Discover expert insights on machining fixtures including types design benefits and optimization for precision CNC workholding solutions.

What Are Machining Fixtures Understanding the Basics Core Functions Fixture vs Jig

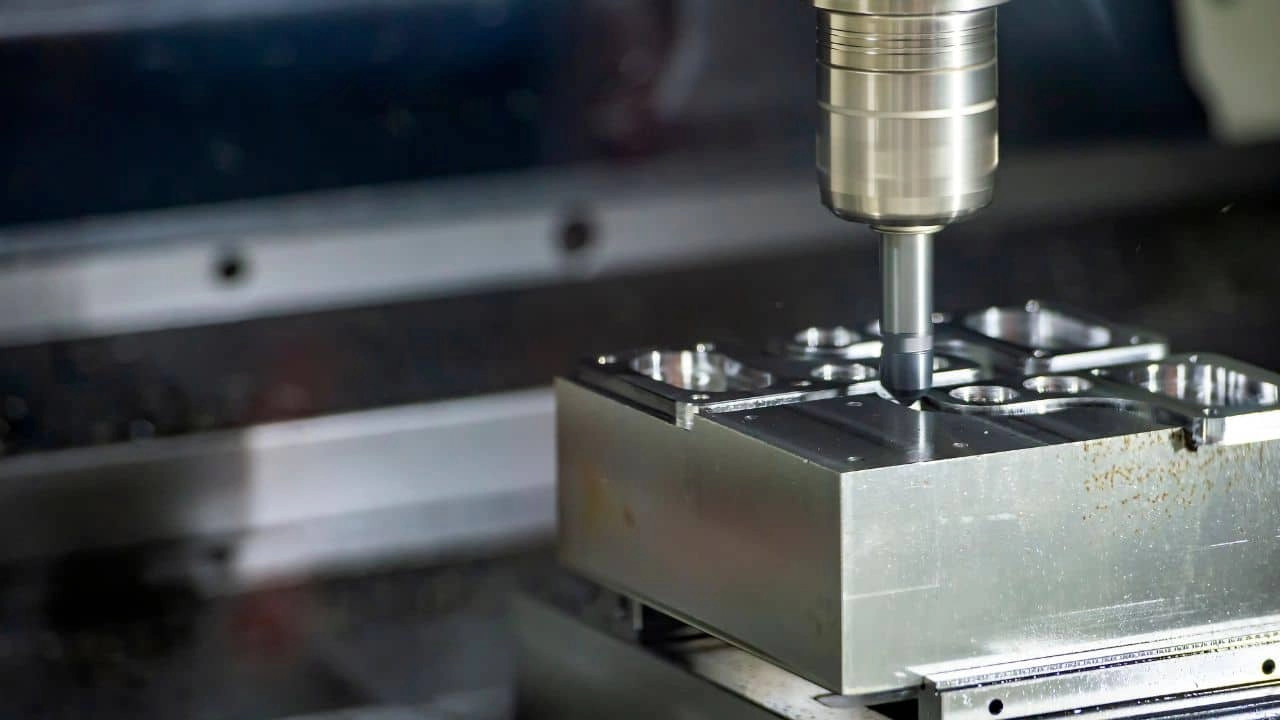

If you’ve ever wondered how manufacturers hold parts steady during machining, the answer often lies in machining fixtures. Simply put, machining fixtures are custom workholding devices designed to securely clamp and position a workpiece throughout various machining processes like milling, turning, drilling, or welding. Their main job is to ensure precision and repeatability.

The core functions of machining fixtures include:

- Locating: Positioning the workpiece accurately using features like pins or stops

- Clamping: Holding the workpiece firmly to prevent movement or vibration

- Supporting: Providing stability to avoid deflection during cutting or assembly

One common confusion is the difference between a fixture and a jig. While both support workpieces, a fixture holds the part stationary, letting the cutting tool follow its programmed path without guidance. A jig, on the other hand, guides the tool to the right spot—think drill jigs that direct drill bits precisely. In modern CNC machining, fixtures are more prevalent due to automated tool paths and precision clamping systems.

Understanding these basics can help you choose or design the right CNC workholding devices that optimize efficiency and accuracy for your manufacturing needs.

Why Machining Fixtures Matter Key Benefits for Modern Manufacturing

Machining fixtures play a vital role in modern manufacturing because they save time, improve accuracy, and boost overall efficiency. Here’s why they matter for businesses in the U.S.:

Consistent Precision

Fixtures hold the workpiece firmly in place, so every cut or operation is precise. This reduces errors and keeps quality high, especially when using CNC workholding devices.

Faster Production

By speeding up setup times and minimizing adjustments, machining fixtures help keep production lines moving. This is crucial for meeting tight delivery schedules.

Improved Safety

Proper clamping systems prevent workpieces from shifting, which lowers the risk of accidents during milling, turning, drilling, or welding.

Cost Savings

Reducing scrap and rework lowers expenses. Plus, durable fixtures cut downtime caused by frequent changes or repairs.

Flexibility for Various Operations

Different fixtures like milling fixtures, turning chucks, and modular fixturing solutions support multiple machining processes—making it easy to switch between jobs without a full reset.

Better Automation Integration

Machining fixtures designed for automated machining setups streamline workflows, especially in CNC environments. This means less manual input and smoother production runs.

For manufacturers looking to stay competitive, choosing the right machining fixtures isn’t just a good idea—it’s a necessity. It helps keep operations lean, quality consistent, and costs under control.

