Learn about porosity in casting its causes types effects and proven prevention methods to ensure defect-free metal castings and improved quality control.

If you’re in manufacturing or foundry work, porosity in casting is likely a challenge you’ve faced firsthand. These tiny voids or gas pockets can seriously compromise the strength and quality of your metal parts—leading to costly defects and production delays. But understanding what causes porosity, how to spot it, and, most importantly, how to prevent it can save you time, material waste, and headaches down the line. In this post, you’ll get clear, practical insights into the main types of porosity defects, why they happen, and proven strategies that top manufacturers use to achieve flawless castings. Ready to cut scrap and boost quality? Let’s get started.

Introduction to Porosity in Casting

Porosity in casting refers to the presence of tiny voids, gas pockets, or cavities trapped inside metal castings. These hidden or visible defects often form during processes like die casting, sand casting, and investment casting. Porosity can significantly weaken the structural integrity of parts by creating stress points that lead to cracks, leaks, or early failure.

For manufacturers, controlling porosity is crucial. Reducing these defects lowers scrap rates, cuts down on costly rework, and improves overall product reliability—especially important in high-volume production where even small defect rates add up. Addressing porosity not only enhances mechanical performance but also boosts customer confidence and reduces warranty claims.

At Vast, we understand the challenges of achieving defect-free castings. Our expertise combines advanced simulation tools, precise process controls, and innovative post-casting treatments to help you deliver consistent, high-quality parts with minimal porosity-related issues.

Types of Porosity in Casting

Porosity in casting shows up in different forms depending on its cause. The main types are:

Gas porosity

These are rounded voids trapped by gases like hydrogen in aluminum castings. Common subtypes include:

- Pinholes: Tiny surface bubbles

- Blowholes: Larger, deeper gas pockets

- Blisters: Raised areas on the casting surface from gas buildup

Shrinkage porosity

This happens when the metal contracts as it cools and solidifies, leaving irregular cavities. Shrinkage defects include:

- Closed shrinkage: Cavity is sealed inside the casting

- Sponge shrinkage: Porous, sponge-like internal voids

- Open shrinkage: Surface-connected cavities or cracks

Other forms

- Micro porosity: Tiny, scattered voids inside the metal that can weaken the casting

- Blind porosity: Pores enclosed within the casting but not connected to the surface

- Reaction surface porosity: Voids caused by chemical reactions between the molten metal and mold material

Understanding these porosity types helps pinpoint problems and improve foundry processes.

Causes of Porosity Defects

Porosity in casting usually comes from a few main causes, and understanding them helps us prevent defects.

