Explore the square thread form with zero-degree flanks offering high efficiency in power transmission, precise dimensions, and key machining insights.

What Is a Square Thread Form Geometry and Key Characteristics

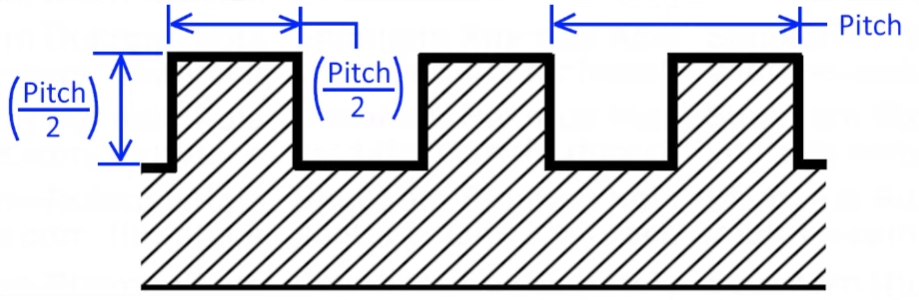

A square thread form is a type of screw thread with a distinctive square-shaped profile, commonly used in applications requiring efficient power transmission and high load capacity. Its geometry features straight, perpendicular flanks that create a 90-degree or zero-degree flank angle, meaning the thread sides are perfectly vertical instead of angled like in most other thread types.

Basic Profile and Zero Degree Flank Angle

The key characteristic that sets square threads apart is the zero-degree flank angle. This means the thread profile sides run straight up and down, forming a square cross-section. Unlike triangular or trapezoidal threads, square threads don’t create any radial pressure when loaded — all force is directed along the axis of the screw. This reduces friction and wear, making it ideal for power screw applications such as jackscrews and leadscrews.

The thread crest and root are flat, and the pitch—the distance between thread peaks—is uniform, allowing smooth sliding movement without backlash when parts are precisely machined.

Standards and Nomenclature

Square threads are standardized under organizations like ISO (International Organization for Standardization) and ANSI (American National Standards Institute). Common terms used include:

- Pitch (P): Distance from one thread to the next

- Lead (L): Distance the nut moves axially in one revolution (equals pitch for single-start threads)

- Minor diameter: Smallest diameter at the root of the thread

- Major diameter: Largest diameter at the crest of the thread

Each parameter follows strict tolerances to ensure interchangeability and performance.

Modified Variants

Though the classic square thread is perfectly vertical and flat, several modified variants exist:

- Half-square threads: Often used for ease of manufacturing

- Rounded flanks or roots: To improve strength by reducing stress concentration

- Multistart square threads: Multiple threads starting at different points around the shaft to increase lead without changing pitch

These variants aim to balance manufacturing challenges with mechanical performance.

In , the square thread form’s clean, zero-degree flank angle and square profile make it a unique and highly efficient solution where axial load handling and minimal friction are critical.

Advantages and Disadvantages of Square Thread Forms

Square thread forms are known for their high efficiency and excellent load-handling capabilities. The main advantage is that their straight sides mean less friction compared to other threads like Acme or trapezoidal, making them ideal for power transmission in leadscrew threading. This efficiency translates to smoother movement and less effort required to turn screws under heavy loads.

Another plus is their strength when handling axial loads. The square shape distributes force evenly, reducing wear and extending the life of components used in jackscrew applications or other heavy-duty equipment.

However, square threads also come with some challenges. Their fabrication is more complex and expensive because machining the sharp, precise square profile requires specialized tools and careful attention. Unlike Acme or trapezoidal threads, square threads lack angled flanks, which makes cutting and measuring them more difficult.

Additionally, the square thread’s design can lead to reduced strength in situations where bending forces occur, as the sharp corners might stress more easily compared to rounded thread forms.

In short, if efficiency and load capacity are top priorities, square thread forms are an excellent choice. But keep in mind the increased costs and machining challenges when deciding if it’s the right fit for your project.

Calculations and Dimensions for Square Thread Forms

When working with square thread form, getting the calculations and dimensions right is crucial. This ensures the threads perform well, handle loads properly, and fit in with other components.

Essential Formulas

- Thread Pitch (P): The distance from one thread crest to the next. This helps define the lead of the screw.

- Effective Diameter (d): The diameter where the thread thickness equals the space between threads. Used for load calculations.

- Lead (L): Usually equal to the pitch for single-start screws, defines how far the nut moves per revolution.

Size Charts and Tolerances

Square threads follow standards like ISO square thread standards that specify dimensions like pitch, depth, and thread height. Tolerances here are tight because inaccurate sizing can lead to poor fits or excessive wear. Typical parameters include:

- Pitch diameter tolerance

- Thread angle accuracy (flank angles are 0 degrees for square form)

- Thread depth and width limits

Measurement Techniques

To check square thread profiles accurately:

- Use a profile projector or optical comparator to inspect thread form details.

