Discover the precision of wire cut EDM for complex metal parts with high accuracy fast processing and versatile materials handling.

Understanding the Fundamentals of Wire Cut EDM

Ever wonder how a thin wire can cut through tough metal with pinpoint accuracy? That’s the magic of wire cut EDM (Electrical Discharge Machining), a process that uses electrical sparks to shape metal precisely.

The Basic Process: How Electrical Sparks Shape Metal

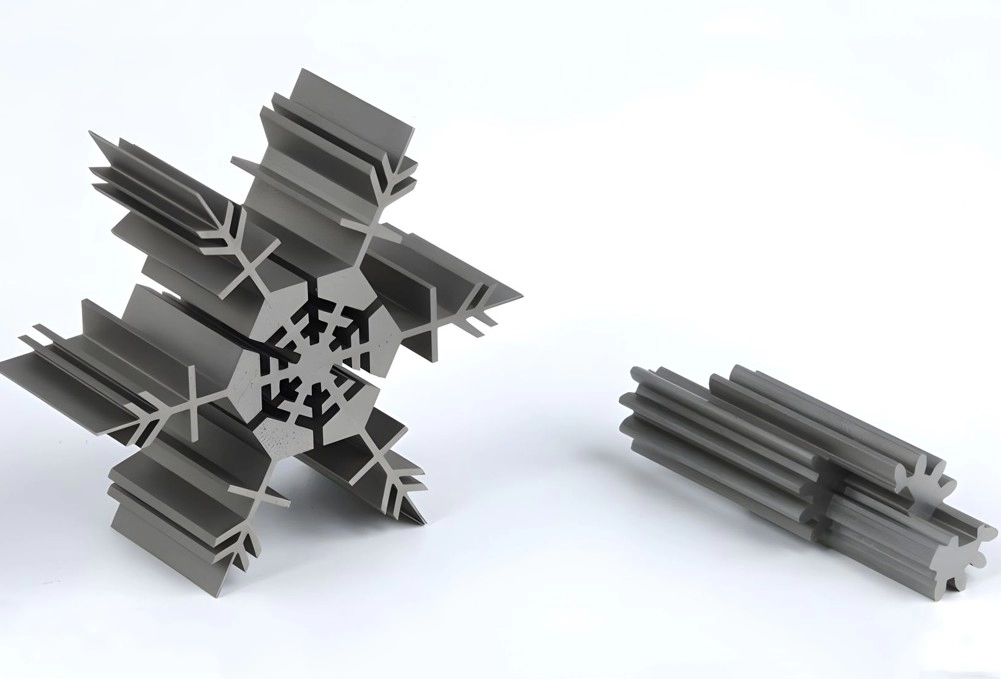

Wire cut EDM works by sending a thin, electrically charged wire (called an EDM wire electrode) between the wire and the metal workpiece. Tiny, controlled sparks jump across the gap, eroding the metal bit by bit without any direct contact. Think of it like lightning sculpting metal at a microscopic level. This spark erosion technology melts away material, creating complex shapes and tapered holes with incredible accuracy.

Key Components: Wire Guides and CNC Controls

To keep this precise, the wire is guided through a series of wire guides that maintain perfect tension and positioning. Behind the scenes, a powerful CNC (Computer Numerical Control) system controls the wire’s path, speed, and spark intensity. This coordination ensures every cut follows the programmed design flawlessly, allowing for intricate geometries on even the hardest materials.

By combining non-contact subtractive machining with smart controls, wire cut EDM delivers unmatched precision—exactly why it’s a go-to method in modern manufacturing.

Evolution of Wire Cut Technology

Wire cut EDM has come a long way since its early days. Originally developed in the mid-20th century, this electrical discharge cutting method started as a simple way to handle tough metals that regular tools couldn’t easily shape. Over time, advances in CNC wire threading and spark erosion technology made wire cut machining faster and far more precise.

Today’s setups use smart CNC controls that allow for intricate cuts with minimal error, helping machine makers create complex shapes like tapered holes and detailed die components without compromising quality. Materials once considered too hard for traditional machining, like hardened steel, are now routine with wire EDM.

The technology has also become more reliable, reducing wire breakage and improving surface finishes. From manual machines to fully automated systems, wire cut EDM keeps evolving to meet demanding US manufacturers’ needs for accuracy, repeatability, and productivity. This progress helps companies stay competitive in precision metal erosion and die mold making industries across the country.

The Wire Cut EDM Workflow From Setup to Finish

When it comes to wire cut EDM, the process starts with careful preparation. First, you pick the right material based on what you need—whether it’s hardened steel for prototyping or a specialty alloy for aerospace parts. Then, programming comes in. Using CNC wire threading controls, you set the exact cutting path to shape the metal precisely.

