Learn precise slot milling techniques with expert tips on tools, feeds, speeds, and cutting parameters for flawless CNC groove machining.

Understanding Slot Milling The Fundamentals Every Machinist Needs What Is Slot Milling and When to Use It

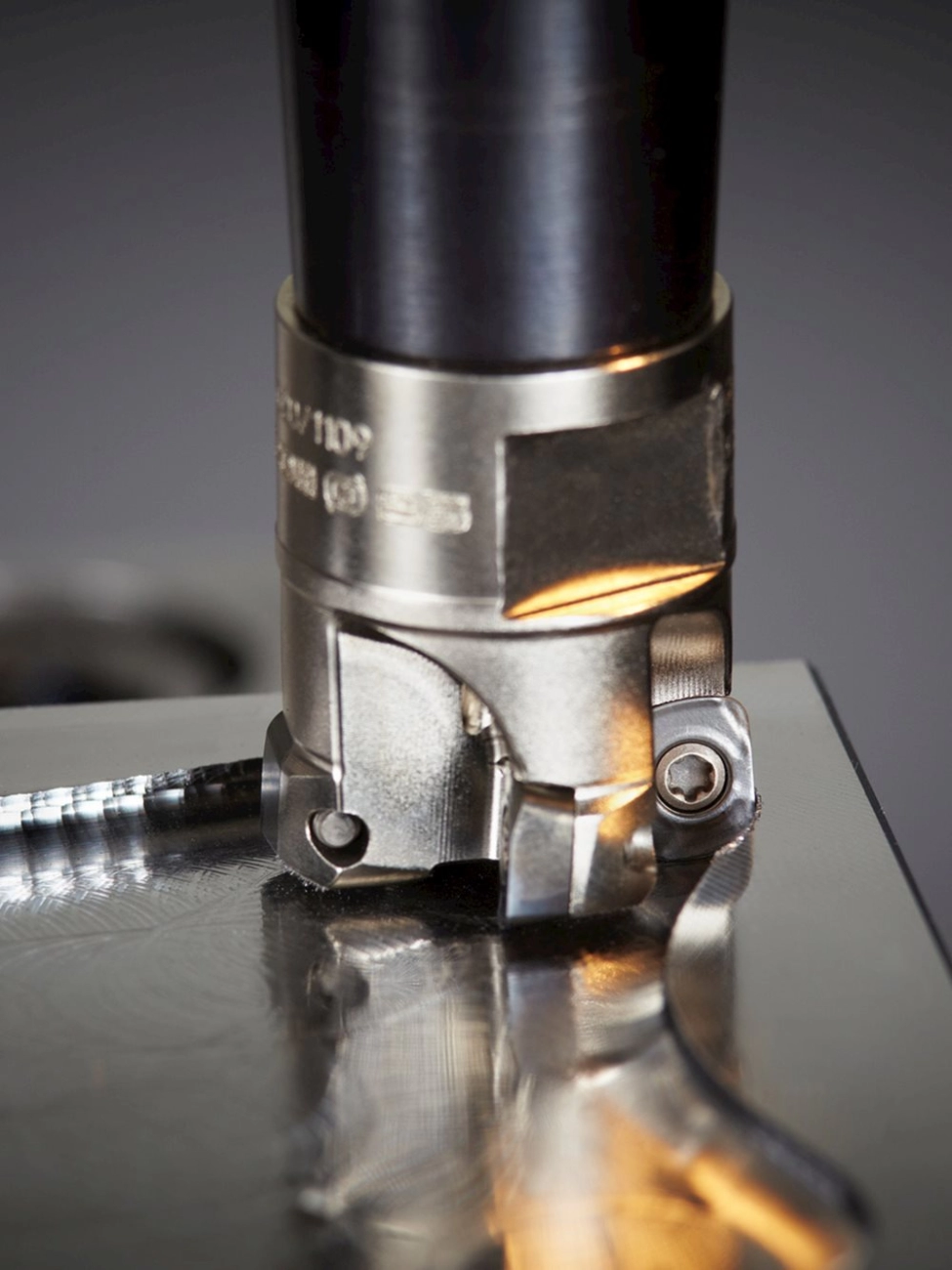

Ever wondered how machinists cut precise grooves or channels into metal parts? That’s where slot milling comes in. Slot milling is a process where a milling cutter removes material from a workpiece to create a straight slot or groove, usually wider than the cutter’s diameter. It’s a fundamental technique for making keyways, T-slots, or channels needed in everything from automotive parts to machine bases.

