Master transition fits explained with key tolerances types applications and selection tips for precise mechanical assembly and engineering design.

Understanding the Basics What Is a Transition Fit

A transition fit is a type of mechanical fit used to join two parts—typically a shaft and a hole—where the fit can result in either a slight clearance or a slight interference. This means the parts may either slide together easily or require a small amount of force to assemble. It strikes a balance between the loose freedom of a clearance fit and the tight grip of an interference fit.

Core Definition and Tolerance Explanation

In engineering, a fit is defined by the tolerance zones for both the hole and the shaft. Transition fits occur when these tolerance zones overlap, allowing either small clearance or small interference. This overlap ensures predictable performance without excessive looseness or excessive tightness.

Key Characteristics and Assembly Methods

- Versatile fit: Allows moderate ease of assembly, sometimes by hand or light press fitting.

- Controlled precision: Ensures parts align accurately with minimal play.

- Moderate force assembly: Can be assembled with slight pressure without damaging components.

Common Misconceptions

- Transition fit is not just a “loose” or “tight” fit—it is a carefully engineered compromise.

- It is not designed for permanent joints needing maximum strength but rather for precise, repeatable connections.

- Some assume transition fit always guarantees zero movement, but slight micro-movements can exist and are often acceptable.

Understanding these basics helps when determining if a transition fit suits your project’s precision and performance needs.

Transition Fits vs Other Types A Side-by-Side Comparison

Understanding how transition fits stack up against clearance and interference fits helps a lot when picking the right fit for your project.

| Fit Type | Clearance Fit | Transition Fit | Interference Fit |

|---|---|---|---|

| Clearance | Always a gap between parts | May have a slight gap or light press fit | Parts always overlap, tight fit |

| Assembly | Easy assembly and removal | Requires moderate force or press fit | Usually needs heating or press to assemble |

| Tolerance Zones | Minimal overlap | Tolerance zones overlap slightly | Tolerance zones overlap significantly |

| Best For | Parts that move freely or need easy disassembly | Precise location with moderate tightness | Permanent joints needing high strength |

| Pros | Easy to assemble/disassemble, less wear | Balanced strength and precision | Strong, resistant to movement |

| Cons | Can allow play or vibration | Harder to assemble than clearance, not as strong as interference | Difficult assembly, risk of damage |

When to Choose Transition Fits

I usually recommend transition fits when you want a secure, precise fit without the hassle of forceful assembly or risk of part damage. They work great if parts must stay aligned but still might need removal down the line. Transition fits are the middle ground—offering better control than clearance fits but easier handling than interference fits.

For more on fit selection, check out our detailed fit selection guide.

Types and Standards Navigating ISO ANSI and Hole Shaft Systems

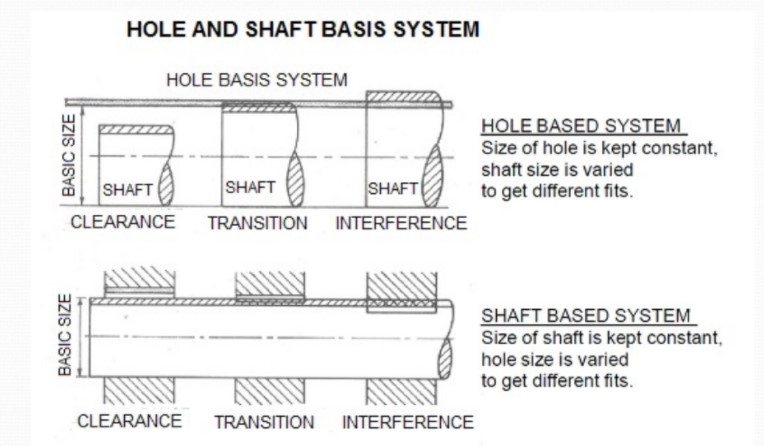

When dealing with transitional fits, understanding the types and standards is key. The most common standards you’ll encounter in the U.S. are ISO 286 and ANSI B4.1. Both lay out clear rules for tolerances, giving you a reliable framework for how tight or loose parts should fit together.

Locational Transition and Semiautomatic Subtypes

Within transitional fits, you’ll find subtypes like locational transition fits and semiautomatic fits. Locational transition fits are designed to precisely position parts with minimal movement, often used when parts need repeatability but not full interference. Semiautomatic fits allow easier assembly than interference fits but still provide a controlled tightness—perfect when you need some balance between force and accuracy.

