Discover what a pump house is its design types functions and maintenance tips for efficient water system management in homes and industries.

What Exactly Is a Pump House Core Definition and Purpose

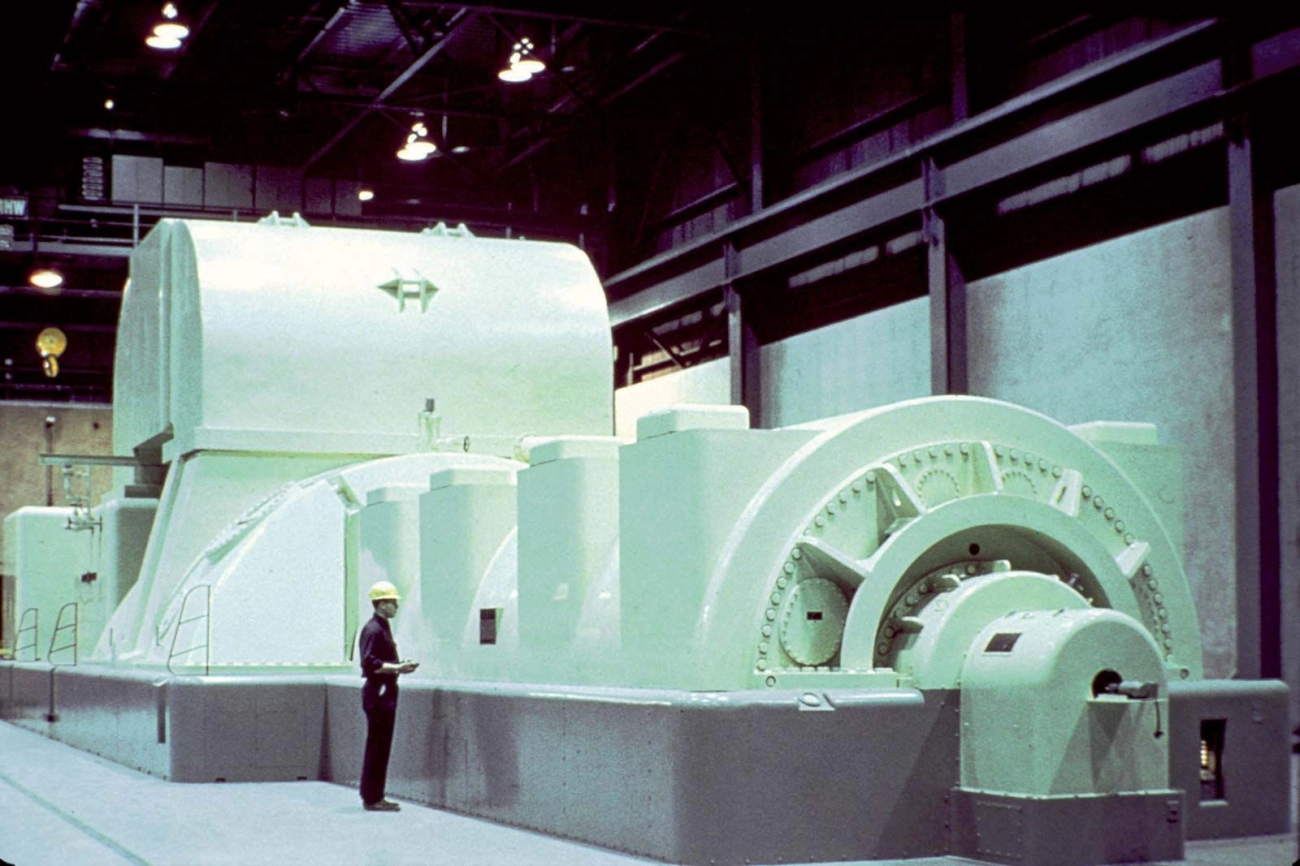

A pump house is a protective building designed to house essential pumping equipment like pumps, motors, control panels, and piping systems. Its main role is to safeguard this equipment from weather, debris, and vandalism while ensuring smooth and reliable water flow. Additionally, a pump house helps maintain compliance with safety and environmental regulations, protecting both the system and the people around it.

