Compare titanium vs aluminum strength in 2025 with data on tensile strength, fatigue, weight ratios, corrosion, and real-world uses.

Understanding “Strength” – The Key Mechanical Properties That Actually Matter

When comparing titanium vs aluminum strength, it’s crucial to get clear on what “strength” really means. In engineering, strength isn’t just one number — it’s a collection of mechanical properties that dictate how a metal performs under different stresses and conditions. Let’s break down the key ones that actually matter:

- Tensile Strength (Ultimate): This is the maximum stress a material can handle while being stretched or pulled before it breaks. Think of it as the metal’s breaking point.

- Yield Strength: The stress at which a material begins to deform permanently. Before this point, it can bounce back; after, it’s permanently bent or stretched.

- Fatigue Strength (Endurance Limit): How well the metal resists crack formation and grows under repeated loading cycles—critical for parts like aircraft wings or bike frames that see constant stress.

- Shear Strength: Ability to withstand forces that try to slide one part of the material past another.

- Hardness (Brinell / Rockwell): Measures resistance to surface indentation or scratching — a key factor for knives and tools.

- Stiffness (Young’s Modulus): Reflects how much a material deforms elastically under load. A higher modulus means less flex under pressure.

To put these into perspective, here’s a quick side-by-side of common grades:

| Property | Ti-6Al-4V (Grade 5) | 6061-T6 Aluminum | 7075-T6 Aluminum |

|---|---|---|---|

| Ultimate Tensile Strength (ksi) | ~128 ksi (880 MPa) | ~45 ksi (310 MPa) | ~83 ksi (570 MPa) |

| Yield Strength (ksi) | ~120 ksi (827 MPa) | ~40 ksi (276 MPa) | ~73 ksi (503 MPa) |

| Fatigue Strength (ksi) | ~50+ ksi (345+ MPa)* | ~20 ksi (137 MPa) | ~33 ksi (228 MPa) |

| Shear Strength (ksi) | ~79 ksi (545 MPa) | ~30 ksi (207 MPa) | ~58 ksi (400 MPa) |

| Hardness (Rockwell) | ~36 HRC | ~95 Brinell | ~150 Brinell |

| Young’s Modulus (GPa) | ~113 GPa | ~69 GPa | ~71 GPa |

| Density (g/cm³) | 4.43 | 2.70 | 2.81 |

*Fatigue strength varies widely with surface finish and treatment in Ti-6Al-4V.

Bottom line: Titanium, especially Ti-6Al-4V, boasts much higher tensile and yield strength than common aluminum alloys. It’s also notably stiffer and harder. But aluminum isn’t weak, especially in high-strength alloys like 7075-T6, which packs a surprising punch considering its low density.

This table gives you the raw numbers, but as we dive deeper, you’ll see why those figures translate into very different real-world behaviors. Next up: head-to-head raw numbers and what they really mean.

Raw Numbers Head-to-Head (Most Common Alloys)

Let’s dive straight into the key numbers comparing popular titanium and aluminum alloys used in the U.S. market.

Table 1: Ti-6Al-4V (Grade 5) vs 6061-T6 vs 7075-T6

| Property | Ti-6Al-4V (Grade 5) | 6061-T6 Aluminum | 7075-T6 Aluminum |

|---|---|---|---|

| Tensile Strength (ksi) | 130 | 45 | 83 |

| Yield Strength (ksi) | 120 | 40 | 73 |

| Fatigue Strength (ksi) | ~55 | ~27 | ~40 |

| Hardness (Rockwell) | 36 HRC | 95 HRB | 150 Vickers (approx) |

| Density (g/cm³) | 4.43 | 2.70 | 2.81 |

| Young’s Modulus (GPa) | 113 | 69 | 71 |

Key Takeaways:

- Ti-6Al-4V offers roughly 1.5–2 times higher tensile and yield strength than 7075-T6, and about 3 times more than 6061-T6.

- While titanium is denser than aluminum, it’s still much lighter than steel but heavier than aluminum alloys.

- Titanium’s stiffness is about 50% higher, meaning it resists bending better than aluminum under load.

