Discover top zinc die casting applications across automotive electronics and more with key alloy insights and benefits for precision manufacturing.

If you’re exploring zinc die casting applications, you’ve tapped into one of manufacturing’s most versatile secrets. From automotive parts that shave weight and boost durability to electronics housings that demand precision and reliability, zinc die casting is reshaping how industries innovate and scale. Why? Because zinc alloys deliver unbeatable surface finish, remarkable ductility, and faster production cycles—giving engineers and designers a powerful edge. In this post, we’ll break down where zinc die casting shines and why it’s becoming the go-to choice for high-performance, cost-effective manufacturing. Ready to unlock the potential of zinc in your next project? Let’s dive straight in.

Why Choose Zinc Die Casting Key Advantages Over Alternatives

Are you wondering why zinc die casting stands out compared to other metal casting options? Zinc alloys offer several advantages that make them a top choice for high-performance parts. Their unique material properties and cost benefits deliver strong value for many industries.

Advantages of Zinc Alloy Die Casting for High Performance Parts

Zinc die casting provides excellent ductility and impact strength, making parts more durable without adding extra bulk. Unlike aluminum, zinc has a lower melting point. This means it requires less energy to cast, improving production efficiency and reducing costs. Additionally, zinc’s ability to create thinner walls allows for lighter, more intricate components without sacrificing strength.

Cost and Efficiency Benefits

Choosing zinc die casting can offer major cost savings. Here’s why:

- Higher production rates due to faster cycle times

- Thinner walls possible without compromising structural integrity

- Longer tool life because of lower casting temperatures

- Lower lifecycle costs thanks to reduced maintenance and material waste

These factors make zinc die casting an economical solution, especially for large production runs or complex designs.

Sustainability Angle

Zinc alloys are fully recyclable, which supports sustainability goals. Using zinc helps reduce environmental impact through:

- Recycled material usage maintaining alloy quality

- Lower energy consumption compared to aluminum casting

- Reduced waste and emissions in manufacturing

This makes zinc die casting an eco-friendly choice as industries push for greener production methods.