Gas-related causes

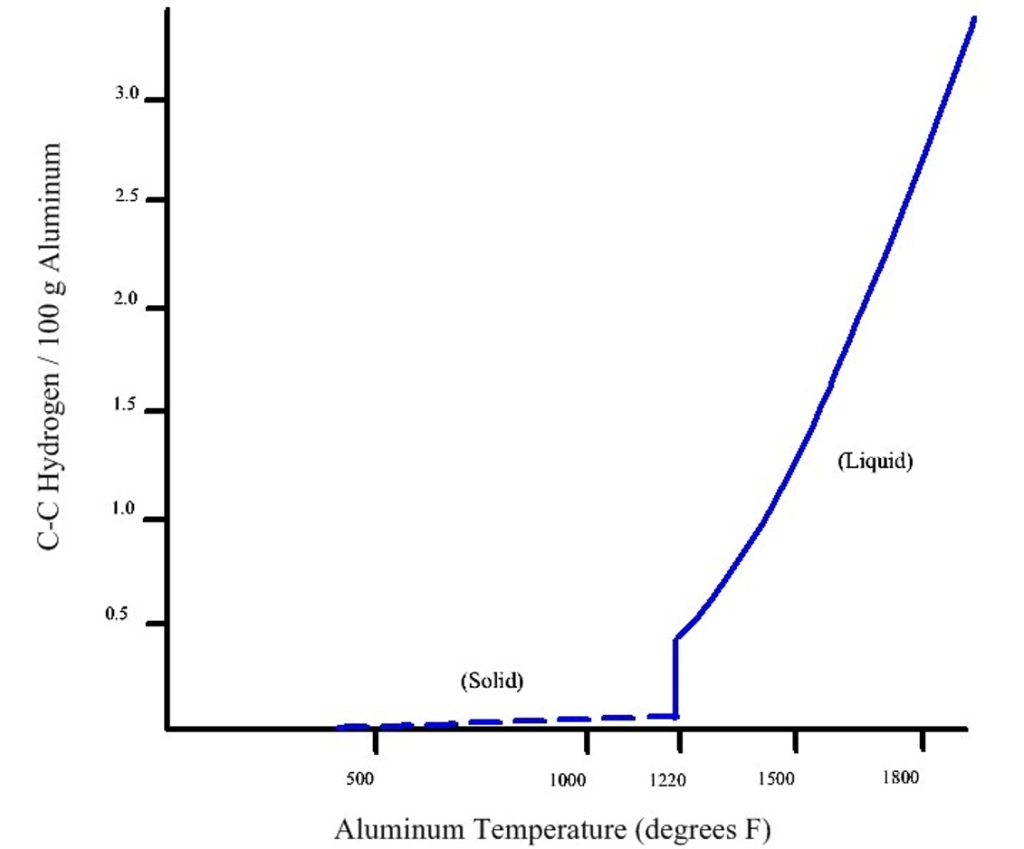

- Hydrogen absorption in molten metal is a top culprit, especially in aluminum.

- Turbulence during pouring traps gases inside the metal.

- Poor mold venting means gases can’t escape properly.

- Decomposition of mold releases or fluxes can release gases that form pores.

Shrinkage-related causes

- Uneven cooling creates voids as metal contracts.

- Insufficient risering or feeding areas don’t supply enough molten metal to compensate for shrinkage.

- Hot spots in thick sections cool slower, causing premature solidification in other areas and forming shrinkage cavities.

- Poor mold design can worsen all these problems by blocking metal flow or heat escape.

External factors

- Contaminants in the metal or mold can introduce pores.

- Using the wrong alloy for the process might increase porosity risk.

- High pouring temperatures create more gas absorption and shrinkage issues.

- Environmental gases especially during aluminum die casting can get trapped and cause defects.

Spotting these causes early allows us to target fixes like better degassing, improved mold design, or temperature control to reduce porosity in casting.

Effects and Detection of Porosity in Casting

Porosity in casting can seriously weaken your parts. Mechanically, it lowers tensile strength, reduces fatigue resistance, and cuts down ductility. This means your castings are more likely to crack, leak, or fail under pressure. For things like engine components, these weaknesses can lead to costly breakdowns or safety issues.

From a functional side, porosity creates tiny corrosion pathways that eat away at the metal over time. It also makes machining harder because the surface isn’t smooth or consistent. Plus, parts with porosity often don’t look right, causing aesthetic problems and sometimes won’t hold pressure like they’re supposed to.

Detecting porosity early is key. You can spot surface pores by visual inspection, but internal voids need more advanced methods. X-ray CT scans show inside the part, ultrasonic testing checks for internal flaws, and density analysis helps quantify the amount of porosity in your casting. Using these detection methods helps catch defects before parts go into production or use, saving you money and hassle down the road.

Prevention and Control Techniques

Controlling porosity in casting starts with smart process improvements. Key steps include:

- Degassing the molten metal: Using argon purging or other inert gases helps remove hydrogen and other trapped gases before pouring.

- Controlling cooling rates: Slow, even cooling reduces shrinkage porosity by minimizing metal contraction stresses.

- Vacuum-assisted casting: This technique lowers the chance of gas pockets by reducing air and gases in the mold.

- Proper venting and gating design: Good venting lets trapped gases escape, while well-designed gates prevent turbulence that can trap air.

On the design side:

- Solidification simulation software: Helps predict where shrinkage and porosity might form, so you can adjust the mold or process ahead of time.

- Risers for feeding: Adding risers feeds metal into shrinking areas, preventing cavities.

- Choosing low-porosity alloys: Selecting suitable alloys less prone to gas absorption limits defects.

- Optimized pouring parameters: Controlling pour speed and temperature reduces turbulence and gas entrapment.

After casting, vacuum impregnation is a proven way to seal small pores and ensure leak-proof parts without changing the metal’s strength or properties—especially useful for critical components needing high integrity.

At Vast, we focus on tailored solutions like advanced simulation and vacuum impregnation services to help manufacturers achieve zero-defect castings. Our expertise in these areas supports long-term quality improvements and cost savings.

Case Studies and Best Practices

Let’s look at some real-world examples where controlling porosity in casting made a big difference. In aluminum die casting, simple steps like degassing molten metal with argon and tweaking the gating system helped drastically reduce gas porosity defects. These changes not only cut down scrap rates but also improved the strength and finish of parts.

On the investment casting side, failures often traced back to shrinkage cavity causes or poor mold venting. Learning from these, foundries adjusted cooling rates and improved mold design to avoid internal porosity detection issues.

Here are some industry best practices to keep in mind:

- Integrate Non-Destructive Testing (NDT) early in the production process to catch porosity before parts go further down the line.

- Conduct thorough material purity checks to avoid gas absorption or contamination.

- Collaborate with experts like Vast who offer tailored solutions such as advanced simulation and vacuum impregnation sealing to prevent defects and guarantee leak-proof, strong castings.

Following these strategies helps U.S. manufacturers reduce costs, improve quality, and meet tight production schedules without sacrificing reliability.