- This makes Ti-6Al-4V a go-to when strength and toughness matter, despite its higher density and cost.

Table 2: Pure Titanium vs Pure Aluminum vs High-Strength Alloys

| Material | Tensile Strength (ksi) | Yield Strength (ksi) | Density (g/cm³) | Notes |

|---|---|---|---|---|

| Pure Titanium | 50 | 35 | 4.51 | Soft but corrosion-resistant |

| Pure Aluminum | 13 | 7 | 2.70 | Lightweight, low strength |

| Ti-6Al-4V Alloy | 130 | 120 | 4.43 | Aerospace-grade, tough |

| 7075-T6 Aluminum | 83 | 73 | 2.81 | High-strength aluminum alloy |

Key Takeaways:

- Pure titanium isn’t inherently “strong,” but alloys like Ti-6Al-4V boost it to levels that surpass most aluminum alloys by a wide margin.

- Pure aluminum is lightweight but very weak; metal strength really comes down to the alloy and heat treatment.

- High-strength aluminum alloys like 7075-T6 close the gap but still can’t fully match the titanium alloy strength.

- For applications requiring both strength and corrosion resistance, titanium alloys are usually the better pick, even if they cost more.

These raw numbers help us understand why titanium is favored in aerospace and high-end gear, while aluminum shines where lightness and cost are priorities.

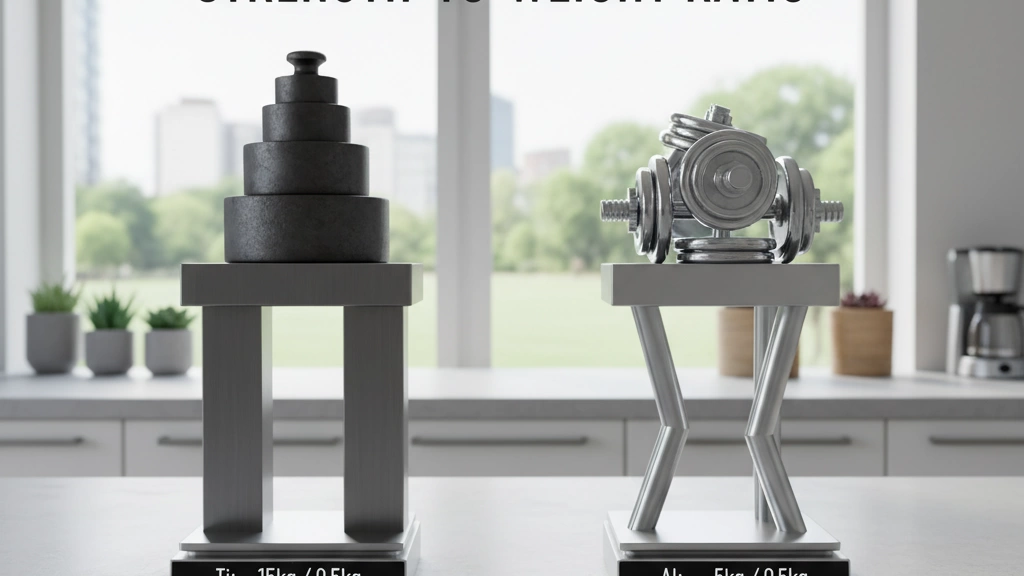

Strength-to-Weight Ratio – The Real Deciding Factor

When it comes to choosing between titanium vs aluminum strength, strength-to-weight ratio is where the real difference shows up. This ratio compares how strong a metal is relative to its weight — basically, how much strength you get per pound.

Specific Strength Comparison

- Titanium (Ti-6Al-4V) has an ultimate tensile strength around 130,000 psi and a density of about 4.43 g/cm³.

- 6061-T6 Aluminum has a tensile strength at about 45,000 psi with a density of 2.7 g/cm³.

- 7075-T6 Aluminum is stronger at roughly 83,000 psi but weighs the same as 6061-T6.

If you divide strength by density (specific strength), titanium clearly pulls ahead. Titanium’s specific strength is nearly double that of 7075-T6 aluminum, which explains why industries that need super strong yet lightweight parts — like aerospace and high-end everyday carry (EDC) gear — favor titanium.

