like weather monitoring or vacuum systems where you need a fixed reference point.

- Gauge Pressure TransmittersMeasure pressure relative to atmospheric pressure. This is the most common type used in HVAC, water, and general process control.

- Differential Pressure TransmittersMeasure the difference between two pressure points. These are key in flow measurement, filter monitoring, and liquid level sensing.

- Multivariable Pressure TransmittersCombine measurements like pressure, temperature, and sometimes flow in one device. They’re useful for complex process controls needing multiple data streams.

Emerging Wireless and IoT-enabled Models

Newer pressure transmitters are wireless and IoT-ready. These transmitters offer:

- Remote monitoring without wiring hassles

- Integration with cloud systems for real-time data analytics

- Easy upgrades and maintenance through digital platforms

They’re becoming popular in smart factories and facilities investing in Industry 4.0 technologies.

Selection Matrix to Choose the Right Transmitter

| Tipo | Measurement Range | Output Signal | Ideale per |

|---|---|---|---|

| Absolute | 0 to 15 psi up to 0-10k psi | 4-20 mA, HART | Vacuum systems, weather stations |

| Gauge | -14.7 psi (vacuum) to full scale | 4-20 mA, 0-5 V | HVAC, water treatment, tank monitoring |

| Differential | Wide differential ranges | 4-20 mA, digital protocols | Flow metering, filter monitoring |

| Multivariable | Complex ranges | Digital outputs, Modbus | Process automation requiring multiple inputs |

| Wireless IoT Models | Varia | Wireless communication | Remote monitoring, smart plants |

When selecting a transmetteur de pression, consider the pressure range, output type, and the specific application environment to get the right fit. Keep an eye on certifications and connectivity options to match your facility’s system.

Key Specifications and Features to Consider for Transmetteur de Pression

When choosing a transmetteur de pression (pressure transmitter) for your application, focusing on the right specs will save time and boost accuracy. Here are key features to prioritize:

Measurement Range and Overpressure Tolerance

- Make sure the transmitter covers the pressure range of your process.

- Check the overpressure rating to ensure it can handle occasional spikes without damage.

Accuracy and Stability

- Look for accuracy values that match your industry standards — typically expressed in percent of full scale.

- Stability over time is crucial to avoid frequent recalibration.

Output Connectivity

- Most industrial pressure transmitters use 4-20 mA output for reliable signal transmission.

- Consider options with digital outputs like HART or wireless if your system supports it.

Materials and Certifications

- Verify the transmitter’s wetted parts are made of corrosion-resistant materials like stainless steel.

- Certifications such as ATEX are essential if you operate in hazardous environments.

Environmental Ratings

- Check IP ratings for dust and water protection, especially for outdoor or harsh conditions.

- Temperature ranges should match your site’s climate.

Buyer’s Checklist for Transmetteur de Pression

- Fits your pressure range with safety margin

- Accuracy meets process needs

- Compatible output signals (4-20 mA, HART, etc.)

- Durable materials matched to your fluid or gas

- Required certifications (ATEX, FDA, etc.)

- Proper environmental protection (IP rating)

- Easy installation and maintenance features

Choosing the right specs upfront means your transmitter will provide reliable, long-term performance, making your pressure monitoring smoother and more efficient.

Applications of Pressure Transmitters in Industry

Pressure transmitters play a crucial role across many industries in the U.S., helping monitor and control processes with precision. Here’s how they’re used in key sectors:

- Oil and Gas: Measure wellhead pressure, pipeline monitoring, and safety controls to prevent leaks or accidents.

- Water and Wastewater: Track water pressure in treatment plants and distribution networks to ensure consistent supply and detect leaks.

- Food and Pharma: Maintain strict pressure levels during processing and packaging to meet sanitary standards and ensure product quality.

- HVAC: Monitor air and refrigerant pressure for efficient heating, ventilation, and cooling system performance.

- Energia: Control boiler pressure, monitor turbines, and manage renewable energy systems like wind and solar for optimal output.

