Explore 7075 aluminum’s high strength, corrosion resistance, and aerospace-grade properties ideal for bikes, machining, and high-performance projects.

Chemical Composition and Key Properties of 7075 Aluminum

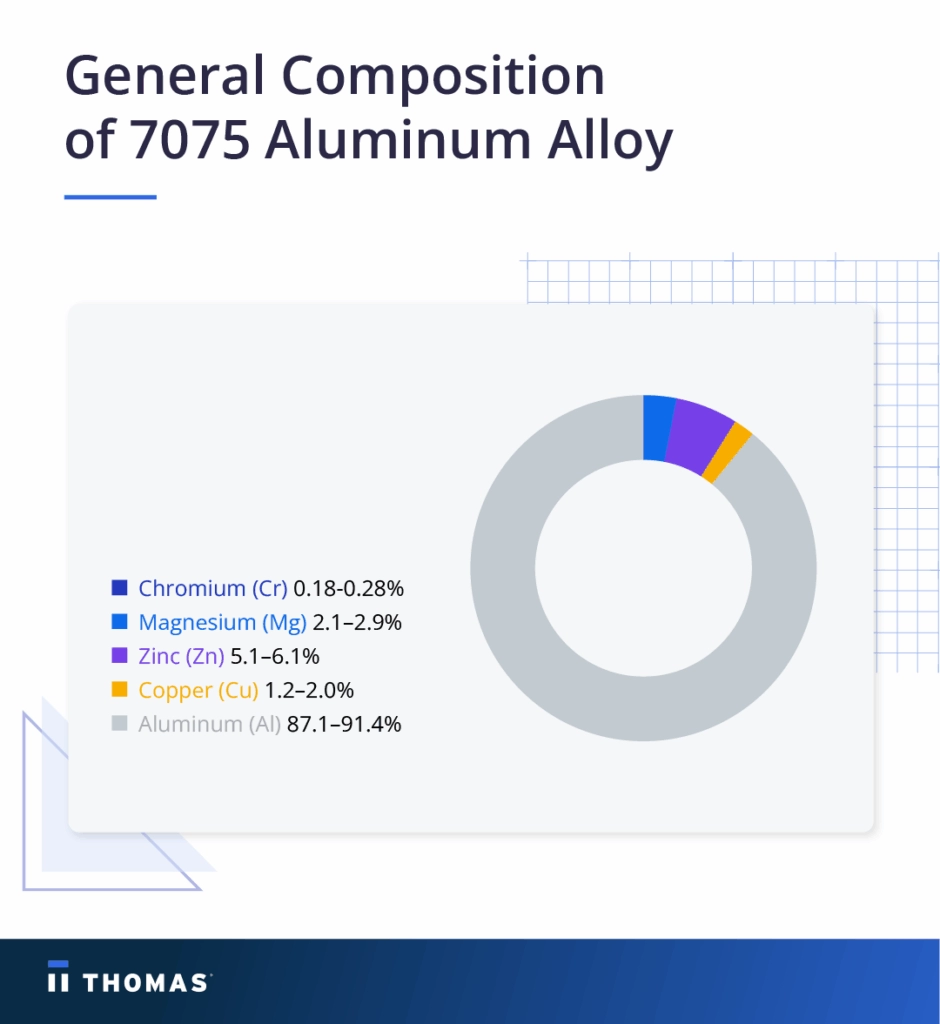

7075 aluminum is a high-strength aluminum-zinc alloy known for its exceptional mechanical properties and versatility. Its chemical makeup primarily includes zinc (about 5.6-6.1%), which plays a key role in achieving its impressive strength. Other elements like magnesium (2.1-2.5%) and copper (1.2-1.6%) contribute to hardness and toughness, while small amounts of chromium improve corrosion resistance and grain structure.

Elemental Breakdown

- Zinc: 5.6-6.1%

- Magnesium: 2.1-2.5%

- Copper: 1.2-1.6%

- Chromium: 0.18-0.28%

- Aluminum: Balance (around 90%)

Mechanical Properties

7075 aluminum stands out with a tensile strength typically around 83,000 psi (572 MPa) in the common T6 temper, putting it among the strongest aluminum alloys. Its high yield strength and good fatigue resistance make it a top choice for demanding structural applications. Despite this power, it remains relatively lightweight, supporting designs where weight savings are critical.

Physical and Corrosion Traits

Physically, 7075 aluminum offers good machinability and can be heat-treated to further enhance strength. However, it is less corrosion-resistant than some other alloys like 6061. Protective treatments like anodizing or cladding help improve its resistance, which is essential in environments exposed to moisture or harsh chemicals.

