Explore expert insights on 5-axis CNC machining precision efficiency and applications in aerospace automotive and electronics manufacturing in China.

Fundamentals of 5-Axis CNC Machining

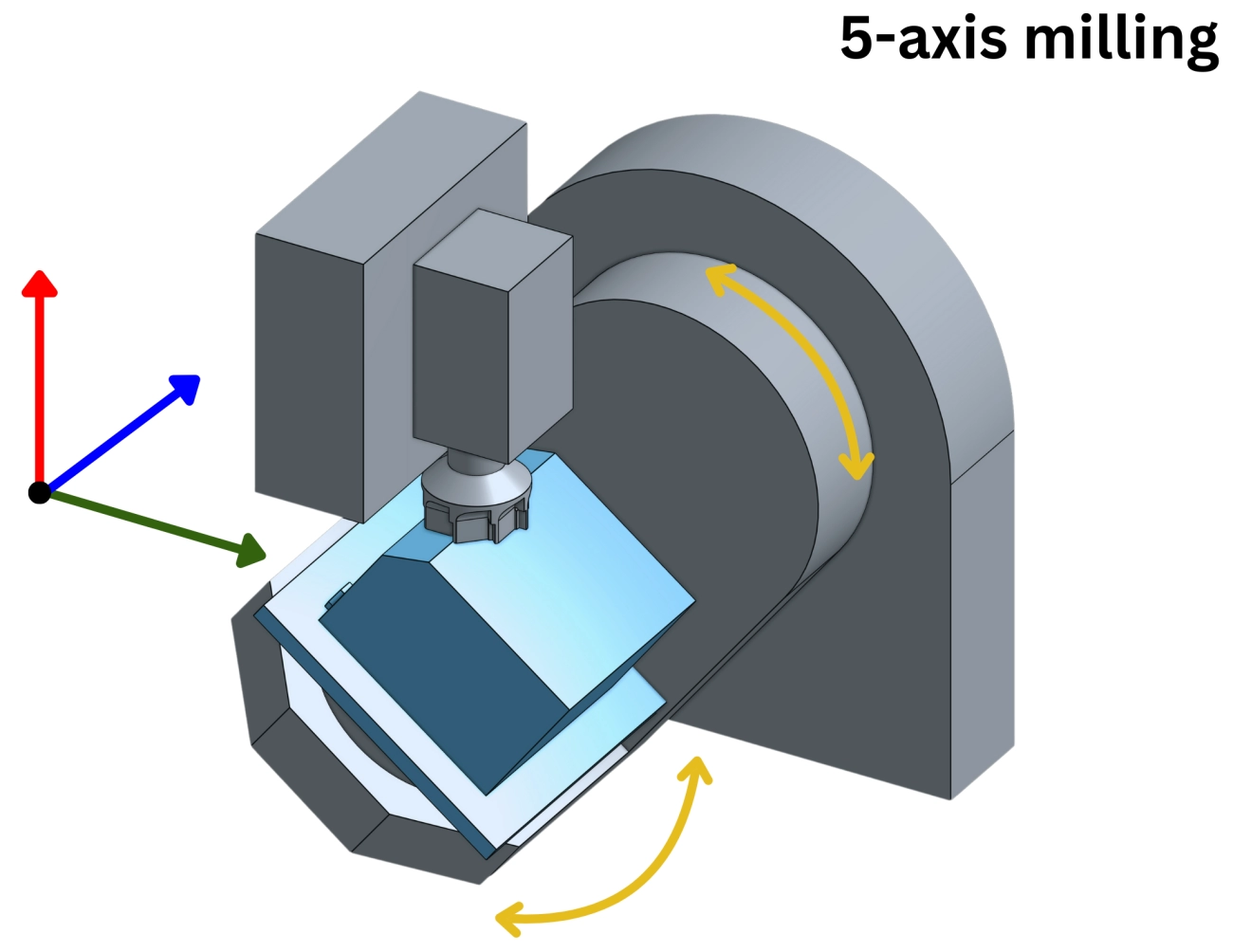

Understanding 5-axis CNC machining starts with grasping its core mechanics and components. Unlike traditional 3-axis machines that move only along the X, Y, and Z linear axes, 5-axis CNC milling adds two additional rotational axes—commonly labeled A, B, and sometimes C. These extra axes allow the cutting tool or the workpiece to rotate, enabling complex shapes and angles to be machined in a single setup.