So when should you use slot milling? Think anytime you need a clean, precise cut that goes deep or wide, especially when other methods like drilling or broaching don’t fit the job. Slot milling works great for:

- Creating narrow or wide slots in metals or plastics

- Making T-slots for securing workpieces on a machine table

- Cutting keyways that allow mechanical parts to lock together

- Precision groove milling for guide rails or channels

Thanks to CNC slot milling, these tasks are quicker and more accurate than ever. The process removes material in controlled passes, giving you clean edges and consistent dimensions. Knowing the basics of slot milling lets you match the right tools and setup to the job, boosting accuracy and reducing tool wear.

In short, slot milling is the go-to operation when you need precise, reliable slots** in your workpiece that hold tight tolerances and strong finishes. Getting comfortable with this technique is key for any shop aiming to produce quality parts fast.

Understanding Slot Milling The Fundamentals Every Machinist Needs Slot Milling vs Similar Operations Hog Plunge and Gang Milling

Slot milling is often confused with other milling operations like hog milling, plunge milling, and gang milling, but each has its own role on the shop floor.

- Slot Milling focuses on cutting narrow grooves or slots in a workpiece, typically using an end mill designed for slots. It’s precise and ideal for making T-slots or deep channel cuts.

- Hog Milling is more about removing large amounts of material quickly with less concern for surface finish. It’s rough cutting compared to slot milling’s detail work.

- Plunge Milling means feeding the cutter straight down into the material vertically instead of moving sideways. It’s useful for heavy cuts but isn’t the same as slot milling since slot milling involves lateral movement to create grooves.

- Gang Milling uses multiple cutters lined up on a single arbor or spindle. This method can cut several slots or features in one pass, making it efficient but requiring the right setup and tooling.

Understanding these differences helps you choose the right method for your job. If you need precise grooves or slots, slot milling is the go-to. For aggressive material removal, hog or plunge milling may be better. And when speed is key, gang milling can boost productivity.

Essential Tools and Setup for Optimal Slot Milling

Selecting the Right End Mills and Cutters

Choosing the right end mill or cutter is a key step for successful slot milling. The tool you pick directly affects the quality of the cut, tool life, and the overall efficiency of the job. Here’s what to keep in mind:

- Use carbide slot cutters for durability and sharp edges. Carbide tools handle tough materials like steel and titanium better than high-speed steel.

- Match tool size to slot width. The end mill diameter should be close to the desired slot width to reduce extra passes and minimize tool deflection.

- Consider tool geometry. Square end mills are common for slot milling, but if you need a cleaner finish or less tool wear, a radius or ball nose end mill might be better.

- For deep slots choose longer length cutters, but be cautious of tool deflection, which can ruin precision.

- Multi-flute vs. two-flute cutters: Two-flute tools offer better chip clearance for deep slots, while multi-flute cutters give a smoother finish on shallow slots.

- Coatings improve performance. TiN, TiAlN, or similar coatings help reduce heat build-up and extend tool life, especially in harder metals.

Selecting the right end mill and cutter based on these points sets you up for smooth, precise slot milling, keeping both quality and efficiency high.

Essential Tools and Setup for Optimal Slot Milling

Machine Considerations CNC Mills Lathes with Attachments and Multi Axis Setups

Choosing the right machine is key when it comes to slot milling. Most machinists prefer CNC mills because they offer precise control over the tool path and allow for repeatable, accurate cuts. CNC slot milling is ideal for complex slots and grooves, especially when tight tolerances matter.

Lathes with milling attachments can handle slot milling too, but they’re best for simpler, smaller jobs. These setups work well for making slots on round parts without removing the piece from the lathe.

