Learn rapid prototyping methods tools and benefits to speed up product development with practical tips and expert insights for all industries.

If you’ve ever felt stuck watching your product ideas get tangled in lengthy development cycles, you’re not alone. Rapid prototyping is the secret weapon that’s revolutionizing how innovators, designers, and engineers bring concepts to life—fast, lean, and with less risk. In this post, you’ll discover exactly what rapid prototyping is, why it matters, and how to use it to cut down costly revisions and launch smarter products quicker than ever before. Ready to unlock faster innovation? Let’s dive in.

The Fundamentals What Exactly is Rapid Prototyping

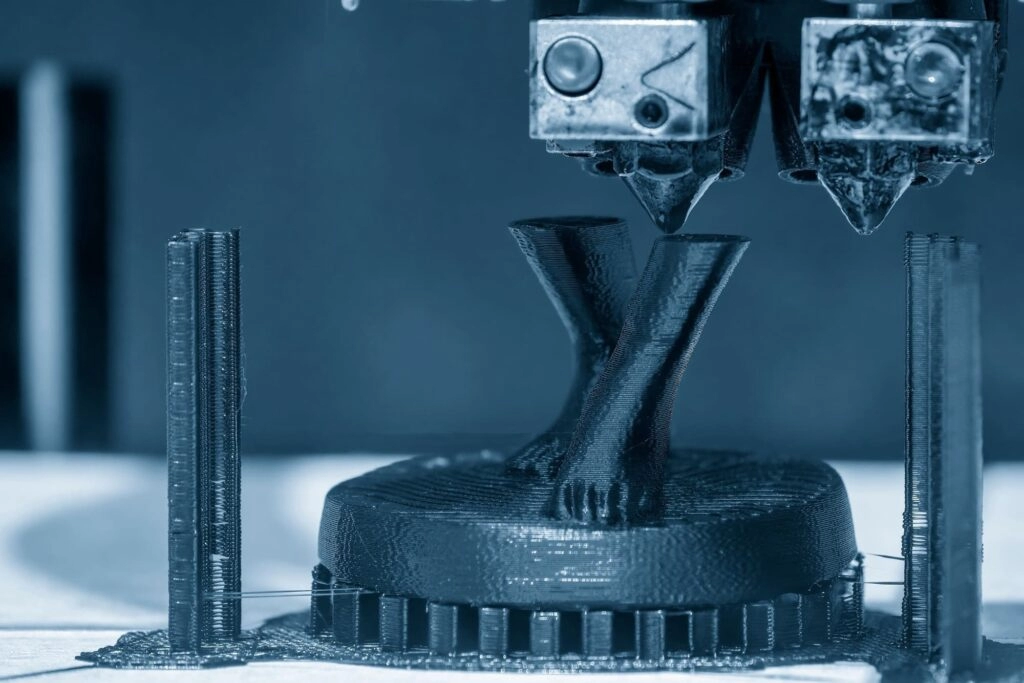

Rapid prototyping is a fast, cost-effective way to create physical models or digital versions of a product before full-scale production. It allows designers and engineers to turn ideas into tangible prototypes quickly, helping to identify design flaws, test functionality, and refine concepts. By using techniques like 3D printing, CAD modeling, and CNC machining for prototypes, rapid prototyping cuts down the lengthy development cycles common in traditional manufacturing.

At its core, rapid prototyping is about speed and iteration. You can move from low-fidelity mockups to detailed, functional versions with ease. This process supports agile design validation and product iteration cycles, making it ideal for both startups and established companies looking to stay competitive. Whether you’re developing a new device, improving an existing one, or testing UX wireframing tools, rapid prototyping is a foundational step to bring your vision closer to reality, without costly delays or setbacks.

The Rapid Prototyping Process A Step-by-Step Blueprint

Rapid prototyping starts with an idea that you want to bring to life quickly. Here’s a simple step-by-step breakdown of how it usually works:

- Concept DevelopmentYou begin with sketches or low-fidelity mockups to outline your product’s basic shape and function. This early stage helps get your ideas down fast without investing too much time.

- CAD ModelingNext, you turn your sketches into detailed 3D models using CAD modeling techniques. This digital version allows you to visualize everything before building anything physical.

- Selecting the Right MethodDepending on your project, you pick a rapid prototyping method. 3D printing prototypes are common for quick turns, but sometimes CNC machining for prototypes or other additive manufacturing basics fit better for your needs.

- Building the PrototypeThe physical model is created based on your digital design. This step involves the actual printing or machining, depending on the method selected.

- Testing and FeedbackOnce your prototype is ready, you use prototype testing methods to see how well it works. This could be functional testing, user feedback, or checking the fit and finish.

- Iteration CyclesRapid prototyping is all about fast product iteration cycles. You go back to your CAD model, tweak it based on test results, and build improved versions until it meets your goals.