Types of Machining Fixtures Choosing the Right One for Your Operation

When it comes to machining fixtures, picking the right type for your operation is critical. Each fixture serves a specific purpose, helping you improve accuracy, reduce setup time, and boost efficiency in your shop. Here’s a quick breakdown of the main types you’ll encounter:

Milling Fixtures

Used primarily for milling machines, these fixtures hold the workpiece steady during cutting. Milling fixture design focuses on solid workpiece locating principles and precision clamping systems to prevent any movement under cutting forces. They can be custom-built or use modular fixturing solutions to adapt quickly to different parts.

Turning Fixtures

Turning fixtures are designed for lathes and include various turning chuck types to securely hold round or irregular-shaped workpieces. Proper clamping is key since the workpiece rotates at high speeds. This category includes collets, chucks, and custom CNC tombstone style fixtures for versatile setups.

Drilling and Boring Fixtures

Used to guide and secure parts during drilling or boring, these fixtures ensure the drill bit hits the exact spot every time. Precision is crucial here to avoid misalignment and poor hole quality. Often, these fixtures integrate with CNC systems for automated machining setups.

Welding and Assembly Fixtures

Though not strictly machining fixtures, welding and assembly fixtures are essential for holding components in place during joins. They offer strong, stable support designed for repetitive and consistent welds or precise assembly tasks.

Advanced Options

With the growth of technology, you now find 3D printed workholding devices and smart fixtures that communicate with CNC controls. These can adapt on the fly and offer greater flexibility and speed, perfect for smaller U.S.-based shops looking to innovate without heavy investment.

Choosing the right fixture depends on your specific machining operations, material types, and production volume. The right fixture streamlines your workflow and helps maintain tight tolerances across runs.

Design Principles for Effective Machining Fixtures

Creating effective machining fixtures is all about smart design that improves precision, repeatability, and efficiency in your manufacturing process. Here are the core principles to keep in mind:

Location and Clamping Strategies

- Precise workpiece locating is crucial. Fixtures must hold the part exactly where needed, preventing any movement during machining.

- Use precision clamping systems that secure the workpiece firmly without damaging it. Balanced clamping helps avoid distortion and vibration.

- Plan for quick and repeatable setups to cut down on downtime. Modular fixturing solutions are great for flexible location and clamping adjustments.

Material Selection

- Choose fixture materials that withstand the rigors of machining but don’t add unnecessary weight. Common choices include hardened steel for durability or aluminum for lighter, versatile setups.

- Consider wear resistance, thermal expansion, and cost-effectiveness. Proper material selection gives you a stable, long-lasting fixture.

Integration with CNC Machines

- Modern CNC workholding devices need to fit seamlessly with your machining center. That means ensuring your fixtures can mount securely and align properly with machine components.

- Design for automated machining setups where possible, allowing fixtures to work with robotic arms or pallet changers—speeding production while keeping accuracy tight.

- Don’t forget compatibility with software and controls to support custom CNC tombstone setups or 3D printed workholding solutions when applicable.

By focusing on these design elements, you’ll get fixtures that not only improve machining quality but also fit your workflow and production demands.

Best Practices for Implementation and Optimization

Getting the most out of your machining fixtures means focusing on smart implementation and continuous optimization. Here are some best practices to help you streamline your machining process and boost efficiency:

- Start with proper fixture setup: Ensure your fixture is securely mounted and workpieces are positioned accurately using solid workpiece locating principles. This reduces errors and improves repeatability.

- Choose the right clamping system: Precision clamping systems provide consistent pressure without deforming the part. Avoid over-tightening, which can damage the workpiece or the fixture.

- Keep fixtures clean and well-maintained: Debris or worn components can lead to inaccuracies. Regular cleaning and inspection extend fixture life and maintain machining quality.

- Leverage modular fixturing solutions: Modular fixtures allow quick changes between jobs, minimizing downtime in automated machining setups, especially when working with different part sizes or shapes.

- Integrate with CNC machines effectively: Design or adjust fixtures to fit seamlessly with your CNC workholding devices. This helps reduce setup time and improves cycle times.

- Use custom machining fixtures where needed: For complex or unique parts, custom fixtures like CNC tombstones can deliver superior stability and precision.

- Continuously monitor and optimize: Track production data and inspect finished parts to identify any fixture-related issues. Make incremental adjustments to improve accuracy and efficiency over time.

Following these practices ensures your machining fixtures support consistent quality and faster production, helping your shop stay competitive in the U.S. manufacturing market.

Future Trends in Machining Fixtures

Machining fixtures are evolving fast, driven by the push for greater precision, flexibility, and automation in manufacturing. Here are some of the key trends shaping the future:

- Automation and Smart FixturesMore shops are using automated machining setups where fixtures communicate with CNC machines. Smart fixtures come with sensors that monitor clamping force and workpiece position in real time, reducing errors and setup time.

- Modular Fixturing SolutionsThe shift towards modular fixturing lets manufacturers quickly swap out components, making it easier to handle different parts without designing new fixtures from scratch. This boosts efficiency and reduces downtime.

- Additive Manufacturing and 3D Printed Workholding3D printing allows custom CNC tombstone parts and complex fixtures to be produced rapidly and cost-effectively. This opens up new possibilities for lightweight, optimized workholding systems tailored to specific jobs.

- Advanced Materials and Precision Clamping SystemsNew materials like carbon fiber composites are entering fixture design for their strength and weight advantages. Meanwhile, precision clamping systems continue to improve, offering consistent holding force and better workpiece accuracy.

- Integration with Industry 4.0Connected factory floors use data from CNC workholding devices to optimize machining processes on the fly. This integration supports predictive maintenance and smarter resource planning.

For U.S. manufacturers aiming to stay competitive, adopting these innovations in machining fixtures will be crucial. Whether you’re running milling fixtures, turning chucks, or drilling setups, staying ahead with flexible, smart workholding can save time, cut costs, and improve quality.