For more advanced work, multi-axis machines shine. They let you approach the material from different angles without resetting your workpiece. This is great for deep slot machining and tricky T-slot cutting techniques where you need access from multiple directions.

Here’s what to keep in mind when picking your machine setup:

- CNC mills: Best for precision groove milling and handling complex shapes

- Lathes with attachments: Ideal for slotting on turned parts, limited complexity

- Multi-axis setups: Perfect for deep slots and complicated geometries

- Gang slot milling machines: Use these if you’re running high volume or need to cut multiple slots efficiently

Make sure your machine is rigid enough to handle the forces of slot milling without tool deflection. This will keep your slots clean and accurate, cutting down finishing time.

In the U.S. market, many shops lean towards CNC mills paired with high-quality carbide slot cutters to balance speed and precision. Getting your machine setup right means smoother feeds and speeds, better surface finish, and less downtime overall.

Step by Step Guide How to Perform Slot Milling Like a Pro Preparing Your Workpiece and Programming the Path

Before you start slot milling, preparation is key to getting a clean, precise cut. Here’s what I focus on when setting up the workpiece and programming the milling path:

1. Secure the Workpiece Properly

- Use a sturdy vise or clamps to hold your material tight. Any movement during cutting can ruin the slot and damage your cutter.

- For longer or thinner pieces, consider additional supports to prevent vibration.

2. Choose the Right Material Setup

- Clean the surface to remove oil, dirt, or debris that might throw off your tool path or measurement.

- Measure and mark the rough slot location if needed, but rely mainly on the CNC program.

3. Program the Milling Path

- Select the correct tool diameter and type for your slot milling operation—typically a carbide slot cutter or appropriate end mill for slots.

- Input slot dimensions including width, depth, and length into your CAM software.

- Plan your cutting strategy: start with roughing passes (deeper cuts with slower feeds) then move to finishing passes for a smooth surface.

4. Set Entry and Exit Points

- Program lead-in and lead-out paths to avoid tool marks at the slot start and end.

- Use ramping or helical entry moves instead of plunging straight down to protect the tool and extend its life.

5. Double-Check Parameters

- Ensure feed rates, spindle speed, and depth of cut match your material’s needs. For instance, aluminum allows faster speeds than steel or titanium.

- Utilize a feeds and speeds calculator or refer to recommended slot milling parameters.

Getting these setup steps right avoids costly mistakes and sets you up for a perfect slot every time. Take the time now, and your final cuts will pay off.

Step by Step Guide How to Perform Slot Milling Like a Pro Executing the Cut From Roughing to Finishing Passes

Once your workpiece is set and the CNC slot milling path is programmed, it’s time to start cutting. Here’s how to execute the slot milling smoothly from roughing to finishing:

1. Start with Roughing Passes

- Use a slightly larger end mill for roughing to remove most of the material quickly.

- Set conservative feeds and speeds to avoid tool deflection and chatter.

- Take multiple shallow passes rather than trying to cut the full slot depth at once.

- Keep coolant or air blast on to manage heat and chip evacuation.

2. Check Your Cut

- After roughing, inspect the slot for any tool marks or unexpected deviations.

- Clean out chips to prevent them from scratching or damaging the surface during finishing.

3. Move to Semi-Finishing

- Switch to a narrower or more precise carbide slot cutter if needed.

- Reduce the depth of cut to increase accuracy while still removing remaining material.

- Fine-tune feeds and speeds based on how the material responds.

4. Finishing Pass

- Use the smallest tool that fits the slot for the cleanest finish.

- Apply slower feed rates and higher spindle speeds for a smooth surface.

- Consider a climb milling approach to reduce tool wear and improve finish.

- Double-check dimensions with calipers or micrometers to ensure precision.

5. Final Clean-Up

- Deburr the slot edges if necessary.

- Remove any burrs or rough spots to prevent issues in assembly or function.

By carefully progressing through these steps, you’ll avoid common issues like tool deflection in milling and get precise, clean slots every time. This process works well for various materials, from aluminum to tougher steels and titanium.

