Compare titanium vs aluminum weight with clear insights on density strength and applications to choose the best lightweight metal for your project.

Core Properties Breakdown

When comparing titanium vs aluminum weight, it helps to start with their core properties. Titanium is a strong, lustrous metal known for its excellent strength-to-weight ratio, while aluminum is valued for being lightweight and highly versatile.

Chemical Composition and Basic Traits

- Titanium is a transition metal with atomic number 22, known for forming strong, corrosion-resistant alloys. It has a silver-gray color and is highly resistant to rust, which makes it ideal for harsh environments.

- Aluminum is a lightweight metal with atomic number 13 and is abundant in the Earth’s crust. It’s softer than titanium but easily alloyed with metals like copper and magnesium to improve strength.

Thermal and Electrical Conductivity

- Titanium has a lower thermal conductivity (~22 W/m·K) compared to aluminum. This means it doesn’t transfer heat as efficiently, which can be an advantage in some aerospace and medical applications where heat resistance is needed.

- Aluminum outperforms titanium in thermal and electrical conductivity (~235 W/m·K), making it a better choice for applications like heat exchangers or electrical wiring where rapid heat and electricity transfer are essential.

Overall, titanium’s core properties center on strength and corrosion resistance, while aluminum emphasizes lightweight versatility and good conductivity. Understanding these traits sets the stage for comparing their weight differences and performance in real-world uses.

Head-to-Head Weight Comparison

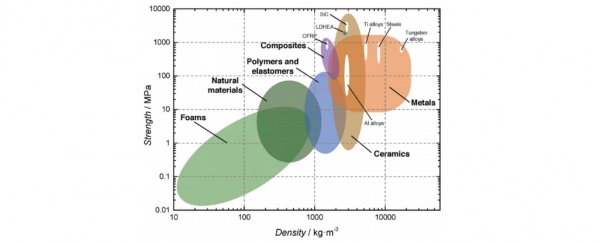

When it comes to comparing titanium vs aluminum weight, the main factor is their density. Aluminum is much lighter, with a density around 2.7 g/cm³, while titanium is heavier at about 4.5 g/cm³. This means aluminum is roughly 40% the weight of titanium for the same volume.

However, the raw weight difference doesn’t tell the whole story. The strength-to-weight ratio is where titanium often shines. Titanium has a much higher tensile strength, meaning you can use less material to achieve the same strength as aluminum—and sometimes even less weight overall depending on the application.

Alloy variations also affect weight. Both metals come in different grades and mixes, which can change their density and strength. For example:

- Aircraft-grade aluminum alloys can be stronger but slightly heavier.

- Titanium alloys differ too, with some designed to maximize strength while keeping weight down.

So while aluminum wins on absolute lightness, titanium’s better strength-to-weight ratio makes it the go-to for situations where durability meets weight savings. This balance is especially important in aerospace, cycling, and high-performance gear where every ounce counts.

Strength Durability and Performance Trade-Offs

When it comes to strength and durability, titanium and aluminum each have their pros and cons. Titanium typically outperforms aluminum in tensile strength and fatigue resistance, meaning it can handle repeated stress better without breaking down. This makes titanium a favorite in high-stress environments like aerospace and medical equipment.

On the other hand, aluminum is lighter and easier to shape but generally has lower fatigue resistance. It’s often chosen for applications where weight savings and cost matter more than extreme durability—for example, in consumer goods or automotive parts.

Corrosion resistance is another key difference. Titanium naturally forms a protective oxide layer, giving it excellent resistance to rust and harsh environments. Aluminum does resist corrosion but can wear down faster in salty or acidic conditions unless treated or alloyed properly.

Regarding machinability and formability, aluminum is generally easier to work with. It cuts, bends, and welds more readily, reducing manufacturing time and cost. Titanium can be tough to machine because it’s harder and generates more heat, requiring specialized tools and techniques. That’s something to keep in mind if you’re balancing performance benefits against production budgets.