- Calipers measure pitch diameter and thread width for a quick check.

- Thread gauges ensure the threads meet standard dimensions and tolerances, especially in leadscrew threading applications.

Accurate calculations and measurements make sure your square threaded components work smoothly and last longer, especially in high-load setups like jackscrew or power screw efficiency tasks often seen in the U.S. manufacturing landscape.

Applications of Square Thread Forms in Modern Engineering

Square thread forms are a go-to choice for many heavy-duty applications where efficiency and load capacity matter most. Their design offers minimal friction and excellent power transmission, making them ideal for high load power transmission situations such as:

- Jackscrews and lifting equipment: Square threads handle large axial loads smoothly, providing reliable, precise movement for jacks and presses.

- Leadscrews in machine tools: They ensure accurate positioning with less wear thanks to their efficient thread profile.

- Power transmission systems: Often used in heavy machinery where high torque and load handling are crucial.

In industries like manufacturing, automotive, and aerospace, these threads support components that require long-lasting durability under repeated stress. For example, leadscrews in CNC machines commonly use square thread profiles to maintain precision over time.

Overall, the square thread form is favored when performance and longevity are key, even though they demand more careful manufacturing. This is why many engineers still rely on them for tough applications where power screw efficiency matters.

Square Thread Form vs Other Threads Acme Trapezoidal and V Threads

When comparing the square thread form to other common thread types like Acme, trapezoidal, and V threads, it’s clear each has strengths and specific uses. Here’s a straightforward look at how they stack up.

Head to Head Comparison

- Square Threads

- Profile: Straight sides, zero-degree flank angle

- Efficiency: Very high due to less friction

- Load Handling: Excellent for heavy axial loads

- Wear: Less wear from sliding action

- Difficult to machine because of sharp corners

- Acme Threads

- Profile: 29-degree flank angle, trapezoidal shape

- Efficiency: Slightly lower than square threads

- Load Handling: Good, easier to manufacture than square

- Common in power screws and leadscrews

- Better at handling side loads than square threads

- Trapezoidal Threads

- Profile: Similar to Acme, but standardized for metric sizes

- Efficiency: Comparable to Acme

- Widely used in Europe and for general power transmission

- Good trade-off between strength, efficiency, and ease of machining

- V Threads

- Profile: 60-degree flank angle

- Efficiency: Lower due to higher friction

- Load Handling: Less suitable for heavy loads, more for fastening

- Common in bolts, nuts, and general fastening

When to Switch from Square Threads

You might choose to switch away from square threads in these cases:

- When manufacturing convenience is more important—Acme and trapezoidal threads are easier and cheaper to machine.

- If your application needs better resistance to side loads, Acme or trapezoidal threads offer better stability.

- For fastening purposes rather than power transmission, V threads are more practical.

- When standardization and availability come into play, Acme and trapezoidal threads are more common in the U.S. market, making replacements and tools easier to find.

In short, if you want top-notch power screw efficiency and can handle the more complex machining, square threads are your go-to. But for a good balance of strength, cost, and availability, Acme or trapezoidal threads might be the smarter choice.

Manufacturing Square Thread Forms Tools Techniques and Best Practices

Making precise square thread forms requires careful planning and the right tools. Because of the unique square thread profile, machining these threads typically involves specific techniques tailored to maintain the geometry and strength of the thread.

Machining Methods

- Single-point Threading: The most common method uses a lathe with a single-point cutting tool shaped to the square thread profile. This allows for high precision but can be time-consuming.

- Grinding: For high-accuracy square threads, thread grinding is preferred. It provides smooth finishes and tight tolerances, especially needed in power screw applications.

- Thread Milling: CNC thread milling cutters shaped for square profiles are also used in modern shops, offering flexibility in different sizes and faster production rates.

Tools and Equipment

- Specialized Thread Cutters: Square thread cutting tools have flat flanks to match the zero-degree flank angle of the thread form. Carbide inserts are often chosen for durability.

- Measuring Instruments: Precision thread gauges, optical comparators, and coordinate measuring machines (CMM) are essential to verify correct thread dimensions and pitches according to ISO square thread standards.

Materials and Finishing

- Material Selection: Square threads are usually cut into metals with good machinability like steel alloys, stainless steel, or bronze. The material choice depends on load requirements and environment.

- Surface Treatments: After machining, threads often undergo finishing steps such as heat treatment, plating, or coating. These improve wear resistance and reduce friction—critical in high-load leadscrew applications.

- Deburring: Because square threads have sharp edges, careful deburring is required to avoid stress concentrations that can lead to premature failure.

By combining appropriate tools, precise machining techniques, and quality finishing, manufacturers can produce reliable square thread forms that perform well in demanding engineering applications.