Learn how to ream holes precisely with expert tips on tools, techniques, and troubleshooting for smooth finishes and tight machining tolerances.

Fundamentals of Reaming

The Reaming Process Explained

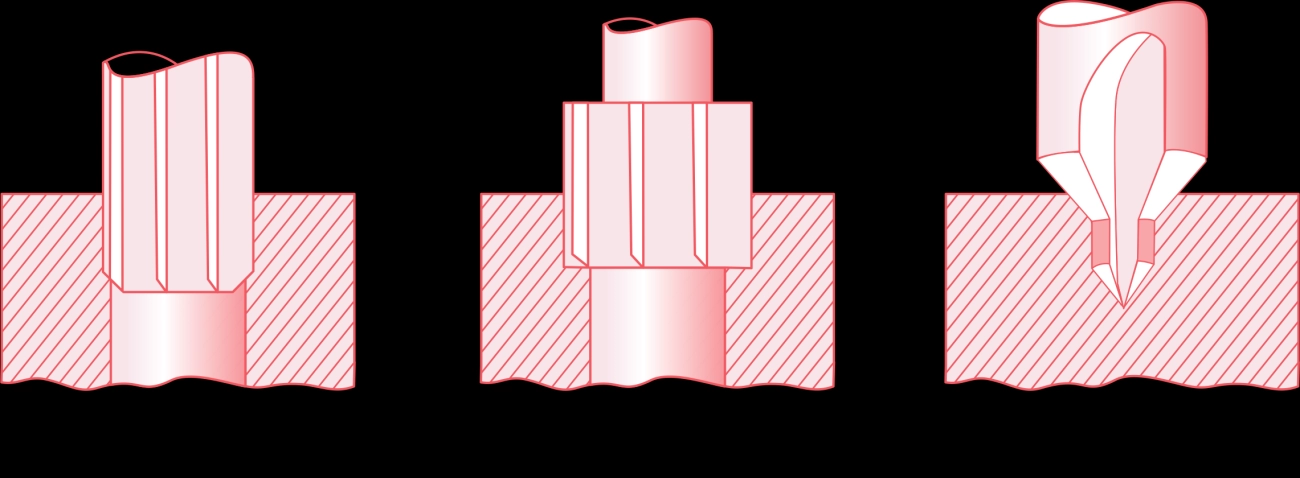

Ever wondered what reaming holes really means and why it’s a crucial step in precision machining? Reaming is a machining process designed to enlarge and finish drilled holes to exact sizes with smooth, accurate surface finishes. Unlike drilling, which creates the initial hole, reaming refines that hole—removing a thin layer of material to achieve precise diameters and better roundness.

The process uses a cutting tool called a reamer, available in various types like hand reamers, machine reamers, and CNC reamers. Reamers have multiple straight or helical cutting edges that gently shave off material, improving hole surface finish and dimensional accuracy.

When to Use Reaming

You should use reaming holes whenever you need:

- Tight machining tolerances — When hole diameter has to be exact within thousandths of an inch.

- Improved surface finish — To reduce roughness left by drilling for better fit and sealing.

- Consistent roundness — For precise fitment of parts like bushings, bearings, or pins.

- Hole size correction — Slightly enlarging drilled holes to match design specifications.

Reaming is the go-to finishing process if you’re dealing with critical fits in automotive components, aerospace parts, and high-precision DIY projects. It’s not just a punch-list step, but a key process for functional and reliable assemblies.

Essential Tools and Materials from Vast

When prepping for reaming, having the right tools and materials makes all the difference. Here’s what you typically need from trusted suppliers like Vast:

- Precision reamer tools tailored to hole size and material type.

- Cutting fluid for reaming to reduce heat, prevent tool wear, and improve surface finish.

- Machine setup whether hand reaming tools or CNC hole enlargement machines.

- Measurement instruments such as micrometers and bore gauges to ensure machining tolerances are met.

Choosing quality tools and proper cutting fluids from a reliable source helps ensure efficient cutting, longer tool life, and flawless hole finishing techniques.

Mastering the fundamentals of reaming holes sets the stage for precise, smooth, and perfectly sized holes that meet demanding specifications. In the next sections, we’ll walk through a step-by-step guide to executing flawless reaming every time.

Step by Step Guide to Reaming Holes

Pre Reaming Preparation

Before you start reaming holes, make sure the drill size matches the rough hole you want to finish. A hole slightly smaller than the final diameter is ideal for the drill and ream process. Check your precision reamer tools for any damage or wear. Clean the hole and work area to remove chips and debris, which can affect the surface finish improvement. Also, pick the right cutting fluid for reaming—this helps reduce heat and gives a smoother finish.

Executing the Ream

Set your reamer speeds and feeds according to the material you’re working with. Too fast can cause chatter or tool breakage, too slow can leave poor finishes. Use steady, gentle pressure—don’t force the tool. Keep the reamer straight to avoid oversized or undersized holes. If you’re working by hand, follow a hand reaming guide: start slow, keep the tool aligned, and finish in one smooth pass if possible. For CNC hole enlargement, programming the correct feed rates is key for consistent results.

