Explore the 32-125 surface finish range explaining Ra values, measurement methods, machining tips, and applications for precise industrial parts.

What Does 32-125 Surface Finish Mean

When you hear 32-125 surface finish, it refers to the range of surface roughness measured in microinches (µin). Specifically, this is about Ra, or the arithmetic average roughness, which is the most common way to quantify how smooth or rough a surface is on a microscopic level. Ra calculates the average height deviations of a surface profile from its mean line, helping engineers understand the texture of the surface.

A 32 µin Ra finish means a very smooth, finely ground surface often used for sealing areas or precision fits. In contrast, a 125 µin Ra finish is rougher, typical of standard machined parts like those made by milling or turning, where a finely polished surface isn’t essential.

Surface texture isn’t just about roughness (Ra); it also includes:

- Waviness: Larger scale surface deviations or waves that occur over a longer distance.

- Lay: The direction of the surface pattern or texture, usually influenced by the manufacturing process.

It’s important not to confuse Ra with other measurements like RMS (root mean square) or Rz (average peak-to-valley roughness). Ra gives an arithmetic average of surface peaks and valleys, while RMS offers a slightly different statistical average often a bit higher, and Rz measures the average height between the highest peaks and lowest valleys. Knowing these differences helps you get a more comprehensive picture of surface quality depending on your application.

Surface Roughness Conversion Charts for 32-125 Ra Values

Understanding how 32-125 Ra microinches translate to other units and standards helps when specifying surface finishes in the U.S. market.

| Ra (µin) | Ra (µm) | ISO Grade | Approximate Grit Equivalent | Typical Use Example |

|---|---|---|---|---|

| 32 | 0.8 | N7 | 400-600 grit | Sealing surfaces, precision fits |

| 63 | 1.6 | N8 | 220-320 grit | General machined surfaces |

| 125 | 3.2 | N8-N9 | 100-180 grit | Standard machined parts, flanges |

Visual comparators, often used in quality control, clearly show the difference between a 32 Ra surface and a 125 Ra one. The finer 32 Ra surface feels smooth to the touch and is perfect for seals or gaskets where tight sealing is critical. Meanwhile, 125 Ra is the typical finish for general machining—rougher but cost-effective and functional for parts where extreme smoothness isn’t necessary.

Knowing these conversions helps you pick the right finish and avoid overspending on unnecessarily tight tolerances.

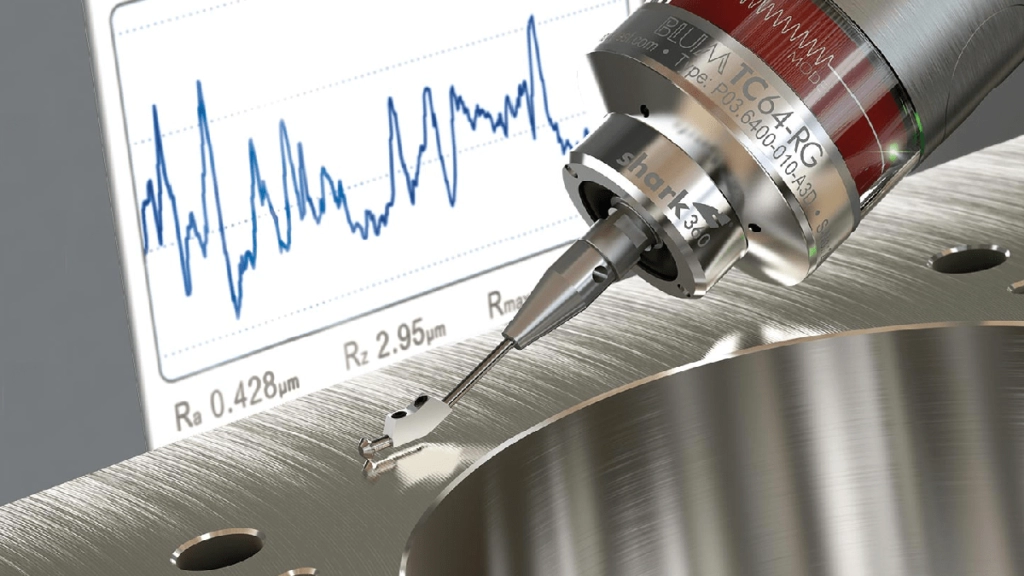

How to Measure and Specify 32-125 Surface Finish

Measuring surface finish between 32 and 125 microinches (Ra) usually involves tools like profilometers. These come in two main types:

- Stylus profilometers that use a tiny needle to trace the surface, giving precise roughness readings

- Optical profilometers that scan without touching the part, great for delicate or soft materials

On engineering drawings, surface finish is shown with standardized symbols—most commonly following the ASME Y14.36 standard. These symbols specify the required Ra value and sometimes the evaluation length, or the exact surface area to measure.

A common mistake is overspecifying the surface finish. For example, requiring 32 microinch finish when 125 microinch is perfectly fine for the part. This drives up costs unnecessarily and can cause compliance issues if local manufacturing standards don’t match the spec. Always match the surface finish to actual functional needs to balance quality and budget.

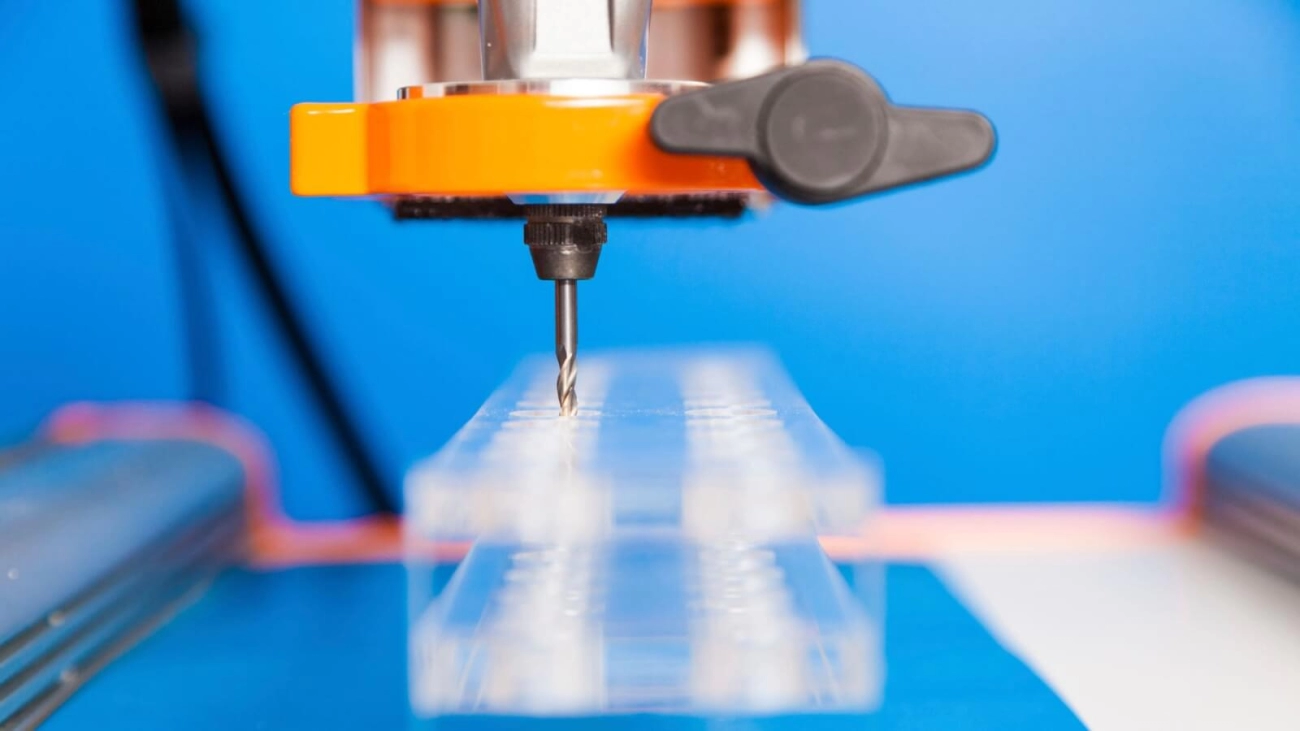

Achieving 32-125 Surface Finish in Machining Processes

Getting a surface finish between 32 and 125 Ra involves controlling several machining factors. For a typical 125 Ra finish, common in general machining, CNC milling or turning with moderate feed rates works well. Using the right tool nose radius and stepover helps maintain consistent roughness without overworking the material.

