Discover precise bore machining techniques for high-tolerance holes using advanced CNC processes tools and expert tips for optimal results.

What Is Bore Machining Core Principles and Why It Matters

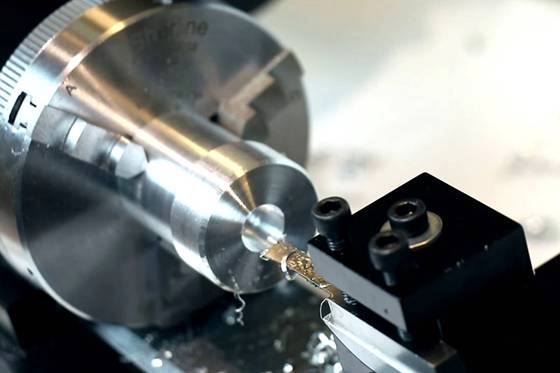

Bore machining is the process of enlarging, finishing, or shaping an existing hole with precision. Unlike drilling, which creates holes from scratch, bore machining focuses on refining the internal surface, improving size, roundness, and surface finish. This process is crucial in industries where precision holes are key, such as automotive engines, aerospace components, and heavy machinery.

At its core, bore machining relies on controlling tool alignment, cutting speed, and feed rate to achieve tight bore tolerance standards. Proper setup minimizes issues like boring bar deflection, ensuring the hole stays true to design specifications. The goal is not just to make a hole bigger but to maintain exact dimensions and perfect surface quality.

Why does this matter? Precise bores ensure parts fit together correctly, reduce wear and tear, and improve overall equipment performance. Whether it’s a deep bore machining project or a micro boring task, getting it right can mean the difference between smooth operation and costly failure. Understanding these core principles helps manufacturers deliver reliability and efficiency in their products.

Types of Bore Machining From Micro to Line Boring

Bore machining covers a range of techniques depending on the size, precision, and purpose of the bore. Here’s a quick rundown of common types used in the U.S. market:

Micro Boring

Used for very small, precise holes, micro boring relies on specialized micro boring tools. This method is popular in industries like medical devices and electronics, where tiny, accurate holes are crucial.

Line Boring

Line boring is all about enlarging and aligning existing holes in heavy machinery. It usually involves line boring equipment that repairs large bores to restore proper tolerances. This is key in construction and manufacturing plants maintaining heavy equipment.

Horizontal and Vertical Boring Mills

These machines handle larger bores and offer flexibility:

- Horizontal boring mills are great for deep, wide bores and provide easy access to horizontal surfaces.

- Vertical boring mills work better for larger, heavy parts that need vertical access.

Both types are widely used in fields like automotive, aerospace, and metal fabrication.

Jig Boring for Ultra Precision

When precision is non-negotiable, CNC jig boring steps in. This method delivers extremely tight tolerances and smooth finishes, enhancing the accuracy of precision holes in tooling and aerospace parts.

Specialized Methods

Other bore machining methods serve niche purposes, including:

- Tapered bore process for angled holes

- Deep bore machining for very long, narrow bores

- Techniques focusing on minimizing boring bar deflection to maintain accuracy in deeper cuts

Each method is tailored to the needs of the product and industry, helping U.S. manufacturers stay competitive with precise and reliable bore machining.

The Bore Machining Process Step by Step Guide

Bore machining follows a clear process to create precise internal holes. Here’s how it breaks down:

Preparation and Setup

- Workpiece Inspection: Make sure the part is clean and free of damage.

- Machine Setup: Align the workpiece securely on the machine, whether it’s a horizontal boring mill or a jig boring setup.

- Tool Selection: Choose the right boring bar or micro boring tools depending on hole size and depth. Using the right tool reduces boring bar deflection and improves accuracy.

- Programming: For CNC jig boring or line boring equipment, program the cutting path carefully to match bore tolerance standards.

Rough Boring

- Initial Cut: Remove the bulk of material from the hole with a larger feed and depth to save time.

- Parameters: Use moderate cutting speed and feed rate to avoid tool wear. Keep an eye on heat and chip flow, especially in deep bore machining.

Finish Boring

- Fine Cutting: Take smaller passes to achieve tight size tolerances and smooth surface finish.

- Adjustments: Measure bore diameter regularly and adjust tool position or speed as needed.

- Internal Turning Techniques: Sometimes used here for taper correction or improving surface finish.

