Discover the ultimate 2025 reamer buyer’s guide with types, speeds, feeds, materials, and expert tips for precision hole finishing.

What a Reamer Actually Does

A reamer is a precision cutting tool that finishes and sizes holes to exact dimensions by removing a tiny layer of material.

![Animated GIF: Reamer smoothing the inside of a hole]

| Tool | Purpose | Typical Tolerance | Finish Quality |

|---|---|---|---|

| Drill | Create the initial hole | ±0.010″+ | Rough, burrs possible |

| Bore | Rough hole sizing | ±0.001″ to ±0.003″ | Cleaner, but not final |

| Ream | Final bore size and finish | ±0.0002″ (½″ hole) | Smooth, precise bore |

Real-world gains: When reaming a ½″ hole, expect to hit ±0.0002″ tolerance—crucial for parts that need perfect fits or tight assemblies. This precision beats drilling or boring alone and saves you from scrap or rework.

[Size My Reamer →]

8 Reamer Types U.S. Shops Buy Most (With 2025 Pricing)

1. Chucking (Machine) Reamers

- Specs: Straight shank, 4–8 flutes for smooth cutting

- Diameter Range: 1/8″ to 2″+

- RPM/Feed: 100–300 SFM, 0.002–0.004 IPR

- 2025 Price: $45–$120 each

2. Hand Reamers

- Specs: Square tang handle, left-spiral for blind hole chip evacuation

- Diameter Range: 1/16″ to 1″

- RPM/Feed: 30–60 SFM, slow manual feed

- 2025 Price: $15–$60 each

3. Taper-Pin Reamers

- Specs: 1:50 taper, sets #0–#14 for alignment pins

- Diameter Range: 0.060″ to 0.250″ taper ends

- RPM/Feed: 50–100 SFM, moderate feed

- 2025 Price: $120–$400 per set

4. Bridge/Alignment Reamers

- Specs: Sized 3/8″ to 1 ½″, made for structural steel alignment

- Diameter Range: 0.375″ to 1.5″

- RPM/Feed: 80–180 SFM, steady feed rate

- 2025 Price: $80–$220 each

5. Adjustable & Expansion Reamers

- Specs: Covers up to 0.006″ diameter range, adjustable blade tips

- Diameter Range: 3/16″ to 2″

- RPM/Feed: 50–150 SFM, variable feed

- 2025 Price: $100–$250 each

6. Carbide vs Cobalt vs HSS Reamers

- When to Pay 3× for Carbide: Cutting tough materials like stainless or titanium, or high-volume CNC work where life and precision matter most

- HSS: Best for mild steel, aluminum, cost-effective for low volume

- Cobalt: Better heat resistance, ideal for harder steels

7. Shell Reamers

- Specs: For holes ¾″ and larger, use on arbor systems to save up to 40% on big sizes

- Diameter Range: 0.75″ to 6″+

- RPM/Feed: 70–120 SFM, steady feed

- 2025 Price: $180–$600 per shell

8. Combination Drill-Reamers

- Specs: Single-pass tool combines drilling and reaming, boosting CNC line speeds

- Diameter Range: 1/4″ to 1″

- RPM/Feed: High speed, optimized feed rates per material

- 2025 Price: $90–$250 each

This lineup covers what most U.S. machine shops need for precision hole finishing in 2025—matching size, speed, and budget with material and tolerance requirements.

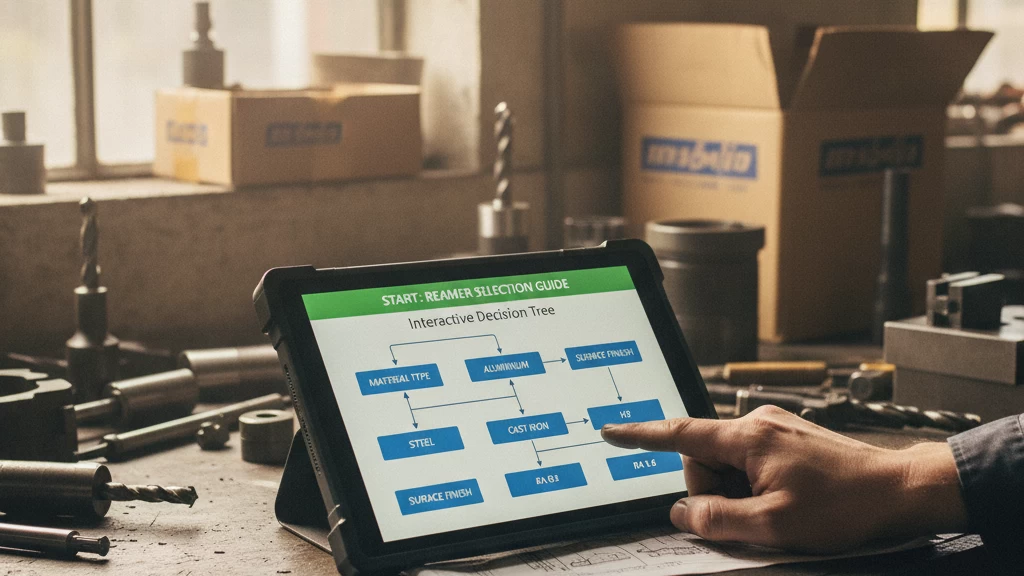

How to Pick the Exact Reamer in 3 Questions

Choosing the right reamer doesn’t have to be confusing. Just ask yourself these three simple questions:

1. Hole Depth & Through or Blind?

- Through holes usually allow standard chucking or machine reamers.