The actual cutting happens in stages:

- Roughing: This is the first pass, where the machine removes the bulk of material quickly.

- Finishing: Next, it smooths out the shape to get closer to the final dimensions.

- Skimming: Finally, it polishes the surface, ensuring the highest accuracy and quality finish.

One of the biggest advantages here is post-processing—or rather, the lack of it. Wire EDM doesn’t generate heat affected zones since it uses electrical discharge cutting instead of mechanical force. This means no distortions or stresses on the metal, just pure precision right off the machine. You get clean edges, tight tolerances, and parts ready for use or next steps without extra work.

Advantages of Wire Cut EDM Why It Outshines Traditional Machining

Wire cut EDM stands out because it offers precision and flexibility that traditional machining can’t match. Here’s why it’s a game changer for many U.S. manufacturers:

Top Benefits for Precision Manufacturing

- Unmatched Accuracy: Wire EDM machining uses electrical discharge cutting, which lets you shape metal down to microns. This means tighter tolerances and smoother finishes without extra work.

- Complex Geometries Made Simple: Unlike conventional tools, wire cut can easily create tricky shapes—like tapered holes or fine details in hardened steel prototypes—thanks to its precise spark erosion technology.

Versatility Across Hard Materials and Low Volume Runs

- Works great on tough metals that are difficult to machine traditionally, whether you’re making dies, molds, or small batch parts.

- Perfect for low volume runs and prototypes because there’s no need for expensive tooling changes or setups.

Cost and Efficiency Gains

- Saves time since it cuts metal without physical contact, reducing wear and tear on tools.

- Minimal material waste and no heat affected zones means less finishing work—cutting down overall costs.

- CNC wire threading and automated controls improve repeatability and cut lead times, helping U.S. shops stay competitive.

In short, wire cut EDM combines precision, adaptability, and cost-effectiveness—ideal for American manufacturers focusing on quality and speed.

Applications and Real World Use Cases of Wire Cut EDM

Wire cut EDM stands out in many industries where precision and complex shapes are a must. Here’s where this technology really shines:

- Aerospace and AutomotivePerfect for making turbine blades, fuel system components, and extrusion dies. These parts often use hardened steel or exotic alloys that are tough to machine by traditional methods. Wire EDM handles them with ease, producing consistent, accurate parts critical for performance.

- Medical and ToolingFrom implants to blanking punches, wire EDM delivers flawless results. The process creates sharp edges and intricate designs without altering the metal’s properties, which is essential for medical tools and dies where precision matters most.

- Electronics and EnergyEmerging sectors heavily rely on wire EDM for parts like micro connectors, specialized contacts, and components used in cutting-edge energy devices. Its ability to cut small, intricate shapes without heat damage makes it ideal for these sensitive applications.

Wire cut EDM’s flexibility across hard materials, tiny tolerances, and complex geometries makes it the go-to choice for many demanding manufacturing needs in the U.S. market.

Challenges Limitations and Best Practices for Wire Cut EDM

Wire Cut EDM is powerful, but it’s not without its challenges. Knowing what to watch for can save time and money and get you better results.

Common Pitfalls to Watch Out For

- Wire Breakage: One of the biggest headaches. It often happens due to too high cutting speed, improper tension, or tough material properties. Keep your wire tension steady and adjust the feed rate based on the metal type.

- Surface Finish Issues: Not every cut comes out smooth. The finish can suffer if the machine parameters aren’t dialed in or if the wire electrode wears out. Using multiple passes—roughing, finishing, and skimming—helps get that perfect surface.

- Slow Cutting Speed on Thick Materials: Wire EDM isn’t the fastest method for very thick or large parts. Sometimes it requires compromising between speed and precision.

When to Consider Alternatives

Wire Cut EDM is ideal for hard metals and complex shapes, but there are times when other processes might be better:

- For very high volume runs, traditional milling might be more cost-effective.

- When you need super fast cuts on softer metals, laser cutting or waterjet may offer better turnaround.

- If the part geometry is simple and doesn’t require ultra-tight tolerances, conventional machining could be faster.

Pro Tips from Experienced Operators

- Keep Your Machine Maintained: Regular cleaning and wire replacement enhance cutting stability.

- Optimize Programming: Customizing your CNC programming for each job reduces wire breaks and improves surface quality.

- Use High Quality EDM Wire Electrodes: Better wire means less downtime, fewer defects, and more consistent cuts.

- Start with a Roughing Pass: Don’t try to finish in one go. Removing bulk with roughing passes saves your wire and improves accuracy.

- Monitor Spark Gap Constantly: Adjusting spark voltage helps maintain precision and protect the wire.

Wire Cut EDM is a reliable process when you know its quirks and limits. By following best practices and choosing it wisely, you unlock unrivaled precision for your toughest jobs.