Pump houses are crucial in various applications—from supplying water in residential areas to managing large-scale industrial or municipal water systems. They create a controlled environment that optimizes pump performance and extends equipment life.

Here’s a quick comparison to clarify how a pump house differs from related structures:

| Feature | Pump House | Well House | Pumping Station |

|---|---|---|---|

| Main Use | Protects pumps & controls | Covers well head & basic controls | Large-scale water transfer & treatment |

| Scale | Residential to industrial | Mostly residential or small farms | Municipal, industrial |

| Equipment Housed | Pumps, motors, electrical controls | Well pumps, simple controls | Multiple pumps, filtration, valves |

| Purpose | Reliable water distribution | Water access & protection | High-capacity water management |

| Complexity | Moderate to high | Low to moderate | High |

Understanding this helps when deciding the right solution for your water system needs, whether you’re managing a backyard well or a city’s water supply.

Anatomy of a Pump House Essential Components and How They Work

A pump house is more than just a shelter—it’s a carefully designed system where several parts come together to keep water flowing smoothly. The core components include pumps and motors, control systems, as well as piping and ventilation.

Pumps and Motors are the heart of any pump house. The most common types you’ll see are centrifugal pumps, which use spinning action to move water, and submersible pumps, which sit underwater and push water up. Choosing the right pump affects how efficiently your system runs, so it’s key to match pump size and type to your water needs to save energy and avoid overworking the motor.

Control Systems and Electricals include components like PLC (Programmable Logic Controllers) and RTU (Remote Terminal Units). These are the brains behind automation, helping to optimize pump operation, monitor performance, and reduce energy costs. Modern pump houses may use these systems for seamless automatic control, making sure everything runs reliably without manual intervention.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

When building a pump house, the first thing to consider is sizing and site selection. Make sure you calculate the space needed for all equipment, including pumps, motors, controls, and piping. Keep clearances in mind, especially following NFPA codes, to allow for proper maintenance and safety access.

Next up is materials and construction. Common choices include concrete for durability, or polyethylene for lightweight, weather-resistant options. Pick materials that hold up well against your local climate—whether it’s humid, hot, or freezing cold. This ensures your pump house stays solid year-round.

Don’t forget about regulations and permits. Depending on where you are, you’ll need to comply with US EPA guidelines, local zoning laws, and any residential restrictions. Getting permits upfront avoids headaches down the road.

Here’s a simple step-by-step build process with rough cost basics:

- Plan and design layout

- Obtain permits

- Prepare foundation

- Construct walls and roof

- Install pumps, motors, controls, and piping

- Connect electrical and control systems

- Final inspection and testing

Costs typically range from a few thousand dollars for a small residential pump house to tens of thousands for larger or custom builds.

Case study: A homeowner in a suburban neighborhood blended their pump house into their backyard by using a small, brick enclosure with a sloped roof matching their home style. This design kept the structure low profile while meeting all operational needs and local codes, proving that practical can also look good.

In short, careful planning with the right materials and compliance will get you a durable, efficient pump house that fits your property and water systems perfectly.

Maintenance Essentials Keeping Your Pump House Running Smoothly

To keep your pump house reliable, regular maintenance is a must. Here’s a quick checklist to stay on top of things:

- Routine Inspections: Check pumps, motors, and piping for any signs of wear or leaks.

- Cleaning Strainers: Remove debris regularly to prevent clogs that can reduce water flow.

- Electrical Checks: Inspect wiring, control panels, and switches to avoid unexpected failures.

If you run into problems, these are common issues and how to handle them:

- Motor BurnoutcURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- Seamless integration with your landscape or existing facilities for better aesthetics

- Enhanced energy efficiency with advanced pump control systems included

Customer Success

We’ve helped numerous U.S. customers improve water reliability and reduce downtime. One recent project saw a suburban community upgrade their well pump house with our modular enclosure, cutting installation time by 40% and reducing maintenance calls by half. That’s the kind of results you can expect with Vast.

Choosing Vast means getting a durable, efficient, and smart pump house solution designed with your local needs in mind.