- Blind holes require hand reamers or left-spiral reamers to avoid damaging the bottom of the hole.

2. What Material Are You Working With?

- 4140 steel and similar alloys? Go cobalt for better heat and wear resistance.

- 7075 Aluminum or soft metals? Polycrystalline diamond (PCD)-tipped reamers give a super clean finish and last longer.

3. What Tolerance & Finish Do You Need?

- Tight tolerance (around IT6) means you’ll want a high-quality carbide or coated reamer.

- Looser tolerance (IT8 or above) can often work with HSS reamers, saving you money.

Ready to make the perfect pick? Try our interactive decision tree to match your hole size, material, and finish needs—streamlining your choice for 2025 buying.

(Embed Google Sheets or Typeform here for easy selection.)

Stock Allowance & Speeds/Feeds Cheat Sheet

When prepping for reaming, always drill your hole 0.005″ to 0.010″ undersize to leave enough stock for a smooth finish and tight tolerance. This gap is key to avoiding chatter and tool wear.

Here’s a quick mobile-friendly guide for common materials — with Surface Feet per Minute (SFM) and Inches per Revolution (IPR) speeds and feeds, plus notes on coolant use:

| Material | SFM (speed) | IPR (feed) | Coolant? |

|---|---|---|---|

| 1018 Steel | 60–90 | 0.002–0.004 | Yes, always |

| 304 Stainless | 40–60 | 0.0015–0.003 | Yes, crucial |

| Ti-6Al-4V | 20–40 | 0.001–0.0025 | Yes, recommended |

Tips:

- Run slower with stainless and titanium to preserve tool life.

- Use coolant on all steels to reduce heat and improve finish.

- For softer aluminum alloys, speeds can be higher, but monitor feed to avoid chatter.

Keep this cheat sheet handy on the shop floor or your phone for quick reference during any reaming job.

Top 12 Reamer Mistakes That Scrap Parts

Avoid these common reamer mistakes that waste time and scrap parts:

- Wrong stock allowance: Leaving too little or too much material causes oversized holes or tool damage.

- No chamfer on hole: Skipping chamfering leads to poor tool entry and rough finishes.

- Dry reaming stainless steel: Always use coolant to prevent heat buildup and premature wear.

- Using the wrong spiral direction: Left-spiral reamers are best for blind holes; using the wrong one can ruin the part.

- Excessive speed/feeds: Over-speeding can cause chatter and uneven finishes.

- Ignoring tool wear: Dull reamers reduce accuracy and surface quality.

- Improper setup/clamping: Loose parts cause deflection and oversized holes.

- Reaming too deep in one pass: Increases tool stress and poor finish.

- No pilot hole or undersized pilot: Leads to tool walking and out-of-round holes.

- Not matching reamer type to material: Carbide vs HSS matters—use the right one for the job.

- No coolant on high-alloy metals: Heat buildup damages both tool and workpiece.

- Skipping deburring after reaming: Burrs interfere with assembly and fit.

For each of these mistakes, a quick 15-second video shows exactly how to fix it on the shop floor—saving you scrap, time, and headaches every day.

vast™ Pro-Series Reamers: Why 2,400 Shops Switched in 2024

The vast™ Pro-Series reamers have become the go-to for over 2,400 U.S. shops this year. Here’s why:

- 6-flute micro-grain carbide with AlTiN coating offers tougher wear resistance and longer tool life compared to cobalt or HSS.

- Ultra-tight tolerance of ±0.0001″, perfect for precision tasks requiring IT6 or better finish.

- Same-day shipping from 3 U.S. distribution centers means no waiting on critical orders.

- Price-match guarantee plus a free re-grind program cuts your long-term tooling costs.

- A handy live spec matcher widget on the website helps you pick the exact reamer based on diameter, material, and finish needs.

This combination of speed, precision, and service has set vast™ apart, making it a popular choice for shops focused on accuracy and uptime.

Where to Buy Reamers Today (Map + 1-Click)

Finding quality reamers near you is easier than ever. Use the embedded Google Maps with the search term “vast reamer dealers near me” to locate trusted local suppliers fast.

For online orders, here are quick links to top sellers with vast™ reamer ASINs ready to ship:

- Amazon – great for fast delivery and easy returns

- MSC Industrial Supply – stocked for pros with lots of options

- Travers Tool – deep inventory and expert support

Local Pro Tip:

- Home Depot carries reliable HSS hand reamers, perfect if you need something quick and affordable for light jobs.

- For tougher materials and fast turnaround on carbide reamers, check Grainger—they offer overnight shipping and a solid selection.

Wherever you buy, stick with dealers that support wide diameters and offer good return policies so you get the right reamer every time.

FAQ About Reamers

Can a reamer originate a hole?

No. Reamers are designed to finish a hole, not create one. They remove just 0.003″ to 0.010″ of stock after drilling or boring.

Left-spiral vs right-spiral reamers—what’s the difference?

Left-spiral reamers pull chips away from blind holes, reducing damage and improving finish. Right-spiral types work best for through holes, pushing chips out the other side.

What’s the best reamer sharpener under $200?

Several bench-top sharpeners fit this budget, but look for one with adjustable angles to maintain proper flute geometry. Brands like Dorian and Arboga offer affordable, reliable options.