ISO 286 and ANSI B4.1 Standards Overview

- ISO 286: Widely international, this system organizes fits by hole and shaft basis, defining tolerance zones that match specific assembly needs.

- ANSI B4.1: Common in the U.S., this standard specifies engineering tolerances for shafts and holes, providing familiar references for American manufacturing.

These standards categorize fits into tolerance grades, guiding you on how much clearance or interference you’re working with.

Tolerance Chart Examples

Tolerance charts based on these standards help you quickly pick the right fits. For example, a transition fit on a 50 mm shaft might have its tolerance limits set from a slight clearance to a tiny interference, ensuring parts fit snugly but are still easy to assemble or disassemble.

Effects of Thermal Expansion

One often overlooked factor is thermal expansion. Materials expand or contract with temperature changes, which can immediately affect fits. When choosing a transition fit, consider the operating temperature range, especially in industries like aerospace or automotive where temperature swings are common. Proper allowances ensure that parts won’t seize up or loosen unexpectedly.

By sticking to these standards and understanding the nuances of each subtype and tolerance, you’ll make better, more reliable assemblies every time. For a deeper dive into how these fits compare with others, check out our guide on Fit selection guide.

Real-World Applications Where Transition Fits Shine in Engineering Projects

Transition fits are a go-to choice in many engineering fields because they strike the right balance between clearance and interference. Here’s where they really stand out:

Automotive Use Cases

In car manufacturing, transition fits are used for assembling parts like shafts and bearing housings. They ensure components are secure without causing damage or requiring excessive force during assembly. This helps maintain performance and extends part life.

Aerospace Applications

Flight-critical parts demand high precision, and transition fits provide just that. They offer a reliable connection that can handle vibration and thermal expansion in engines and control systems without loosening or excessive stress.

Machinery Maintenance and Assembly

Transition fits make it easier to replace parts during maintenance without needing special tools or heating. This reduces downtime and speeds up repairs in factories or heavy machinery.

Additive Manufacturing and Hybrid Approaches

As 3D printing advances, designers use transition fits to combine printed parts with traditional components. This combination allows for precise assembly while accommodating slight variations from additive processes.

Case Study on Robot Arm Joint

In robotics, joints must be accurate and smooth. Transition fits are perfect here—they allow for controlled movement without play, ensuring the robot’s arm moves precisely while staying firmly connected at pivot points.

Transition fits offer practical, reliable solutions across these industries, making them essential for precise, durable mechanical joints.

How to Select and Implement the Right Transition Fit A Step by Step Guide

Choosing the right transition fit means balancing precision, load, and material factors to ensure your mechanical joint works smoothly. Here’s a simple step-by-step to help you get it right every time.

1. Assess Your Requirements

- Load: Know the forces your joint will face — heavy or light?

- Motion: Will parts rotate, slide, or stay still?

- Materials: Different metals or composites expand differently, affecting fit.

2. Calculate Tolerances

Use tolerance calculation tools and standards like ISO 286 or ANSI B4.1 to find the right hole and shaft tolerances. This ensures your fit is neither too loose nor too tight.

| Fit Type | Tolerance Goal | Typical Use |

|---|---|---|

| Clearance Fit | Always some play | Easy assembly, low precision |

| Transition Fit | Small clearance/interference | Controlled tightness for precision |

| Interference Fit | Always interference | Permanent, high strength |

3. Prototype and Test

Build samples and check:

- Fit smoothness

- Movement and load response

- Wear over time

This early testing helps catch problems before full production.

4. Scale to Production

- Standardize procedures based on your prototypes.

- Use precision machining and inspection tools.

- Train your crew on fit importance and checks.

5. Watch Out for Common Pitfalls

- Ignoring thermal expansion—different materials expand differently.

- Relying solely on theory—always test physically.

- Over-tight fits causing damage during assembly.

Quick Checklist

- Define load and motion needs

- Select material types

- Calculate tolerances from ISO or ANSI tables

- Prototype and test fit

- Adjust based on test results

- Prepare production guidelines

- Train staff and implement inspections

Following these steps keeps your transitional fit precise and reliable, meeting the demands of US engineering projects without surprises.