Why Titanium Dominates Aerospace & High-End EDC

- Lightweight and strong: Titanium parts can be thinner and lighter without sacrificing durability.

- Fatigue resistant: Titanium’s excellent strength-to-weight helps components last longer under stress.

- Corrosion resistance: Staying strong over time even in tough environments.

Aluminum is great for many applications but when lightweight strength matters most — think aircraft frames, premium bike parts, or tough pocket knives — titanium’s superior specific strength makes it worth the extra cost.

Bottom line: While aluminum is lighter, titanium gives you more strength per pound, and that’s why it rules when every ounce counts.

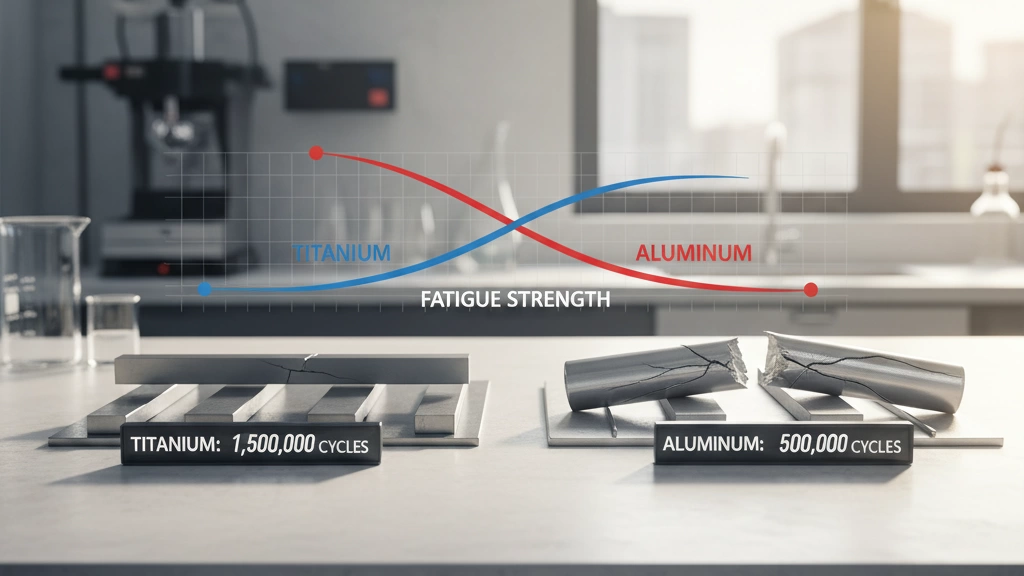

Fatigue and Long-Term Durability

When it comes to long-term use, fatigue strength is a big deal. Aluminum’s weak spot is crack propagation—over time, tiny cracks can grow under repeated stress, leading to failure sooner than you’d want. This is why aluminum parts, especially in high-stress applications like bike frames or aircraft wings, often need more frequent inspection or replacement.

Titanium, on the other hand, shines with near-infinite fatigue life in many conditions. It resists crack growth much better, which means it can handle repeated stress cycles without breaking down. That’s why you see titanium in top-end bike frames and aircraft components where durability counts.

For example, titanium bike frames remain strong and safe after thousands of miles, while aluminum frames might show fatigue damage earlier. Aircraft wings made partly of titanium benefit from this fatigue resistance, allowing for longer service lives and added safety. Even knife blades made from titanium take advantage of this toughness, holding up better under repeated impacts and stresses compared to their aluminum cousins.

In short, titanium’s fatigue strength gives it a serious edge for durability when long-term stress resistance is a must.

Impact Resistance and Toughness

When it comes to impact resistance, titanium clearly has the edge over aluminum. Tests like Charpy and Izod impact values measure how much energy a material can absorb before fracturing. Titanium generally scores higher, meaning it takes more of a hit before cracking or breaking.

This toughness is why titanium is the go-to metal for knives and tools that need to handle drops, rough use, and sudden shocks. Aluminum, while lightweight, tends to be more brittle under impact, especially the high-strength alloys. It can dent or crack more easily.