In :

- Titanium has stronger tension strength and better fatigue resistance

- Titanium resists corrosion better in harsh environments

- Aluminum is easier and cheaper to machine and shape

- Aluminum works well where weight and cost are the main concerns

Choosing between these two depends on where you want to lean—performance or production ease.

Cost and Manufacturing Considerations

When comparing titanium vs aluminum weight, cost plays a big role in deciding which metal to use. Titanium tends to be much more expensive per pound than aluminum. This is mainly due to its complex extraction and processing methods. Aluminum is widely available and simpler to refine, making it the cheaper option up front.

But looking at price per pound only tells part of the story. Total ownership costs include not just raw material price but also manufacturing, machining, and maintenance expenses. Titanium’s strength and corrosion resistance can reduce long-term costs since products last longer and need less upkeep, despite the higher initial price.

Sourcing and processing at scale also impact costs. Aluminum enjoys a well-established global supply chain, which keeps prices stable and predictable. Titanium production is more limited and energy-intensive, making it less accessible for large-scale, low-cost manufacturing. This is why aluminum often dominates industries focused on volume and affordability, like automotive or consumer goods, while titanium is reserved for high-performance or specialized uses.

In short:

- Aluminum is cheaper per pound and easier to process

- Titanium costs more upfront but can save money over time due to durability

- Large-scale manufacturing favors aluminum due to supply availability and ease of sourcing

Choosing between the two often comes down to balancing budget with performance needs.

Real-World Applications and Case Studies

When it comes to real-world use, both titanium and aluminum have carved out important spots, especially in aerospace and automotive industries. Titanium’s high strength-to-weight ratio and corrosion resistance make it perfect for critical aerospace parts like engine components and airframes where safety and durability are key. Aluminum, on the other hand, shines in automotive manufacturing, helping reduce vehicle weight for better fuel efficiency without breaking the bank.

In the world of consumer and sporting goods, aluminum is a go-to for items like bike frames, camping gear, and electronics because it’s lightweight and easy to work with. Titanium gets picked for premium products like high-end bike frames, golf clubs, and watches where durability and corrosion resistance justify the higher price.

A growing trend is using both metals in 3D printing and prototyping. Aluminum alloys are popular for rapid prototyping due to their machinability and cost-effectiveness, while titanium is favored in applications needing strong, lightweight parts but at a higher cost. This shift is helping industries bring new designs to life faster with sustainable lightweight metals options.

Choosing between titanium and aluminum often depends on the balance of weight, strength, cost, and the specific needs of the product or project.

How to Choose Between Titanium and Aluminum

Picking between titanium and aluminum really comes down to what you need most from the metal. Here’s a quick guide that helps you decide:

Consider the Weight

- If keeping things super light is your top priority, aluminum usually wins. Its lower density makes it easier to handle and less costly to ship.

- But if your project demands strength without adding much weight, titanium’s better strength-to-weight ratio is a game-changer.

Think About Strength and Durability

- For items that face tough wear and tear, like bike frames or aerospace parts, titanium’s higher tensile strength and corrosion resistance give it an edge.

- Aluminum is great for less demanding uses where corrosion isn’t as big a deal, like some consumer goods or prototypes.

Check Your Budget

- Aluminum is more affordable upfront and easier to machine, so if cost is critical, it’s often the smarter choice.

- Titanium costs more to buy and work with but could save money over time thanks to its durability.

Match It to Your Application

- For aerospace, military, and high-performance automotive parts, titanium’s benefits often outweigh the price.

- For everyday applications, consumer products, and quick prototyping, aluminum’s lighter weight and lower cost make it popular.

In short, choose titanium when strength, corrosion resistance, and long-term durability are essential and you can stretch the budget. Pick aluminum if you want a lightweight, cost-effective metal for general use or prototyping. Both have their place, so focusing on your project’s needs will point you in the right direction.