Explore expert tips on grooving tools for CNC machining including types materials and precision features to boost efficiency and tool life.

If you’re working in precision machining, then you already know how critical a grooving tool is for producing flawless parts every time. Choosing the wrong tool—or not fully understanding how to use it—can cost you valuable minutes and compromise quality. Whether you’re cutting O-ring grooves, prepping threads, or parting off sections, mastering the right grooving tool can boost your cycle times and extend tool life significantly.

In this guide, we’ll cut through the noise to show you exactly what makes a top-tier grooving tool, how to pick the right type for your job, and practical tips to get flawless results on your CNC lathe. Ready to ditch the guesswork and upgrade your machining game? Let’s get started.

What Are Grooving Tools A Quick Breakdown

If you’ve ever wondered how precise grooves and slots are cut into metal parts on a CNC lathe, you’re looking at the work of grooving tools. These specialized cutting tools create narrow channels or grooves of varying depths and widths on workpieces, essential for applications like O-ring seats, retaining rings, or decorative finishes.

The Fundamentals of Grooving in Machining

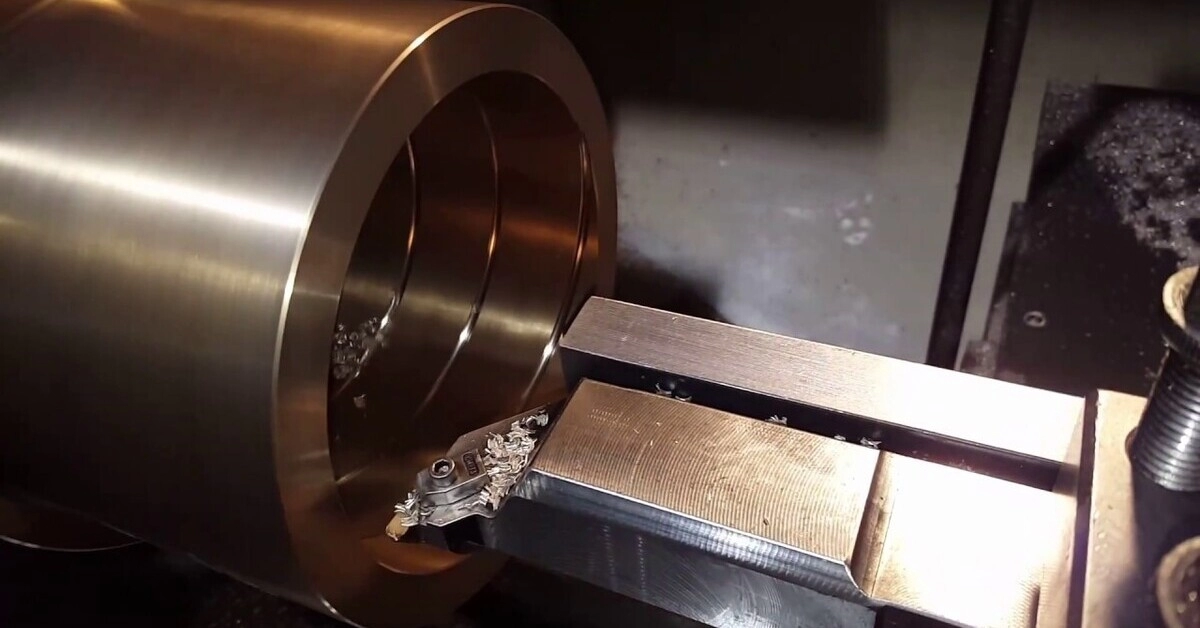

Grooving in machining involves removing material to form a clean, accurate groove on the surface of a part. Unlike general turning, grooving tools focus on accuracy and surface finish in confined spaces. They work by sliding the cutting edge precisely along a defined path while controlling depth and width tightly. This process requires stable tool holding and sharp, robust inserts to avoid chatter, ensure dimensional accuracy, and extend tool life.