This process helps save you tons of time and money compared to traditional development. Whether you’re working in the U.S. or looking for rapid prototyping options like rapid prototyping Foundry or rapid prototyping China, understanding these steps gets you closer to your final product faster.

Key Methods and Tools Choosing the Right Fit for Your Project

When it comes to rapid prototyping, picking the right method and tools can make all the difference. You want something that matches your project’s needs, timeline, and budget.

Popular Rapid Prototyping Methods

- 3D Printing PrototypesGreat for creating detailed, physical models fast. Ideal if you need a quick look or feel of your design. Commonly used with additive manufacturing basics like FDM or SLA technologies.

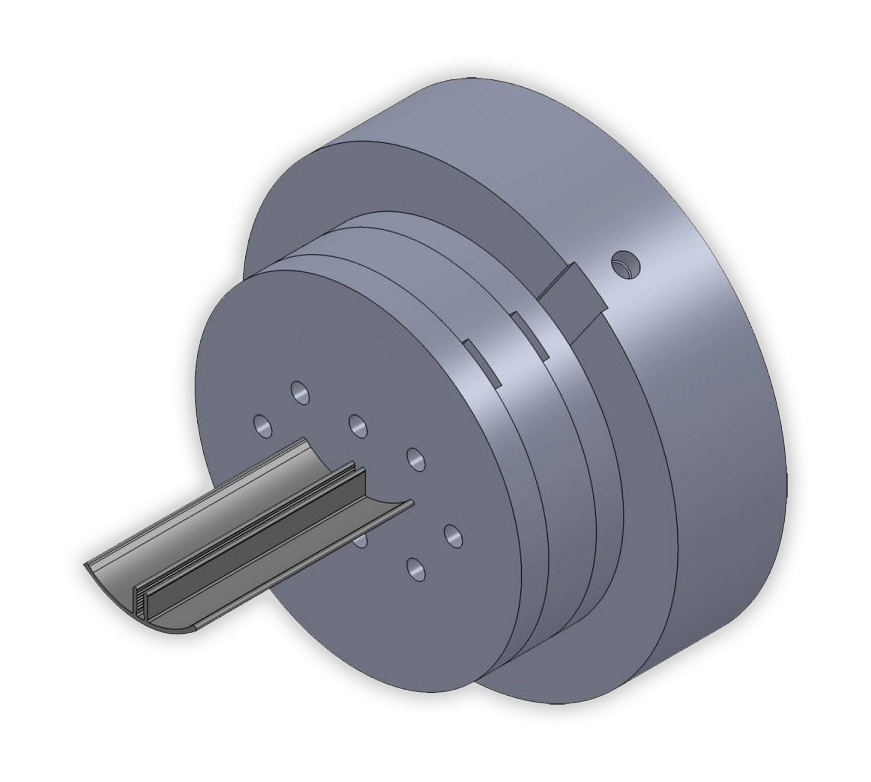

- CNC Machining for PrototypesBest for parts that need precision and durability. It’s a subtractive method that carves your design from solid materials, perfect for testing mechanical fits.

- Low-Fidelity MockupsSimple and cost-effective, these are rough versions made from cardboard, foam, or clay. Great for early-stage UX wireframing tools and design validation.

- CAD Modeling TechniquesDigital blueprints let you iterate product designs quickly. Using CAD software, you can try multiple product iteration cycles without wasting materials.

How to Choose the Right Tool

- Project ComplexityUse 3D printing for complex shapes and CNC machining for precise, mechanical parts.

- BudgetLow-fidelity mockups keep costs low in early testing, while 3D printing offers a middle ground for quick and accurate models.

- TimeframeIf you’re on a tight schedule, go for rapid methods like 3D printing or using UX wireframing tools for fast design validation.

- Material NeedsFor real-world application tests, CNC prototypes with actual materials give the best insights.

Choosing the right mix of these methods can help you save money, reduce product iteration cycles, and get your design to market faster — particularly important if you’re working with local rapid prototyping foundries or looking for rapid prototyping in China options that fit your specifications.

Real-World Applications Rapid Prototyping Across Industries

Rapid prototyping is changing the way businesses build and test products across many industries here in the U.S. From startups to large manufacturers, companies are using this approach to speed up design and improve quality without blowing budgets.

Manufacturing and Engineering

3D printing prototypes and CNC machining for prototypes let manufacturers create precise models quickly. These prototypes help catch design flaws early, reducing costly mistakes on the production floor.

Consumer Electronics

In tech, rapid prototyping supports fast product iteration cycles. Companies use CAD modeling techniques and low-fidelity mockups to test looks, feel, and function before finalizing designs. This means faster launches and better devices for customers.