In , 7075 aluminum’s blend of strengths and physical qualities makes it a versatile, high-performance material suitable for aerospace, automotive, and sporting goods—whenever strength and lightness are priorities.

Available Tempers and Forms Choosing the Right 7075 Configuration

When working with 7075 aluminum, picking the right temper and form is key to getting the best performance for your project. This high-strength aluminum alloy comes in several tempers and product types, each suited for different uses.

Common Tempers Explained

- 7075 T6: The most popular temper, offering excellent strength and good corrosion resistance. Ideal for aerospace and defense use.

- 7075 T651: Similar to T6 but stress-relieved by stretching, reducing warping in fabrication.

- 7075 T73: Offers better corrosion resistance with slightly less strength. Great for applications exposed to harsher environments.

- 7075 T76: Balanced option with good corrosion resistance and mechanical properties.

Product Forms from Vast Options

7075 aluminum is available in many shapes and sizes, making it versatile:

- Sheets and Plates: Perfect for structural parts and aircraft skin.

- Bars and Rods: Common in machining and manufacturing high-precision parts.

- Foils and Coils: Used where lightweight and flexibility matter.

- Extrusions: Custom profiles for construction, automotive, and more.

Fabrication Considerations

- 7075 is heat-treatable but not weld-friendly; welding often weakens the alloy.

- Machining works well, but it’s harder than softer aluminum types like 6061.

- Always choose a temper and form based on the balance between strength, corrosion resistance, and ease of fabrication needed for your project.

By understanding these options, you can select the right 7075 aluminum configuration that fits your specific requirements, especially if sourcing locally in the US or considering customization through a factory partner.

Real World Applications Where 7075 Aluminum

cURL Too many subrequests.

Aerospace and Defense

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Corrosion ResistancecURL Too many subrequests.

- MachinabilitycURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Corrosion ResistancecURL Too many subrequests.

- Applications: 2024 is often found in aerospace where fatigue resistance is critical, while 7075 is preferred for structural strength.

7075 vs 7050

- cURL Too many subrequests.: 7050 is very close to 7075 in strength but often outperforms 7075 in toughness.

- Corrosion Resistance: 7050 offers better corrosion resistance, useful for aerospace parts exposed to more extreme conditions.

- Cost: 7050 is usually more expensive, so 7075 remains popular for cost-conscious projects needing high performance.

Decision Matrix

| cURL Too many subrequests. | 7075 | 6061 | 2024 | 7050 |

|---|---|---|---|---|

| Tensile Strength | Very High | cURL Too many subrequests. | High | Very High |

| Corrosion Resistance | cURL Too many subrequests. | High | Low | High |

| Machinability | Moderate to Low | High | cURL Too many subrequests. | cURL Too many subrequests. |

| Weldability | Poor | Excellent | Poor | cURL Too many subrequests. |

| Cost | cURL Too many subrequests. | Low | cURL Too many subrequests. | High |

| Common Uses | Aerospace, Defense | Automotive, Marine | Aerospace | Aerospace, Defense |

Choosing between these alloys depends on your project’s priorities—strength, corrosion resistance, machinability, or cost. For high-strength needs where weight and toughness count, 7075 aluminum often leads. But if welding or corrosion resistance is top, 6061 or 7050 might suit better.

Sourcing and Best Practices for 7075 Aluminum Projects

When it comes to sourcing 7075 aluminum, especially here in the U.S., quality is non-negotiable. This high-strength aluminum alloy is widely used in aerospace and defense, so you want to make sure you get authentic, heat-treatable aluminum with consistent properties like the well-known 7075 T6 temper. Always choose suppliers with solid quality assurance processes, including certifications like ASTM or AMS standards. That way, you avoid surprises in tensile strength or corrosion resistance that could impact your project.

Cost is another key factor. 7075 aluminum is priced higher than common grades like 6061 because of its advanced composition and superior mechanical traits. But for many users, the investment pays off with better durability and performance in challenging environments. If budget is a top concern, consider working with factories or custom shops in China that specialize in aluminum-zinc alloy products. They often offer competitive pricing and customization options while maintaining good quality—just be sure to verify their track record thoroughly.

Sustainability is becoming a bigger part of material sourcing decisions. 7075 aluminum is fully recyclable, which is a plus if you want to reduce your environmental footprint. Look for suppliers who use recycled content or have responsible manufacturing processes. Also, efficient fabrication practices and minimizing waste during cutting or machining help keep your project greener.

To sum up:

- Choose trusted suppliers with proper certifications

- Balance cost with quality to fit your project needs

- Explore customization options through reputable factories, including those in China

- Prioritize recyclability and responsible manufacturing for sustainability

By following these best practices, you’ll get the most from your 7075 aluminum project with dependable results tailored to the demanding needs of U.S. industries.