Why Grooving Tools Are Essential for Modern CNC Shops

In today’s CNC shops, grooving tools are a must-have, especially for precision lathe grooving. Here’s why:

- Accuracy: Grooving tools enable highly precise cuts, crucial for parts with tight tolerances such as bearing grooves or sealing surfaces.

- Versatility: They handle a wide range of materials from steel to aluminum, often with specialized carbide inserts designed for each job.

- Efficiency: Using the right grooving tool reduces cycle time and tool changes, boosting overall productivity.

- Reliability: Proper grooving tools minimize rework and scrap rates, keeping costs down and quality up.

- Compatibility: Modern grooving tools are designed to fit CNC lathes and Swiss-type grooving holders, making them adaptable to various machining setups.

Simply put, without grooving tools, certain detailed machining tasks would be slower, less accurate, or outright impossible to perform on CNC machines. For shops looking to streamline high-precision production, investing in quality grooving tools is a smart and necessary step.

Ready to find the right grooving tool for your setup? Let’s explore the types and how to choose the perfect one next.

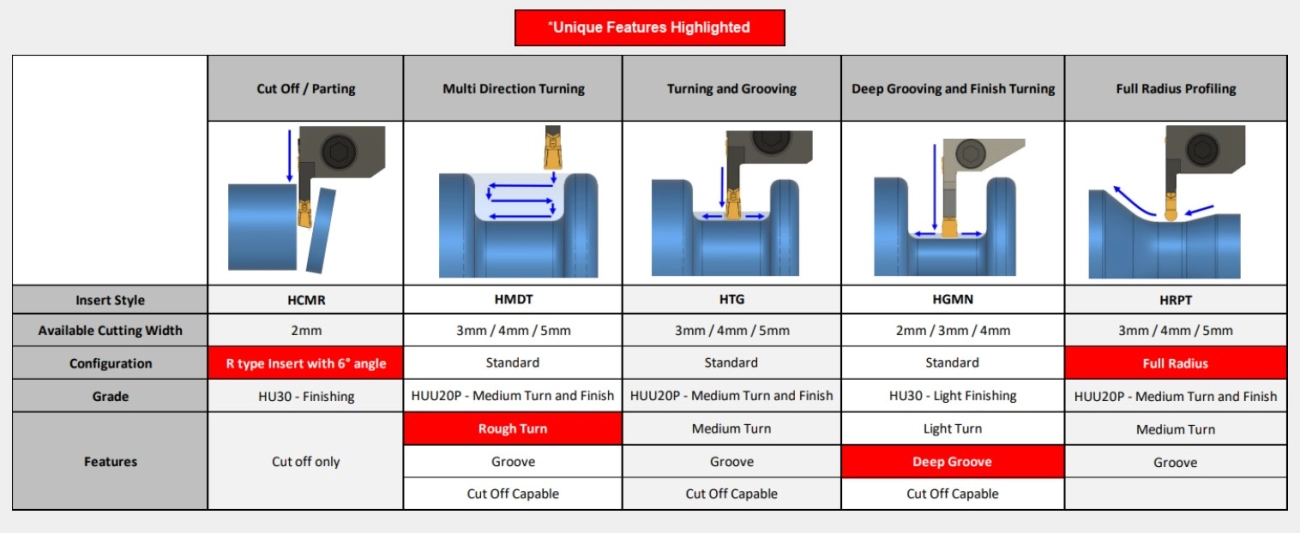

Types of Grooving Tools Choosing the Right One for Your Needs

Choosing the right grooving tool depends on the job and the part you’re working on. Here’s a quick breakdown of the main types you’ll encounter:

External Grooving Tools

These are your go-to for making grooves on the outside diameter of a workpiece. External grooving tools usually come as carbide parting tools or grooving inserts that fit onto CNC lathes. They’re great for precision lathe grooving and can handle a range of groove widths.

Internal and Face Grooving Tools

When you need to cut grooves inside a bore or recess, internal groove machining tools step in. These tools are designed to work within tight spaces and often work alongside Swiss type grooving holders for fine, detailed cuts. Face grooving tools are specialized for grooves on flat surfaces or faces of parts, using face grooving techniques that keep the cuts clean and accurate.

