Precision grinding is a high-accuracy machining process delivering tight tolerances and superior surface finishes for aerospace, automotive, and medical parts.

What Exactly is Precision Grinding The Fundamentals Explained

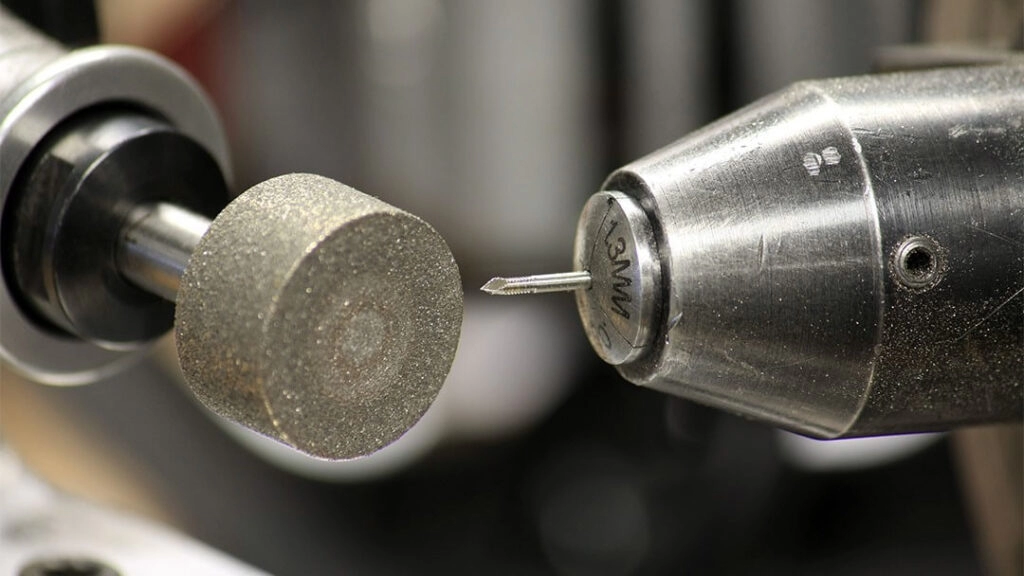

Precision grinding is a specialized machining process where material is carefully removed from a workpiece using a rotating abrasive wheel. This method achieves extremely tight dimensions and exceptional surface finishes that other machining techniques simply can’t match.

Historically, precision grinding evolved from simple manual setups to advanced CNC-integrated systems. This evolution has dramatically improved accuracy, repeatability, and overall efficiency in manufacturing.

The core principles behind precision grinding include:

- Abrasive Action: Tiny abrasive particles on the grinding wheel remove minimal amounts of material with each pass.

- Minimal Stock Removal: Only a small layer of material is removed to maintain the integrity and precision of the part.

- Heat Management: Coolants are used consistently to reduce heat buildup, preventing warping or damage that can affect tolerances.

Understanding these fundamentals sets the stage for appreciating why precision grinding plays such a critical role in industries demanding micron-level tolerances and flawless finishes.

How Does the Precision Grinding Process Work Step by Step Breakdown

Setup

Before grinding, the workpiece needs proper preparation to ensure accuracy. This means cleaning, securing, and sometimes pre-machining it. Choosing the right machine is crucial—whether it’s a surface grinder, cylindrical grinder, or jig grinder. The machine’s rigidity and stability matter a lot to avoid vibrations that can throw off tight tolerance machining.

Execution

During grinding, the abrasive wheel spins at high speed while the workpiece moves in a controlled way. Feed rates and pressure must be carefully set to remove just the right amount of material. Abrasives in the wheel do the cutting by grinding away tiny bits of metal without causing overheating. Managing these variables helps maintain surface quality and micron-level tolerances.

Monitoring

Constant checking is part of precision grinding. In-process gauging measures dimensions as the grinding happens, so adjustments can be made on the fly. After grinding, detailed inspections verify the final surface finish and dimensions meet specs. This step ensures parts are ready for demanding applications like aerospace or medical implants.

Variations

Precision grinding often uses roughing and finishing passes. Roughing removes most of the material quickly, while finishing passes refine the surface and tighten tolerances. This two-stage process balances speed and accuracy to deliver the best results.

Types of Precision Grinding Choosing the Right Method for Your Needs

Precision grinding comes in several key types, each suited to specific jobs and materials. Here’s a quick look at the main methods and when to use them:

Surface Grinding

- Use: For flat surfaces on both small and large parts

- Spindle: Horizontal or vertical

- Best for: Creating smooth, flat finishes with tight tolerance machining

- Materials: Metals, composites, ceramics

Cylindrical Grinding

- Use: For rods, shafts, and cylindrical surfaces

- Types:

- External: Grinding the outside diameter

- Internal: Grinding inside holes or bores

- Center-type: Workpiece supported at each end

- Centerless: No centers needed, ideal for high-volume runs

- Best for: Parts requiring precise roundness and concentricity

Other Specialized Types

- Jig Grinding: For holes, slots, and fine details needing exact dimensions

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | Ideal Materials | cURL Too many subrequests. |

|---|---|---|---|---|

| Surface Grinding | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Cylindrical Grinding | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Creep Feed Grinding | Efficient for deep cuts | Heat build-up risk | Hardened metals | ±0.0001 inch |

| Blanchard Grinding | Fast surface stock removal | Lower precision finish | Large ferrous parts | ±0.001 inch |

Choosing the right precision grinding method depends on your part shape, finish quality, and tolerance needs. For Houston manufacturers, these options provide flexible solutions to meet custom part demands with micron-level tolerances.

Materials and Applications Where Precision Grinding Shines

Precision grinding works well with a wide range of materials. This includes ferrous metals like steel, non-ferrous metals such as aluminum and copper, and even harder materials like titanium, ceramics, and composites. Its ability to handle tough, heat-treated materials makes it a go-to method when tight tolerance machining is required.

In terms of industry use, precision grinding is key in aerospace for parts like turbine components where vibration-free, exact performance is critical. The automotive sector also relies on it to create high-efficiency gears and transmissions that require smooth surface finishes and microscopically precise dimensions.

Medical devices and implants benefit from precision grinding as well. It helps achieve the biocompatibility and exact shapes needed for reliable performance inside the human body. Tool and die makers use it to sharpen tools, extending their life and keeping cutting edges perfectly aligned.

Locally, U.S. manufacturing hubs like Houston use precision grinding to produce custom parts quickly and with great accuracy. This helps local shops compete nationwide by meeting tight specifications faster and maintaining consistent quality for their customers.

Advantages and Benefits Why Precision Grinding Outperforms Alternatives

Precision grinding stands out for several key reasons that make it the go-to choice for tight tolerance machining in the U.S. manufacturing scene.

Precision and Tolerances

- Achieves micron-level accuracy, far better than milling, which usually has looser specs.

- Ideal for parts where every tiny measurement counts.

cURL Too many subrequests.

- Produces very smooth finishes with low Ra values, which reduces friction and wear.

- Critical for parts needing long-term durability, like aerospace components or medical implants.

cURL Too many subrequests.

- Great for high-volume production—it’s cost-effective and boosts output.

- Less rework and scrap due to consistent results.

Versatility

- Works well on a variety of materials, including hardened steels, titanium, and ceramics.

- Can grind parts after heat treatment without damaging them.

How Precision Grinding Compares to Honing and Polishing

| Feature | Precision Grinding | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|---|

| Speed | Faster for tight tolerances | Slower, used for fine sizing | Usually slower, for finish only |

| Cost | Moderate to high | cURL Too many subrequests. | Lower but limited use |

| Surface Finish | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.