Healthcare and Medical Devices

Additive manufacturing basics allow creation of custom implants and surgical tools tailored to patients. Rapid prototyping accelerates validation and compliance testing, helping new medical products reach market faster.

Automotive and Aerospace

Here, prototype testing methods ensure parts meet strict safety and performance standards. Rapid prototyping lets teams try different materials and designs without waiting months, saving time and money.

UX and Software Development

Although less physical, UX wireframing tools for rapid prototyping are critical for validating user interfaces and experience early on. This agile design validation improves digital products before costly coding begins.

Across the board, rapid prototyping helps American companies stay agile, innovate quickly, and meet customer needs more effectively. Whether you’re in Silicon Valley or the industrial Midwest, rapid prototyping is a practical tool for cutting costs and speeding up development.

The Proven Benefits How Rapid Prototyping Saves Time Money and Headaches

Rapid prototyping is a game-changer when it comes to speeding up product development. By creating quick 3D printing prototypes or low-fidelity mockups early on, you can spot design flaws before investing big bucks in full production. This cuts down product iteration cycles, letting you refine your design faster without wasting resources.

Here’s how rapid prototyping saves you serious time and money:

- Faster design validation: Using CAD modeling techniques and prototype testing methods helps you quickly check if your idea works, so you avoid long back-and-forths.

- Reduced development costs: Instead of producing expensive tooling or molds right away, you test concepts with affordable prototypes made through additive manufacturing basics or CNC machining for prototypes.

- Lower risk of errors: Catching problems early means fewer revisions later, which minimizes headaches and delays.

- Better collaboration: Sharing physical models or UX wireframing tools helps your team and clients understand the product better, speeding up approvals.

- Improved customer feedback: You can get real-world input early on by showing prototypes, so final products are more aligned with market needs.

For U.S. businesses working with rapid prototyping foundries or sourcing from places like rapid prototyping China, efficiency and cost control are key. Using rapid prototyping properly lets you stay competitive and bring products to market faster, all while managing budgets more effectively.

Common Challenges and How to Overcome Them

Rapid prototyping offers a lot, but it’s not without its hurdles. Knowing what to expect can save you time and frustration. Here are some common challenges we see and how you can tackle them.

1. Managing Cost Overruns

Rapid prototyping might sound cheap, but costs add up if you don’t watch them. Material waste, multiple iterations, and expensive tools can drive prices higher.

- Tip: Use low-fidelity mockups or basic CAD modeling techniques early on to test ideas without breaking the bank. Reserve expensive 3D printing prototypes or CNC machining for final rounds.

2. Longer Than Expected Turnaround Times

Even with “rapid” in the name, delays happen—shipping parts, printer queues, or design revisions can slow your project down.

- Tip: Build a realistic timeline that includes buffer time. Partner with local rapid prototyping foundries or services in the US to speed up turnaround and cut shipping time.

3. Difficulty in Achieving Exact Specifications

Sometimes printed or machined prototypes don’t perfectly match your CAD designs, especially with complex details or tight tolerances.

- Tip: Collaborate closely with your prototyping provider. Share clear CAD files, use prototype testing methods early, and understand the limits of additive manufacturing basics.

4. Handling Multiple Iterations Efficiently

Rapid prototyping encourages quick product iteration cycles, but managing those versions can get messy. Tracking changes and feedback can slow down the process.

- Tip: Use agile design validation strategies. Keep detailed notes and version controls, and involve your team regularly to align on goals.

5. Integrating UX Wireframing Tools with Physical Prototypes

If you’re working on digital-physical products, syncing UX design with physical form can be tricky.

- Tip: Test UX wireframes alongside low-fidelity mockups and refine before moving to physical models. This saves time and prevents costly redesigns.

Navigating these challenges is part of using rapid prototyping well. Address them early and you’ll find the process smoother, more cost-effective, and quicker—just what you need in today’s fast-paced markets.

Best Practices for Success Tips from Vast Experts

When it comes to rapid prototyping, following expert-backed best practices can seriously boost your chances of success. Here are some practical tips from the pros at Vast, tailored for product developers in the US market:

- Start with Clear GoalsDefine what you want to learn or test with your prototype. Whether it’s form, function, or user experience, having a clear focus saves time and cuts unnecessary rounds of product iteration cycles.

- Choose the Right Tool for the JobDon’t force 3D printing prototypes if a simple low-fidelity mockup or UX wireframing tool will do. Sometimes CAD modeling techniques or CNC machining for prototypes provide better accuracy, depending on your project’s needs.

- Keep It Simple Early OnUse basic, low-cost materials to create early versions. This makes it easier to quickly test, gather user feedback, and tweak designs — part of the agile design validation that accelerates development.

- Test Often and Iterate FastPrototype testing methods should be part of your process from day one. Frequent testing identifies problems early, which prevents expensive fixes later.