Specialized Variants Full Radius Undercut O-Ring

Sometimes, your job calls for something a little different. That’s where specialized grooving tools come into play. Full radius tools help create smooth, rounded grooves instead of sharp corners. Undercut grooving tools are perfect when you need to clear extra space under shoulders or in slots. O-ring groove cutters are tailored specifically to cut grooves accurately for O-rings, a must for sealing applications in hydraulic and pneumatic parts.

Picking the right grooving tool not only affects your finish quality but also how efficient your setup will be. Knowing the differences makes it easier to zero in on the perfect tool for your job.

Key Factors in Selecting a High-Performance Grooving Tool

Choosing the right grooving tool can make a big difference in your shop’s productivity and part quality. Here’s what you need to focus on:

Material and Coating Considerations

- Carbide Inserts are popular for their toughness and heat resistance, ideal for high-speed machining of tough materials.

- Look for advanced coatings like TiN or TiAlN. They reduce wear, extend tool life, and improve cutting performance on steel, aluminum, and other common metals.

- The right material and coating combo helps you avoid frequent tool changes and reduces downtime.

Specifications That Drive Efficiency

- Groove width and depth: Match your tool’s insert size with the groove dimensions required. Oversized tools can cause chatter and poor finishes.

- Consider insert geometrycURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests..

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.: Tighten the grooving tool holder firmly in the turret or tool post. Any wobble will cause poor cuts.

- Zero your tool offsets: Set your tool position exactly in the CNC control system. This keeps your groove placement precise.

- Check spindle speed and feed: Match the cutting speed to your material. Adjust feed rates to avoid tool wear or poor finish.

Execution Techniques for Flawless Results

- Start with a test cut: Always run a small groove test to check dimensions and finish before full machining.

- Use steady, smooth cuts: Avoid rapid or jerky tool moves. Consistent feed and speed give cleaner grooves.

- Monitor chip evacuation: Chips build-up can damage the cutter. Clear them often using coolant or air blast.

- Use coolant properly: It helps reduce heat and prolongs tool life when grooving metals like steel or aluminum.

Troubleshooting Common Issues

- Poor groove finish: Check tool sharpness and feed rates. Dulling tools or incorrect feeds often cause rough edges.

- Tool breakage: Usually caused by incorrect setup or excessive cutting parameters. Reduce speed or depth of cut.

- Incorrect groove size: Recalibrate tool offsets carefully. Double-check your programming input for groove dimensions.

- Chip clogging: Adjust coolant flow and make sure chip clearance is sufficient for your tool.

Following these setup and execution tips will help you nail the groove every run and keep your tooling in great shape. For more tips on CNC grooving inserts and lathe operations, feel free to browse our detailed guides.

Maximizing Tool Life and Efficiency Pro Tips from vast Experts

Getting the most out of your grooving tools means focusing on maintenance, smart use, and making every cut count. Here are some tips from vast experts to help you boost tool life and efficiency in your shop.

Maintenance and Best Practices

- Regular Cleaning: Keep grooves and cutting edges clean. Built-up material can affect the tool’s precision and shorten its lifespan.

- Check Tool Wear Frequently: Don’t wait until performance drops. Inspect carbide parting tools and CNC grooving inserts regularly for wear signs.

- Proper Storage: Store grooving tools in a dry, organized space to prevent damage or corrosion between uses.

- Use Correct Speeds and Feeds: Follow manufacturer recommendations. Running tools too fast or too slow wears them out quickly.

- Sharpness Matters: Dull tools cause chatter and poor finishes. Rotate or replace inserts timely to keep quality high.

Cost-Saving Strategies for Local Manufacturers

- Invest in Quality Tools: High-quality tools might cost more upfront but save money by lasting longer and reducing downtime.

- Optimize Setup Times: Use standard holders and quick-change systems to cut setup and calibration.

- Match Tools to Jobs: cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.