Learn about common welding faults causes types and prevention tips to ensure strong defect-free welds in manufacturing and fabrication processes.

If you’re working with welding, you already know that even a small mistake can lead to costly failures and safety risks. Welding faults aren’t just imperfections—they’re potential weak points that threaten the integrity of your entire project. Whether you’re dealing with weld cracks, porosity, or incomplete fusion, understanding these common issues is crucial to producing strong, reliable joints every time. In this guide, you’ll discover what causes welding defects, how to spot them early, and proven ways to prevent them—empowering you to take control of quality and safety in your welding work. Let’s dive in.

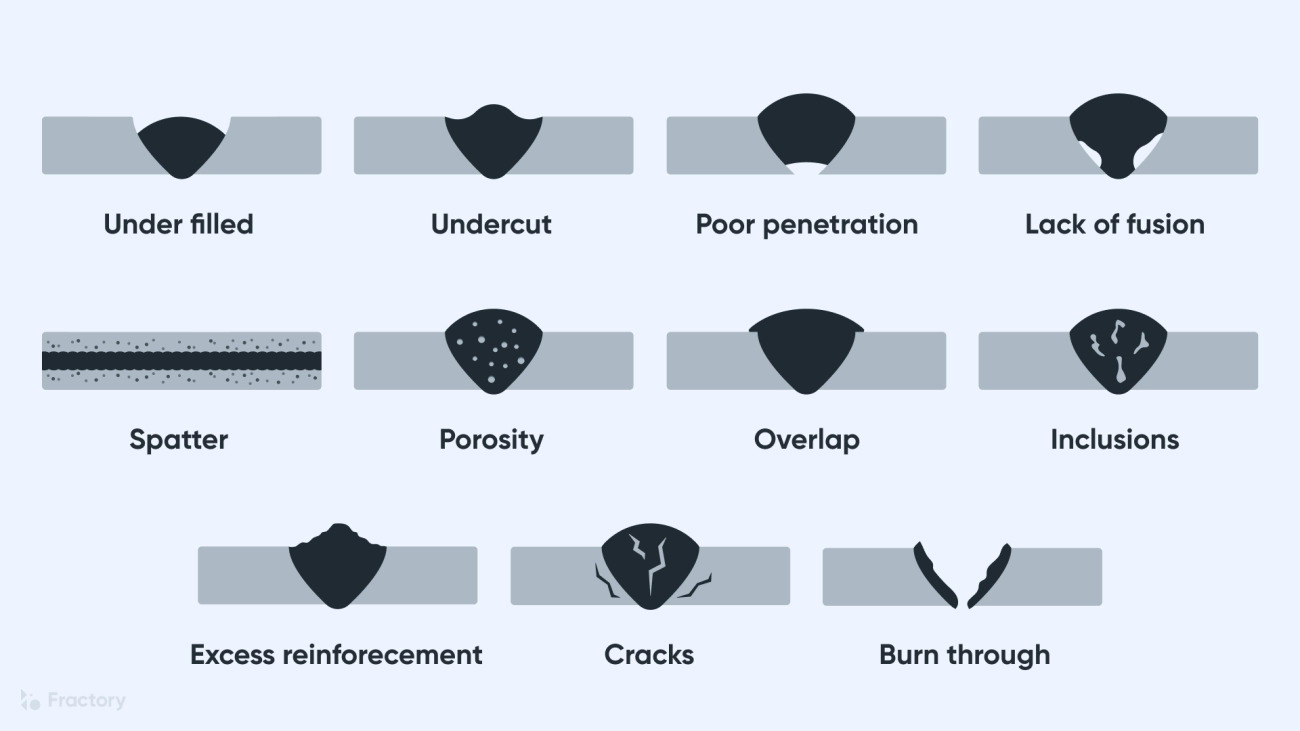

Common Types of Welding Faults

If you’ve ever dealt with welding, you know things don’t always go as planned. Welding faults can cause weak joints, safety risks, and costly repairs. Let’s break down the most common types of welding faults so you can spot and avoid them.

External Surface Defects

These are visible problems on the weld’s surface that affect appearance and strength:

- Undercut: A groove melted into the base metal near the weld toe, which reduces weld thickness and weakens the joint.

- Spatter: Small droplets of molten metal that splash around the weld area, creating a rough and messy surface.

- Overlap: Occurs when the weld metal flows over the base metal without fusing, leading to weak connections.

- Burn Through: Happens when excessive heat causes a hole in the base metal, compromising the weld’s integrity.

Internal Defects

These flaws aren’t visible right away but seriously affect weld strength:

- Porosity: Tiny gas pockets trapped inside the weld, weakening the joint and causing potential failure.

- Slag Inclusions: Non-metallic solid material trapped inside the weld, often from flux residues, that leads to weak spots.

- Incomplete Fusion: When the weld metal doesn’t fully bond with the base metal or previous weld beads, resulting in gaps.

- Incomplete Penetration: This happens when the weld doesn’t extend fully through the thickness of the joint, creating weak areas.