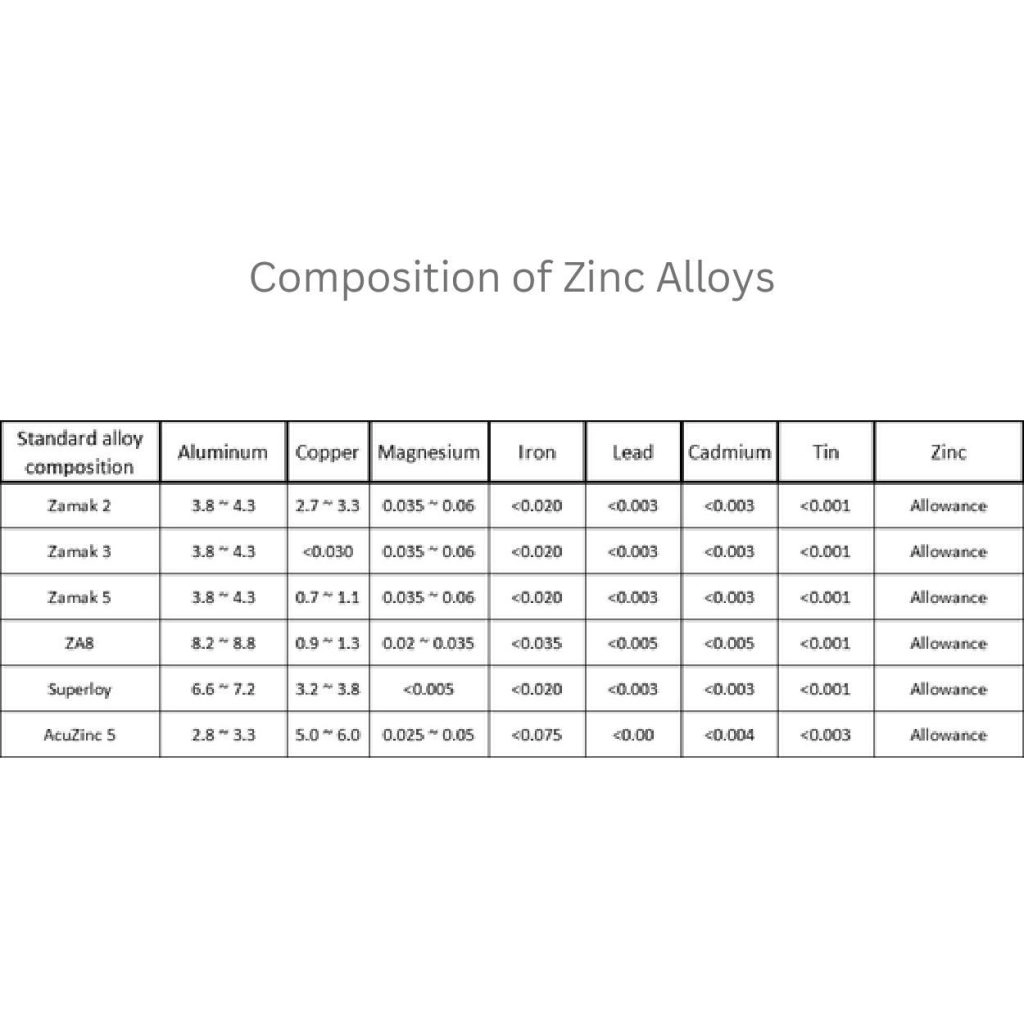

Quick Comparison of Zinc Alloys Table

| Alloy Type | Key Properties | Common Uses |

|---|---|---|

| Zamak 3 | Good ductility, impact | Precision parts, consumer goods |

| Zamak 7 | Higher strength | Automotive, hardware |

| ZA-8 | Excellent wear resistance | Electrical housings, heat sinks |

| ZA-27 | High strength and hardness | Heavy load automotive parts |

This quick overview shows why zinc alloys provide the right balance of performance and efficiency across many applications.

In short, zinc die casting offers a smart mix of mechanical performance, cost-effectiveness, and environmental benefits. This combination is driving its growing popularity in the U.S. market and beyond.

Essential Zinc Alloys for Die Casting Success

When it comes to zinc die casting applications, choosing the right alloy is crucial for getting the best results. Popular zinc alloys fall mainly into two groups: the Zamak series and the ZA alloys.

Zamak Series

- Zamak 3 is the workhorse alloy, known for excellent strength, corrosion resistance, and ease of casting. It’s great for automotive parts, consumer products, and electrical housings.

- Zamak 7 offers better mechanical properties than Zamak 3, especially higher strength and wear resistance, making it ideal for applications needing durability.

ZA Alloys

- ZA 8 combines zinc with aluminum and copper, offering improved strength and dimensional stability. It’s often used in precision components and industrial parts.

- ZA 27 has higher aluminum content for even greater strength and heat resistance, suitable for demanding automotive and machinery parts.

Choosing the Right Alloy

Consider these factors to pick the best zinc alloy for your project:

- Mechanical strength needs

- Corrosion resistance requirements

- Casting complexity and detail

- Operating temperature

- Cost targets

At Vast, we also specialize in custom blending alloys to match exact project needs. This helps achieve defect-free yields and optimal performance every time. Whether you need tight tolerances or enhanced durability, tailored zinc alloys make sure your parts meet and exceed expectations.

Real World Zinc Die Casting Applications Across Industries

Zinc die casting is everywhere—from cars to consumer products—because it delivers strong, lightweight, and cost-effective parts. Here’s a quick rundown of how it’s used across different sectors.

Automotive Parts

Zinc alloys are a big win for automotive, especially in electric vehicles (EVs). Zinc die cast parts help reduce weight without losing strength, improving battery efficiency and overall range. Components like brackets, housings, and connectors benefit from zinc’s durability and precision.

Electronics and Electrical

Zinc is great for making electronic housings, heat sinks, and EMI (electromagnetic interference) shielding. Its excellent dimensional stability and thermal conductivity make sure devices run cooler and last longer, which is crucial for consumer electronics and industrial gear.