In practical terms:

- Titanium knives resist chipping and breaking even after hard drops.

- Tools made with titanium hold up better in demanding environments where impact is common.

So if drop resistance and toughness are important to you, titanium is the stronger, more durable choice.

Corrosion Resistance and Strength Retention

Aluminum is lightweight and strong, but it has a big weakness—corrosion. When exposed to saltwater or humid air, aluminum starts to corrode. This corrosion eats away at its surface, leading to a loss of strength over time. That’s why aluminum gear used near the ocean or in damp environments can weaken faster than you’d expect.

Titanium, on the other hand, is naturally immune to corrosion. It forms a protective oxide layer that prevents rust and degradation, even in harsh saltwater conditions. This corrosion resistance keeps titanium parts strong and reliable for years without special coatings or maintenance.

For anyone using gear in marine settings or rugged outdoor environments—think boat hardware, fishing gear, bike frames, or camping tools—titanium holds a clear advantage. It stays strong longer and requires less upkeep, making it a smarter choice when corrosion resistance matters as much as strength.

Temperature Performance

When it comes to heat, titanium clearly outperforms aluminum. Aluminum alloys generally start losing their strength at around 200 °C (about 390 °F). This means if your project or product regularly faces high temperatures—like engine parts or aerospace components—aluminum might not hold up as well over time.

Titanium, on the other hand, stays strong way beyond that, maintaining its mechanical properties up to 600 °C (over 1100 °F). That’s why titanium is the go-to metal for high-temperature applications in places like jet engines, exhaust systems, and even some industrial tools.

Key points:

- Aluminum strength drops significantly above 200 °C

- Titanium retains strength and stiffness up to 600 °C+

- Ideal for heat-exposed parts, titanium is majorly favored in aerospace and high-performance gear

In simpler terms, if your gear needs to handle serious heat without losing strength, titanium beats aluminum hands down every time.

8. Real-World Applications – When Each Metal Wins

When it comes to titanium vs aluminum strength, knowing where each metal shines helps you pick the right one for your project.

Where Titanium Rules

Titanium, especially alloys like Ti-6Al-4V (Grade 5), is the go-to for applications needing top strength, light weight, and corrosion resistance:

- Aerospace parts: Aircraft frames and engine components rely on titanium’s strength-to-weight ratio and heat resistance.

- Medical implants: Titanium’s biocompatibility means it’s used for bone plates, joint replacements, and dental implants.

- High-end knives: Titanium blades or handles resist corrosion and impact better than aluminum, ideal for premium gear.

- Watches: Luxury timepieces use titanium for durability combined with lightness.

- Bike frames: Titanium frames balance strength, fatigue life, and corrosion resistance for serious riders.

- Space exploration: Withstand extreme conditions with titanium’s longevity and strength.

Where Aluminum Dominates

Aluminum alloys like 6061-T6 and 7075-T6 are common in areas where cost, weight, and ease of manufacturing matter:

- Cars: Aluminum panels and engine parts help reduce weight and improve fuel economy without breaking the bank.

- General aviation: Most private planes use aluminum for a good mix of strength and affordability.

- Cookware: Aluminum’s heat conductivity and low cost make it standard for pots and pans.

- Budget tools: Many tools, including handles and housings, use aluminum to keep prices low.

- AR-15 lowers: The firearm industry favors 7075-T6 aluminum for strength matched with lighter weight.

Hybrid Approaches

Combining metals often gets you the best of both worlds:

- Carbon fiber frames with alum alloy components offer light weight and stiffness.

- Titanium bolts or fasteners used on aluminum parts boost durability without adding much weight or cost.

- Multi-material designs are popular in bikes, aerospace, and cutting tools.

In short, titanium excels where performance and durability are worth the price. Aluminum wins when cost and ease matter more. Many industries blend both to maximize benefits.

Cost vs Performance Reality Check (2025 Prices)

When it comes to cost, titanium and aluminum couldn’t be more different. As of 2025, titanium (especially Ti-6Al-4V, or Grade 5) runs about $30–$40 per kilogram, while common aluminum alloys like 6061-T6 and 7075-T6 come in at around $3–$5 per kilogram. That makes titanium roughly 5 to 10 times more expensive than aluminum.