Optimizing Parameters for Different Materials and Slot Depths Feeds Speeds and Depths for Metals Like Aluminum Steel and Titanium

Getting the right feeds, speeds, and depths is key to efficient slot milling, especially when working with different metals like aluminum, steel, and titanium. Here’s a quick breakdown for each:

Aluminum

- Feed rate: High feed rates work well since aluminum is soft and easy to cut.

- Spindle speed: Use high RPM to get a smooth finish—around 8,000 to 12,000 RPM depending on your machine.

- Depth of cut: Aluminum handles deeper cuts than most metals, so you can go up to 50% of the tool diameter in one pass for roughing.

Steel

- Feed rate: Moderate feed rates to avoid excessive tool wear and heat build-up. Start around 0.001 to 0.004 inches per tooth depending on the steel grade.

- Spindle speed: Lower speeds compared to aluminum, typically between 2,000 and 6,000 RPM.

- Depth of cut: Go lighter – around 10% to 30% of the cutter diameter per pass for slot milling to reduce tool deflection and ensure tool life.

Titanium

- Feed rate: Feed rates should be slower to prevent work hardening and overheating—usually less than steel’s feed rates.

- Spindle speed: Keep RPM on the low side, generally 1,000 to 3,000, to avoid burning the workpiece and tool.

- Depth of cut: Use shallow depths per pass, around 5% to 20% of cutter diameter, to keep the tool stable and preserve sharpness.

General tips for slot milling with metals:

- Always consider the tool material (carbide cutters are popular for tough metals).

- Use a feeds and speeds calculator to tailor your machine settings based on your tooling and material.

- Adjust depths and passes based on the slot depth—deep slot machining needs multiple shallow passes.

- Keep coolant or mist lubrication running to extend tool life and improve surface finish.

By dialing in these parameters for your specific metal and slot depth, you can boost efficiency, reduce tool wear, and get precise slots every time.

Optimizing Parameters for Different Materials and Slot Depths

Troubleshooting Common Slot Milling Issues

Slot milling can throw some curveballs, especially when working with different materials and varying slot depths. Here’s how to tackle the usual problems you might face to keep your cuts smooth and precise.

Common Slot Milling Issues and FixesTool Deflection

Problem: When cutting deep slots or harder materials like titanium, the end mill can bend, causing inaccurate cuts.

Fix: Use shorter, stiffer cutters made of carbide slot cutters, and reduce the depth of cut per pass. Increasing feed rate slightly while maintaining slower spindle speeds helps too.

Chatter and Vibration

Problem: You’ll hear and feel chatter when the cutter isn’t stable, which ruins surface finish and tool life.

Fix: Check your machine’s setup for rigidity. Use the right feeds and speeds calculator settings for your material—steel needs slower speeds than aluminum, for example. Also, closely monitor tool wear.

Poor Chip Evacuation

Problem: Chips get trapped in the slot, causing extra heat and damaging the tool or workpiece.

Fix: Use coolant or air blast to flush chips out regularly. Adjust slot milling parameters to allow smaller chip loads per pass. Consider changing the tool path to avoid recutting chips.

Surface Finish Issues

Problem: Rough or uneven slot surfaces often come from improper cutting parameters or worn cutters.

Fix: Finish with a lighter depth of cut and higher spindle speed where possible. Inspect and replace end mills for slots if the cutting edges are dull.

Overheating

Problem: Excessive heat can ruin the end mill and damage the material, especially alloys like titanium.

Fix: Use coolant effectively and optimize feeds and speeds to avoid rubbing. Carbide tooling helps resist heat better than high-speed steel.

Key Tips for Different Materials

| Material | Spindle Speed | Feed Rate | Depth of Cut |

|---|---|---|---|

| Aluminum | High | High | Moderate to deep |

| Steel | Moderate | Moderate | Shallow to moderate |

| Titanium | Low to moderate | Slow | Very shallow |

Remember, adjusting slot milling parameters is a balancing act. Monitor your process closely, take small steps when tweaking feeds and speeds, and you’ll cut better slots with less downtime.