To reach a finer 32 Ra finish, extra steps like grinding and polishing come into play. Grinding smooths the surface further, while polishing removes even smaller imperfections. These processes require slower feeds and smaller tool marks to achieve that finer texture.

Calculators for scallop height—the small curves left by each tool pass—help predict and adjust surface roughness based on feed rate, tool size, and step-over. Keep in mind, material type plays a big role too. Softer metals may respond differently to cutting parameters than harder alloys, affecting final finish results.

At Vast, we optimize these parameters for the best balance of speed, cost, and precision. Our machining setups focus on efficient techniques that hit target tolerances without wasting time or resources, ensuring your parts meet the desired 32-125 Ra finish every time.

Applications and Importance of 32-125 Ra in Industry

The 32-125 Ra surface finish range plays a key role in many industries, especially where part performance and longevity matter. For example, flanges and gaskets commonly use finishes around 125 microinches for sealing purposes. These finishes help meet industry NDT (non-destructive testing) standards and sanitary requirements, ensuring reliable, leak-free connections.

Here’s why this range matters:

- Reduces friction: Smoother surfaces cut down on friction between parts, which improves efficiency and lowers wear.

- Improves adhesion: Finishes like 32 Ra are ideal for coatings and adhesives, helping materials bond better.

- Prevents corrosion: Proper surface texture can reduce corrosion risks by limiting moisture traps.

- Impacts longevity: Maintaining the right finish supports part durability under stress.

- Standards compliance: Many industry codes like ASME B16.5 specify surface roughness to ensure safe, consistent performance.

When deciding where to use 32-125 Ra, consider this:

- Use 125 Ra for general parts where cost-effectiveness is a priority and extreme precision isn’t critical.

- Go for 32 Ra when high-precision fits or seals are needed, such as in hydraulic systems or critical sealing surfaces.

This balance lets you optimize costs while meeting the quality and performance expectations typical in the U.S. manufacturing sector.

Tips from Vast Optimizing Surface Finish for Your Projects

When working with a 32-125 surface finish, it’s all about finding the right balance between quality and cost. Here are some best practices to help you optimize your surface finish:

- Match finish to function: Use 125 Ra microinches for general parts where cost savings matter. Reserve 32 Ra for critical surfaces like seals or precision fits.

- Communicate clearly: Specify your surface finish on drawings using accepted symbols (like ASME Y14.36) to avoid confusion.

- Avoid overspecifying: Don’t ask for a finer finish than necessary—it drives up machining time and costs without added benefits.

- Use expert machining: Vast’s precision machining capabilities ensure consistent 32-125 Ra finishes with tight tolerances.

- Consider material effects: Different materials respond differently to machining processes; plan accordingly.

- Monitor waviness and lay: These subtle factors often cause problems if overlooked, even when Ra looks good.

Common Questions about Surface Finish

Q: How is Ra different from other roughness measures?

Ra is the arithmetic average of surface irregularities, but RMS (root mean square) or Rz (average peak-to-valley) offer more complete insights in some cases.

Q: Why does waviness matter?

Waviness refers to longer wavelength surface variations and can affect sealing and wear despite a good Ra value.

Q: How do I measure surface finish accurately?

Use stylus profilometers or optical scanners for non-contact measurement, keeping evaluation lengths consistent.

If you’re unsure about which surface finish fits your project or need custom prototypes with reliable 32-125 Ra finishes, contact Vast for expert consultations and solutions tailored to your needs.