When titanium is worth the premium:

- Aerospace parts where strength-to-weight ratio and corrosion resistance are non-negotiable.

- Medical implants demanding biocompatibility and long-term durability.

- High-end knives and tools that need superior toughness and impact resistance.

- Bike frames and watches that benefit from titanium’s fatigue life and lightweight.

- Situations involving extreme temperatures where aluminum would weaken.

When aluminum is smarter:

- Budget-conscious projects like car parts, consumer electronics, cookware, and general aviation components.

- Applications requiring decent strength but where weight isn’t the top priority.

- Use cases where the material needs to be cheap and plentiful without sacrificing moderate performance.

- When easy machinability and recycling matter most.

In short, if your project demands top-level strength-to-weight, corrosion resistance, or high-temperature use, titanium justifies its high price. But for everyday strength needs and cost-effectiveness, aluminum still rules—especially popular alloys like 6061-T6 and 7075-T6 offer impressive strength at a fraction of the cost.

10. Common Myths Debunked

Let’s clear the air on some popular myths about titanium vs aluminum strength.

Myth: Titanium is always stronger

Not true. Strength depends on the exact alloy and application. For example, 7075-T6 aluminum actually has higher tensile strength (up to 83,000 psi) than some titanium grades like Grade 2 pure titanium (~50,000 psi). Ti-6Al-4V (Grade 5 titanium) is stronger overall but is also heavier and more expensive. So “stronger” isn’t a one-size-fits-all claim.

Myth: Aluminum is weak

7075-T6 aluminum is a high-strength alloy that can match or even surpass mild steel in tensile and yield strength, making it far from weak. It’s widely used in aerospace and automotive parts because it’s lightweight and tough. The idea that aluminum is flimsy just isn’t backed by real numbers.

Myth: Titanium can’t be sharpened (for knives)

This is a common misconception. Titanium alloys, especially Ti-6Al-4V, can be sharpened and hold an edge well but aren’t quite as hard as high-carbon steel blades. They shine in corrosion resistance and toughness, making them popular for knives that need durability, although they might not reach razor-sharpness levels like steel blades.

Bottom line: both metals have their strengths and weaknesses. What matters most is picking the right alloy for your specific needs—not just buying into hype.

Final Verdict – Which Is Stronger?

So, which is stronger — titanium or aluminum? The short answer: titanium generally has higher strength and better overall mechanical properties, but aluminum can still be tough and often makes more sense depending on your needs.

The Nuanced Answer

- Titanium (especially Ti-6Al-4V) wins on raw strength, fatigue life, corrosion resistance, and temperature tolerance. It’s light but strong, perfect when strength-to-weight ratio really matters, like aerospace, medical gear, or high-end knives.

- Aluminum alloys (like 6061-T6 and 7075-T6) are strong and much lighter than steel, but they don’t match titanium in fatigue life, corrosion resistance, or high-temperature strength. Aluminum shines in cost-effectiveness and general applications where weight and price are critical.

Decision Matrix: Which Metal Suits You?

| Factor | Titanium (Ti-6Al-4V) | Aluminum (6061-T6, 7075-T6) |

|---|---|---|

| Budget | High cost (5-10× aluminum) | Much more affordable |

| Weight Critical | Better strength-to-weight ratio | Lighter than steel, heavier than Ti |

| Corrosion | Nearly immune (marine/outdoor) | Prone to corrosion without coatings |

| Temperature | Strong above 600°C | Loses strength above ~200°C |

| Fatigue Life | Outstanding durability | More susceptible to crack growth |

| Impact/Toughness | Superior drop/impact resistance | Good, but less tough |

Bottom Line

If you’re working on a project where strength, durability, corrosion resistance, and temperature performance matter — and budget isn’t a huge barrier — titanium is the way to go. On the flip side, if you want a more affordable, still strong, lightweight metal for everyday use, aluminum alloys will cover you well.

Ultimately, both metals have their place. Choose based on where you need strength, weight savings, durability, and how much you want to spend.