Explore a complete guide to engineering tolerance symbols with clear explanations, examples, and GD&T best practices for precision design.

Understanding the Fundamentals of GD&T and Tolerance Symbols

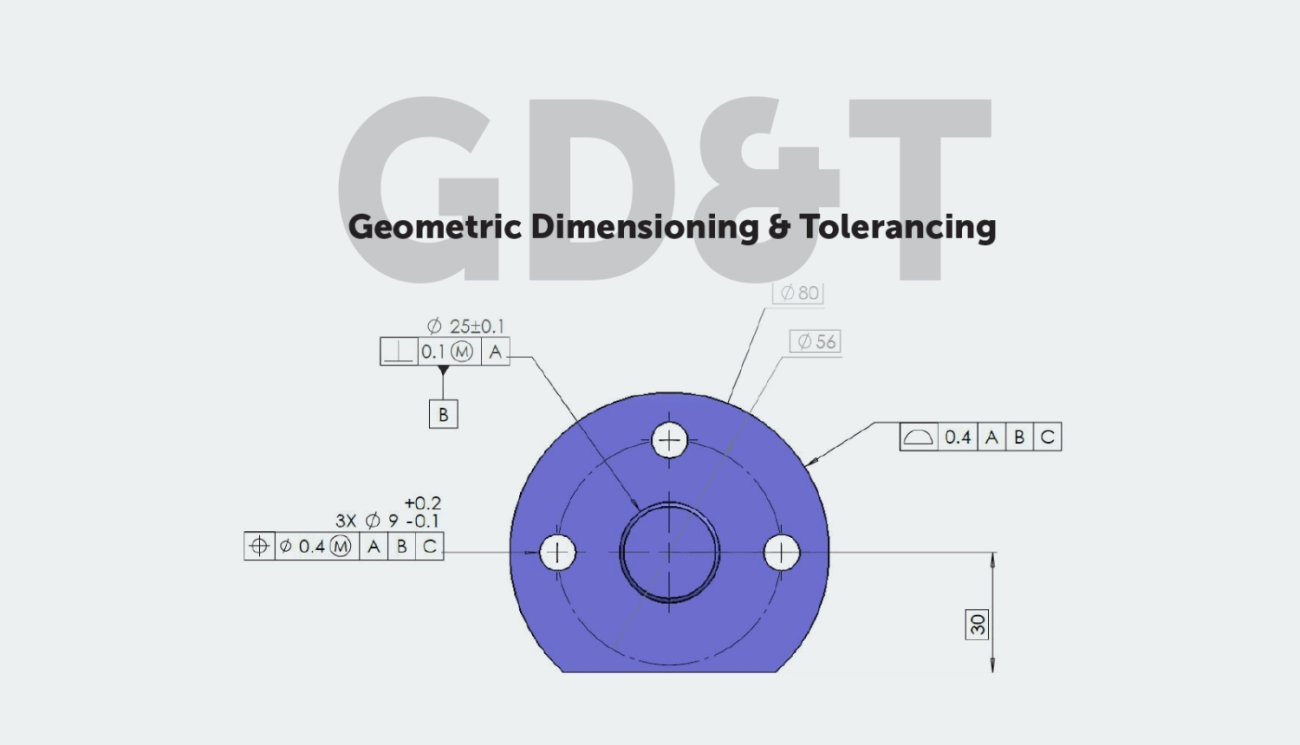

Have you ever wondered how engineers ensure parts fit perfectly together, even if they’re made by different manufacturers? That’s where Geometric Dimensioning and Tolerancing, or GD&T, comes into play. GD&T is a standardized system that communicates engineering tolerances clearly and precisely using specific symbols on drawings.

What is Geometric Dimensioning and Tolerancing GD&T

At its core, GD&T defines allowable variations in part geometry, like shape, size, orientation, and location, using a universal language of symbols. Instead of just giving numbers for dimensions and tolerances, GD&T describes how much a feature can deviate while still functioning as intended. This system follows standards like the ASME Y14.5, which makes it reliable and consistent across industries.

Why Use Engineering Tolerance Symbols Over Traditional Methods

You might ask, why not just use traditional dimensioning with plus-minus values? Here’s why engineering tolerance symbols offer a significant advantage:

- Clarity and Precision: GD&T symbols convey complex geometric controls in a clear, concise way, minimizing misinterpretation.

- Functional Focus: It ties tolerances directly to the function of the part, ensuring real-world performance rather than just manufacturing limits.

- Improved Communication: Using standardized symbols helps engineers, machinists, and quality inspectors speak the same language — reducing costly mistakes.

- Flexibility in Manufacturing: GD&T allows for controlled variation, enabling cost-effective manufacturing without sacrificing quality.

- Better Quality Control: It supports more effective inspection processes, improving consistency and reliability in parts.

By mastering GD&T and engineering tolerance symbols, you gain a powerful toolset to design and manufacture parts with confidence and accuracy. It’s more than just rules — it’s a way to ensure every component fits, functions, and lasts as intended.

The Essential GD&T Symbols Categories and Meanings

Understanding the main categories of engineering tolerance symbols is key to reading and applying GD&T correctly. These symbols fall into several groups, each controlling different aspects of a feature’s geometry.

