X2CrNiMoN22-5-3 Duplex 2205 Stainless Steel Properties and Applications

Explore X2CrNiMoN22-5-3 Duplex 2205 stainless steel with high strength corrosion resistance and precise alloy specifications for industrial applications.

What is X2CrNiMoN22-5-3 Duplex 2205

X2CrNiMoN22-5-3, commonly known as Duplex 2205, is a high-performance stainless steel that combines the best features of both austenitic and ferritic stainless steels. This dual-phase structure gives Duplex 2205 a unique balance of strength, corrosion resistance, and durability.

Definition and Classification

Duplex 2205 is classified as an austenitic-ferritic stainless steel, also referred to as duplex stainless steel. It features a microstructure with roughly equal parts of austenite and ferrite, which enhances its mechanical properties and resistance to various forms of corrosion.

Common Designations

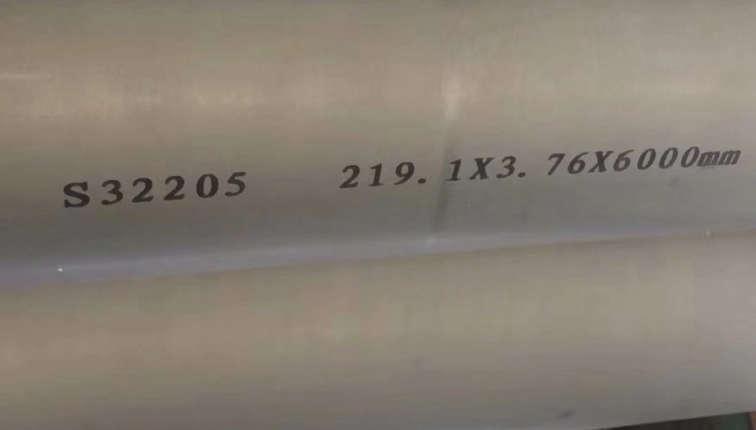

You may see Duplex 2205 identified under different industry standards and codes such as:

- UNS S32205

- ASTM A182 F60

- EN 1.4462

These designations refer to the exact chemical composition and mechanical properties that meet international standards for reliability and performance.

Key Characteristics

Duplex 2205 is widely recognized for its:

- High Strength: Roughly twice the strength of conventional austenitic stainless steels like 316L.

- Superior Corrosion Resistance: Excellent resistance to chloride-induced pitting and stress corrosion cracking.

- Cost-Effectiveness: Offers long service life and durability which reduce maintenance and replacement costs.

Comparison with Other Stainless Steels

Compared to popular stainless steels like 316L and UNS S31803, Duplex 2205 offers:

- Higher strength and better corrosion resistance than 316L.

- Improved resistance to stress corrosion cracking over UNS S31803 due to optimized nitrogen content.

- Enhanced performance in harsh environments such as marine, chemical, and offshore applications.

In , X2CrNiMoN22-5-3 Duplex 2205 is a premium stainless steel choice when you need a dependable, strong, and corrosion-resistant material that performs better than many standard steels at a competitive cost.

Chemical Composition and Standards

X2CrNiMoN22-5-3, also known as Duplex 2205, has a carefully balanced chemical makeup that gives it its outstanding strength and corrosion resistance. Typically, it contains:

- Chromium (Cr): 21-23% – boosts corrosion resistance

- Nickel (Ni): 4.5-6.5% – stabilizes the austenitic phase for toughness

- Molybdenum (Mo): 2.5-3.5% – improves pitting and crevice corrosion resistance

- Nitrogen (N): 0.14-0.20% – enhances strength and resistance to stress corrosion cracking

This combination classifies Duplex 2205 as an austenitic-ferritic stainless steel, striking a balance between durability and corrosion resistance.

The material meets several important standards used widely in the U.S. and globally, including:

- ASTM A182 – covers forgings for high-temperature service

- EN 1.4462 (European Standard designation)

- BS 2338 – British Standard for stainless steels

When selecting Duplex 2205, one key factor to consider is the cURL Too many subrequests.. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. tensile strength cURL Too many subrequests. yield strength cURL Too many subrequests. cURL Too many subrequests., cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests., cURL Too many subrequests., and cURL Too many subrequests.. cURL Too many subrequests. fatigue, cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

Duplex 2205 (X2CrNiMoN22-5-3) shines in industries where strength and corrosion resistance are critical. Here’s where it’s commonly used:

- Oil and GasIt’s a go-to for offshore platforms, underwater pipelines, and subsea equipment, thanks to its ability to handle harsh marine environments and resist corrosion from saltwater and chemicals.