- Communicate Clearly with Your TeamWhether you’re working with a rapid prototyping foundry locally or sourcing parts from rapid prototyping China, clear specs and constant updates help avoid misunderstandings and delays.

- Leverage Cost-effective Product DevelopmentRapid prototyping should reduce overall cost. Use additive manufacturing basics and other modern methods strategically to avoid waste and optimize materials.

- Document EverythingKeeping good records of your prototype versions, feedback, and changes makes it easier to track progress and justify decisions.

Following these straightforward guidelines will help you get the most out of rapid prototyping and streamline your path to a successful product launch.

Case Studies Rapid Prototyping in Action with Vast

At Vast, we’ve seen firsthand how rapid prototyping transforms ideas into real products quickly and efficiently. Here are a few examples showing how our clients across the US have leveraged rapid prototyping to speed up their product iteration cycles and get to market faster.

Medical Device Innovation

A client developing a new medical tool used our CAD modeling techniques paired with 3D printing prototypes to create multiple low-fidelity mockups. This allowed them to test functionality and ergonomics early without high costs. Thanks to additive manufacturing basics, they cut development time by 40%.

Consumer Electronics

For a startup building a smart home gadget, we combined CNC machining for prototypes with rapid 3D printing. This mix helped them validate product design and test UX wireframing tools effectively, resulting in quick agile design validation that minimized costly redesigns.

Automotive Parts Development

An automotive supplier working with us on rapid prototyping in China used our expertise to build accurate, functional parts with both CNC machining and additive methods. This approach saved them money and sped up product iteration cycles, getting prototypes ready for testing faster.

At Vast, our goal is to make rapid prototyping cost-effective product development that meets the unique needs of the US market. We offer personalized guidance, helping you overcome common challenges and delivering reliable prototype testing methods every step of the way.

Future Trends What’s Next for Rapid Prototyping

Rapid prototyping keeps evolving fast, especially here in the U.S. where industries demand quicker, smarter product development. Here’s what’s shaping the future:

1. Advanced 3D Printing Prototypes

Expect more precise and faster 3D printing prototypes with new materials. This means better product iteration cycles and stronger, more functional prototypes right from the start.

2. Integration with AI and Machine Learning

AI-driven CAD modeling techniques will help designers spot flaws early and speed up revisions. This smart automation makes agile design validation smoother and more cost-effective.

3. Hybrid Prototyping Methods

Combining additive manufacturing basics like 3D printing with CNC machining for prototypes is becoming popular. It offers both speed and durability where needed, fitting different project demands.

4. Sustainable Materials and Processes

Eco-friendly prototypes are gaining traction. Using biodegradable or recycled materials in rapid prototyping not only cuts waste but also appeals to environmentally conscious consumers.

5. Cloud-Based Collaboration Tools

With teams often spread across states—or overseas like rapid prototyping from China—cloud platforms make sharing CAD files and UX wireframing tools seamless. This boosts efficiency and keeps everyone on the same page.

6. Customized and On-Demand Prototyping

Local businesses want prototypes tailored to their audience with quicker turnaround times. Rapid prototyping foundries offering on-demand services help U.S. companies meet this need without massive inventory.

Keeping up with these trends means faster, smarter, and more affordable product development. If you’re looking to stay competitive, embracing these future directions in rapid prototyping is key.

FAQ Section

What is rapid prototyping?

Rapid prototyping is a fast way to create a physical model of a product using techniques like 3D printing prototypes or CNC machining for prototypes. It helps teams test and improve designs quickly.

How does rapid prototyping save time and money?

By cutting down product iteration cycles and spotting design issues early, rapid prototyping reduces expensive mistakes and speeds up development, making product development more cost-effective.

What are common rapid prototyping methods?

Popular methods include additive manufacturing basics like 3D printing, CNC machining, and creating low-fidelity mockups or CAD modeling techniques to visualize a product.

Can rapid prototyping be used for software or UX design?

Yes, tools like UX wireframing help create quick, testable versions of apps or websites, following the same agile design validation principles used in physical product prototyping.

Is rapid prototyping suitable for all industries?

Absolutely. From automotive and aerospace to consumer goods and electronics, rapid prototyping is widely used for fast, flexible product development across industries.

What challenges come with rapid prototyping?

Challenges include managing material costs, choosing the right prototype testing methods, and balancing speed with quality. Partnering with a reliable rapid prototyping foundry, including options like rapid prototyping China suppliers, can help.

How do I choose the right rapid prototyping service?

Look for experience with your product type, reliable turnaround times, and clear communication. Local providers familiar with the US market often offer better support and faster service.

Where does rapid prototyping fit in the product development cycle?

It’s best early on for design validation and continues through testing and refinement stages, speeding up feedback and helping teams make informed decisions faster.