Key Parameters and Formulas

- Cutting Speed (S) = (π × Diameter × RPM) / 12 (for feet per minute)

- Feed Rate: Typically in inches per revolution, adjusted based on tool and material type.

- Depth of Cut: Balance between efficient material removal and preventing tool deflection.

This step-by-step keeps bore machining efficient and accurate. Following these practices helps meet precision hole enlargement requirements for everything from automotive parts to aerospace components.

Tools and Materials in Bore Machining Best Practices

When it comes to bore machining, having the right tools and materials is a must for hitting precise tolerances and avoiding common issues like boring bar deflection. Here are some of the essentials to keep in mind:

- Boring Bars and Micro Boring ToolsThese are core to the process. For deep bore machining or micro boring, tools with strong rigidity and sharp inserts help reduce vibration and improve surface finish. Using the right boring bar size minimizes deflection, which keeps bore dimensions on target.

- CNC Jig Boring MachinesPerfect for ultra-precise holes, CNC jig boring offers control down to microns. This technology is key when tight bore tolerance standards need to be met, especially for aerospace or medical applications.

- Line Boring and Horizontal Boring MillsThese machines handle bigger, heavier workpieces. Horizontal boring mills are versatile for precision hole enlargement and tapered bore processes, while line boring equipment handles long flanged parts with consistent accuracy.

- Cutting Tools and InsertsChoosing the right inserts—like carbide or coated types—depends on the material you’re machining (steel, cast iron, or aluminum). Sharp, wear-resistant inserts extend tool life and maintain surface quality.

- Coolants and LubricantsUsing the correct coolant keeps temperatures down, limits tool wear, and prevents workpiece distortion. This also helps with internal turning techniques where chip evacuation is tricky.

Best Practices

- Always inspect tools before use to avoid breakage during the operation.

- Calibrate your setup to match bore tolerance standards every time.

- Maintain clean and sharp tools to deliver consistent finishes and avoid rework.

- Optimize feeds and speeds according to material and bore size to reduce tool wear.

Having the right combination of tools, machines, and materials tailored to your bore machining needs is key to getting high-quality, repeatable results in the U.S. market.

Bore Machining Applications and Industry Impact

Bore machining plays a crucial role across many industries in the United States, especially where precise hole sizing and finish are critical. You’ll find bore machining in sectors like aerospace, automotive, oil and gas, and heavy machinery. These industries rely on precision hole enlargement and deep bore machining to produce parts that fit perfectly and perform reliably under tough conditions.

From horizontal boring mills used in large engine blocks to micro boring tools for tiny internal components, bore machining ensures tight bore tolerance standards are met. This precision helps reduce downtime, extend the life of machinery, and improve safety.

The use of advanced equipment like CNC jig boring and line boring equipment has pushed quality and efficiency even further. These solutions help tackle common issues like boring bar deflection and uneven wear, making production smoother and more consistent.

In short, bore machining isn’t just a process—it’s a backbone of manufacturing where accuracy inside holes means better overall performance of machines and tools used daily across the U.S. market. Whether it’s creating a tapered bore process in heavy equipment or fine-tuning internal turning techniques in aerospace parts, bore machining keeps American manufacturing competitive and dependable.

Common Challenges in Bore Machining and How Vast Solves Them

Bore machining isn’t without its hurdles. Some of the common challenges include boring bar deflection, maintaining tight bore tolerance standards, and handling complex shapes like tapered or deep bores. When the boring bar bends or vibrates, it throws off precision, resulting in uneven holes or extra rework. Plus, ultra-precise jobs like CNC jig boring can be tough to get right without the right equipment and know-how.

Vast tackles these pain points head-on by using advanced technology and expert craftsmanship:

- Minimizing boring bar deflection with high-rigidity tools and smart setups.

- Using horizontal and vertical boring mills tailored to each job’s size and accuracy needs.

- Offering skilled operators trained in internal turning techniques to handle tricky parts.

- Applying precise calculations for feed rate and speed to reduce tool wear and improve finish.

- Access to specialized equipment like line boring equipment and micro boring tools for everything from small to large scale holes.

- Strict quality checks to ensure parts meet all bore tolerance standards.

By combining the right tools, deep knowledge of the bore machining process, and modern equipment, Vast delivers precision and efficiency. This means fewer delays, less waste, and parts that fit perfectly every time. If you want high-quality boring work with less headache, Vast is built to make it happen.