Advanced Techniques and Efficiency Boosts in Slot Milling High Speed Machining and Multi Tool Gang Slotting

To take your slot milling to the next level, using high speed machining (HSM) and multi tool gang slotting can seriously boost efficiency and precision.

High Speed Machining involves running your tools at faster spindle speeds with lighter cuts. This reduces heat buildup and tool wear while improving surface finish. The trick is balancing speed with feed rate to avoid tool deflection, especially with carbide slot cutters. The result is faster cycle times and cleaner slots, even in tough materials like titanium or hardened steel.

Multi Tool Gang Slotting uses a setup where multiple cutters are mounted simultaneously on the same arbor. This lets you cut several slots in one pass, saving time and improving repeatability. Gang slot milling is perfect for jobs with multiple T-slots or precision groove milling, where matching slot spacing is critical—usually found in fixtures or machine tables.

Benefits at a glance:

- Faster production with less tool changes

- Improved accuracy and surface finish

- Less tool wear due to optimized cutting parameters

- Better for deep slot machining where multiple passes are needed

If you’re handling high volume or complicated parts, investing time in mastering these advanced methods can pay off big, trimming hours off your workflow and pushing your shop’s capacity further. For those looking for precision tooling, Vast offers reliable carbide slot cutters designed to handle HSM and gang slot milling demands with ease.

Advanced Techniques and Efficiency Boosts in Slot Milling

Sustainability and Cost Saving Hacks

When it comes to slot milling, working smarter—not just harder—can save you time and money while reducing waste. Here are some solid tips to keep your operations both efficient and sustainable:

- Use High-Quality Carbide Slot Cutters: Carbide tools last longer and retain sharpness better than standard tools. This means fewer tool changes, less downtime, and less waste from worn-out cutters.

- Optimize Feeds and Speeds: Adjust your slot milling parameters for the material you’re working with. Running the right feeds and speeds reduces tool wear and energy consumption, which adds up to cost savings.

- Implement Multi-Tool Gang Slotting: Combining multiple cutters for simultaneous slotting can cut cycle times dramatically, boosting throughput and lowering energy use per part.

- Recycle Metal Chips: Many shops overlook this simple cost saver. Collect and recycle chips from aluminum, steel, and titanium to reduce raw material expenses.

- Minimize Tool Deflection: Using stiffer setups and proper tool lengths ensures cleaner cuts and prolongs tool life, meaning less scrap and rework.

- Regular Machine Maintenance: Well-maintained machines run more efficiently and produce better results, saving on unexpected repair costs and downtime.

By incorporating these tactics, your slot milling process saves money, uses fewer resources, and improves your shop’s overall bottom line. Sustainability and cost savings go hand in hand when you’re tuned into the right setup and operational choices.

Why Choose Vast for Your Slot Milling Needs

When it comes to slot milling, having reliable, high-precision tools makes all the difference. That’s where Vast steps in. Known across the U.S. for delivering top-notch precision tooling solutions, Vast offers a wide range of quality carbide slot cutters, end mills for slots, and accessories designed to boost your machining accuracy and efficiency.

Here’s why Vast stands out for your slot milling projects:

- Premium Quality Tools: Vast’s cutters are made with durable materials that reduce tool deflection in milling and extend tool life, even in demanding jobs like deep slot machining on metals like steel and titanium.

- Wide Selection: Whether you’re running a basic CNC mill or a multi-axis setup, Vast has the perfect tools to fit your needs, including options for T-slot cutting techniques and gang slot milling machines.

- Consistent Performance: Their tooling helps maintain ideal slot milling parameters and keeps your feeds and speeds optimal, helping you avoid common cuts problems and improve surface finish.

- Local Support and Fast Shipping: Based in the U.S., Vast understands local manufacturing demands and offers quick delivery, so you don’t have to wait to keep your production moving.

- Cost Effective: By providing long-lasting tools and reducing machine downtime, Vast helps you save money while maintaining high precision.

If you want to get your slot milling done right the first time, Vast’s precision tooling is the smart choice in today’s competitive manufacturing landscape.