Post Reaming Inspection

After reaming, clean the hole to remove chips and leftover cutting fluid. Use a micrometer or gauge to check the hole diameter and ensure it meets your machining tolerances. Inspect the surface for any rough spots or irregularities. If the finish isn’t perfect, you might need a light polish or to recheck your process steps. Proper inspection helps avoid common reaming errors and keeps your work reliable.

Following these steps makes reaming holes straightforward and consistent, leading to precision fits and high-quality finishes every time.

Advanced Techniques and Best Practices for Flawless Results

When reaming holes, dialing in advanced techniques can make a huge difference in achieving precision and consistency. Here are some tips that help avoid common pitfalls and improve your overall hole finishing techniques.

Material-Specific Adjustments

Different materials need different approaches:

- Aluminum and Soft Metals: Use slower reamer speeds and plenty of cutting fluid to prevent clogging and overheating.

- Steel and Hardened Metals: Opt for harder, high-quality precision reamer tools and maintain stricter machining tolerances by controlling feed rates carefully.

- Plastics and Composites: Apply very light pressure and slower speeds to avoid cracking or melting.

Adapting your process to the material helps maintain sharp cutting edges and prevents oversized or undersized holes.

Scaling for Production

If you’re moving from hand reaming guide techniques to a production environment:

- CNC Hole Enlargement: Integrate CNC machines for consistent hole sizing; program reamer speeds and feeds precisely.

- Tool Monitoring: Regularly check tools for wear to keep reaming holes within tolerance.

- Batch Testing: Inspect samples frequently to catch deviations early and tweak cutters or machine settings.

This approach boosts efficiency and reduces downtime across larger runs.

Integrating with Broader Workflows

Reaming is often part of a bigger machining process, like drill and ream process setups.

- Sequence Planning: Drill first with a slightly smaller bit, then follow up with reaming to achieve tight tolerances and a smooth finish.

- Cutting Fluid Use: Always apply the correct cutting fluid for reaming to reduce tool wear and improve surface finish improvement.

- Post-Reaming Inspection: Implement standardized checks, like measuring diameters and roundness, to ensure quality before moving to assembly or next steps.

Keeping reaming aligned with your entire workflow helps maintain part quality while optimizing time and resources.

By fine-tuning these advanced techniques, you’ll get flawless results that meet the high standards required in industries like automotive and aerospace or even DIY projects needing precision.

Troubleshooting Common Reaming Problems

Reaming holes usually goes smoothly, but sometimes issues pop up. The most common problems are oversized or undersized holes, chatter, poor surface finish, and breakage. Here’s a quick guide to spot and fix these problems.

Oversized or Undersized Holes

- Cause: Wrong reamer size, worn-out tools, or incorrect speeds and feeds.

- Fix: Always double-check the reamer size before starting. Replace dull or damaged reamers. Adjust speeds and feeds to match the material and tool recommended specs.

Chatter and Poor Finish

- Cause: Too high speed, lack of cutting fluid, or a loose setup.

- Fix: Lower the reamer speeds and feeds. Use the right cutting fluid for reaming to improve lubrication and reduce heat. Tighten your setup to avoid vibration during reaming.

Broken Reamer

- Cause: Excessive force, tool wear, or wrong feed rate.

- Fix: Apply steady, moderate pressure. Stop if you feel resistance and check the tool condition. Use a slower feed rate if the material is tough.

Quick Diagnostic Checklist

- Check the reamer condition — sharp and undamaged?

- Confirm speeds and feeds are set properly.

- Ensure workpiece is clamped tightly, no movement.

- Verify use of cutting fluid suitable for reaming.

- Inspect the hole size regularly during the process.

Following these steps avoids most common reaming problems, improving your hole finishing techniques and keeping your projects on track.

Real World Applications and Case Studies

Reaming holes isn’t just a workshop skill—it’s crucial across many industries and projects here in the U.S.

Automotive Reaming Applications

In the automotive world, reaming is key for getting precision fits in engine components and transmission assemblies. Using precision reamer tools ensures holes meet tight machining tolerances, improving parts’ reliability and longevity. It’s common in repair shops and manufacturing plants to improve hole dimensions after drilling to reduce wear and tear.

Aerospace Precision Fits

Aerospace demands flawless holes for critical components, so the surface finish improvement from reaming is a must. Here, CNC hole enlargement combined with precise reaming speeds and feeds guarantees components align perfectly, ensuring flight safety and performance. Tight machining tolerances in aerospace mean even minor errors can be a big deal, so reaming is a go-to step in the manufacturing process.

DIY Garage Projects and User Stories

For hobbyists and garage mechanics, hand reaming guides simplify the process of perfecting holes in engine parts, brackets, or custom builds. Whether you’re upgrading suspension or building a hot rod, reaming provides the finish needed to avoid issues like misalignment or uneven surfaces. Using cutting fluid for reaming and proper hole finishing techniques can make a big difference in results.

Future Trends in Reaming

Looking ahead, automation and smart machining solutions are shaping the future of reaming holes. Integrating reaming with broader workflows—including drill and ream process automation—is making it easier to scale for production while reducing common reaming errors. Expect more CNC-driven precision and adaptive tooling, especially as materials and designs become more complex.

If you want to dig deeper into advanced reaming methods and industrial setups, check out our detailed guides on CNC hole enlargement and machining tolerances to sharpen your process even more.