Breaking Down the Axes

- Linear Axes (X, Y, Z): These control movement left-right, front-back, and up-down, forming the basic foundation of CNC motion.

- Rotational Axes (A, B, C): These allow the tool or table to rotate around one or more linear axes, offering the ability to approach the workpiece from virtually any angle.

Core Components

A 5-axis CNC machine consists of the following key parts:

- Spindle: Holds and rotates the cutting tool.

- Table: The platform where the workpiece is mounted.

- Linear guides and rails: Facilitate smooth movement along X, Y, Z.

- Rotary tables or heads: Provide the additional rotational motions (A, B, or C axes).

- Control system: Converts CAD designs into G-code instructions for precise motion.

cURL Too many subrequests.

5-axis CNC machines come in various styles tailored to different manufacturing needs:

- Vertical Machining Centers: The spindle is vertical; ideal for many aerospace and automotive parts.

- Horizontal Machining Centers: The spindle is horizontal; great for heavy or large workpieces.

- Gantry Style: Large-scale machines where the cutting head moves over a fixed table, suited for very big parts like aerospace turbine blades.

- Bridge Style: A hybrid that offers stability and accessibility, often used in high-precision industries.

How 5-Axis CNC Works

The machining process typically follows these steps:

- Design in CAD Software: Engineers create detailed 3D models using CAD tools.

- Convert to CAM: Computer-Aided Manufacturing software converts designs into toolpaths.

- Generate G-code: The CAM software outputs G-code, guiding every machine movement.

- cURL Too many subrequests. Operators load the workpiece and tools, calibrate the machine, and verify zero points.

- Machining: The CNC controller drives all five axes simultaneously, creating complex geometries with high precision.

- Inspection: Finished parts are inspected to ensure they meet exacting standards.

Mastering these fundamentals of 5-axis CNC machining opens doors to manufacturing complex components with exceptional precision and efficiency. Are you ready to explore how this technology can transform your production line?

Advantages of 5-Axis CNC Over Traditional 3 and 4 Axis Machining

When you compare 5-Axis CNC (5-axis CNC machining) with traditional 3 and 4-axis machining, the differences are clear and impactful. Here’s a quick look at how they stack up:

| Feature | cURL Too many subrequests. | cURL Too many subrequests. | 5-Axis (CNC五轴加工) |

|---|---|---|---|

| Axes Count | 3 (X, Y, Z) | cURL Too many subrequests. | cURL Too many subrequests. |

| Setup Time | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Surface Quality | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

Potential Drawbacks

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

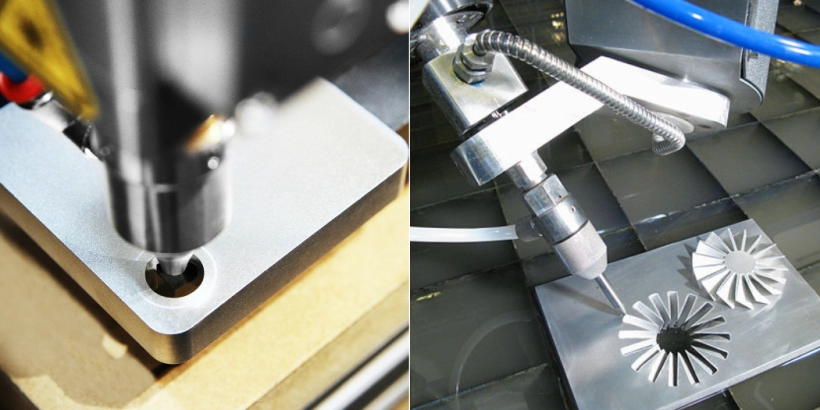

- Aerospace: Manufacturing turbine blades, impellers, and other critical components that require tight tolerances and complex shapes.

- Automotive: Producing aluminum alloy engine parts, dies, and other high-performance components for lighter, stronger vehicles.

- cURL Too many subrequests.: Creating implants and prosthetics with precise fits, often tailored to individual patients.