Cracks

Cracks are among the most critical faults and can appear during or after welding:

- Hot Cracks: Occur as the weld cools and solidifies, often caused by improper cooling rates or weld metal composition.

- Cold Cracks: Appear after welding has cooled; often due to hydrogen absorption or residual stress.

- Crater Cracks: Develop at the end of the weld bead when the molten pool shrinks too quickly.

- Lamellar Tearing: Happens in the base metal next to the weld zone, caused by heavy stresses or poor metal quality.

Dimensional Imperfections

These affect the shape and size of the welded assembly, impacting fit and function:

- Distortion: Warping of the welded parts caused by uneven heating and cooling.

- Excessive Reinforcement: Too much weld metal added, leading to stress concentration or bad appearance.

- Warpage: Twisting or bending of the material due to improper heat control.

By understanding these common welding faults—both visible and hidden—you can better inspect welds and take the right steps to prevent them from causing issues down the line.

Root Causes of Welding Faults

Welding faults often start because of issues with the process itself. Using incorrect parameters like wrong current, voltage, or speed can lead to common defects. Also, applying the wrong welding technique or skipping steps usually causes problems like poor fusion or undercuts.

Material and environmental factors play a big role too. Contamination on the metal surface—like rust, oil, or dirt—can cause porosity in welding or slag inclusions. Using incompatible filler metals or having poor shielding gas flow allows air to mix in, leading to weld cracks and weak joints.

Human and equipment errors are another common root cause. Operator inexperience often results in inconsistent welds or missed defects. Faulty electrodes and uncalibrated machines also mess with the weld quality, causing issues like incomplete penetration or weld distortion.

Finally, some industries face specific triggers. High stress joints, common in automotive and aerospace applications, are more prone to cracks and failures. These industries require stricter control to prevent welding faults that can impact safety and performance.

Detection and Inspection Methods for Welding Faults

Finding welding faults early is key to keeping your projects safe and strong. We use a mix of methods to spot issues like porosity in welding, weld cracks, or slag inclusions before they become serious.

Visual Testing

The simplest and fastest way to catch surface defects like undercut weld or spatter. Just looking closely can reveal overlap, burn through, or excessive reinforcement.

Non Destructive Testing (NDT)

NDT keeps the weld intact while checking for hidden issues. Common types include:

- Dye Penetrant: Helps find cracks and surface flaws by applying a special dye that seeps into defects.

- Magnetic Particle: Uses magnets to detect surface and near-surface weld cracks.

- Ultrasonic Testing: Sends high-frequency sound waves through welds to locate internal defects like incomplete fusion or slag inclusions.

- Radiographic Testing (X-Ray): Provides images inside the weld to spot internal porosity or cracks.

Destructive Testing

Used mostly for verification in critical applications where safety is vital. This involves cutting and testing the weld physically to confirm strength and integrity.

Advanced Tools

In high-demand settings, real-time monitoring systems and sensors catch faults as they happen. Early detection helps avoid rework and costly downtime.

Using these inspection methods ensures weld quality and meets industry standards, especially in fields like automotive and aerospace where reliability matters most.

Prevention and Remedies for Welding Faults

Preventing welding faults starts with following best practices. Proper preparation is key: make sure surfaces are clean and free of contaminants before welding. Preheating the material when necessary can help avoid cracks and improve weld quality. Using optimized welding parameters—like the right current, speed, and angle—and selecting low hydrogen consumables also reduce common issues such as porosity and incomplete fusion.

Adjusting your welding technique plays a big role too. Multi-pass welding helps when working with thick materials, while controlled cooling prevents warpage and distortion. Using precision equipment ensures more consistent welds and fewer mistakes.

Training and quality control are essential for lasting results. Certified welders familiar with procedure specifications produce more reliable work. Regular maintenance of welding machines prevents equipment-related faults.

If welding defects occur, remedies include grinding out the faulty weld and rewelding the area. In some cases, preheat or post weld heat treatment may be necessary to relieve stress and prevent cracks. Properly addressing faults right away saves time and expenses down the line.

Advanced Solutions and Vast Expertise

Welding technology has come a long way, and today’s advanced solutions help tackle welding faults more effectively. Automation plays a big role — machines with sensors monitor weld quality in real time, catching issues before they turn into defects. Vast welding systems now integrate robotics, precise controls, and smart adjustments, reducing human error and improving consistency.

Process improvements have also made a difference. For example, using automated welding in high-volume manufacturing helps prevent common faults like porosity and incomplete fusion by keeping parameters constant. Real-world case studies show lower rejection rates and improved durability when these technologies are in place.

Looking ahead, AI-driven defect prediction is set to change the game. By analyzing welding data, AI can predict when and where faults might occur, helping operators make adjustments right away. Sustainable welding practices are also gaining traction, focusing on reducing waste, using eco-friendly consumables, and improving energy efficiency without sacrificing quality.

With these tools and expertise combined, welding faults are becoming easier to manage, ensuring stronger, more reliable welds for industries across the U.S.