Case Study: French Manufacturing Facility

A French manufacturing facility recently upgraded to advanced piston-type pressure transmitters, resulting in a 15% increase in production efficiency and a 20% reduction in downtime. Accurate pressure data helped optimize their processes and maintenance scheduling, delivering a strong return on investment (ROI).

Visual aids such as industry icons and flow charts help quickly connect these applications with specific transmitter types and features, guiding users to the best solution for their needs.

By leveraging the right pressure transmitteurs de pression, U.S. industries can improve safety, efficiency, and compliance across the board.

Installation Calibration and Maintenance Best Practices

Getting your transmetteur de pression installed and maintained properly is key to reliable readings and long equipment life. Here’s a straightforward guide to keep you on track.

Installation Tips and Mounting Advice

- Choose the right spot: Mount your pressure transmitter where it’s protected from vibration, extreme temperatures, and corrosive environments.

- Proper orientation: Follow manufacturer guidelines—some transmitters work best mounted vertically or horizontally depending on sensor type.

- Avoid pressure spikes: Use snubbers or dampeners if your process experiences sudden pressure changes.

- Correct wiring: Use shielded cables and proper grounding to reduce electrical noise affecting the 4-20 mA output signal.

Calibration Process and Recommended Frequency

- Initial calibration: Always calibrate after installation to ensure accurate pressure measurement.

- Regular checks: Schedule calibration every 6 to 12 months, or more often for critical applications.

- Use certified devices: Calibrate using traceable pressure standards for reliable results.

- Record keeping: Document calibration dates, methods, and results for compliance and troubleshooting.

Risoluzione dei problemi comuni

- Signal drift: Can happen due to sensor aging or environmental factors—recalibrate to fix.

- No output or stuck readings: Check wiring, power supply, and sensor contamination.

- Pressure reading fluctuations: Inspect for leaks, blockages, or mechanical damage.

Maintenance and Predictive Strategies

- Routine cleaning: Keep sensor ports free from dust, debris, and buildup to maintain accuracy.

- Monitor output trends: Watch for gradual changes in readings that may indicate sensor wear or failure.

- Replace seals and gaskets: Prevent leaks by refreshing seals during maintenance.

- Leverage predictive maintenance: Use historical data and IoT-enabled transmitters to forecast potential failures before they disrupt operations.

Following these tips will help your pressure transmitter stay accurate and reliable, saving downtime and enhancing your process control.

Choosing the Right Pressure Transmitter for Your Needs

Picking the right transmetteur de pression comes down to matching the device’s specs with your specific application. Here’s a simple decision framework to help you out:

- Understand your measurement needs: Know the pressure range, type (absolute, gauge, differential), and environment (temperature, humidity, corrosive).

- Check output compatibility: Most industrial systems use 4-20 mA outputs, but some newer models offer wireless or digital signals for easier integration.

- Consider accuracy and stability: Higher accuracy matters in critical processes, but it usually costs more. Think about how stable the reading needs to be over time.

- Look at certifications and materials: For US industries, ATEX certification and corrosion-resistant materials can be important, especially in harsh environments.

- Compare costs versus value: Don’t just buy the cheapest transmitter. Investing a bit more upfront can save you downtime and maintenance later.

Model Spotlight with Pros and Cons

| Model Type | Vantaggi | Svantaggi | Ideale per |

|---|---|---|---|

| Piezoresistive Pressure Transmitter | Good accuracy and affordability | Sensitive to temperature | General industrial use |

| Differential Pressure Transmitter | Measures pressure difference precisely | More complex installation | HVAC and process control |

| Wireless IoT-enabled Transmitter | Easy remote monitoring | Higher upfront cost | Smart factories and remote sites |

| ATEX Certified Transmitter | Safe in explosive atmospheres | Usually more expensive | Oil, gas, and chemical industries |

Future Trends to Watch

Pressure transmitters are evolving fast. AI integration is helping with predictive maintenance—letting you catch issues before they turn into expensive downtime. Wireless and IoT features continue to grow, making monitoring easier and more flexible. When choosing your next transmetteur de pression, keep an eye on these technologies to future-proof your investment.

By following this guide, you can select a transmitter that fits your operation perfectly, balancing cost, performance, and long-term value.