Form Tolerance Symbols Controlling Shape and Straightness

Form symbols focus on the basic shape of a part, making sure its features like flatness, straightness, roundness, and cylindricity meet the required limits. These control the accuracy of individual surfaces without reference to any other features.

Orientation Tolerance Symbols Ensuring Proper Alignment

Orientation symbols ensure features align correctly relative to other parts. Common symbols here include perpendicularity, parallelism, and angularity. They’re vital when fit and function depend on exact directional relationships.

Location Tolerance Symbols Precise Positioning

These symbols control where features are placed, such as holes or slots, relative to datums or each other. Position tolerance is the most frequently used here, ensuring parts fit and assemble without issues.

Profile and Runout Tolerance Symbols Complex Surface Control

Profile symbols handle curved or complex 3D surfaces, controlling how closely they follow a desired shape. Runout symbols are used for features on rotating parts, controlling how much a surface can deviate as it spins, which is critical for balance and smooth operation.

By knowing these categories and what each symbol means, you can better interpret engineering drawings and ensure your parts meet their design intent. For more on how these symbols fit into standards, check out the ASME Y14.5 standards.

Modifiers Datums and Advanced Applications in Engineering Drawings

Understanding key modifiers and datums is essential when working with engineering tolerance symbols in GD&T. These elements help provide clear, consistent instructions for manufacturing and inspection, ensuring parts fit and function correctly.

Key Modifiers MMC LMC and RFS Explained

- MMC (Maximum Material Condition): Means the feature contains the most material possible, like the smallest hole or largest shaft size. It allows for some tolerance bonus during inspection, making manufacturing easier.

- LMC (Least Material Condition): Opposite of MMC, it’s when the feature has the least material, such as the largest hole or smallest shaft size. This is important for ensuring minimum strength or fit.

- RFS (Regardless of Feature Size): Indicates that tolerance applies no matter the size of the feature, offering a straightforward control without size-based bonus.

These modifiers help control how tight or loose the tolerances can be, depending on critical functional requirements.

Datums and Reference Frames Building the Foundation

Datums are imaginary points, lines, or planes that serve as the starting reference for all geometric measurements on a part. A datum reference frame is a combination of these that defines the origin for the dimensional controls shown in a drawing.

- They help align parts during assembly.

- Provide repeatable and precise measurement points in inspection.

- Ensure consistency across different batches or manufacturing locations.

Understanding the foundation datums provide will reduce errors and improve communication between design, manufacturing, and quality teams.

Industry Applications and Best Practices

- Automotive and aerospace heavily rely on MMC and datums to ensure safety-critical parts fit together perfectly under dynamic conditions.

- Manufacturing shops use datums to set up machines and gauge fixtures accurately.

- Always reference ASME Y14.5 standards to stay aligned with industry-accepted practices.

- Use clear and unambiguous datum features to avoid confusion during production.

- Regular training and updated GD&T charts help teams keep up with best practices.

By mastering modifiers and datums, you’ll get the most out of your engineering drawings and reduce costly mistakes in manufacturing and inspection.

How to Read and Apply GD&T Symbols in Your Workflow

Understanding how to read and apply engineering tolerance symbols, especially GD&T, can make a big difference in your manufacturing or design process. A great place to start is learning how to interpret a feature control frame, which is the core of GD&T on any engineering drawing.

Step-by-Step Guide to Interpreting a Feature Control Frame

A feature control frame is a rectangular box containing symbols, numbers, and sometimes letters, giving exact instructions on the allowable variation for a feature. Here’s how to break it down:

- Tolerance Type: The first symbol inside the box shows the type of tolerance (like position, flatness, or runout).

- Tolerance Value: Right after the symbol, you’ll see a number specifying how much variation is allowed (for example, 0.005 inches).

- Modifiers: Symbols like MMC (Maximum Material Condition) or LMC (Least Material Condition) tell you how to apply the tolerance depending on the feature’s size.

- Datum References: If there are letters following the tolerance, these refer to datums—predefined reference points or planes that relate the feature’s location or orientation.

- Additional Notes: Sometimes there are extra details or multiple datums indicating complex relationships between features.

By carefully reading each part of the feature control frame, you get a clear picture of what’s allowed on the part and how to inspect or manufacture it properly.

Common Pitfalls and How to Avoid Them

Working with GD&T can get tricky if you’re not careful. Watch out for these common mistakes:

- Ignoring Modifiers: Skipping MMC or LMC can cause parts to be rejected unnecessarily or lead to assembly issues.

- Misreading Datum References: Using the wrong datum or ignoring datum sequences can mess up alignment, causing dimensional errors.

- Overlooking the Order of Tolerances: Each tolerance and datum is listed in a specific order—mixing this up can change the whole meaning.

- Confusing Similar Symbols: Symbols like flatness and straightness look alike but control different things; understanding their differences is key.

- Not Consulting ASME Y14.5 Standards: This is the go-to guide for GD&T in the US, and following it prevents miscommunication.

Avoid these pitfalls by double-checking drawings, using GD&T symbols charts, and consulting with your team. With practice, reading and applying GD&T symbols will become second nature, making your workflow smoother and parts more reliable.