- Chemical ProcessingDuplex 2205 is trusted for making heat exchangers, pressure vessels, and storage tanks because it withstands aggressive chemicals and high temperatures.

- Marine EngineeringFrom shipbuilding to desalination plants and coastal structures, this material resists rust and wear even in salty, humid conditions.

- ConstructionYou’ll find Duplex 2205 in bridges, structural supports, and architectural cladding where durability and long-term performance are priorities.

Case Study: Vast’s Offshore Project Supply

Vast recently supplied Duplex 2205 for a major offshore platform project in the Gulf of Mexico. The steel met strict ASTM A182 F60 standards and handled extreme marine conditions flawlessly, proving its reliability and durability for heavy industrial use.

Benefits of Using X2CrNiMoN22-5-3 in Your Projects

Choosing X2CrNiMoN22-5-3 (Duplex 2205) for your projects brings several clear advantages. First off, its superior corrosion resistance stands out against standard austenitic stainless steels like 304 or 316. This means you get much better protection in harsh environments, especially against pitting and crevice corrosion, which are common concerns in marine, chemical, and offshore settings.

Another big plus is its high strength-to-weight ratio. Duplex 2205 offers nearly double the strength of regular austenitic steels, so you can use less material without sacrificing durability. This often translates into reduced material costs and easier handling during construction or installation.

Versatility is key with Duplex 2205. It’s used across many industries — from oil and gas, chemical processing, and marine engineering to construction and desalination. Its combined toughness and corrosion resistance make it a go-to choice where reliability and longevity are critical.

Finally, sustainability plays a growing role in material selection. Duplex 2205 has a long service life thanks to its resistance to wear and corrosion, which lowers replacement frequency. Plus, it’s fully recyclable, supporting eco-friendly practices without compromising performance.

These benefits make X2CrNiMoN22-5-3 a smart choice if you want a cost-effective, durable, and sustainable stainless steel solution tailored for demanding U.S. industrial applications.

Why Choose Vast as Your Duplex 2205 Supplier

At Vast, we bring years of experience in stainless steel manufacturing and supply, specializing in premium-grade Duplex 2205 like X2CrNiMoN22-5-3. Our expertise ensures you get consistently high-quality materials tailored to your project needs.

We strictly follow ASTM, EN, and ISO standards to guarantee quality and reliability in every batch. Whether you need standard stock, custom forgings, fasteners, or precision components, we offer flexible solutions that fit your specifications.

With a strong global network, Vast delivers promptly and reliably to industrial clients across the U.S. and worldwide. Our commitment to quality and service has earned us trusted partnerships in challenging sectors like oil and gas, chemical processing, and marine engineering.

Here’s what one customer said after working with us on a major offshore project:

“Vast’s Duplex 2205 supply exceeded our expectations. Their support and on-time delivery made a huge difference for our tight schedule and demanding environment.”

Choose Vast for Duplex 2205 stainless steel and experience dependable sourcing with expert support every step of the way.

Comparing Duplex 2205 with Other Alloys

When looking at Duplex 2205 versus UNS S31803, the differences are minor because they are closely related grades. Both have similar chemical compositions with balanced amounts of chromium, nickel, and molybdenum. However, Duplex 2205 (X2CrNiMoN22-5-3) often has slightly higher nitrogen content, which boosts strength and corrosion resistance a bit more compared to UNS S31803.

Comparing Duplex 2205 to 316L, the differences are more noticeable:

- cURL Too many subrequests.: Duplex 2205 is roughly twice as strong as 316L, allowing for thinner, lighter components.

- Corrosion resistance: Duplex 2205 performs much better in harsh environments, especially against pitting and crevice corrosion, thanks to higher chromium, molybdenum, and nitrogen.

- Cost: 316L is generally cheaper upfront, but Duplex 2205’s longer lifespan and reduced maintenance can lower overall expenses.

When to Choose Duplex 2205

Pick Duplex 2205 if you need:

- Superior corrosion resistance in chloride-rich or aggressive environments.

- Higher strength to reduce material thickness and weight.

- Long-term reliability with less downtime and maintenance.

- Applications in oil and gas, marine, or chemical processing where conditions are tough.

If your project requires only moderate corrosion resistance or a tighter budget, 316L can still be a practical choice. But for demanding jobs, Duplex 2205 gives you extra confidence and durability, making it often the smarter investment.

cURL Too many subrequests.

cURL Too many subrequests.

- Material Selection: cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- Budget: cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

Frequently Asked Questions

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.