Medical and Precision Devices

In the medical field, zinc die casting supports manufacturing parts that need tight tolerances and biocompatibility. Tools, small components, and housings can be crafted with precision, helping improve reliability and performance in medical equipment.

Consumer Products and Hardware

From door handles and locks to power tools and decorative fittings, zinc die casting offers attractive finishes and strong wear resistance. It’s perfect for products needing a sleek look plus toughness for everyday use.

Industrial and Other Uses

Zinc’s versatility extends to furniture fittings, toy components, and other industrial parts. It’s easy to mold complex shapes with good surface detail, while keeping production costs down.

Case Study: Reducing EV Part Weight and Costs

At Vast, we’ve helped automotive clients slash part weight and costs by switching to zinc die casting. This meant lighter EV components, faster production cycles, and better overall vehicle performance—all while meeting strict quality standards.

Zinc die casting isn’t just a material choice; it’s a strategic advantage across many industries looking to innovate and stay competitive.

Design and Manufacturing Best Practices for Zinc Die Cast Parts

When it comes to zinc die casting applications, good design and smart manufacturing practices make all the difference. From our experience at Vast, optimizing your zinc die cast parts starts with a few key design tips.

Optimizing Zinc Die Casting Design

- Draft Angles: Make sure to include draft angles between 1° and 3°. This helps the parts to eject smoothly from the mold and reduces surface defects.

- Wall Thickness: Aim for uniform wall thickness, typically between 0.030 and 0.125 inches. Thin walls save material and improve cooling but watch out—they shouldn’t be so thin that they cause porosity or warping.

- Bosses and Ribs: Design bosses with adequate thickness and avoid sharp corners by using fillets. This strengthens the part without creating weak points.

Surface Finishes and Post Processing

Zinc castings offer excellent surface finish options. You can choose from:

- Polishing or buffing for a smooth, shiny look.

- Powder coating or painting to improve corrosion resistance.

- Plating such as chrome or nickel plating for added durability and aesthetics.

These finishes not only enhance appearance but also extend the life of the part in demanding environments.

Common Challenges and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Porosity | Rapid cooling, uneven walls | Control wall thickness, optimize cooling channels |

| Surface blemishes | Poor mold maintenance | Regular mold cleaning and polish |

| Warping or distortion | Uneven shrinkage | Uniform wall thickness, proper gating design |

| Incomplete filling | Insufficient injection pressure | Adjust pressure and injection speed |

Regular quality assurance protocols like X-ray inspection and dimensional checks help catch issues early.

Integration with Technology

Using 3D simulation tools is a game changer. These allow you to:

- Predict potential flaws before the mold is made.

- Optimize flow of molten zinc inside the die.

- Forecast cooling and solidification patterns.

This proactive approach lowers tooling costs, speeds up prototyping, and delivers better yields—great for local U.S. manufacturers aiming to keep production efficient and cost-effective.

By following these best practices, you can fully leverage zinc die casting advantages and create high-quality parts with consistent performance.

The Future of Zinc Die Casting Trends and Innovations

Zinc die casting is set for exciting growth and new trends, especially in the U.S. market where electric vehicles (EVs) and miniaturized electronics are booming. Demand for lightweight, precise, and durable parts is driving zinc alloy die casting to center stage because of its unique material advantages.

Emerging Trends in Zinc Alloy Die Casting Applications

- EV Market Growth: Zinc parts help cut weight and improve efficiency in electric vehicles, crucial for battery life and performance.

- Miniaturization: Smaller, more complex parts are possible thanks to zinc’s ability to fill thin walls and intricate molds quickly.

- Hybrid Alloys: Combining zinc with other metals to boost strength and corrosion resistance is becoming more common.

- Closed-Loop Recycling: Reusing zinc alloys reduces waste and energy consumption, aligning with U.S. sustainability goals.

Innovations Shaping the Future

Cutting-edge developments like AI-optimized molds are speeding up prototyping and reducing defects. Companies like Vast are leading the pack in research and development to make zinc die casting faster, cleaner, and more cost-effective.

By embracing these trends, zinc die casting remains a versatile, eco-friendly choice that meets the evolving needs of automotive, electronics, and consumer markets across the United States.