- Consumer Electronics: Crafting phone casings and intricate molds for durable, sleek products.

- Industrial Molds: Building molds for various industries with complex undercuts and fine details.

Emerging Trends

The future of 5-axis CNC is closely tied to smart tech and new manufacturing methods. Here’s what’s on the rise:

- AI Integration: Smarter machines that predict maintenance needs, reducing downtime.

- Predictive Maintenance: Sensors monitor machine health for proactive repairs.

- Hybrid Manufacturing: Combining additive (3D printing) and subtractive (milling) processes for better flexibility and faster turnaround.

These trends are helping U.S. manufacturers stay competitive by improving efficiency and expanding what’s possible with 5-axis CNC machining.

Step by Step Guide Implementing 5 Axis CNC in Your Workflow

Getting started with CNC five-axis machining can feel complex, but breaking it down makes it manageable. Here’s a straightforward guide to help you implement 5-axis CNC into your workflow efficiently.

Preparation Phase

- cURL Too many subrequests.: Choose CAD/CAM software that supports simultaneous 5-axis machining. Popular options include Fusion 360, Mastercam, and SolidWorks CAM. These help you design complex parts and generate accurate 5-axis toolpaths.

- Materials Selection: Consider the material’s machinability—for example, aluminum alloys used in automotive parts are easier to machine compared to tough aerospace-grade titanium. Knowing your material helps you set the right speeds and feeds.

Programming Essentials

- Collision Avoidance: This is critical in 5-axis CNC milling. Use software features that simulate tool movement to prevent crashes and tool damage.

- Toolpath Strategies: Focus on smooth transitions and simultaneous axis control to ensure a quality finish. Common toolpath types include swarf milling and contouring.

- Tips for Beginners: Start with simpler shapes before moving to complex geometries. Double-check your G-code for accuracy and run simulations whenever possible.

Setup and Operation

- Fixturing Best Practices: Secure the workpiece firmly but avoid over-tightening. Use fixtures that allow access from multiple angles, essential for 5-axis operations.

- Calibration Checklist: Regularly calibrate your machine’s linear and rotational axes (X, Y, Z, A, B, C) to maintain precision. Check tool length offsets and probe accuracy before starting.

cURL Too many subrequests.

- Tool Selection: Use specialized 5-axis tools like ball-end mills and tapered cutters for better surface finishes and complex profiles.

- Coolant Use: Apply proper coolant flow to avoid overheating and improve tool life, especially when machining tough materials.

- Common Errors and Fixes: Watch for issues like chatter, tool deflection, and chatter marks. Adjust feed rates and speeds, and verify toolpath angles to fix these.

Vast Spotlight on Streamlining Solutions

Investing in training and advanced CAM software can significantly reduce setup times and improve consistency. Cloud-based nesting and real-time monitoring tools help streamline production and keep your 5-axis CNC processes running smoothly.

Ready to optimize your workflow with 5-axis CNC machining? Reach out to vast for expert guidance and tailored solutions.

Challenges and Best Practices Overcoming Barriers in 5 Axis CNC

Implementing CNC五轴加工 isn’t without its challenges. Common hurdles include programming errors, machine rigidity issues, and skilled labor shortages. Programming 5-axis toolpaths can get complex fast, which often leads to mistakes that slow down production. Machine rigidity is crucial since any vibration or flex can affect precision, and finding experienced operators who understand simultaneous 5-axis machining is not always easy.

Overcoming These Challenges

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Lead TimescURL Too many subrequests.

- ExperiencecURL Too many subrequests.

cURL Too many subrequests.

| Feature | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Lead Times | Average project turnaround | Meets your project deadlines |

| Customer Support | Availability and technical help | Smooth communication, problem-solving |

Why Choose Vast

Vast stands out by combining state-of-the-art equipment with tailored 5-axis CNC services for the U.S. market. Their strong brand reputation means you get reliability and expertise—essential for aerospace, automotive aluminum parts, and medical implants.

- Cutting-edge machines for flawless performance

- Customized solutions to fit your exact needs

- Experienced engineers for seamless 5-axis toolpath programming

Take Action Now

Ready to improve your manufacturing with reliable 5-axis CNC ? Request a quote from Vast today or download our free e-guide to learn how to get started.